When selecting a manufacturing process for aluminum components, understanding the differences between forged vs machined aluminum is crucial for achieving optimal performance, durability, and cost-effectiveness. Each process offers distinct advantages and limitations that directly impact the final product’s properties. At MAIKONG, we specialize in both aluminum forging and precision CNC machining services, providing comprehensive solutions tailored to your specific requirements. This guide explores the fundamental differences between these two manufacturing methods to help you make an informed decision for your next project.

Understanding Forged vs Machined Aluminum Processes

The fundamental difference between forging and machining aluminum processes

The fundamental difference between forging and machining aluminum processes

The Aluminum Forging Process

Forging is a manufacturing process where aluminum is heated to a malleable state and then shaped using compressive force. This process fundamentally alters the metal’s grain structure, aligning it with the part’s shape. At MAIKONG, our aluminum forging services utilize advanced techniques to create parts with exceptional strength and durability.

The forging process typically involves:

- Heating aluminum billets to specific temperatures

- Applying controlled pressure using specialized dies

- Reshaping the metal while maintaining material integrity

- Aligning the grain structure to enhance mechanical properties

- Cooling and heat treatment to achieve desired characteristics

The CNC Machining Process for Aluminum

CNC machining is a subtractive manufacturing process where computer-controlled cutting tools remove material from an aluminum block to create the desired shape. MAIKONG’s precision CNC machining services deliver components with excellent dimensional accuracy and surface finish.

The machining process typically involves:

- Creating a digital model using CAD software

- Converting the design into machine instructions via CAM software

- Securing the aluminum workpiece in the CNC machine

- Removing material using various cutting tools

- Achieving precise dimensions and surface finishes

Need Expert Guidance on Your Project?

Our engineers can help determine whether forging or machining is best suited for your specific application.

Get Expert Advice

Material Properties: How Forged vs Machined Aluminum Differ

Grain Structure and Strength

Microscopic view of grain alignment in forged aluminum (left) vs. machined aluminum (right)

The most significant difference between forged vs machined aluminum lies in their internal grain structure. Forging aligns the metal’s grain flow with the part’s geometry, creating a continuous, uninterrupted structure that significantly enhances strength and durability. In contrast, machining simply removes material without altering the original grain structure, which may include random grain orientation and potential weak points.

| Property |

Forged Aluminum |

Machined Aluminum |

| Tensile Strength |

Up to 26% higher |

Limited by base material |

| Fatigue Resistance |

Up to 37% higher |

Limited by base material |

| Impact Resistance |

Superior |

Moderate |

| Grain Structure |

Aligned with part geometry |

Random orientation |

| Material Density |

Higher (fewer voids) |

Unchanged from base material |

Defect Elimination and Material Integrity

Forging significantly improves material integrity by eliminating internal defects such as porosity, voids, and inclusions that may be present in the original material. The intense pressure applied during forging closes these gaps, resulting in a denser, more homogeneous structure. Machined parts, however, retain any defects present in the original material, which can potentially compromise performance in high-stress applications.

“Forged aluminum components can withstand up to six times more stress cycles before failure compared to their machined counterparts, making them ideal for safety-critical and high-performance applications.”

– MAIKONG Engineering Team

Applications and Industry Uses of Forged vs Machined Aluminum

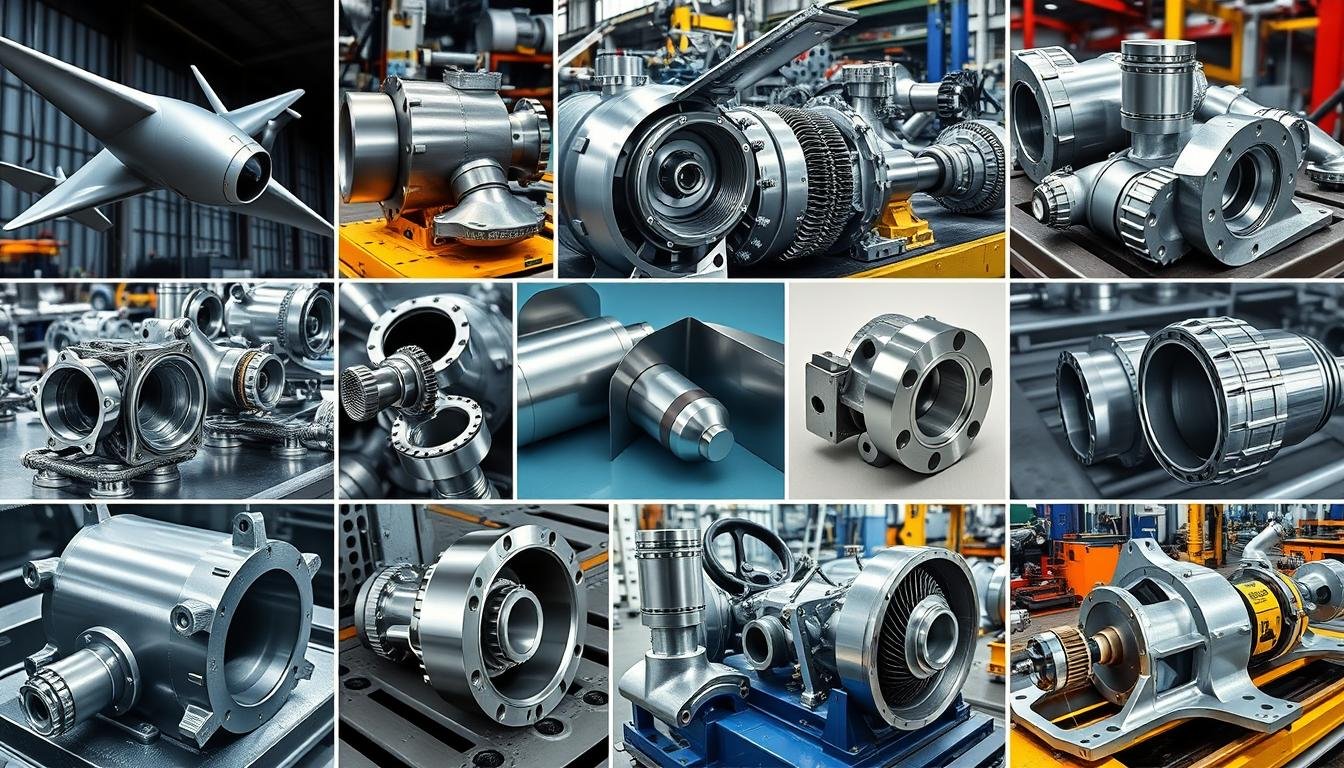

Industrial applications for forged and machined aluminum components

Ideal Applications for Forged Aluminum

Forged aluminum excels in applications requiring exceptional strength, durability, and resistance to fatigue and impact. The aligned grain structure makes forged components particularly suitable for:

- Aerospace structural components

- Automotive suspension and drivetrain parts

- High-performance wheels and chassis components

- Marine propellers and hardware

- Industrial machinery components

- Oil and gas equipment

- Defense and military applications

- High-stress sporting equipment

- Power generation components

- Safety-critical structural elements

Ideal Applications for Machined Aluminum

CNC machined aluminum is best suited for applications requiring precise dimensions, complex geometries, and excellent surface finish. Common applications include:

- Precision electronic enclosures

- Optical equipment housings

- Complex fluid control components

- Prototype development

- Low-volume production runs

- Medical device components

- Robotics and automation parts

- Semiconductor manufacturing equipment

- Intricate decorative elements

- Components with internal features

Forged aluminum automotive components manufactured by MAIKONG

Choosing Between Forged vs Machined Aluminum: Key Decision Factors

Performance Requirements

When deciding between forged vs machined aluminum, consider the performance demands of your application. For components subjected to high stress, impact, or fatigue, forged aluminum typically offers superior performance due to its enhanced mechanical properties and aligned grain structure.

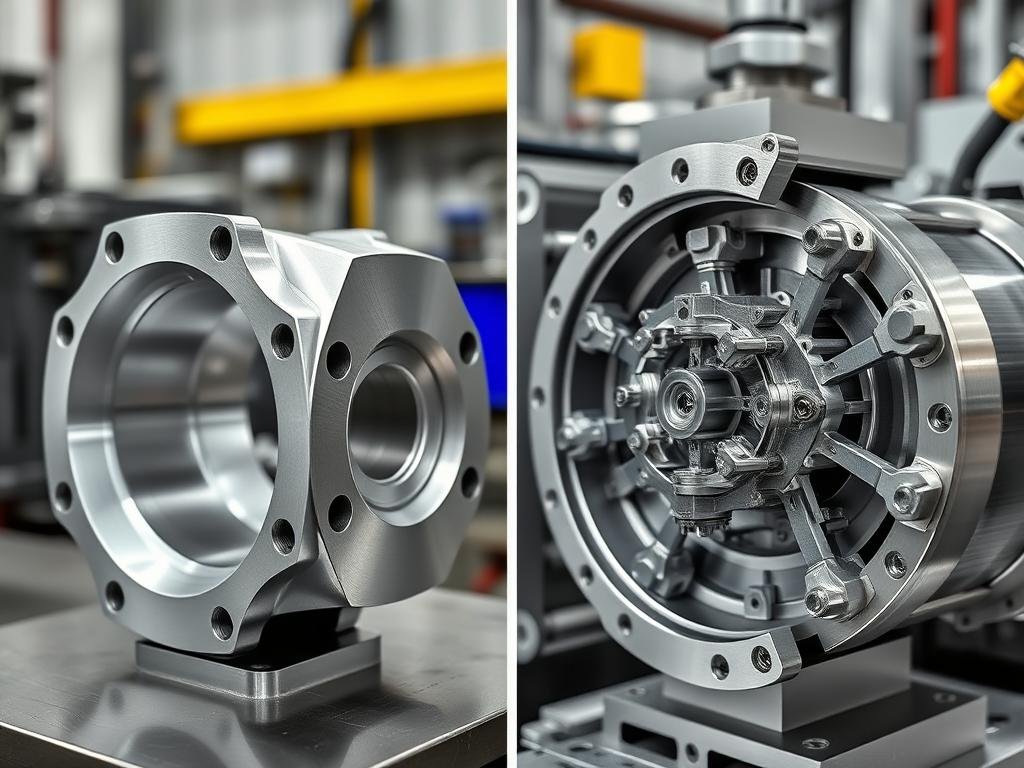

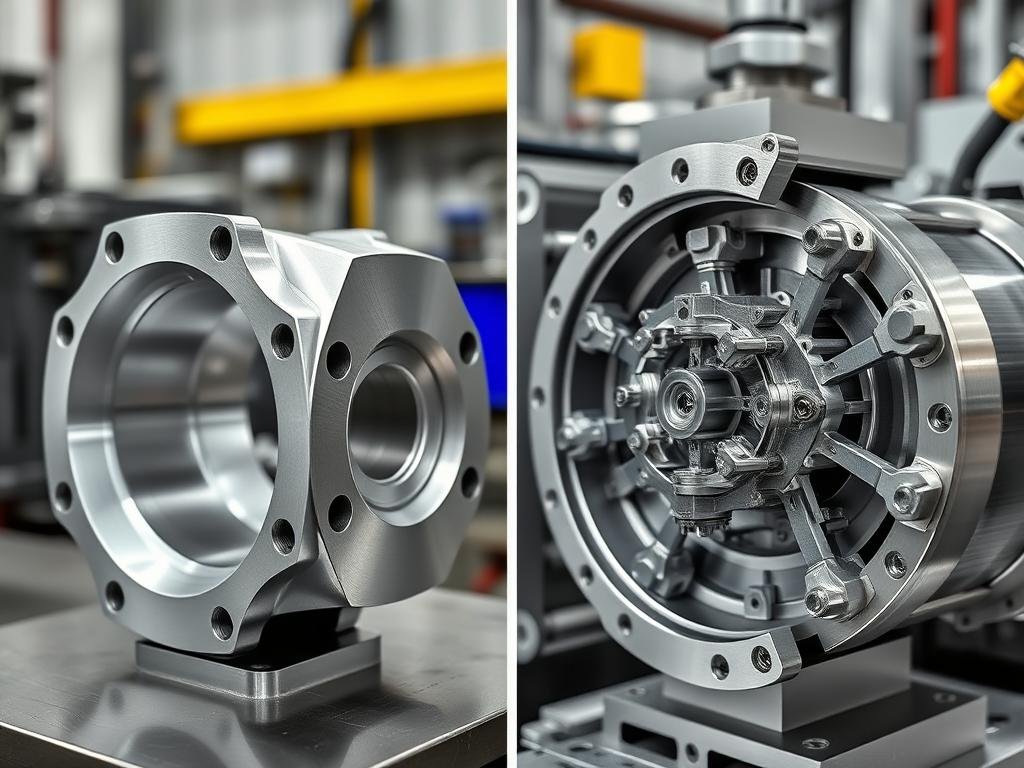

Complexity and Precision

Geometric complexity comparison: forged parts (left) vs. machined parts (right)

Machining excels at creating complex geometries, internal features, and tight tolerances that may be difficult or impossible to achieve through forging alone. For intricate designs requiring precise dimensions, CNC machining offers greater flexibility.

Production Volume and Cost Considerations

Production volume significantly impacts the cost-effectiveness of each process:

Forging Advantages

- More cost-effective for high-volume production

- Less material waste (near-net shape capability)

- Faster production cycles for established designs

- Lower per-unit costs at scale

- Superior strength-to-weight ratio

Machining Advantages

- Lower initial tooling costs

- More economical for low-volume production

- Greater design flexibility and iteration

- Easier to modify designs

- Higher precision and surface finish

Hybrid Approach: Combining Forging and Machining

At MAIKONG, we often recommend a hybrid approach that leverages the strengths of both processes. Many high-performance components begin as forgings to establish optimal grain structure and mechanical properties, then undergo precision machining to achieve final dimensions, surface finish, and features.

MAIKONG’s hybrid manufacturing approach combining forging and machining processes

Not Sure Which Process Is Right For Your Project?

Contact our engineering team for a personalized consultation and recommendation based on your specific requirements.

Contact Us on WhatsApp

MAIKONG’s Manufacturing Capabilities

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

Aluminum Forging Expertise

MAIKONG specializes in advanced aluminum forging techniques that deliver exceptional quality and performance. Our forging capabilities include:

- Closed-die forging for precise, near-net shapes

- Open-die forging for larger components

- Upset forging for specialized applications

- Custom alloy selection and optimization

- Comprehensive heat treatment services

- Advanced surface treatments and finishing

Precision CNC Machining Services

Our state-of-the-art CNC machining center is equipped with over 60 advanced machines, providing 100+ tons of metal processing capacity monthly. Our machining capabilities include:

- Multi-axis CNC milling for complex geometries

- Precision CNC turning for cylindrical components

- Swiss-type machining for small, intricate parts

- Surface grinding for superior finishes

- Laser engraving for part identification

- Comprehensive quality control and inspection

Quality control inspection of finished aluminum components

Integrated Quality Assurance

At MAIKONG, quality is built into every step of our manufacturing process. Our comprehensive quality assurance program includes:

- Material verification and testing

- In-process inspections at critical stages

- Advanced dimensional measurement

- Mechanical property testing

- Surface finish verification

- ISO 9001:2015 certified processes

Case Studies: Forged vs Machined Aluminum in Action

Automotive Suspension Component

Forged aluminum suspension component with optimized grain structure

Challenge: An automotive manufacturer needed a lightweight suspension component with exceptional strength and fatigue resistance.

Solution: MAIKONG developed a custom forging process that aligned the grain structure with the load paths, followed by precision machining of critical surfaces.

Result: The hybrid approach delivered a component with 30% higher fatigue resistance than the previous machined-only design, while reducing weight by 15%.

Aerospace Structural Fitting

Precision machined aerospace fitting with complex geometry

Challenge: An aerospace client required a structural fitting with complex geometry, tight tolerances, and high strength-to-weight ratio.

Solution: Starting with a custom aluminum forging to establish optimal grain structure, MAIKONG applied precision 5-axis machining to achieve the complex final geometry.

Result: The component passed all structural tests with a 25% margin above requirements while meeting the stringent dimensional tolerances.

Frequently Asked Questions About Forged vs Machined Aluminum

Which is stronger, forged or machined aluminum?

Forged aluminum is typically stronger than machined aluminum due to its aligned grain structure and increased density. The forging process aligns the metal’s grain flow with the part’s geometry, creating a continuous structure that enhances strength, fatigue resistance, and impact toughness. Machined aluminum retains the original grain structure of the base material, which may include random grain orientation and potential weak points.

Is forged aluminum more expensive than machined aluminum?

The cost comparison between forged and machined aluminum depends on several factors, including production volume, part complexity, and performance requirements. Forging typically has higher initial tooling costs but becomes more cost-effective for higher production volumes due to reduced material waste and faster cycle times. Machining has lower setup costs but higher per-part costs due to material waste and longer processing times. For optimal cost-efficiency, MAIKONG often recommends a hybrid approach that combines the strengths of both processes.

What are the limitations of forged aluminum compared to machined aluminum?

Forged aluminum has several limitations compared to machined aluminum:

- Limited geometric complexity and internal features

- Higher initial tooling costs

- Rougher surface finish requiring secondary operations

- Size limitations based on available equipment

- Less precise dimensional control

- Less flexibility for design changes

Machining excels at creating complex geometries, internal features, and tight tolerances that may be difficult or impossible to achieve through forging alone.

Can forged aluminum parts be machined afterward?

Yes, forged aluminum parts are commonly machined after forging to achieve final dimensions, surface finish, and features. This hybrid approach combines the strength advantages of forging with the precision of machining. At MAIKONG, we frequently employ this strategy to deliver components with optimal performance characteristics and dimensional accuracy.

Conclusion: Making the Right Choice Between Forged vs Machined Aluminum

Choosing between forged vs machined aluminum requires careful consideration of your specific application requirements, including performance needs, geometric complexity, production volume, and budget constraints. While forging offers superior strength and durability through its optimized grain structure, machining provides greater precision and geometric flexibility.

At MAIKONG, we leverage our expertise in both processes to deliver the optimal manufacturing solution for your aluminum components. Whether you need the enhanced strength of forged aluminum, the precision of machined aluminum, or a hybrid approach that combines the advantages of both, our team is ready to help you achieve the perfect balance of performance, quality, and cost-effectiveness.

Contact MAIKONG today to discuss your project requirements and discover how our comprehensive aluminum manufacturing capabilities can support your success.

Ready to Discuss Your Project?

Our engineering team is available to provide expert guidance on selecting the optimal manufacturing process for your aluminum components.

Contact Us Today

The fundamental difference between forging and machining aluminum processes

The fundamental difference between forging and machining aluminum processes