When it comes to creating authentic vintage aluminum parts, manufacturers face a critical decision: should they opt for traditional hand forging or modern CNC machining? The choice between aluminum hand forged vs machined vintage components significantly impacts aesthetics, durability, performance, and cost. This comprehensive guide explores the fundamental differences, helping you determine which manufacturing method best suits your specific requirements for vintage aluminum components.

the Basics: Aluminum Hand Forged vs Machined Vintage Manufacturing

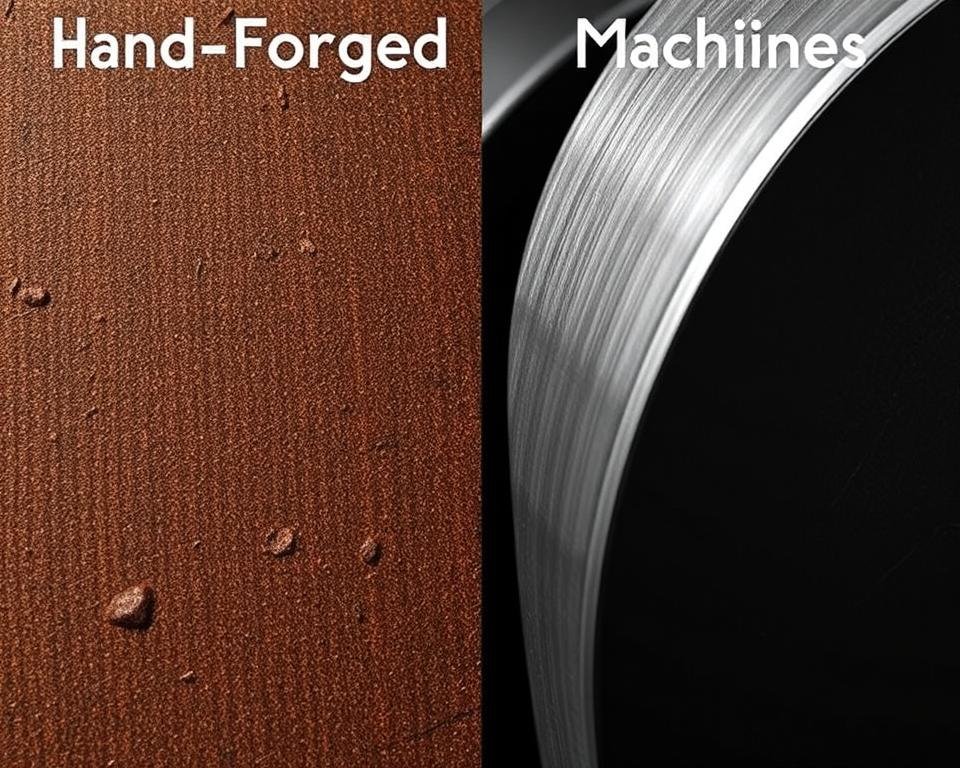

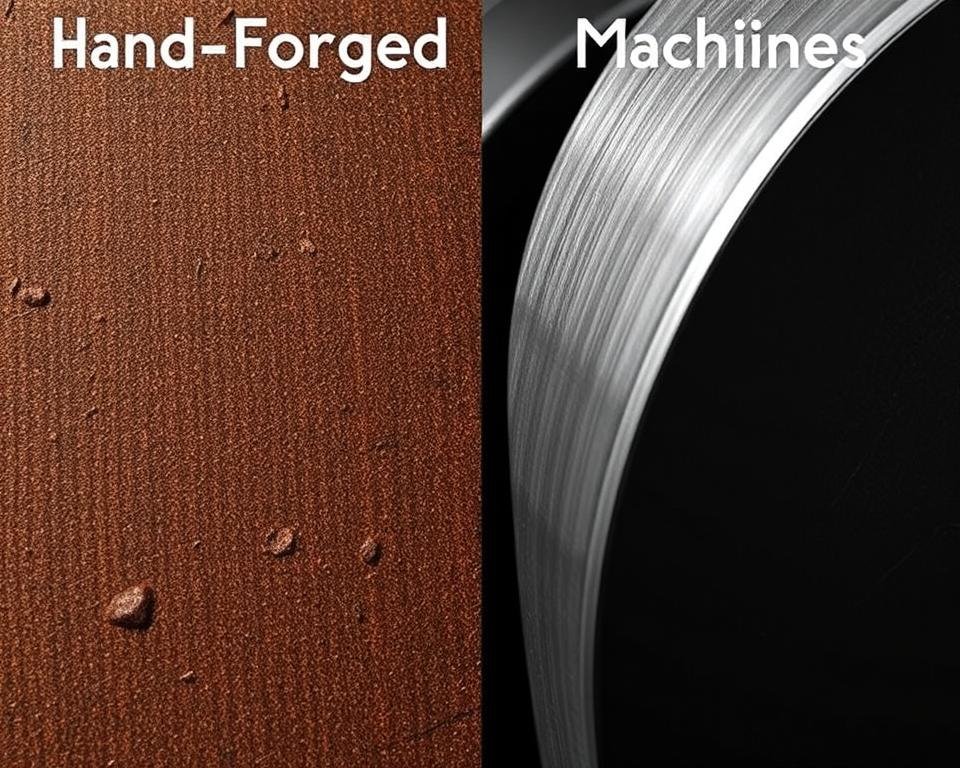

Visual comparison of hand forged (left) and machined (right) vintage aluminum components

Visual comparison of hand forged (left) and machined (right) vintage aluminum components

Before diving into the specifics, it’s essential to understand what each manufacturing process entails. Both methods create high-quality aluminum parts but follow fundamentally different approaches that result in distinct characteristics.

What is Hand Forged Aluminum?

Hand forging aluminum is a traditional metalworking technique where skilled artisans heat aluminum to a malleable state and shape it using hammers, anvils, and specialized tools. This age-old process creates unique pieces with distinctive hammer marks and texture variations that many enthusiasts prize for their authentic vintage appearance.

What is Machined Vintage Aluminum?

Machined vintage aluminum refers to parts created using modern CNC (Computer Numerical Control) technology programmed to replicate vintage designs. This process involves cutting away material from aluminum blocks or billets to achieve precise dimensions and features. While machined parts lack the handcrafted variations of forged components, they offer exceptional consistency and precision.

Material Properties: How Manufacturing Affects Aluminum Structure

Microscopic comparison of grain structure in forged vs. machined aluminum

The manufacturing method significantly impacts the internal structure of aluminum, which directly affects performance characteristics. Understanding these differences is crucial when deciding between aluminum hand forged vs machined vintage parts.

Grain Structure and Strength

Hand forging fundamentally alters aluminum’s grain structure. The hammering process compresses and realigns the metal’s internal grain, creating a directional flow that follows the part’s shape. This realignment significantly enhances strength, impact resistance, and fatigue performance. In contrast, machined aluminum retains its original, unaltered grain structure, which may not be optimally aligned for maximum strength in all directions.

| Property |

Hand Forged Aluminum |

Machined Aluminum |

| Grain Structure |

Directional, compressed, follows part contours |

Original, unaltered, random orientation |

| Tensile Strength |

Enhanced (typically 15-25% higher) |

Standard for the alloy |

| Impact Resistance |

Superior due to compressed grain |

Good but less than forged |

| Fatigue Resistance |

Excellent, better crack resistance |

Good but may develop stress points |

| Density |

Higher due to compression |

Standard for the alloy |

Mechanical Performance

The altered grain structure of hand-forged aluminum typically results in superior mechanical performance for applications subject to stress, impact, or fatigue. This makes forged components particularly valuable in high-stress vintage applications like automotive suspension components, aircraft parts, or structural elements. Machined parts, while strong, may not offer the same level of durability under extreme conditions.

Aesthetic Differences: The Visual Appeal of Forged vs. Machined

Surface texture comparison between hand forged (left) and machined (right) aluminum

Perhaps the most immediately noticeable difference between aluminum hand forged vs machined vintage parts is their appearance. Each manufacturing method creates a distinctive aesthetic that appeals to different preferences and applications.

Surface Characteristics

Hand-forged aluminum typically exhibits subtle hammer marks, slight irregularities, and a distinctive texture that many enthusiasts consider the hallmark of authentic vintage craftsmanship. These visual cues tell the story of the artisan’s work and create a warm, organic aesthetic that’s difficult to replicate. Machined aluminum, by contrast, features precise, consistent surfaces with visible tool paths that create their own unique pattern. The machined finish is typically smoother and more uniform.

Patina Development

Over time, both forged and machined aluminum develop patinas, but they do so differently. Hand-forged aluminum often develops a more uneven, character-rich patina that enhances its vintage appeal. The slight surface variations create micro-environments where oxidation occurs at different rates. Machined aluminum tends to age more uniformly, developing a consistent patina across its surface.

Hand Forged Aesthetic Advantages

- Authentic vintage appearance with visible craftsmanship

- Unique character with no two pieces exactly alike

- Organic texture that catches light in interesting ways

- Develops character-rich patina over time

- Tells the story of its creation through surface details

Machined Aesthetic Advantages

- Precise, clean lines and perfect symmetry

- Consistent appearance across multiple parts

- Ability to create extremely fine details

- Smooth, uniform surfaces where desired

- Precise replication of vintage designs

Manufacturing Process Comparison

Traditional hand forging process for aluminum parts

CNC machining process for vintage-style aluminum parts

The creation of aluminum hand forged vs machined vintage parts involves fundamentally different processes, each with its own workflow, requirements, and limitations.

Hand Forging Process

Hand forging aluminum is a multi-step process that requires significant skill and experience:

- Material selection and preparation of aluminum stock

- Heating the aluminum to proper forging temperature (typically 750-900°F)

- Shaping using hammers, anvils, and specialized tools

- Periodic reheating as needed to maintain malleability

- Rough shaping followed by refinement of details

- Controlled cooling to prevent warping

- Finishing operations (grinding, polishing, etc.)

- Heat treatment if required for specific properties

CNC Machining Process

Creating machined vintage aluminum parts follows a more technology-driven approach:

- CAD (Computer-Aided Design) modeling of the part

- CAM (Computer-Aided Manufacturing) programming

- Material selection and preparation of aluminum billet

- Setup of CNC machine with appropriate tooling

- Rough cutting to remove bulk material

- Precision finishing passes for final dimensions

- Detail work for specific features

- Surface finishing operations

Expert Manufacturing at MAIKONG

At MAIKONG, we specialize in both hand forging and precision CNC machining of aluminum parts. Our skilled artisans and advanced technology allow us to create authentic vintage components using either method based on your specific requirements.

Explore Our Manufacturing Capabilities

Cost Considerations: Balancing Budget with Quality

Cost comparison between hand forging and CNC machining for vintage aluminum parts

The decision between aluminum hand forged vs machined vintage parts often comes down to budget considerations. Understanding the cost factors for each method helps in making an informed decision that balances quality with financial constraints.

| Cost Factor |

Hand Forged Aluminum |

Machined Aluminum |

| Initial Setup |

Low (basic tooling) |

High (CAD modeling, programming) |

| Per-Unit Cost (Small Batch) |

High (labor intensive) |

High (setup amortization) |

| Per-Unit Cost (Large Batch) |

High (limited economies of scale) |

Low (efficient once programmed) |

| Material Efficiency |

High (minimal waste) |

Low (significant material removal) |

| Labor Requirements |

High (skilled artisans) |

Moderate (skilled operators) |

| Equipment Investment |

Low to moderate |

Very high (CNC machines) |

Economies of Scale

One of the most significant cost differences between the two methods relates to economies of scale. Hand forging requires similar effort for each piece, meaning costs remain relatively constant regardless of quantity. CNC machining involves substantial upfront programming and setup costs, but once established, can produce additional units efficiently. For small, custom batches, hand forging may be more economical, while machining becomes increasingly cost-effective as quantities increase.

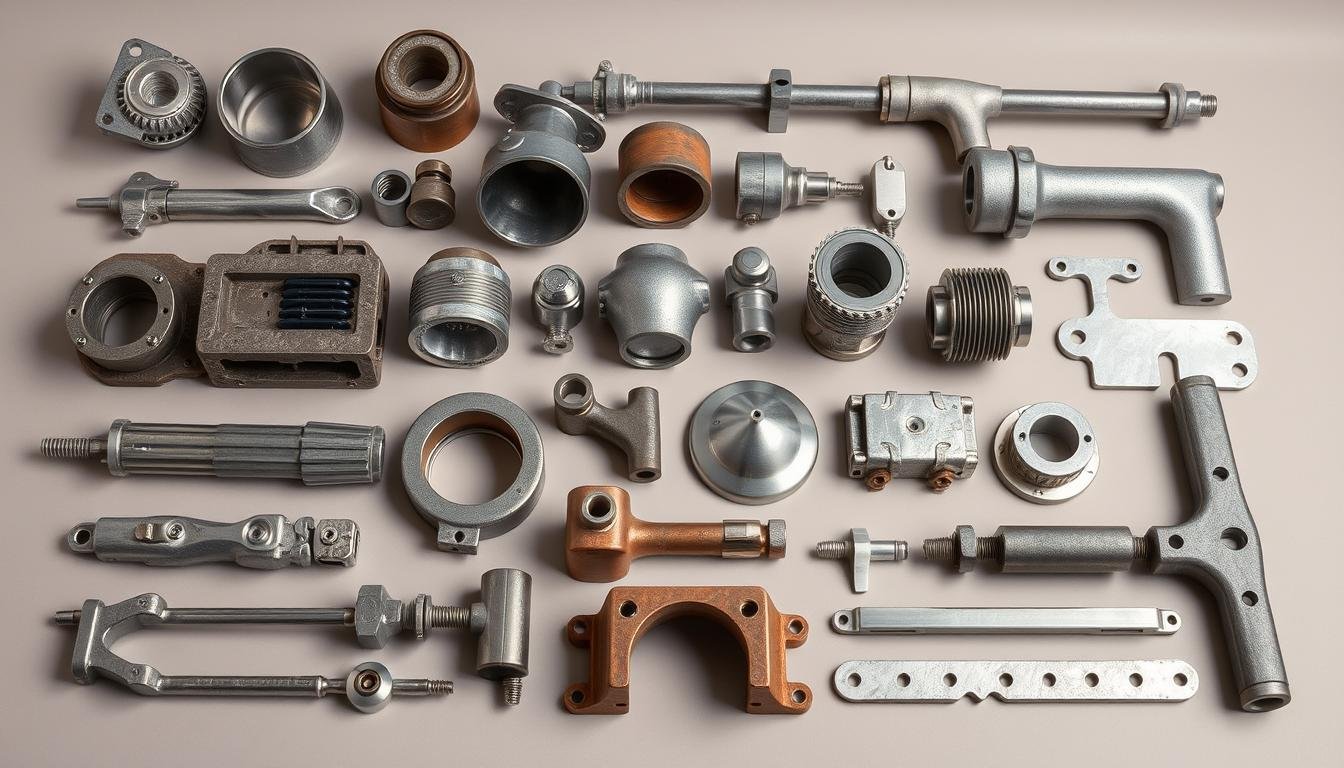

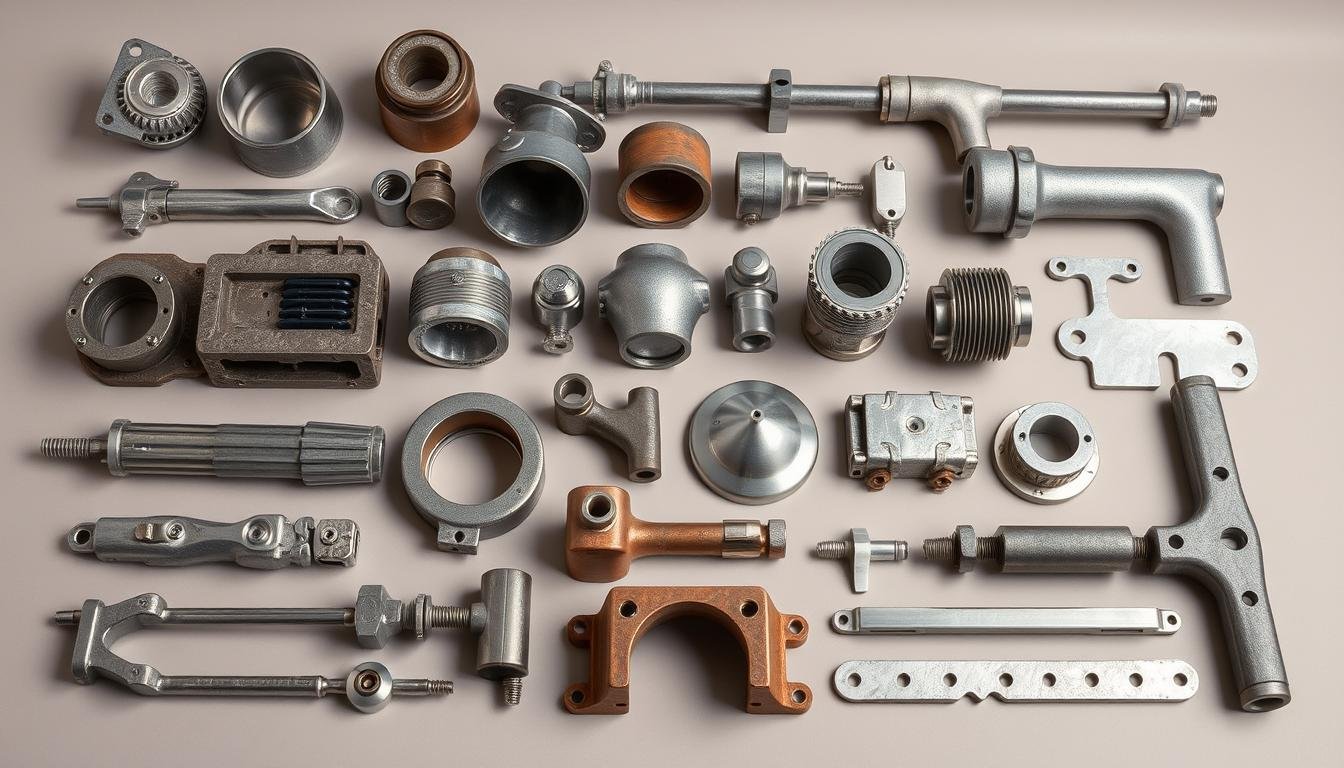

Application Scenarios: Choosing the Right Method

Common applications for hand forged and machined vintage aluminum parts

Different projects call for different manufacturing approaches. Understanding when to choose hand forging versus machining for your vintage aluminum parts is crucial for achieving the desired results.

Ideal Applications for Hand Forged Aluminum

- Restoration of historically significant vehicles or artifacts where authenticity is paramount

- Structural components subject to high stress such as suspension parts, frame elements, or load-bearing components

- Visible components where the distinctive aesthetic of hand-forged aluminum enhances the vintage appeal

- One-off or small batch custom projects where tooling costs for machining would be prohibitive

- Parts requiring superior fatigue resistance for safety-critical applications

Ideal Applications for Machined Vintage Aluminum

- Components requiring precise dimensions such as engine parts, bearings, or mating surfaces

- Complex geometries that would be difficult to achieve through hand forging

- Parts needing consistent replication across multiple units

- Components with internal features like channels, threaded holes, or precise bores

- Medium to large production runs where economies of scale make machining more cost-effective

“The choice between aluminum hand forged vs machined vintage parts isn’t about which is better overall, but rather which method better serves the specific requirements of your project. Sometimes, the ideal approach combines both techniques.”

– MAIKONG Engineering Team

Hybrid Approaches: Combining Forging and Machining

Hybrid manufacturing combining traditional forging with precision machining

In many cases, the optimal approach to creating vintage aluminum parts involves combining the strengths of both hand forging and machining. These hybrid approaches leverage the structural benefits of forging with the precision of CNC technology.

Common Hybrid Techniques

Several effective hybrid approaches have emerged that deliver exceptional results for vintage aluminum components:

Forge-Then-Machine

- Start with hand forging to establish grain structure

- Create near-net shape with forging

- Finish critical dimensions with CNC machining

- Preserves forged strength while adding precision

- Ideal for structural parts requiring accurate mating surfaces

Machine-Then-Texture

- CNC machine the entire part to precise dimensions

- Hand-apply hammer marks or texture for vintage appearance

- Combines precision with authentic aesthetics

- Good for visible parts where appearance matters

- More economical than full hand forging

Component Combination

- Use forged components for structural elements

- Use machined components for precision features

- Assemble into a cohesive final product

- Optimizes each element for its specific role

- Best of both worlds approach for complex assemblies

These hybrid approaches often deliver the best overall results, especially for complex vintage components where both structural integrity and precision are important. At MAIKONG, we specialize in these combined techniques to deliver optimal results for challenging vintage aluminum projects.

Choosing the Right Manufacturer for Your Vintage Aluminum Needs

MAIKONG’s comprehensive manufacturing facility in GD, SZ

Selecting the right manufacturing partner is crucial for achieving exceptional results with your vintage aluminum components. Whether you need hand-forged authenticity, machined precision, or a hybrid approach, your manufacturer’s capabilities directly impact the quality of your final product.

Key Considerations When Selecting a Manufacturer

- Technical expertise in both forging and machining – Look for manufacturers who understand the nuances of both processes

- Quality control procedures – Ensure they have rigorous testing and inspection protocols

- Material knowledge – They should understand different aluminum alloys and their properties

- Equipment capabilities – Both traditional forging tools and modern CNC technology

- Portfolio of similar projects – Previous experience with vintage aluminum components

- Communication and collaboration – Willingness to work closely with you on custom requirements

Why Choose MAIKONG for Your Vintage Aluminum Projects

At MAIKONG, we combine traditional craftsmanship with cutting-edge technology to deliver exceptional vintage aluminum components. Our comprehensive capabilities include:

- Expert hand forging by skilled artisans

- State-of-the-art CNC machining centers

- Hybrid manufacturing approaches

- Comprehensive quality control

- Extensive experience with vintage restoration projects

- Competitive pricing and reliable delivery

Conclusion: Making the Right Choice for Your Vintage Aluminum Project

Beautiful finished vintage aluminum components created through different manufacturing methods

The debate between aluminum hand forged vs machined vintage components ultimately comes down to your specific project requirements. Each manufacturing method offers distinct advantages that make it suitable for different applications.

Hand forging delivers exceptional structural integrity, authentic vintage aesthetics, and superior performance under stress, making it ideal for restoration projects where authenticity and durability are paramount. CNC machining provides unmatched precision, consistency, and the ability to create complex geometries, perfect for components where exact dimensions and repeatability matter most.

For many vintage aluminum projects, a hybrid approach that combines the strengths of both methods delivers the best overall results. By partnering with MAIKONG, you gain access to comprehensive manufacturing capabilities that span traditional craftsmanship and cutting-edge technology, ensuring your vintage aluminum components meet the highest standards of quality, performance, and authenticity.

Ready to Start Your Vintage Aluminum Project?

Contact MAIKONG today to discuss your specific requirements and discover how our expertise in both hand forging and precision machining can deliver exceptional results for your vintage aluminum components.

Visit Our Website

Visual comparison of hand forged (left) and machined (right) vintage aluminum components

Visual comparison of hand forged (left) and machined (right) vintage aluminum components