Welcome to MAIKONG, your trusted partner for precision Quality Aluminum Forge LLC services. With over two decades of experience, we specialize in delivering superior aluminum forgings, CNC machining, and custom metal fabrication to meet the mission-critical needs of aerospace, automotive, and defense industries. Our commitment to excellence, on-time delivery, and competitive pricing makes us the preferred choice for clients seeking reliable forging solutions worldwide.

POWERFUL SOLUTIONS UNDER ONE ROOF

MAIKONG’s Quality Aluminum Forge LLC division delivers on-time and superior customer service to meet the mission-critical needs of our global customer base. We specialize in precision, near net shaped, seamless aluminum forgings and finished machined components and assemblies. With our state-of-the-art facility in SZ, GD, we have the capability to meet all your aluminum forging and CNC machining needs.

MAIKONG’s state-of-the-art Quality Aluminum Forge LLC facility in SZ, GD

MAIKONG is not just a build-to-print shop, but an all-source solution provider incorporating powerful CATIA modeling and Deform simulation software to produce forge models from machined part configurations. This gives our customers another option when sourcing their machined part requirements, ensuring optimal results with competitive pricing.

COMPREHENSIVE PRODUCT RANGE

MAIKONG’s Quality Aluminum Forge LLC products span the delivery of precision, near net shaped seamless forgings to finished parts and assemblies for the aerospace, commercial, and defense industries. We manufacture parts utilizing hydraulic presses ranging from 500 up to 2500 tons. Approximately 50% of the parts we forge are fully machined, assembled, and ready for the next higher assembly, delivered directly to the assembly line.

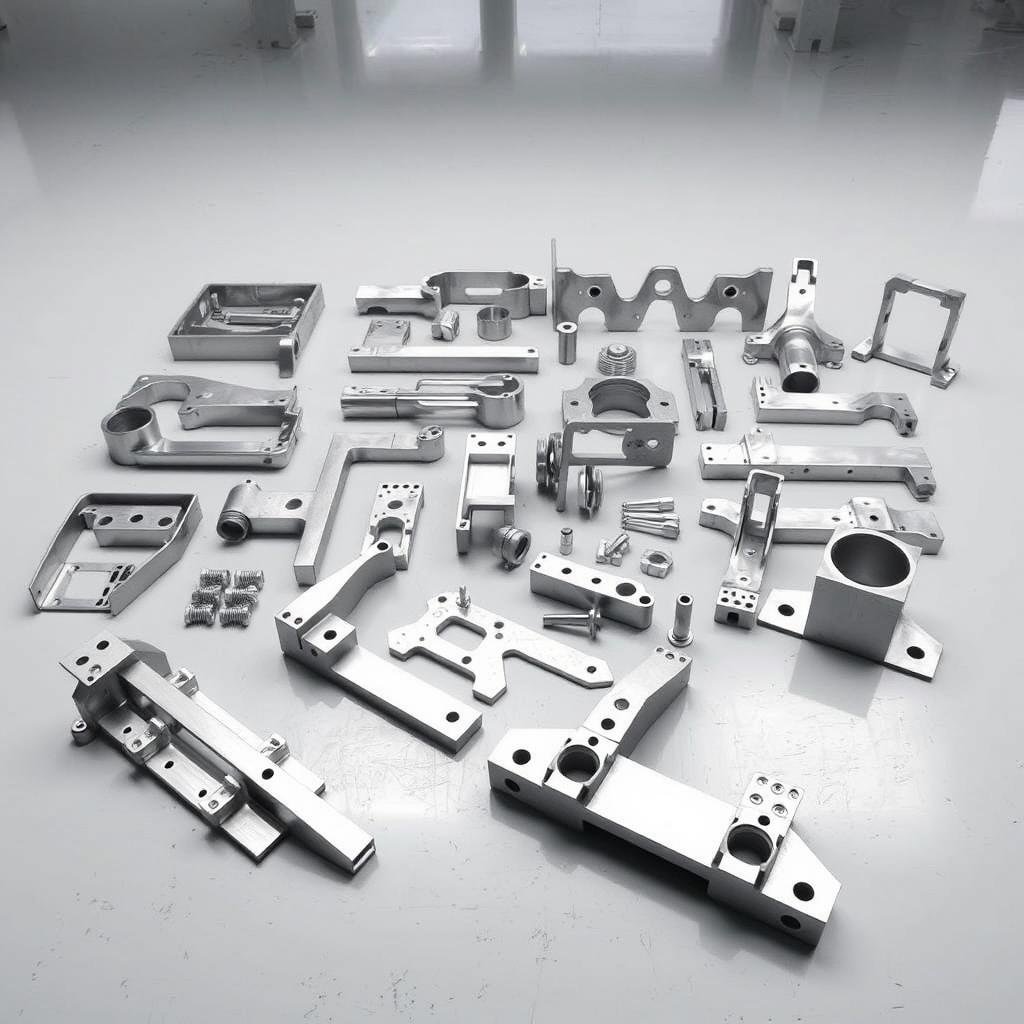

Precision aluminum forged components for aerospace applications

- Near net-shaped aluminum forgings and finished machined components and assemblies

- Machining, finishing, assembly, and kitting capabilities provide a comprehensive solution

- Powerful modeling and simulation expertise produces forge models from machined parts configuration

- Competitive pricing with superior quality control

- Global shipping capabilities with fast turnaround times

MAIKONG is able to work with our customers to meet their needs for the development of precision aluminum forged products based on finished machined part configurations and digital design specifications. Our engineering team can help optimize your designs for manufacturability and cost-effectiveness.

INDUSTRY APPLICATIONS

Airframe Structural Components

Precision-forged aluminum components for aircraft structural integrity and performance.

Engine Nacelle Applications

High-strength aluminum forgings for critical engine housing and mounting systems.

Actuation/Systems Forgings

Custom aluminum forgings for hydraulic and mechanical actuation systems.

Landing Gear Components

High-strength aluminum forgings designed to withstand extreme landing forces.

MATERIALS EXPERTISE

MAIKONG’s Quality Aluminum Forge LLC division supplies more than 6,000 configurations of forgings made from 250 different alloy systems, with new offerings continually being added to meet evolving industry needs.

| ALLOY TYPE |

MAX PLAN VIEW |

MAX WEIGHT |

COMMON APPLICATIONS |

| Aluminum |

125in² |

100Lbs |

Aerospace, Automotive, Defense |

| 1050 Series |

100in² |

80Lbs |

General Engineering, Electrical |

| 6061 Series |

125in² |

100Lbs |

Structural, Marine, Transportation |

| 6063 Series |

110in² |

90Lbs |

Architectural, Extrusions |

Various aluminum alloys (1050, 6005A, 6061, 6063, 6351, 6360, 6463) used in our forging operations

OUR CNC MACHINING SERVICES

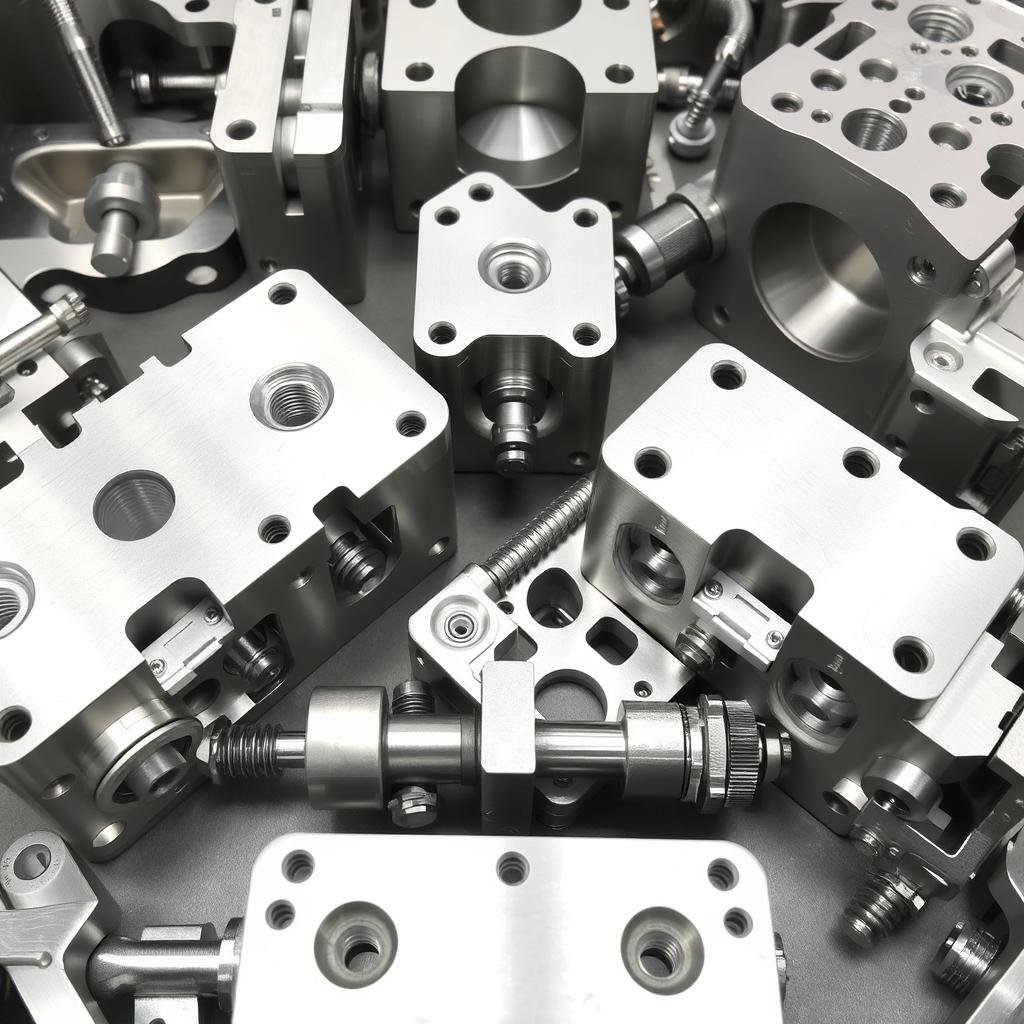

MAIKONG has 60+ CNC machines providing 100+ tons of metal processing capacity per month. Our CNC machining services offer precision fabrication of plastic and metal parts in any volume. We specialize in turning, milling, swiss machining, multi-axis machining, surface grinding, laser engraving, and much more. All raw materials meet your exact specifications thanks to our best-in-class testing and verification laboratory.

CNC Turning Services

CNC turning is ideal for making deep holes, machined threads, and cylindrical shapes with superior surface finishes. When you need precisely manufactured parts with fast turnaround, our CNC turning services are your solution.

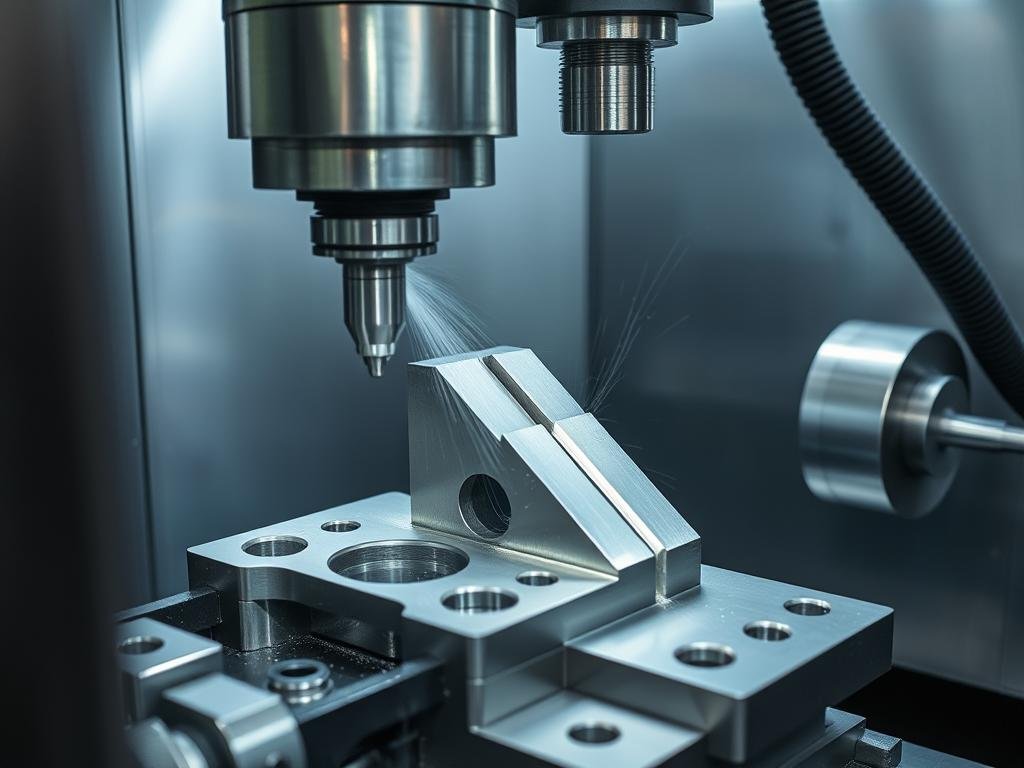

CNC Milling Services

CNC milling creates complex prismatic shapes and flat surfaces for a limitless variety of commercial and industrial products. Our multi-axis metal CNC machines require no fixed tooling, are highly flexible, and extremely accurate.

CNC SWISS Type Machining

Our CNC Swiss-type machining specializes in precision small parts and long shaft parts. Our equipment features dual spindles and 3-axis, 4-axis, 5-axis capabilities, allowing for a one-stop solution with the highest level of accuracy.

WHY CHOOSE MAIKONG’S QUALITY ALUMINUM FORGE LLC?

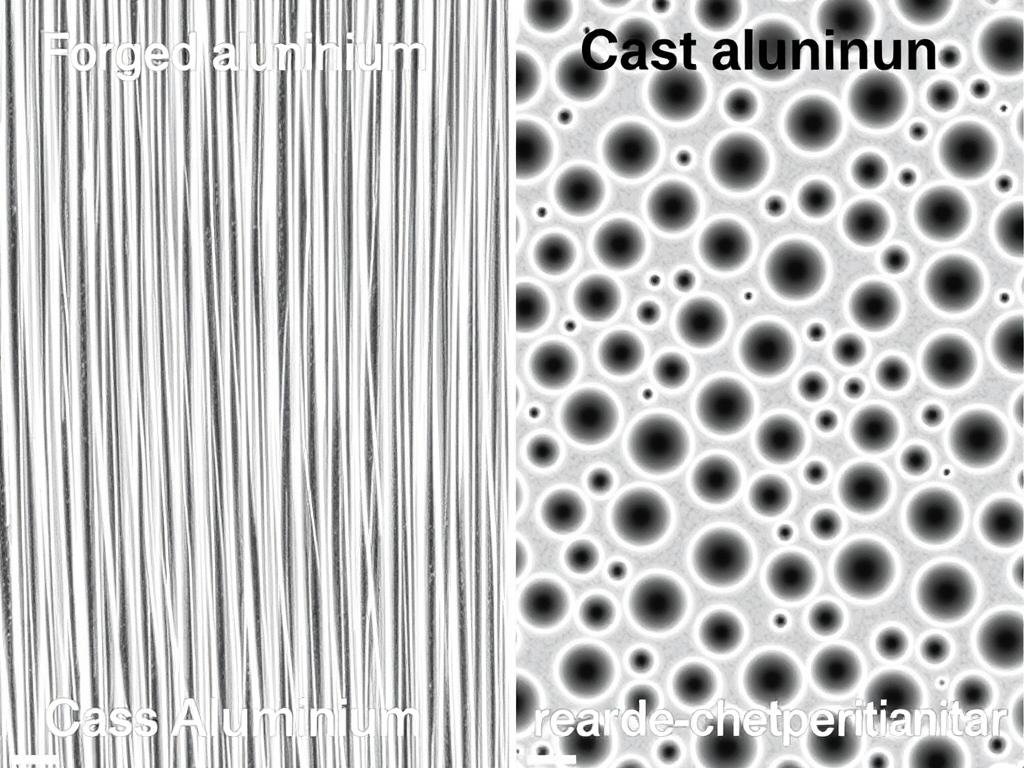

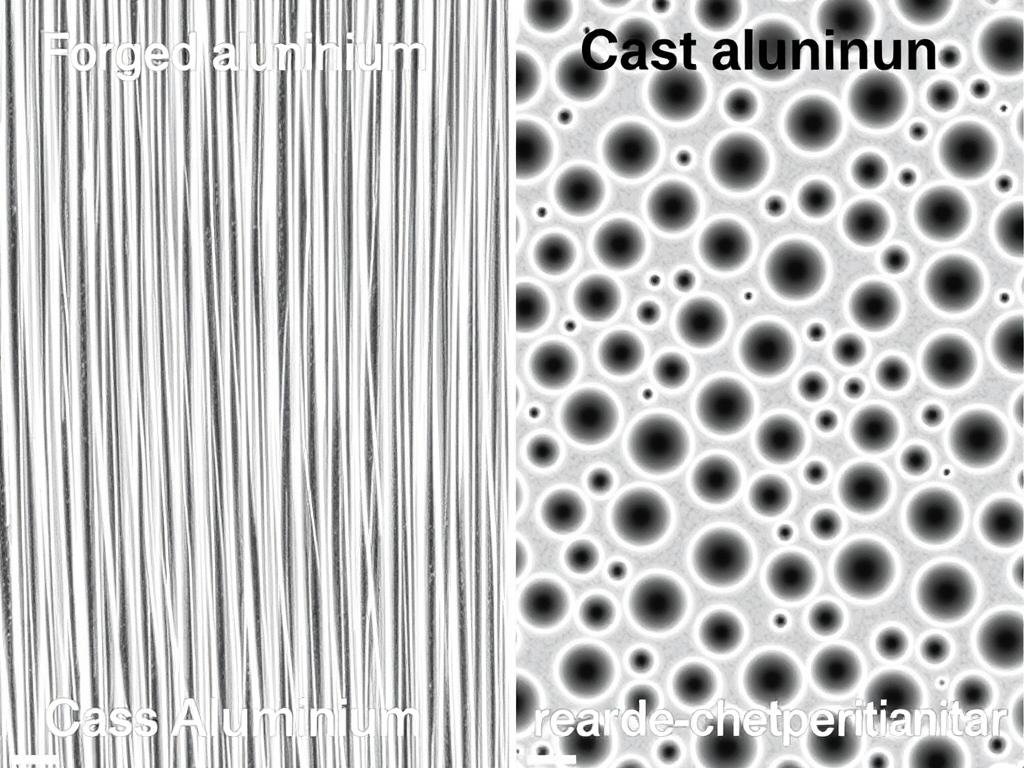

Forging vs. Casting: The Superior Choice

Aluminum forging offers significant advantages over casting, particularly in applications where strength, reliability, and performance are critical. Our forging process aligns the grain structure of aluminum, resulting in superior mechanical properties.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Critical Applications |

✅ Ideal for structural and load-bearing components |

Limited suitability for critical applications |

Microstructure comparison: Forged aluminum (left) shows aligned grain structure for superior strength vs. cast aluminum (right)

Optimal Strength-to-Weight Ratio

Strength-to-weight ratio is a fundamental engineering principle that addresses the balance between material strength and weight—an essential consideration in industries prioritizing performance, efficiency, and safety. Aluminum, recognized for its lightweight properties and robust mechanical characteristics, is enhanced through forging, refining its internal grain structure for enhanced resilience and strength.

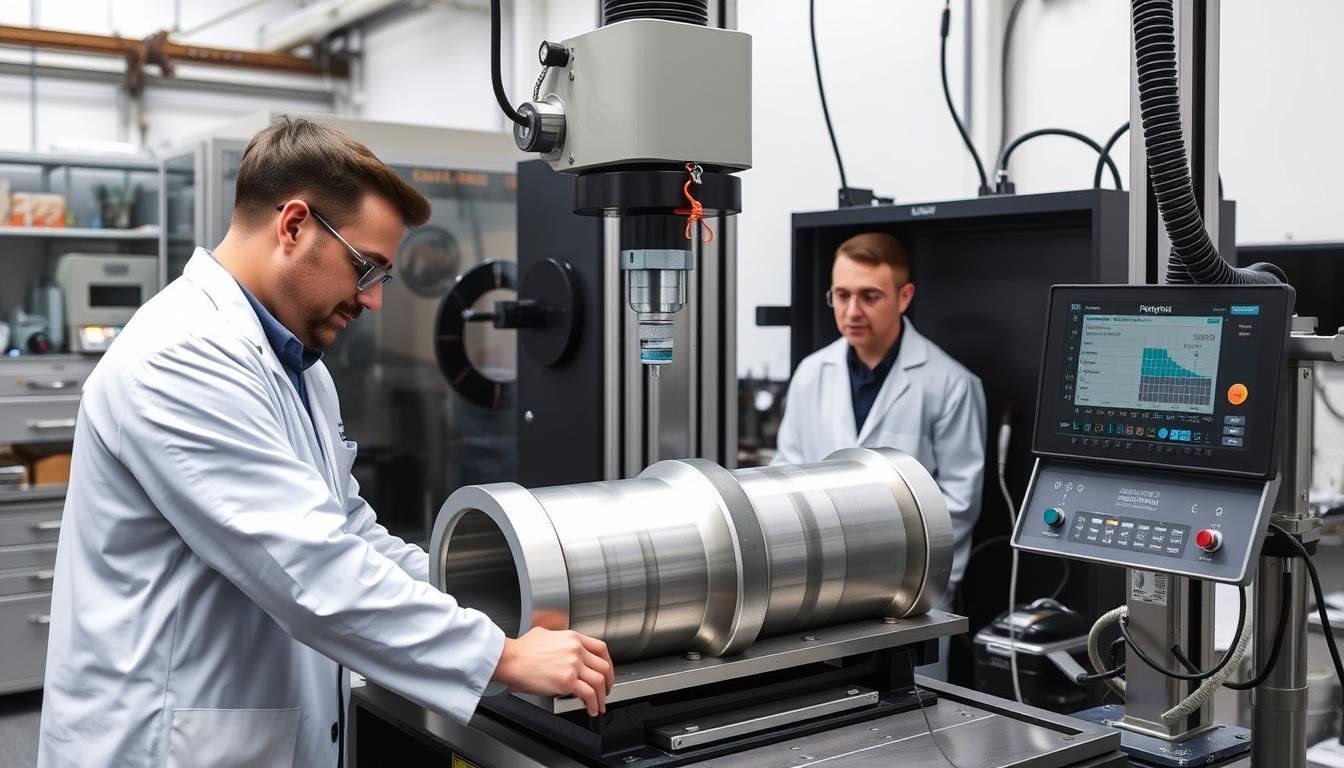

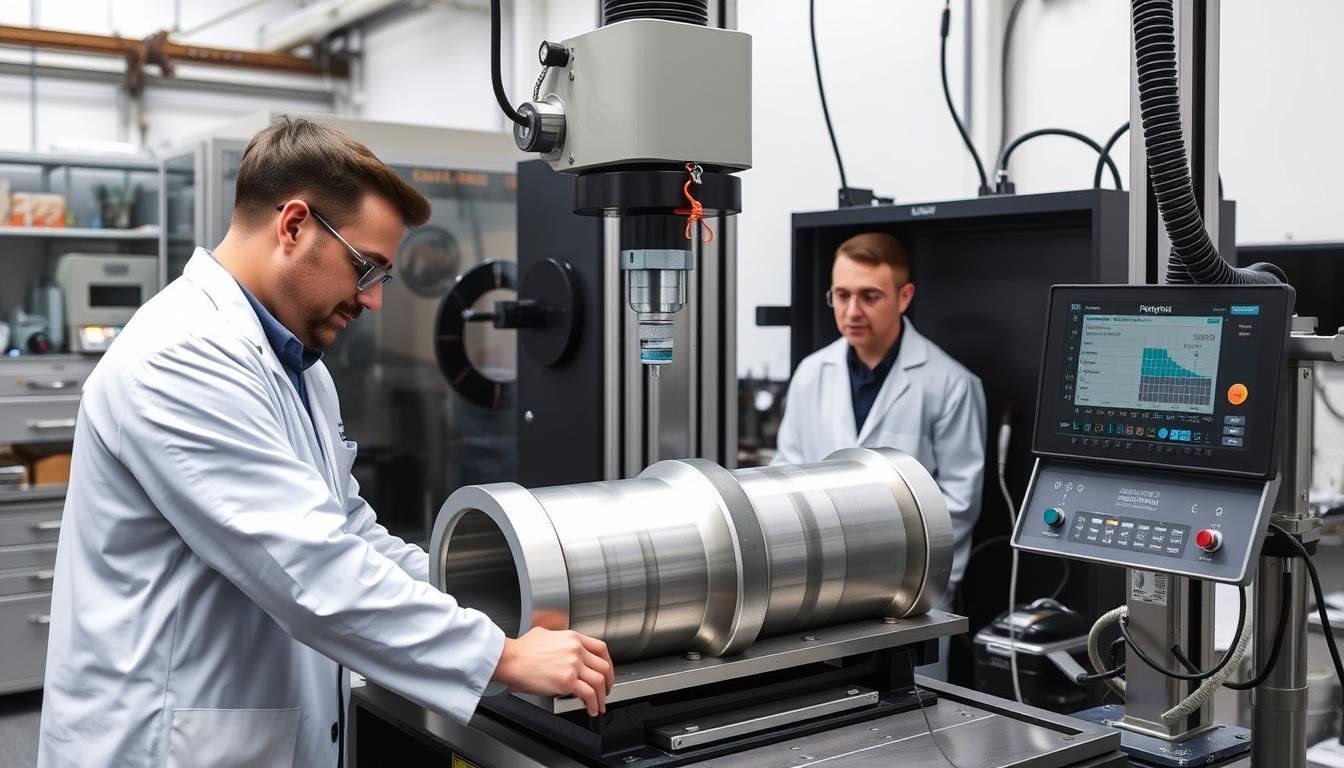

Strength testing of MAIKONG forged aluminum components demonstrates superior mechanical properties

OUR COMPREHENSIVE FORGING PROCESS

CAD/CAM Design

Our team utilizes advanced analysis software to facilitate early-stage issue identification and mitigation. This includes CATIA modeling and Deform simulation software to optimize the forging process before production begins.

Material Selection

We thoroughly consider the mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness of each aluminum alloy to ensure optimal performance for your specific application.

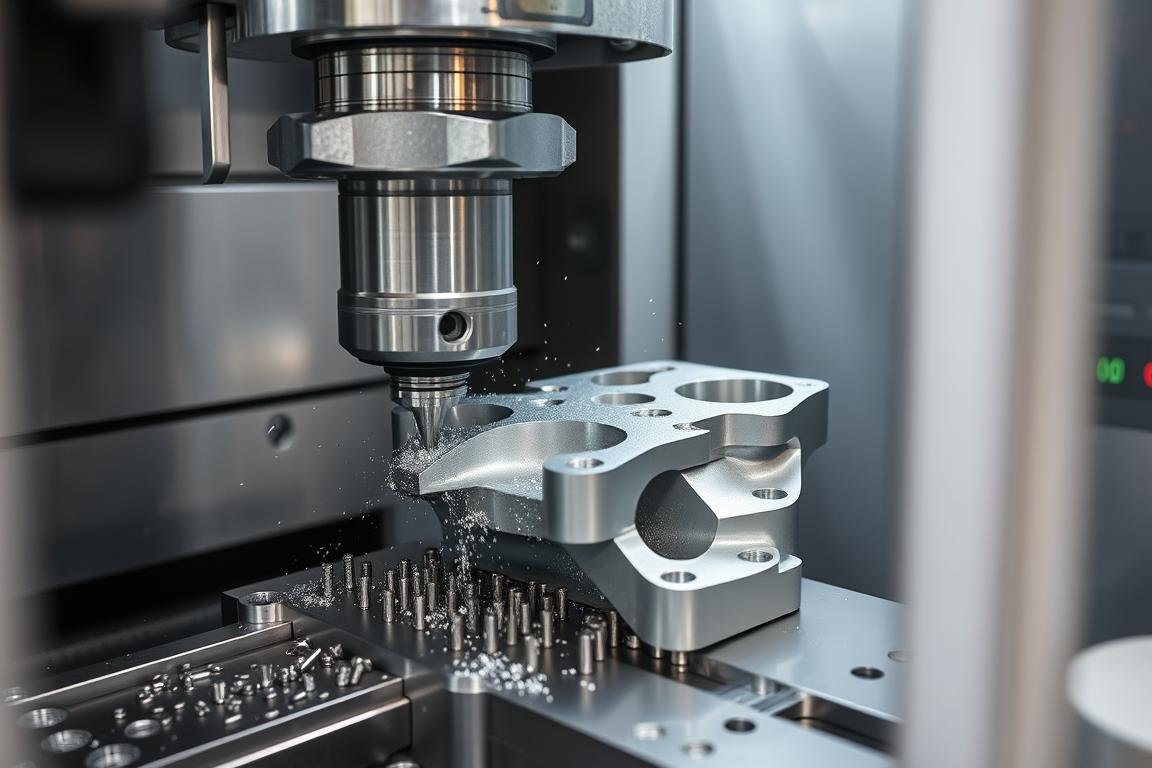

Precision Forging

Our forging workshop is equipped with hydraulic presses ranging from 500 to 2500 tons to accommodate diverse aluminum forging specifications, ensuring precision and consistency in every part we produce.

Heat Treatment

We conduct comprehensive statistical analysis and documentation for our in-house heat treatment processes, ensuring consistent material properties and performance across all forgings.

CNC Machining

Our machining workshop is equipped with state-of-the-art CNC machines capable of precise and intricate forging machining operations, transforming near-net forgings into finished components with tight tolerances.

Quality Control

Quality control procedures are essential to ensure that forged components meet stringent standards. Our comprehensive inspection processes include dimensional verification, material testing, and surface finish evaluation.

QUALITY CERTIFICATIONS

MAIKONG is committed to providing world-class services to meet customer requirements and specifications. Together, we institute a culture of integrity and relentless continuous improvement to eliminate waste, improve quality, and reduce throughput time.

We proudly maintain third-party quality certifications for our Quality Management System, ensuring all of our products comply with strict ISO 9001:2015 standards. Since November 2015, we have held the ISO 9001:2015 certification.

Reliable Quality Assurance featuring:

- ISO 9001:2015 certified

- ROMER arm, CMM, Manual Inspection as well as in-process visual inspection

- Rockwell Hardness and Conductivity Testing

- Digital Product Definition (DPD) approval

- Comprehensive material testing and verification

Superior Quality Management System:

- Ensures all suppliers and processors meet or exceed customer requirements

- Requires use of customer-approved sources for special processes and material manufacturing

- Evaluates all suppliers and processors against our stringent quality and delivery guidelines

- Evaluates based on timely delivery, acceptance rates, and customer approvals

BECOME A US AGENT FOR MAIKONG

We are currently recruiting agents throughout the United States to represent our high-quality, competitively priced aluminum forging and CNC machining services. Join our team and benefit from our industry-leading capabilities and customer service.

Contact Us About Agency Opportunities

WHY PARTNER WITH MAIKONG FOR YOUR ALUMINUM FORGING NEEDS

As both a producer and consumer of our customers’ products, MAIKONG recognizes the crucial importance of consistency, strength, and weight in each forged part for the final product. With a dedicated focus on crafting superior forged parts, we can fulfill your requirements for heat treating, machining, and testing.

Our material laboratory plays a vital role in our production process, enabling us to achieve the precise results you demand. Our team is committed to delivering optimal outcomes by possessing a profound understanding of materials, their properties, and their interactions. We are devoted to ensuring that our Quality Aluminum Forge LLC products consistently meet the highest standards of quality and performance.

Contact us today to discover how MAIKONG can support your aluminum forging and CNC machining requirements with competitive pricing, superior quality, and exceptional customer service.

Our team is ready to assist with your custom forging requirements. Get a competitive quote today!

Our team is ready to assist with your custom forging requirements. Get a competitive quote today!