Billet Machining

- Machined Aluminum Forgings 7075 T6: Superior Strength for Critical Applications

- Machined Forged Aluminum Center: Premium Manufacturing Solutions

- Decoding Billet Machining: Essential Terminology for US Procurement Teams

- Machined Forged Aluminum Center Wheel Manufacturing Excellence

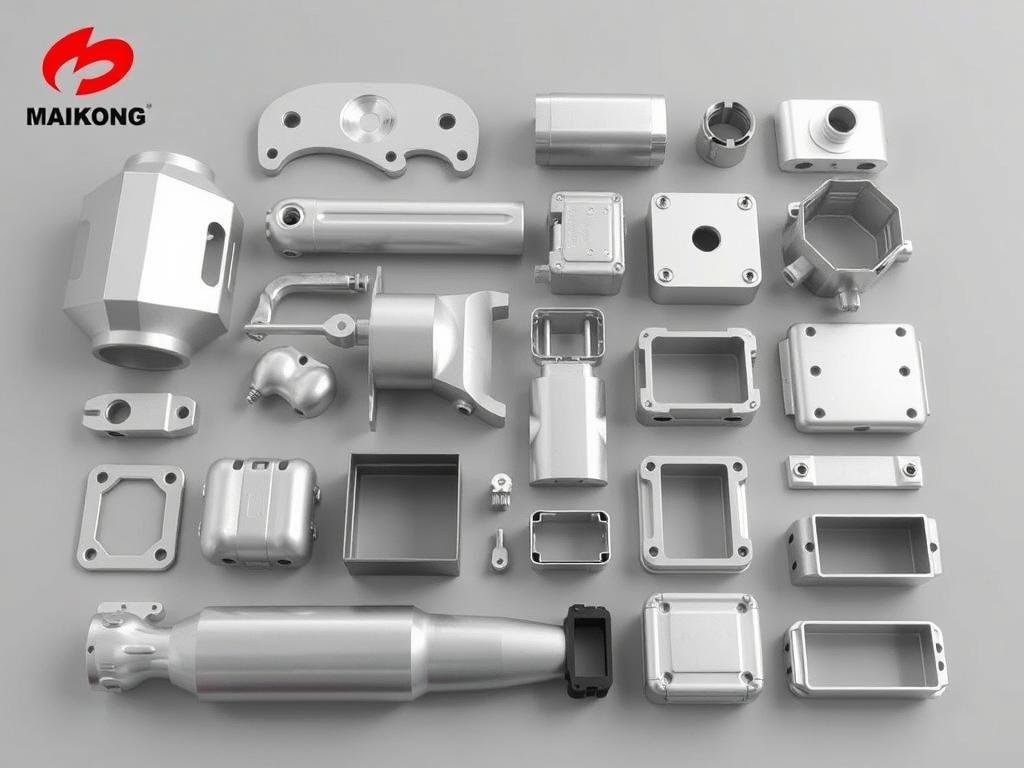

- Premium Aluminum Forging Machining: Complete Solutions from MAIKONG

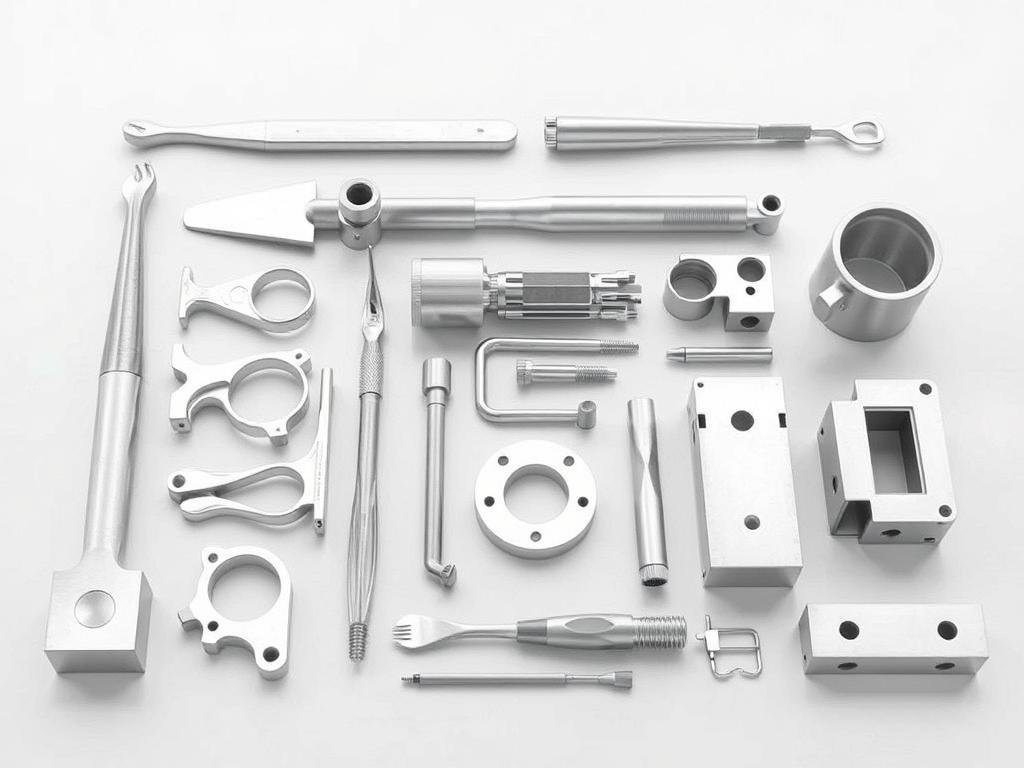

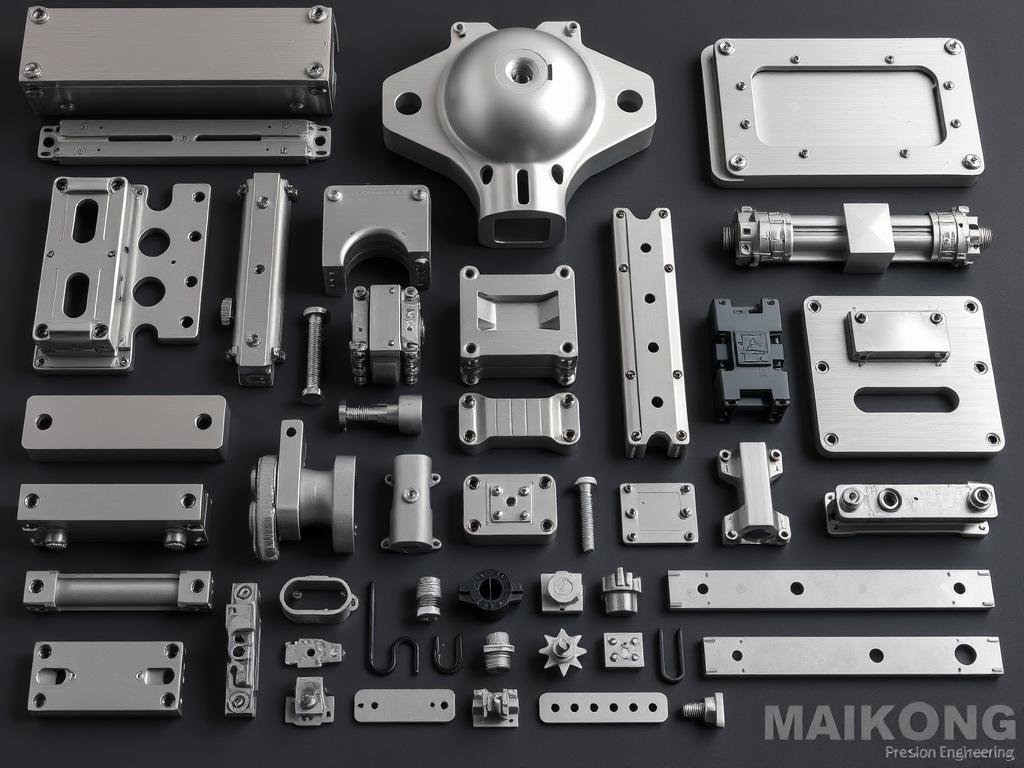

- The Versatility of Billet Machining: Crafting Diverse Custom Parts

- Premium Aluminum Forging Machining and 9001 Certification Services

- Premium Aluminum Forging and Machining Solutions

- Aluminum Hand Forged vs Machined: Comprehensive Comparison Guide

- Cold Forged Type-II Anodized Machined Aluminum: The Ultimate Guide

- Premium Cold Forged Type-II Anodized Machined Aluminum Spool Manufacturing

- What is Billet Machining? A Comprehensive Introduction for US Industrial Buyers

- Aluminum Hand Forged vs Machined Vintage: The Definitive Comparison

- The Core Benefits of Machining Parts from Billet for High-Performance Applications

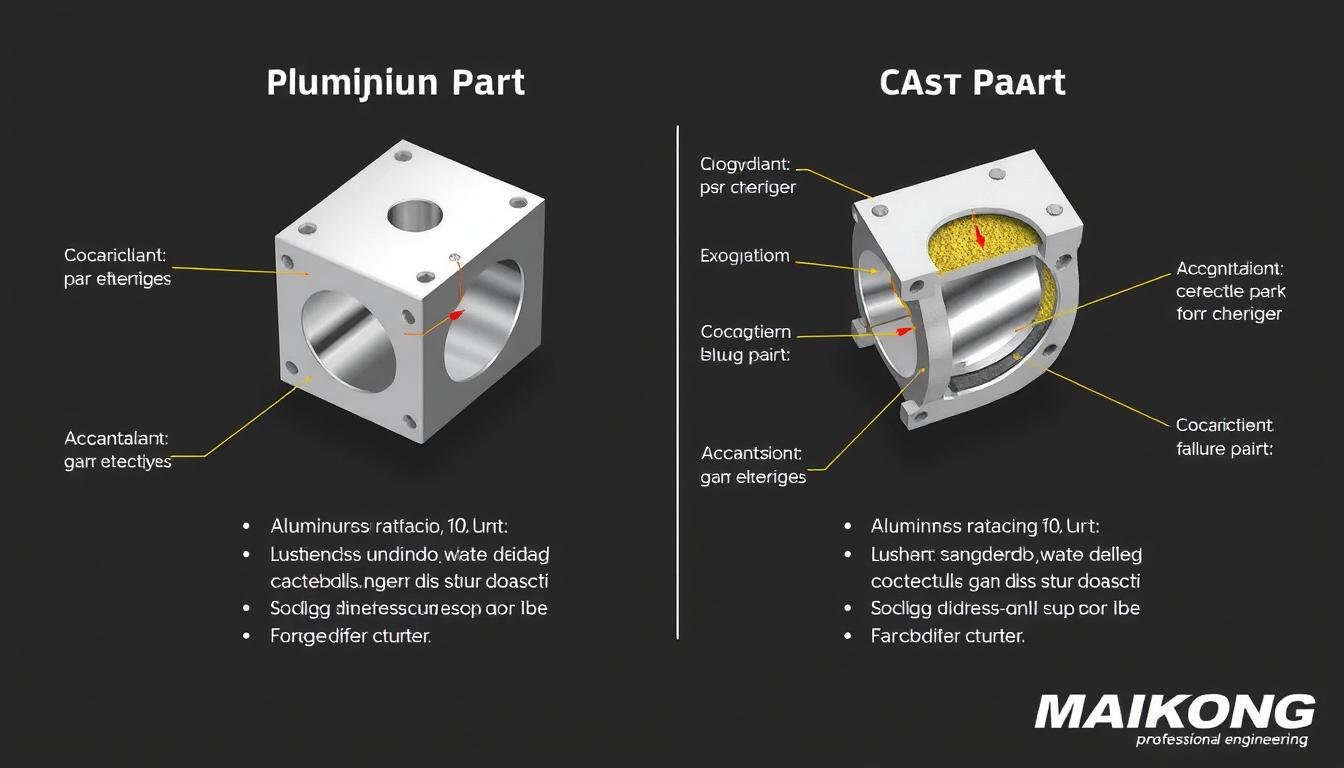

- Forged Aluminum Engine Block vs Machined: The Ultimate Comparison Guide

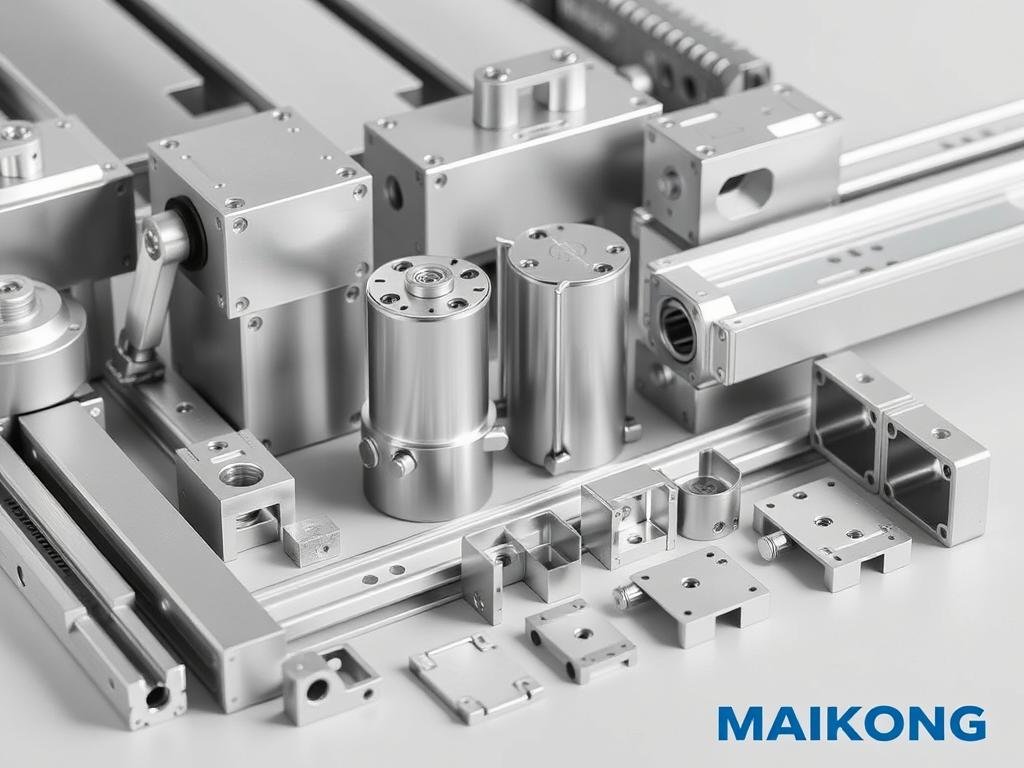

- Billet Machining Process: From Raw Stock to Finished Component

- Forged Aluminum vs Machined Steel: Comprehensive Material Comparison

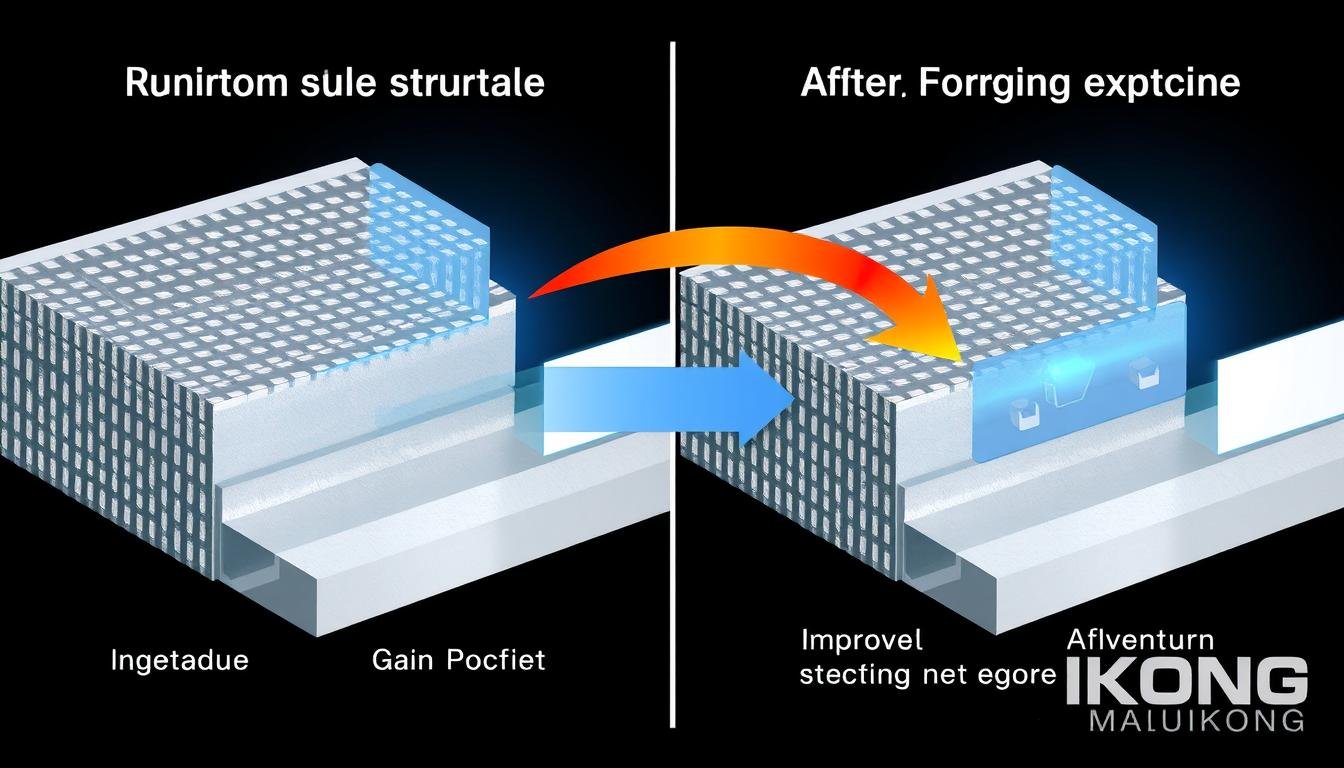

- Forged vs Machined Aluminum: Complete Comparison Guide

- Why Choose Billet Machining for Your Next US Manufacturing Project?

- A Brief History of Machining from Solid Billet and Its Evolution in the US

- Key Advantages of Billet Machining Process in Modern Engineering

- How Billet Machining Contributes to Quality and Durability in American Manufacturing

- Gear Forged Aluminum vs Machined Steel: The Ultimate Comparison

- The Future of Billet Machining: Trends and Innovations for US Industries