Choosing between aluminum hand forged vs machined processes is a critical decision that impacts product performance, cost-efficiency, and application suitability. This comprehensive guide examines the fundamental differences, advantages, and ideal applications for each manufacturing method, helping you make informed decisions for your specific requirements. As experts in both aluminum forging and CNC machining, MAIKONG offers insights based on decades of manufacturing experience to guide your selection process.

Understanding Aluminum Manufacturing Processes

MAIKONG’s state-of-the-art facilities for aluminum hand forging and CNC machining

MAIKONG’s state-of-the-art facilities for aluminum hand forging and CNC machining

What is Aluminum Hand Forging?

Aluminum hand forging is a metalworking process that shapes aluminum using localized compressive forces. The process typically involves heating aluminum to a malleable state and then applying pressure through hammering, pressing, or rolling. This ancient yet highly effective technique creates parts with exceptional strength and durability by refining the internal grain structure of the metal.

“The forging process fundamentally transforms aluminum’s internal structure, creating components with superior strength-to-weight ratios and enhanced mechanical properties.”

At MAIKONG, our aluminum forging process involves several carefully controlled stages:

- Material selection and preparation of aluminum alloy billets

- Heating the aluminum to optimal forging temperature (typically 400-500°C)

- Applying precisely controlled pressure using hydraulic presses

- Cooling and heat treatment to achieve desired mechanical properties

- Secondary operations including trimming, grinding, and machining

What is Aluminum CNC Machining?

CNC machining is a subtractive manufacturing process where material is removed from an aluminum workpiece to create the final part. This process uses computer-controlled cutting tools to achieve precise dimensions and complex geometries. Unlike forging, machining doesn’t alter the internal structure of the aluminum but excels in creating intricate shapes with tight tolerances.

MAIKONG’s CNC machining capabilities include:

- Multi-axis CNC milling for complex geometrical shapes

- CNC turning for cylindrical components with high precision

- Swiss-type machining for small, intricate parts

- Surface grinding for superior finishes

- Precision drilling and tapping operations

Key Differences Between Aluminum Hand Forged vs Machined Parts

| Characteristic |

Aluminum Hand Forged |

Aluminum CNC Machined |

| Internal Structure |

Refined, aligned grain structure |

Unaltered grain structure |

| Strength |

Superior strength and fatigue resistance |

Dependent on base material properties |

| Precision |

Moderate (±0.2mm typical) |

Excellent (±0.01mm possible) |

| Complexity |

Limited to moderately complex shapes |

Highly complex geometries possible |

| Surface Finish |

Requires secondary operations |

Excellent as-machined finish |

| Material Utilization |

85-90% efficient |

40-60% efficient (higher waste) |

| Production Volume |

Cost-effective for medium to high volumes |

Economical for low to medium volumes |

| Lead Time |

Longer due to tooling requirements |

Shorter for small batches and prototypes |

Need Expert Guidance on Process Selection?

Our engineering team can analyze your specific requirements and recommend the optimal manufacturing process for your application.

Get Expert Consultation

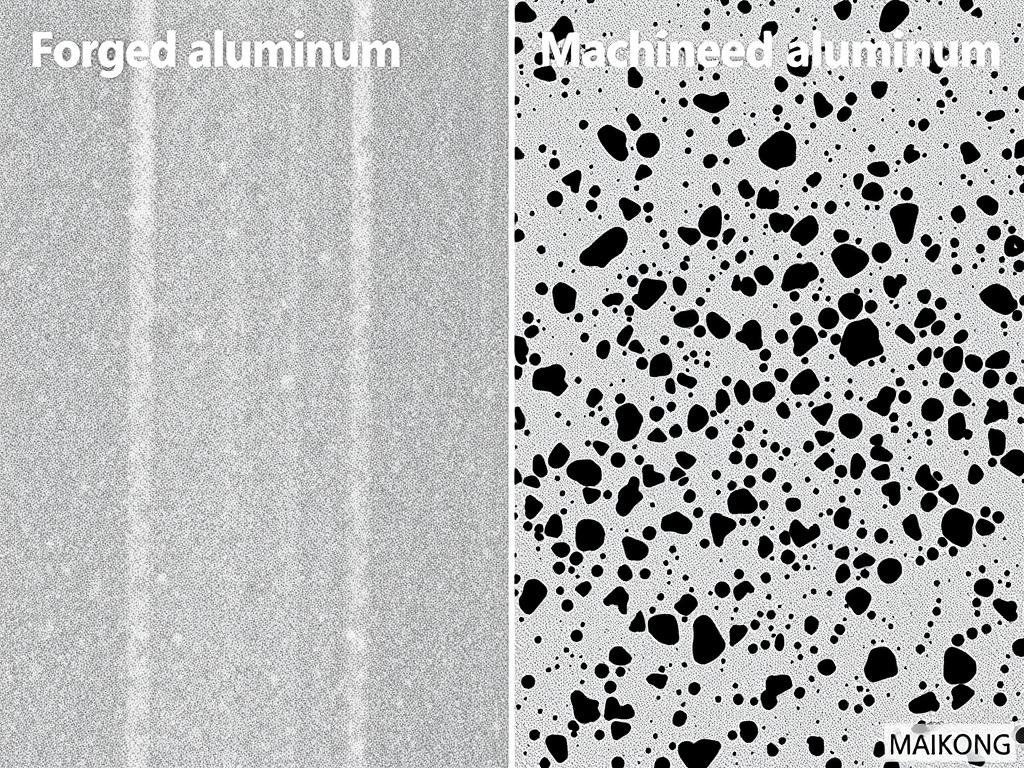

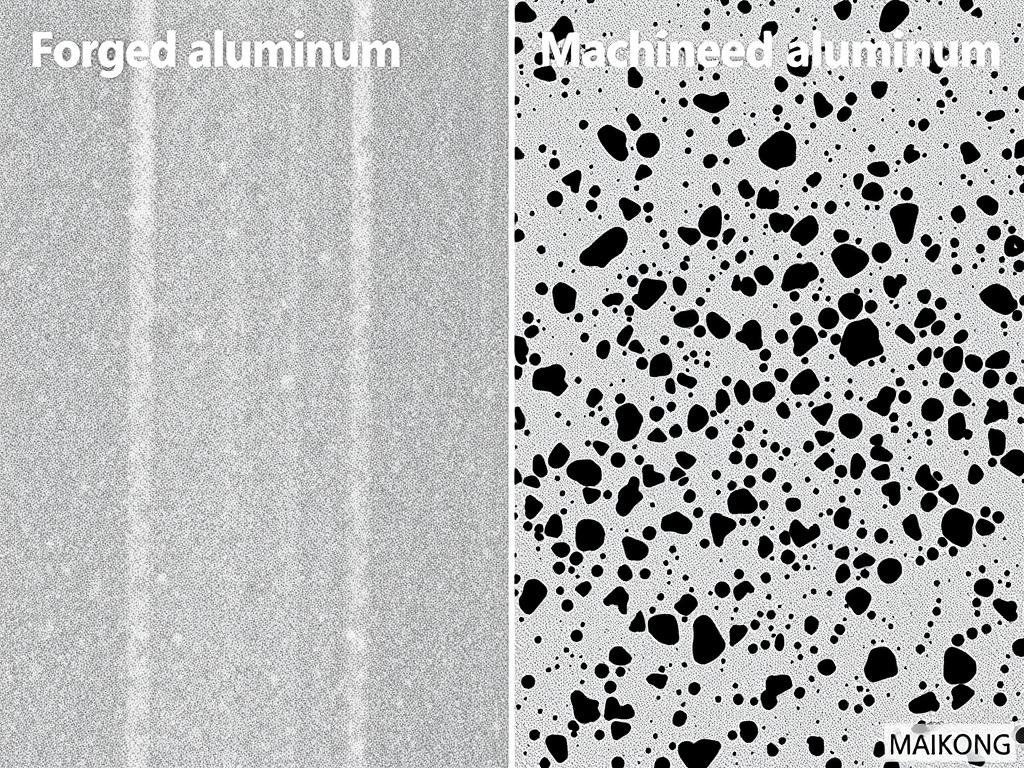

Strength and Durability: Forging vs Machining

Microscopic comparison of grain structures: forged (left) vs machined (right) aluminum

Strength of Forged Aluminum Parts

Forged aluminum components exhibit superior strength characteristics due to the fundamental changes in their internal structure during the forging process. When aluminum is forged, the grain structure becomes refined and aligned, following the contours of the part. This alignment significantly improves mechanical properties, particularly:

- Enhanced tensile strength (up to 30% higher than machined parts)

- Superior fatigue resistance for cyclic loading applications

- Improved impact resistance and toughness

- Better performance under dynamic loading conditions

- Reduced risk of internal defects and porosity

- Greater resistance to deformation under stress

- Enhanced structural integrity throughout the component

- Consistent mechanical properties across the part

These strength advantages make aluminum hand forged vs machined parts the preferred choice for critical applications where component failure could have serious consequences, such as aerospace components, automotive suspension parts, and high-performance sporting equipment.

Strength of Machined Aluminum Parts

CNC machined aluminum parts maintain the inherent properties of the base material since the machining process doesn’t alter the internal structure. While machined parts can still offer good strength characteristics, they generally don’t match the performance of forged components in high-stress applications.

The strength of machined aluminum depends primarily on:

- The specific aluminum alloy selected (6061-T6, 7075-T6, etc.)

- Heat treatment condition of the starting material

- Design features that may create stress concentrations

- Surface finish and potential micro-cracks from machining

Expert Insight: For applications requiring maximum strength-to-weight ratio and fatigue resistance, MAIKONG typically recommends forged aluminum components. However, for applications where precision and complex geometries are paramount, CNC machining often provides the optimal solution.

Precision and Dimensional Accuracy

MAIKONG’s high-precision CNC machining operation achieving tight tolerances

Precision of CNC Machined Parts

When it comes to dimensional accuracy and precision, CNC machining excels significantly over forging. Modern CNC machines can achieve extremely tight tolerances, often within ±0.01mm (0.0004 inches) for critical dimensions. This level of precision makes machining the preferred method for components requiring:

- Exact dimensional specifications

- Precise fitting with mating components

- Complex geometrical features

- Fine surface finishes (as low as 0.4μm Ra)

- Intricate internal features like threaded holes or channels

Precision of Forged Aluminum Parts

Forged aluminum parts typically have looser tolerances due to the nature of the forging process. Factors such as die wear, thermal expansion during heating, and springback after forging contribute to dimensional variations. Standard tolerances for forged aluminum parts are typically:

- ±0.2mm to ±0.5mm (0.008 to 0.020 inches) for most dimensions

- Surface roughness values between 3.2 and 25 micrometers Ra

- Limited capability for creating fine details or internal features

For applications requiring both the strength advantages of forging and the precision of machining, MAIKONG often recommends a combined approach: forging to create a near-net shape with superior strength characteristics, followed by precision machining of critical surfaces and features.

Need High-Precision Aluminum Components?

MAIKONG offers both precision CNC machining and forging services with secondary machining operations to meet your exact specifications.

Contact Our Engineering Team

Cost Efficiency and Production Considerations

MAIKONG’s integrated manufacturing facility optimizes cost efficiency

Cost Factors for Forged Aluminum

The economics of aluminum forging are heavily influenced by production volume. Initial tooling costs (dies, fixtures) are relatively high, but the per-part cost decreases significantly as volume increases. Key cost considerations include:

Initial Investment

- Die design and fabrication costs

- Setup and testing expenses

- Longer lead time for production start

Ongoing Production

- Lower material waste (85-90% utilization)

- Faster cycle times for high volumes

- Reduced secondary operations for simple parts

Cost Factors for CNC Machined Aluminum

CNC machining offers different economic advantages, particularly for low to medium production volumes and complex parts. The cost structure typically includes:

Initial Investment

- Minimal tooling costs

- CAD/CAM programming expenses

- Shorter setup time for production

Ongoing Production

- Higher material waste (40-60% utilization)

- Longer cycle times for complex parts

- Higher labor and machine time costs

Production Volume Guidance: For quantities under 500 pieces, CNC machining is often more economical. For quantities over 1,000 pieces, forging typically becomes more cost-effective. Between 500-1,000 pieces, a detailed cost analysis is recommended to determine the optimal approach.

MAIKONG’s integrated manufacturing capabilities allow us to offer both processes, enabling cost-optimized solutions based on your specific requirements and production volumes.

Ideal Applications for Aluminum Hand Forged vs Machined Parts

Industry applications for forged (left) and machined (right) aluminum components

Best Applications for Forged Aluminum

Aluminum forging is particularly well-suited for applications requiring:

Aerospace

- Structural components

- Landing gear parts

- Engine mounts

- Control system components

Automotive

- Suspension components

- Connecting rods

- Wheel hubs

- Steering knuckles

Sports Equipment

- Bicycle components

- Golf club heads

- High-performance equipment

- Motorcycle parts

Best Applications for Machined Aluminum

CNC machining of aluminum is ideal for applications requiring:

Electronics

- Enclosures and housings

- Heat sinks

- Mounting brackets

- Precision components

Medical

- Surgical instruments

- Imaging equipment parts

- Laboratory devices

- Custom implant prototypes

Robotics

- Structural frames

- Actuator components

- Custom end effectors

- Precision linkages

Not Sure Which Process Is Right For Your Application?

Our engineering team can review your specific requirements and recommend the optimal manufacturing approach.

Email Our Technical Team

MAIKONG’s Manufacturing Capabilities

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

MAIKONG offers comprehensive manufacturing capabilities for both aluminum forging and CNC machining, providing clients with flexibility to choose the optimal process for their specific requirements.

Forging Capabilities

- Multiple hydraulic presses with capacities up to 2,500 tons

- Hot, warm, and cold forging capabilities

- Precision die design and fabrication

- In-house heat treatment facilities

- Secondary operations including trimming and grinding

- Capability to forge various aluminum alloys (2xxx, 6xxx, 7xxx series)

CNC Machining Capabilities

- 60+ CNC machines with 100+ tons monthly processing capacity

- 3-axis, 4-axis, and 5-axis machining centers

- CNC turning with live tooling capabilities

- Swiss-type machining for small, precise components

- Surface grinding for superior finishes

- Precision measurement and quality control equipment

Integrated Manufacturing Approach

MAIKONG’s unique advantage lies in our ability to combine forging and machining processes to deliver optimal components. Our integrated approach includes:

- Near-net shape forging to maximize strength and material efficiency

- Precision machining of critical surfaces and features

- Comprehensive quality control throughout the manufacturing process

- Full material traceability and certification

- ISO 9001:2015 certified quality management system

Material Selection for Aluminum Manufacturing

Common aluminum alloys used in MAIKONG’s manufacturing processes

Selecting the appropriate aluminum alloy is crucial for optimizing component performance, regardless of whether you choose forging or machining. Different alloys offer varying combinations of strength, machinability, corrosion resistance, and cost.

Popular Aluminum Alloys for Forging

| Alloy |

Key Properties |

Typical Applications |

| 2014 |

High strength, good machinability |

Aircraft fittings, wheels, structural components |

| 2024 |

High strength-to-weight ratio, fatigue resistance |

Aerospace structural parts, aircraft fittings |

| 6061 |

Good corrosion resistance, weldability |

Automotive parts, bicycle components, marine fittings |

| 7075 |

Very high strength, good fatigue resistance |

Aerospace components, high-stress parts |

Popular Aluminum Alloys for Machining

| Alloy |

Key Properties |

Typical Applications |

| 6061-T6 |

Excellent machinability, good strength |

General purpose components, electronic housings |

| 7075-T6 |

High strength, good machinability |

Aerospace parts, high-performance components |

| 2011 |

Excellent machinability, free-cutting |

Precision parts, fasteners, hardware |

| 5052 |

Good corrosion resistance, formability |

Marine components, electronic chassis |

Material Selection Guidance: MAIKONG’s engineering team can assist with material selection based on your specific application requirements, including strength, weight, corrosion resistance, and cost considerations.

Quality Assurance for Aluminum Hand Forged vs Machined Parts

MAIKONG’s quality control laboratory ensures precise specifications

MAIKONG maintains rigorous quality control processes for both forged and machined aluminum components, ensuring consistent performance and reliability. Our ISO 9001:2015 certified quality management system governs all aspects of production.

Quality Control for Forged Components

- Material certification and verification before forging

- Die inspection and maintenance protocols

- In-process monitoring of forging parameters

- Metallurgical testing for grain structure and flow

- Dimensional inspection using coordinate measuring machines

- Non-destructive testing (ultrasonic, magnetic particle)

- Mechanical property testing (tensile, hardness)

Quality Control for Machined Components

- First article inspection and approval

- In-process dimensional verification

- Surface finish measurement

- Geometric dimensioning and tolerancing (GD&T) verification

- Thread gauge inspection for threaded features

- Final inspection with detailed reporting

- Statistical process control for critical dimensions

Quality Is Our Priority

MAIKONG’s commitment to quality ensures that your components meet or exceed specifications, regardless of manufacturing method.

Request Quality Documentation

Case Studies: Successful Applications

Case study: Optimized component design through proper process selection

Case Study 1: Automotive Suspension Component

A leading automotive manufacturer needed to reduce weight while maintaining strength in a critical suspension component. After analyzing the application requirements, MAIKONG recommended:

- Switching from machined 6061-T6 to forged 7075-T6 aluminum

- Optimizing the design for the forging process

- Precision machining only critical mating surfaces

Results: The redesigned component achieved a 22% weight reduction while increasing strength by 15%. Production costs were reduced by 18% for the high-volume application.

Case Study 2: Precision Electronic Housing

An electronics manufacturer required complex housings with tight tolerances and specific thermal management characteristics. MAIKONG’s solution included:

- 5-axis CNC machining from 6061-T6 aluminum plate

- Custom fixturing to maintain ±0.02mm tolerances

- Integrated heat sink features machined directly into the housing

Results: The machined housings met all precision requirements while reducing assembly complexity. The integrated thermal management features improved product performance by 30%.

Become a US Distributor for MAIKONG

MAIKONG is expanding its US distribution network for aluminum components

MAIKONG is actively seeking distribution partners across the United States to represent our high-quality aluminum forging and CNC machining capabilities. As a MAIKONG distributor, you’ll gain access to:

Manufacturing Capabilities

- 60+ CNC machines with 100+ tons monthly capacity

- Comprehensive aluminum forging facilities

- ISO 9001:2015 certified quality management

- Full-service manufacturing from design to delivery

Distributor Benefits

- Competitive pricing for high-quality components

- Technical support from our engineering team

- Exclusive territorial rights

- Marketing and sales support materials

Interested in Becoming a US Distributor?

Contact us today to discuss partnership opportunities and how MAIKONG can support your business growth.

Contact Our Distribution Team

Conclusion: Making the Right Choice

When deciding between aluminum hand forged vs machined processes, there is no one-size-fits-all answer. The optimal choice depends on your specific application requirements, including strength needs, precision requirements, production volume, and budget constraints.

Choose Forging When You Need:

- Maximum strength and durability

- Superior fatigue resistance

- Optimal grain structure

- Cost-effective high-volume production

- Excellent material utilization

Choose Machining When You Need:

- Highest precision and tight tolerances

- Complex geometries and features

- Excellent surface finish

- Low-volume or prototype production

- Shorter lead times

MAIKONG’s expertise in both aluminum forging and CNC machining allows us to recommend and implement the optimal manufacturing approach for your specific requirements. In many cases, a combination of both processes—forging for strength and near-net shape, followed by precision machining of critical features—provides the best overall solution.

Ready to Discuss Your Aluminum Component Needs?

Contact MAIKONG today to speak with our engineering team about your specific requirements.

Get A Quick Quote

Frequently Asked Questions

What are the main advantages of aluminum forging over machining?

Aluminum forging offers superior strength, improved fatigue resistance, better grain structure, and higher material utilization. The forging process aligns and refines the grain structure, resulting in components that can withstand higher stress and have better mechanical properties. Forging is typically more cost-effective for higher production volumes once tooling costs are amortized.

When is CNC machining preferred over forging for aluminum parts?

CNC machining is preferred when precision, complex geometries, and tight tolerances are required. It’s also advantageous for low-volume production, prototyping, and parts with intricate internal features that cannot be achieved through forging. Machining offers excellent surface finish and dimensional accuracy without the need for expensive tooling, making it ideal for smaller production runs.

What aluminum alloys work best for forging?

The most commonly used aluminum alloys for forging include 2014, 2024, 6061, and 7075. These alloys offer excellent formability during the forging process and respond well to heat treatment after forging. The 7xxx series alloys provide the highest strength, while 6xxx series offers a good balance of strength, corrosion resistance, and formability.

How does MAIKONG ensure quality for both forged and machined components?

MAIKONG maintains ISO 9001:2015 certified quality management systems for all manufacturing processes. For forged components, we conduct material verification, die inspection, in-process monitoring, and various testing methods including metallurgical analysis and mechanical property testing. For machined components, we perform first article inspection, in-process verification, and final dimensional inspection using precision measurement equipment. All components undergo rigorous quality control to ensure they meet or exceed specifications.

What production volumes make forging more cost-effective than machining?

Generally, forging becomes more cost-effective than machining at production volumes exceeding 1,000 pieces. The initial tooling costs for forging are higher, but the per-part cost decreases significantly with volume due to faster cycle times and better material utilization. For quantities under 500 pieces, CNC machining is typically more economical. Between 500-1,000 pieces, a detailed cost analysis is recommended to determine the optimal approach based on part complexity and specific requirements.

MAIKONG’s state-of-the-art facilities for aluminum hand forging and CNC machining

MAIKONG’s state-of-the-art facilities for aluminum hand forging and CNC machining