Aluminium Forged Wheels: The Ultimate Guide to Performance and Quality

Welcome to MAIKONG’s comprehensive guide to aluminium forged wheels. As industry leaders in precision metal forging and CNC machining, we combine cutting-edge technology with decades of manufacturing expertise to create wheels that deliver unmatched performance, durability, and aesthetic appeal. Whether you’re seeking high-performance wheels for automotive applications, racing, or specialized vehicles, our aluminium forged wheels offer the perfect balance of strength, weight reduction, and customization options.

The Superior Advantages of Aluminium Forged Wheels

When it comes to wheel manufacturing, the forging process stands apart from other methods. Aluminium forged wheels offer exceptional benefits that make them the preferred choice for performance applications and premium vehicles.

Why Choose Aluminium Forged Wheels?

- Superior strength-to-weight ratio for enhanced performance

- Improved structural integrity through grain alignment

- Enhanced durability in demanding conditions

- Better heat dissipation for improved brake performance

- Precision manufacturing for perfect balance

- Reduced unsprung weight for better handling and acceleration

- Customizable designs and finishes

Ready to Experience Premium Quality?

Discover how MAIKONG’s aluminium forged wheels can transform your vehicle’s performance and appearance.

Request a Quote

The Aluminium Forged Wheels Manufacturing Process

At MAIKONG, we’ve perfected the art and science of creating premium aluminium forged wheels. Our manufacturing process ensures exceptional quality and performance in every wheel we produce.

Material Selection

We begin with premium 6061-T6 aluminum alloy billets, selected for their optimal combination of strength, weight, and machinability.

Precision Forging

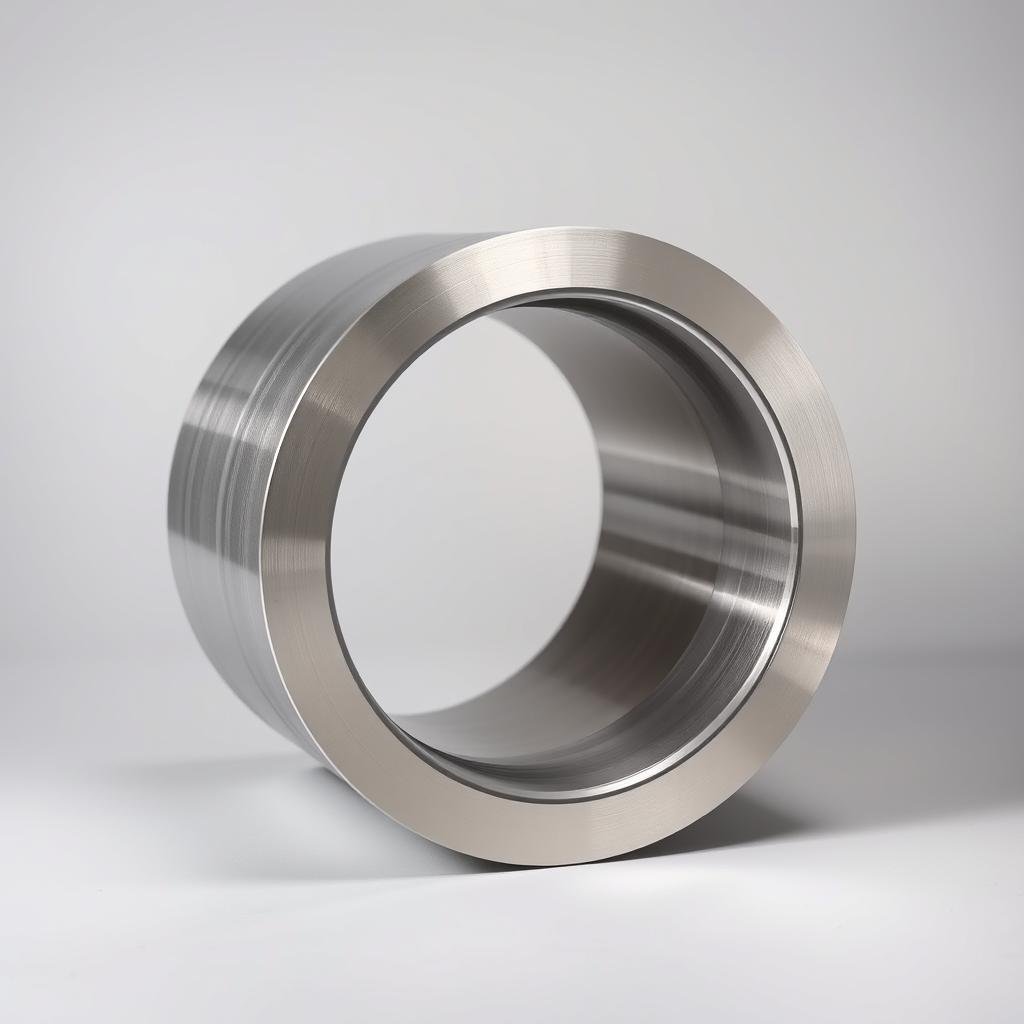

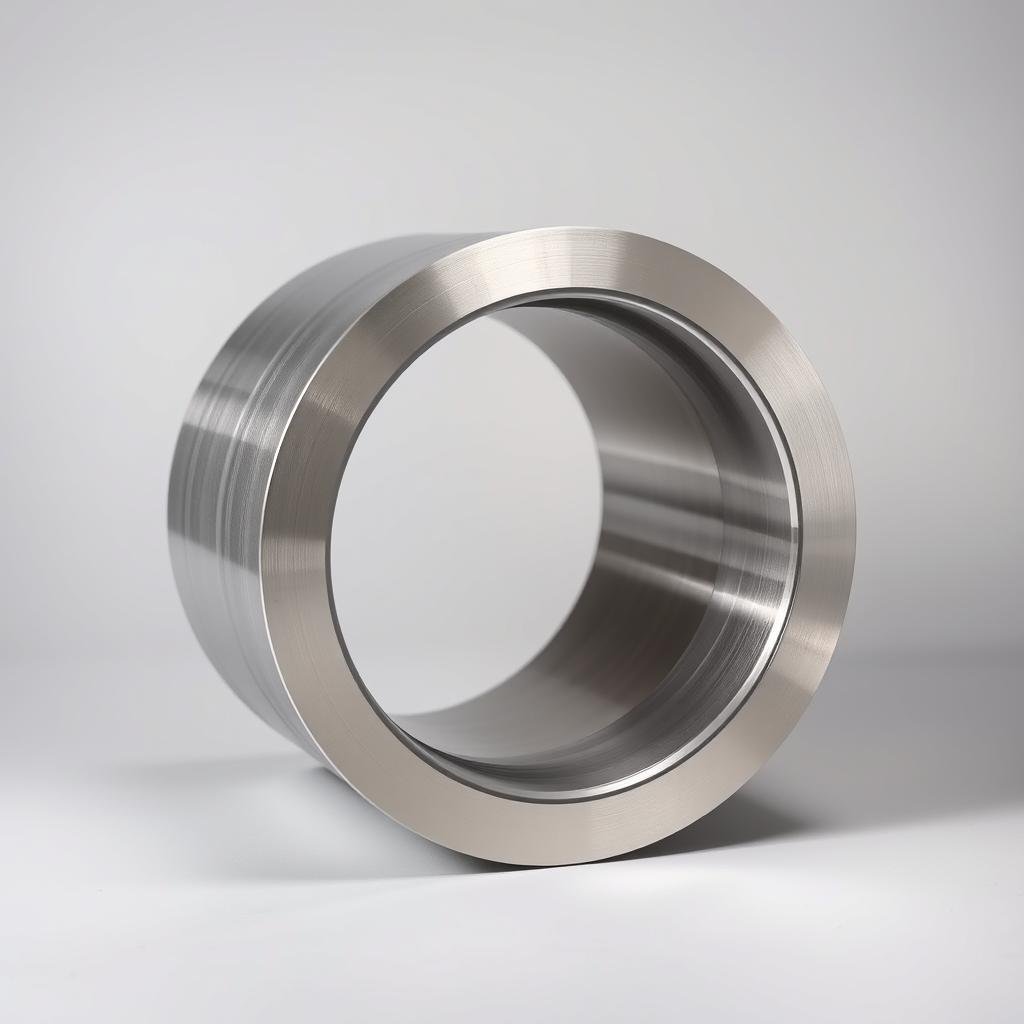

Using advanced rotary forging technology, we apply extreme pressure to align the metal’s grain structure, dramatically enhancing strength and durability.

CNC Machining

Our state-of-the-art CNC machines precisely shape each wheel to exact specifications, creating both functional excellence and aesthetic beauty.

Heat Treatment

Specialized heat treatment processes optimize the molecular structure of the aluminum, enhancing strength while maintaining lightweight properties.

Quality Testing

Rigorous testing ensures each wheel meets or exceeds industry standards for structural integrity, dimensional accuracy, and performance.

Surface Finishing

Premium finishing options including anodizing, powder coating, and polishing provide both protection and customized aesthetics.

Forged vs. Cast Aluminium Wheels: The Critical Differences

Understanding the differences between forging and casting is essential when selecting wheels for performance applications. MAIKONG specializes in the superior forging process that delivers exceptional results.

| Comparison Categories |

Aluminium Forged Wheels |

Cast Aluminium Wheels |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Lower due to potential air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Weight-to-Strength Ratio |

✅ High strength-to-weight ratio |

Bulkier parts may be needed for equivalent strength |

| Ideal Applications |

✅ Performance vehicles, racing, premium automotive |

Standard consumer vehicles, non-critical applications |

Expert Consultation Available

Not sure which wheel manufacturing process is right for your application? Our engineers are ready to help.

Contact Our Experts

Applications of MAIKONG Aluminium Forged Wheels

Our premium aluminium forged wheels are designed to excel in a variety of demanding applications, delivering exceptional performance wherever they’re installed.

Performance Automotive

Our aluminium forged wheels are the preferred choice for high-performance vehicles where every gram matters. The reduced unsprung weight improves acceleration, handling, and braking performance while enhancing fuel efficiency.

- Sports cars and supercars

- Performance sedans and coupes

- Luxury SUVs and crossovers

- Custom automotive builds

Racing and Motorsports

In the competitive world of motorsports, aluminium forged wheels provide the critical advantage of strength without weight. Our racing wheels are engineered to withstand extreme forces while maximizing performance.

- Circuit racing and track days

- Drag racing applications

- Rally and off-road competition

- Time attack and drift competitions

Specialized Vehicles

The exceptional durability of aluminium forged wheels makes them ideal for specialized vehicles operating in demanding environments where reliability is paramount.

- Off-road and adventure vehicles

- Commercial and fleet applications

- Military and tactical vehicles

- Emergency and service vehicles

Find the Perfect Wheels for Your Application

MAIKONG offers customized aluminium forged wheels solutions for any vehicle or performance requirement.

Email Our Sales Team

MAIKONG’s Manufacturing Capabilities

At MAIKONG, we combine advanced technology with decades of manufacturing expertise to deliver exceptional quality aluminium forged wheels and other precision metal components.

CNC Machining Services

Our facility houses over 60 CNC machines with a monthly capacity exceeding 100 tons of metal processing. We specialize in turning, milling, Swiss machining, multi-axis machining, surface grinding, and laser engraving.

Learn More

Metal Forging Excellence

Our forging workshop is equipped to handle diverse aluminum specifications, utilizing rotary forging technology to create components with exceptional strength-to-weight ratios and structural integrity.

Learn More

Quality Assurance

Our comprehensive quality control procedures ensure every component meets stringent standards. Our material laboratory enables precise results through profound understanding of materials and their properties.

Learn More

“At MAIKONG, we don’t just supply aluminum forgings; we consider how to best support the end application at each step of our one-stop forging process. We’ve established an unprecedented service center for aluminum forgings, providing comprehensive technical support and solutions to our customers.”

– MAIKONG Engineering Team

Custom Aluminium Forged Wheels Solutions

MAIKONG specializes in creating bespoke aluminium forged wheels tailored to your exact specifications and performance requirements.

Our Custom Wheel Development Process

- Consultation: We begin with a detailed discussion of your requirements, including performance goals, aesthetic preferences, and technical specifications.

- Design & Engineering: Our team utilizes CAD/CAM technology to create precise designs, optimized for both performance and manufacturability.

- Material Selection: We select the ideal aluminum alloy based on mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness.

- Prototype Development: Rapid prototyping allows for validation of design concepts before full production.

- Production: State-of-the-art forging and machining processes bring your custom wheels to life with precision and quality.

- Quality Assurance: Comprehensive testing ensures your wheels meet all performance and safety requirements.

Ready to Create Your Custom Wheels?

Contact our engineering team to discuss your custom aluminium forged wheels project.

Start Your Project

US Distribution Opportunities

MAIKONG is actively seeking distribution partners across the United States for our premium aluminium forged wheels and other high-quality metal components.

Partner With MAIKONG

As a MAIKONG distributor, you’ll gain access to our complete range of high-performance aluminium forged wheels and precision metal components, backed by our commitment to quality and customer satisfaction.

Distributor Benefits:

- Exclusive territory rights

- Competitive pricing structure

- Comprehensive marketing support

- Technical training and resources

- Reliable supply chain and logistics

- Custom product development options

Become a MAIKONG Distributor

Join our growing network of US distributors and offer your customers the finest aluminium forged wheels available.

Apply for Distributorship

Quality Standards for Aluminium Forged Wheels

At MAIKONG, we maintain rigorous quality standards throughout our manufacturing process to ensure our aluminium forged wheels deliver exceptional performance and reliability.

Material Certification

Every batch of aluminum alloy undergoes comprehensive testing to verify chemical composition, mechanical properties, and structural integrity before entering our production process.

Dimensional Accuracy

Advanced coordinate measuring machines (CMM) ensure every wheel meets precise dimensional specifications, with tolerances measured to within hundredths of a millimeter.

Structural Testing

Our wheels undergo rigorous impact, fatigue, and radial load testing to verify they exceed industry standards for structural performance and safety.

MAIKONG Quality Certifications

Our manufacturing facility maintains ISO 9001:2015 certification, ensuring consistent quality management systems across all our operations. We also adhere to industry-specific standards for automotive and aerospace applications.