At MAIKONG, we deliver exceptional aluminum forging and machining services that combine advanced technology with decades of manufacturing expertise. Our comprehensive capabilities ensure high-quality, cost-effective custom metal components that meet the most demanding specifications across diverse industries. Whether you need precision-forged aluminum parts or complex CNC machined components, our team provides end-to-end solutions from design to delivery.

MAIKONG’s state-of-the-art aluminum forging and machining facility in GD, SZ

Comprehensive Aluminum Forging and Machining Capabilities

MAIKONG operates a cutting-edge manufacturing facility in GD, SZ with over 60 CNC machines and monthly production capacity exceeding 100 tons. Our integrated approach combines advanced forging techniques with precision machining to deliver superior aluminum components that meet the highest quality standards.

Forging Excellence

Our aluminum forging process enhances material properties through controlled deformation and grain flow alignment. This results in components with superior strength-to-weight ratios, improved mechanical properties, and consistent performance – ideal for applications where reliability is critical.

Precision Machining

Our comprehensive CNC machining capabilities include multi-axis milling, turning, and Swiss-type machining. This allows us to achieve tight tolerances, complex geometries, and superior surface finishes on forged aluminum components.

Ready to Elevate Your Manufacturing?

Discover how MAIKONG’s integrated aluminum forging and machining solutions can enhance your product quality while reducing costs.

Get A Quick Quote

Advanced Aluminum Forging Services

MAIKONG specializes in custom aluminum forging that delivers components with exceptional mechanical properties. Our forging process creates parts with improved strength, durability, and performance compared to casting or machining from billet.

MAIKONG’s aluminum forging process creates components with superior mechanical properties

Closed Die Forging

Our closed die forging process creates complex shapes with tight tolerances, making it ideal for high-performance components in aerospace, automotive, and industrial applications.

Custom Alloy Selection

We work with various aluminum alloys including 2014, 6061, and 7075 series, selecting the optimal material based on your application requirements and performance needs.

Heat Treatment

In-house heat treatment capabilities allow us to achieve specific tempers such as T6, T651, and T73, optimizing the mechanical properties of your forged aluminum components.

Why Choose Aluminum Forging?

Advantages of Forged Aluminum

- Superior strength-to-weight ratio

- Enhanced mechanical properties

- Improved grain structure and flow

- Better fatigue resistance

- Higher impact toughness

- Excellent corrosion resistance

- Reduced material waste

Limitations of Alternative Methods

- Casting: Potential air pockets and inclusions

- Machining from billet: Excessive material waste

- Extrusion: Limited to fixed cross-sectional profiles

- Steel components: Excessive weight

- Casting: Lower tensile strength

- Billet machining: Higher production costs

- Casting: Unpredictable material properties

Precision CNC Machining Services

MAIKONG offers comprehensive CNC machining services that complement our aluminum forging and machining capabilities. Our advanced equipment and experienced technicians ensure precise, high-quality components for every application.

Precision CNC machining of forged aluminum components at MAIKONG

CNC Turning

Our CNC turning services create precise cylindrical shapes, deep holes, and machined threads with superior surface finishes. Ideal for shafts, bushings, and other rotational components.

CNC Milling

Multi-axis CNC milling capabilities allow us to create complex prismatic shapes and flat surfaces with high precision. Our flexible approach requires no fixed tooling while maintaining extreme accuracy.

Swiss-Type Machining

Specialized in precision small parts and long shaft components, our Swiss-type machining features dual spindles and multi-axis capabilities for one-stop manufacturing solutions.

Aluminum Forging vs. Casting: Making the Right Choice

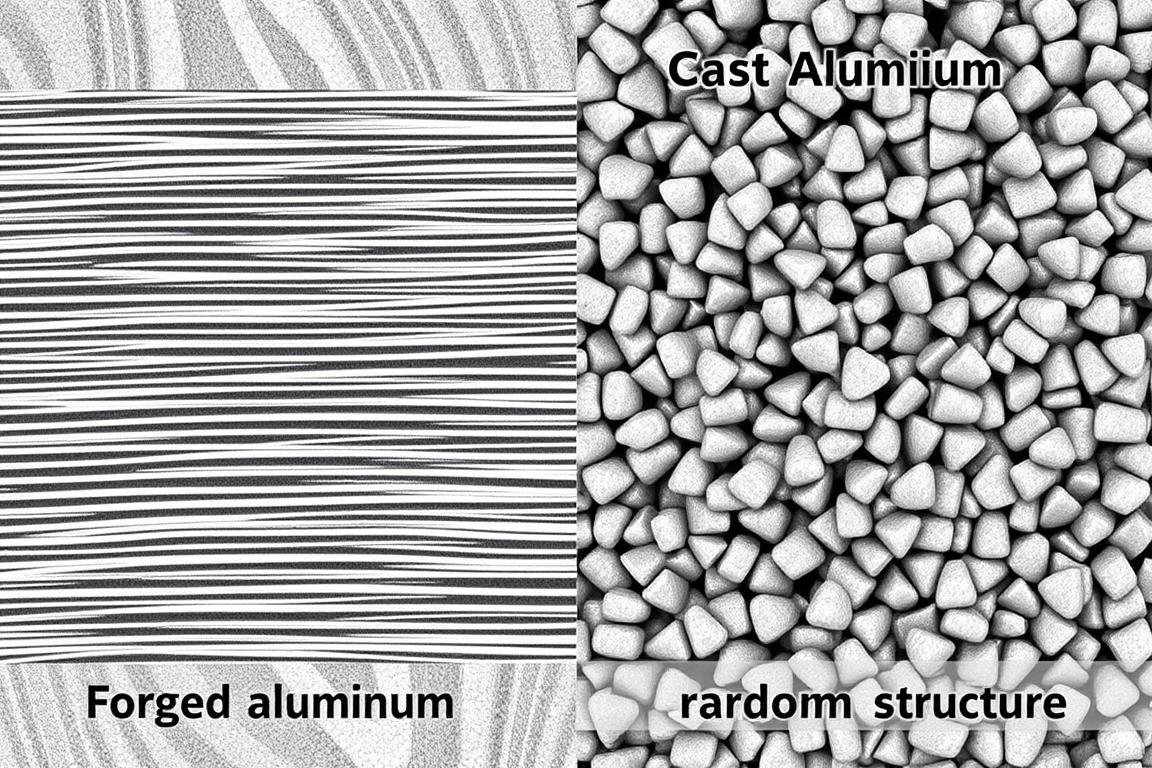

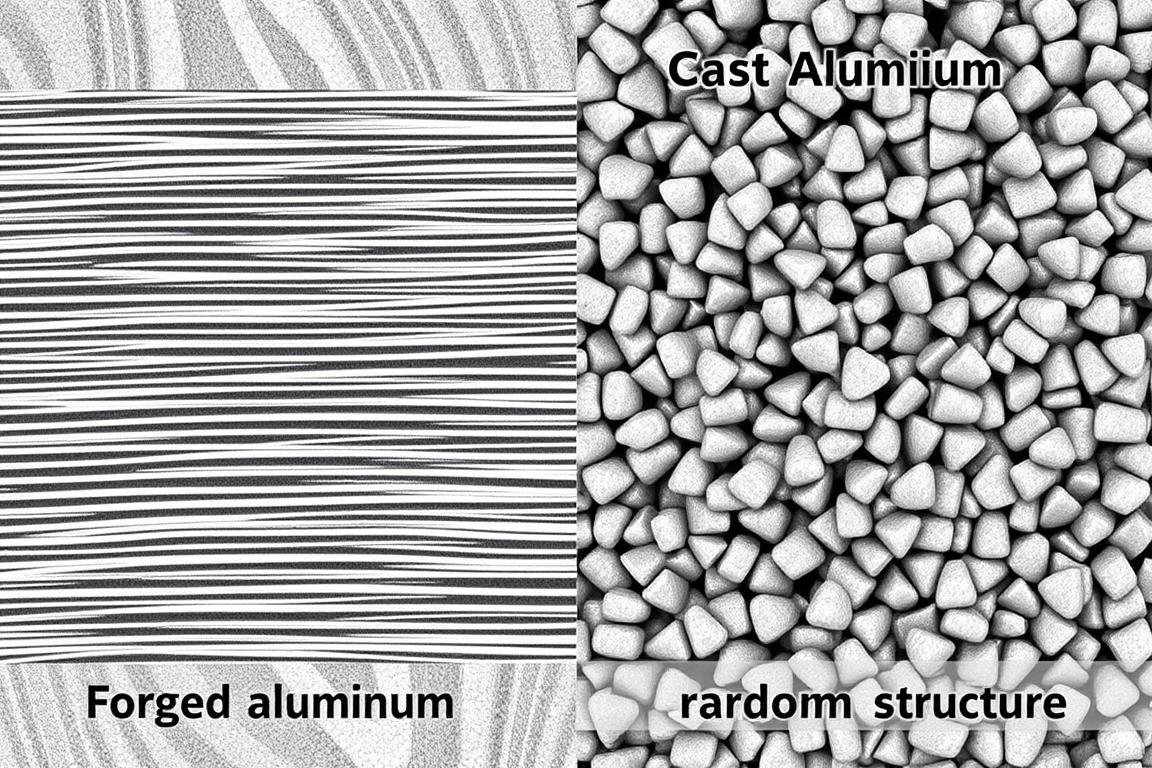

Understanding the differences between forged and cast aluminum is crucial for selecting the optimal manufacturing process for your components. The table below highlights key differences to help you make an informed decision.

| Comparison Criteria |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

Can achieve complex shapes in one session |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Ideal Applications |

Aerospace, automotive, high-performance components |

Consumer goods, simple parts, non-critical applications |

Microstructure comparison: Forged aluminum (left) shows aligned grain structure versus cast aluminum (right)

Full-Service Aluminum Forging and Machining Solutions

MAIKONG provides comprehensive end-to-end manufacturing services, from initial design consultation through final delivery. Our integrated approach ensures quality, consistency, and cost-effectiveness at every stage of production.

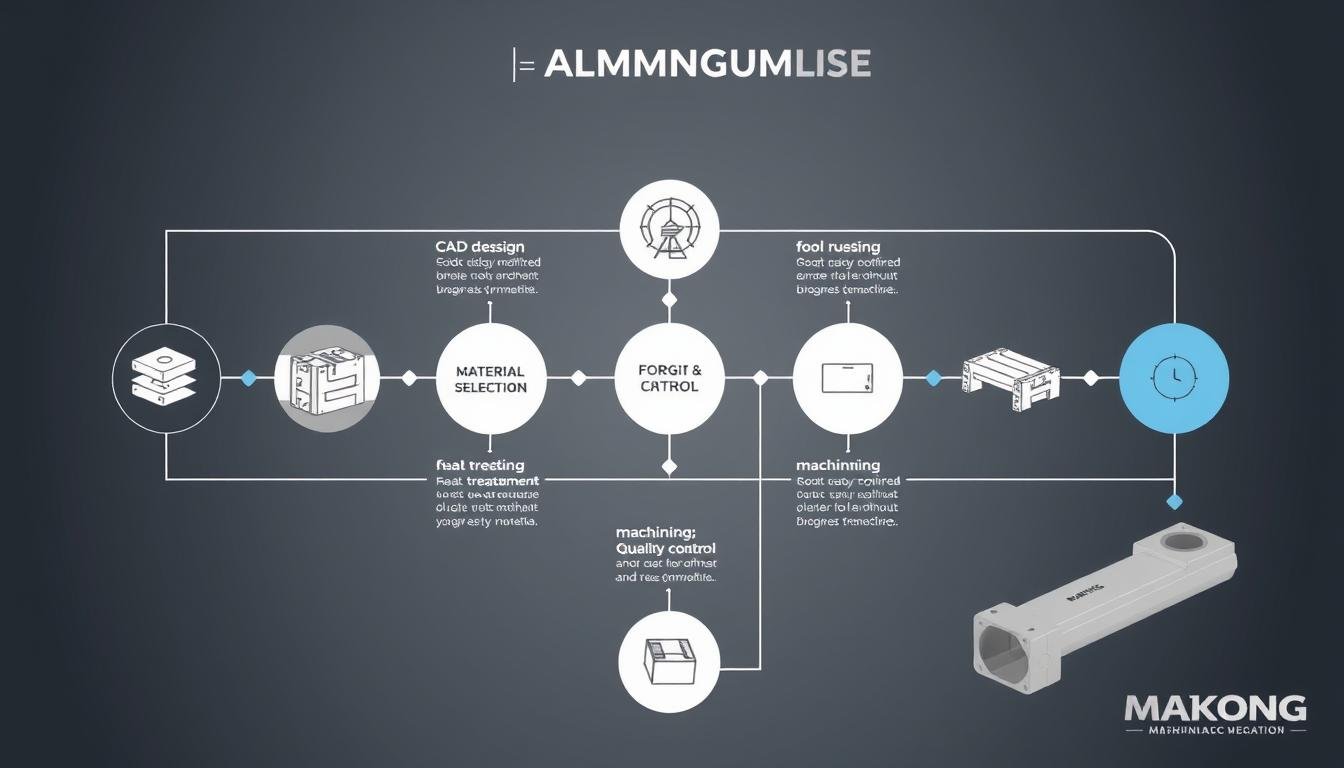

MAIKONG’s comprehensive aluminum forging and machining process flow

Design & Engineering

Our CAD/CAM capabilities and engineering expertise help identify and resolve potential issues early in the design phase, optimizing your components for both performance and manufacturability.

Material Selection

We carefully consider mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness when selecting the optimal aluminum alloy for your application.

Tooling Design

Precision tooling design ensures initial quality, while our regular maintenance program preserves consistency throughout production runs of any size.

Heat Treatment

In-house heat treatment with comprehensive statistical analysis and documentation ensures your aluminum components achieve the precise mechanical properties required.

Surface Treatment

We offer various finishing options including anodizing, painting, laser engraving, and sand blasting to enhance both appearance and performance of your components.

Quality Assurance

Rigorous quality control procedures throughout the manufacturing process ensure every component meets stringent standards for dimensional accuracy and performance.

Experience Our Comprehensive Manufacturing Solutions

From design to delivery, MAIKONG provides end-to-end aluminum forging and machining services to meet your exact specifications.

Contact Us on WhatsApp

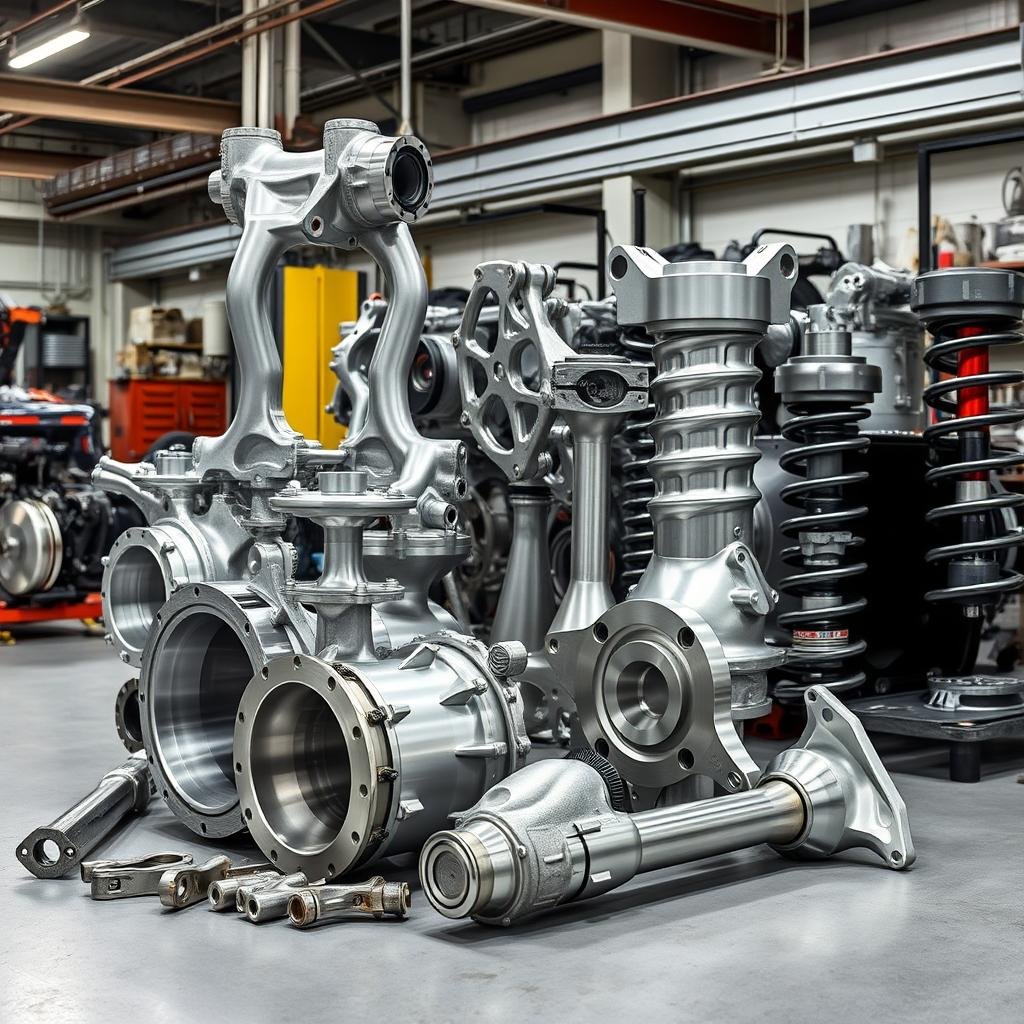

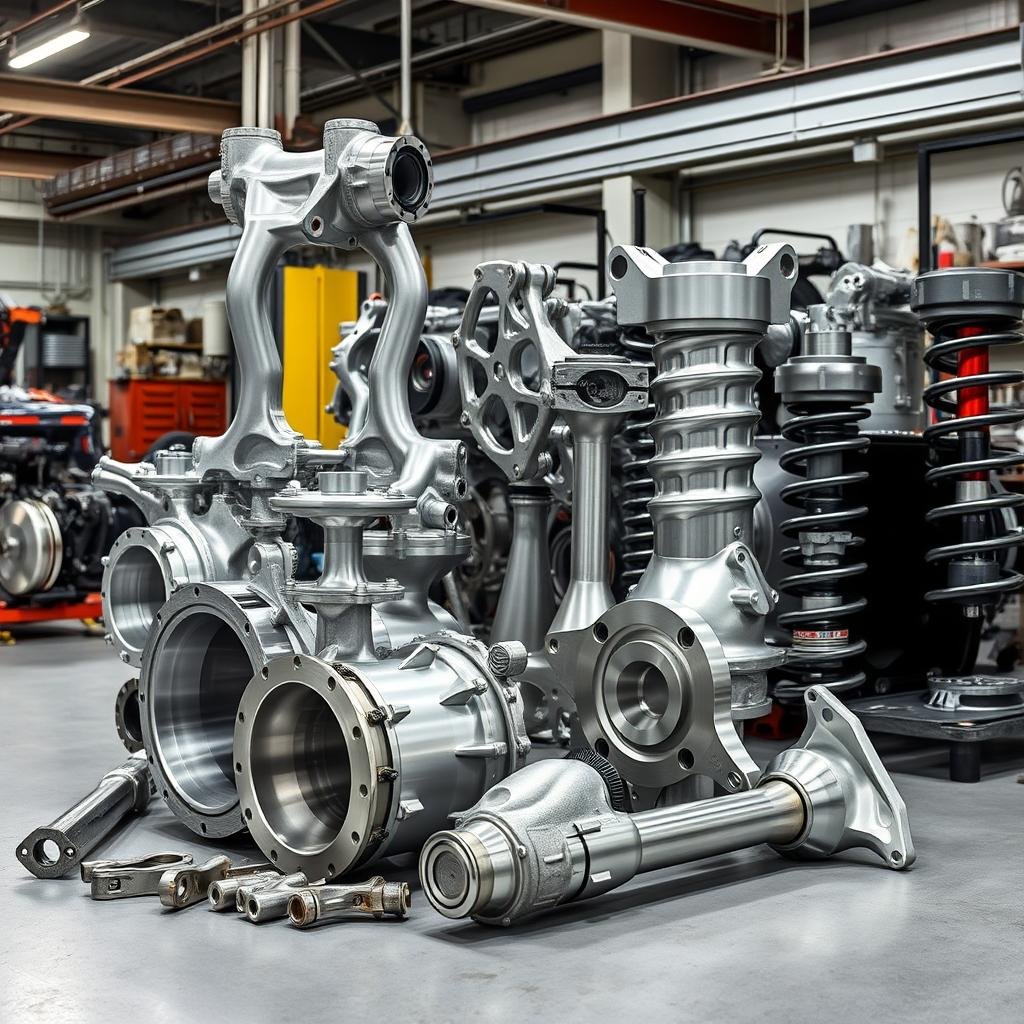

Industry Applications

MAIKONG’s aluminum forging and machining capabilities serve diverse industries with custom components that meet specific performance requirements. Our expertise spans multiple sectors where precision, reliability, and quality are paramount.

Aerospace Components

Automotive Parts

Industrial Equipment

Aerospace

- Structural components

- Landing gear parts

- Engine components

- Aircraft fittings

Automotive

- Suspension components

- Brake calipers

- Engine parts

- Transmission components

Industrial

- Valve bodies

- Hydraulic components

- Structural elements

- Heavy machinery parts

MAIKONG produces a wide range of custom aluminum forged and machined components for diverse applications

Quality Assurance

At MAIKONG, quality is built into every step of our aluminum forging and machining process. Our ISO 9001:2015 certified quality management system ensures consistent, reliable components that meet or exceed your specifications.

Rigorous quality inspection ensures every component meets precise specifications

Testing Capabilities

- Dimensional inspection

- Material composition analysis

- Mechanical property testing

- Non-destructive testing

- Surface finish measurement

Quality Control Process

- Incoming material verification

- In-process inspection

- Final quality verification

- Comprehensive documentation

- Traceability throughout production

“At MAIKONG, we don’t just check quality – we build it into every step of our manufacturing process. Our commitment to excellence ensures your components perform reliably in even the most demanding applications.”

– Quality Assurance Director, MAIKONG

Aerospace Components

Aerospace Components

Automotive Parts

Automotive Parts

Industrial Equipment

Industrial Equipment