7050 aluminum forgings represent the pinnacle of aerospace-grade aluminum technology, offering an exceptional combination of high strength, excellent corrosion resistance, and superior stress crack resistance. As a premier manufacturer of precision aluminum components, MAIKONG specializes in delivering custom 7050 aluminum forgings that meet the most demanding specifications across aerospace, defense, and high-performance industrial applications.

Key Properties of 7050 Aluminum Forgings

Known as “flying aluminum” in the aerospace industry, 7050 aluminum alloy delivers outstanding performance characteristics that make it ideal for critical applications where failure is not an option.

Mechanical Properties

- Exceptional tensile strength (524 MPa)

- High yield strength (469 MPa)

- Excellent fatigue resistance

- Superior stress corrosion cracking resistance

- Enhanced fracture toughness

Physical Advantages

- Low quench sensitivity

- Excellent dimensional stability

- Good machinability

- Superior anodizing performance

- Maintains strength in thick sections (3-6 inches)

Need High-Performance Aluminum Components?

Our engineering team can help you select the optimal aluminum alloy for your specific application requirements.

Get A Quick Quote

Chemical Composition of 7050 Aluminum

The exceptional performance of 7050 aluminum forgings stems from its carefully balanced chemical composition. The precise combination of alloying elements creates the unique properties that make 7050 ideal for aerospace and high-stress applications.

| Element |

Mass Fraction (%) |

| Aluminum |

86.4-90.0 |

| Zinc |

6.0-7.0 |

| Magnesium |

2.1-2.9 |

| Copper |

1.4-2.0 |

| Manganese |

≤0.10 |

| Chromium |

≤0.04 |

| Titanium |

≤0.06 |

| Other impurities (each) |

≤0.05 |

| Total impurities |

≤0.15 |

Why Choose 7050 Aluminum Forgings Over Castings?

The forging process creates significant advantages over casting methods, particularly for high-performance applications where reliability is critical. Understanding these differences helps engineers select the optimal manufacturing process for their aluminum components.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Grain Structure |

✅ Directional grain flow for improved properties |

No directional grain structure |

| Critical Applications |

✅ Ideal for structural members and load-bearing components |

Limited suitability for critical applications |

Need Expert Guidance on Aluminum Selection?

Contact our metallurgical specialists to determine whether forged 7050 aluminum is right for your application.

Contact via WhatsApp

Primary Applications for 7050 Aluminum Forgings

The exceptional combination of high strength, corrosion resistance, and stress crack resistance makes 7050 aluminum the material of choice for critical applications across multiple industries.

Aerospace Applications

- Aircraft fuselage structures

- Wing-fuselage connections

- Wing frames and spars

- Control surfaces

- Landing gear components

Defense Applications

- Missile structural components

- Military aircraft frames

- Armor components

- Weapon mounting systems

- Tactical vehicle parts

Industrial Applications

- High-stress machinery components

- Mold tooling

- Fixtures and jigs

- Structural components

- High-performance equipment

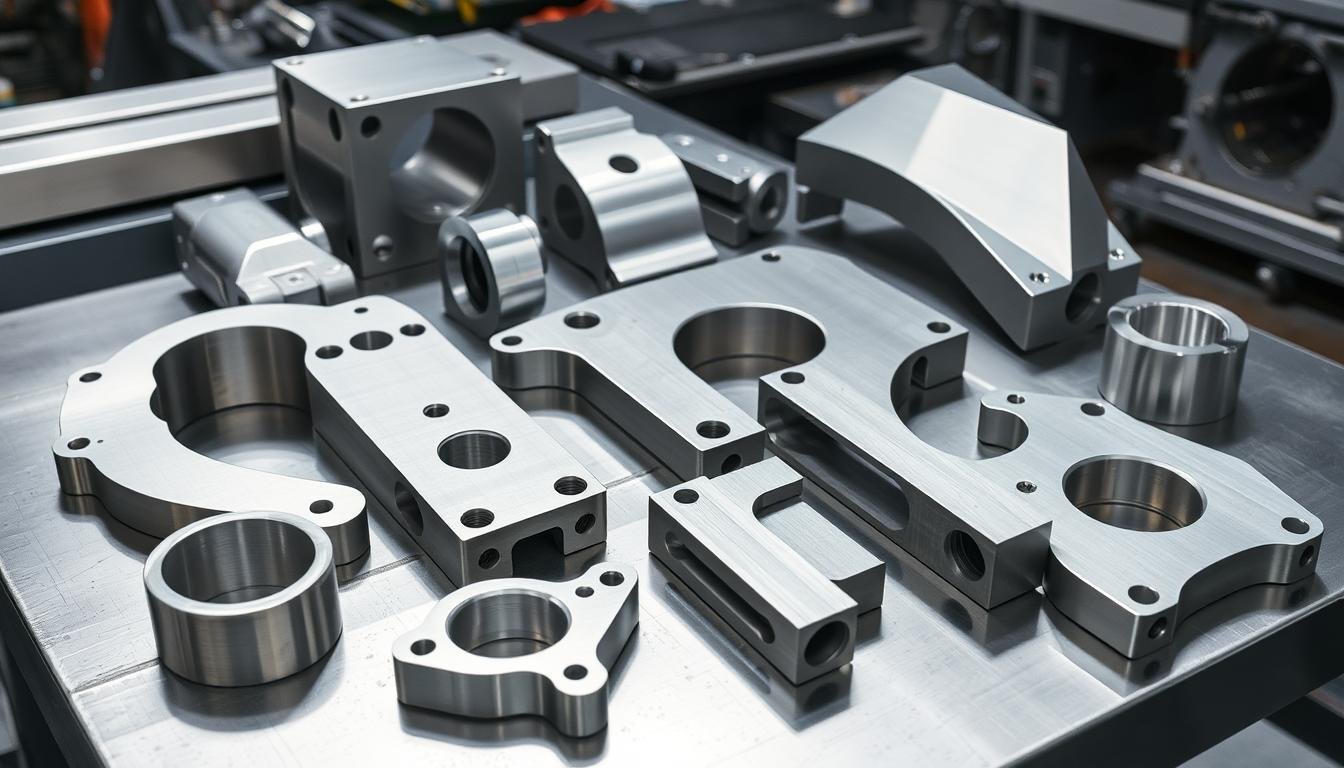

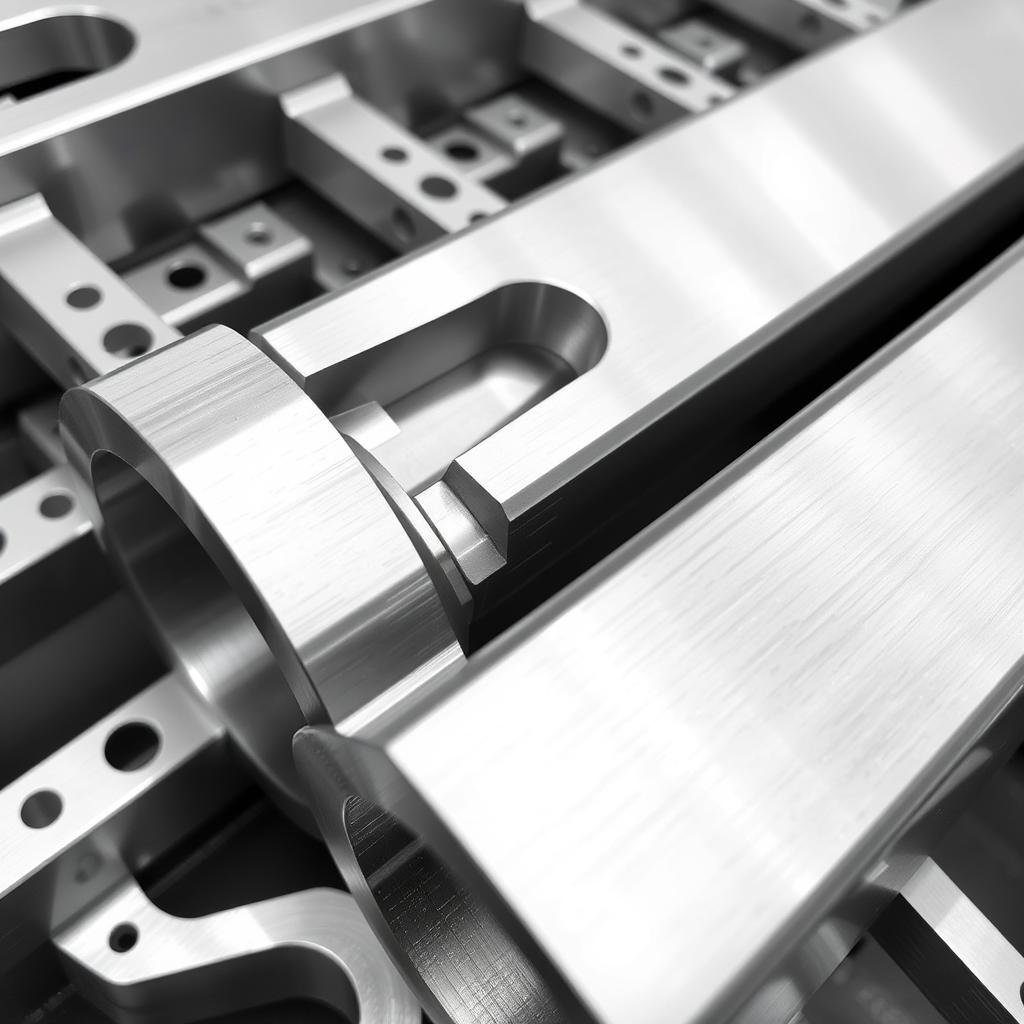

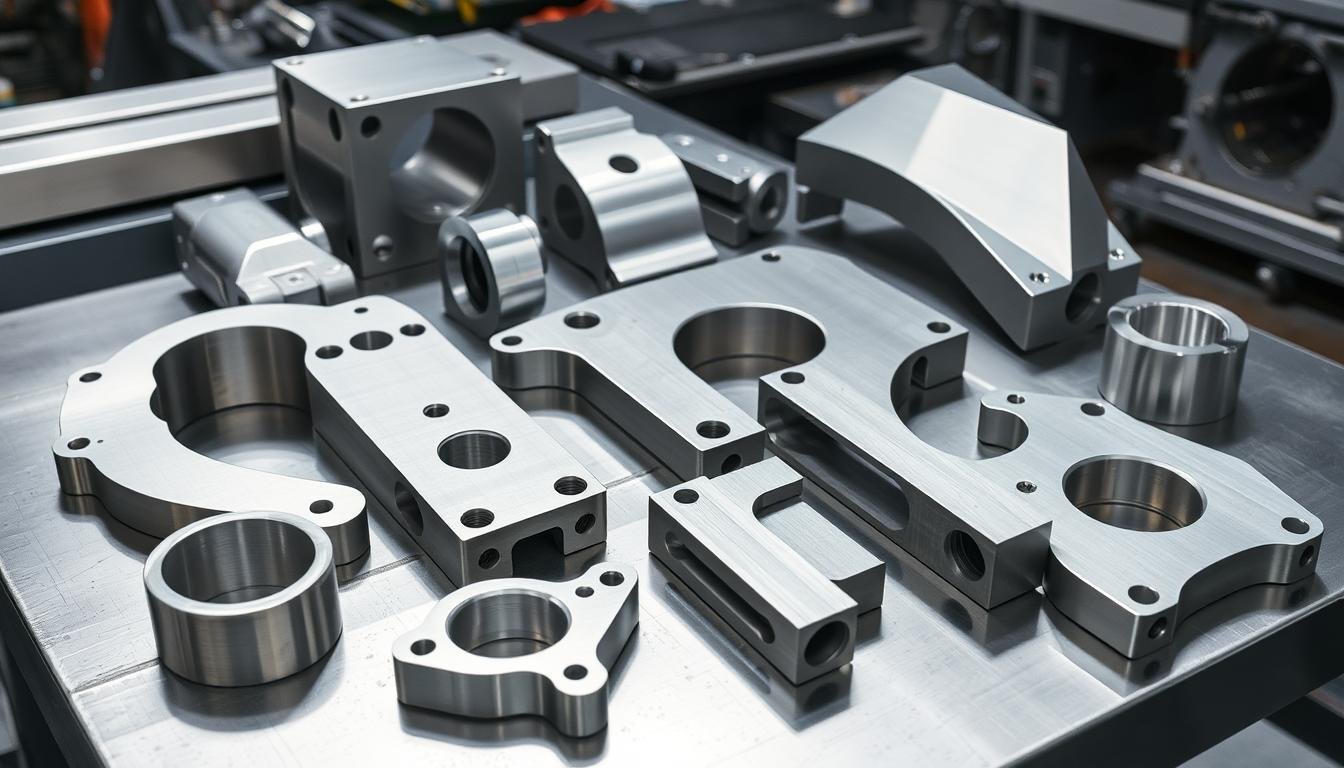

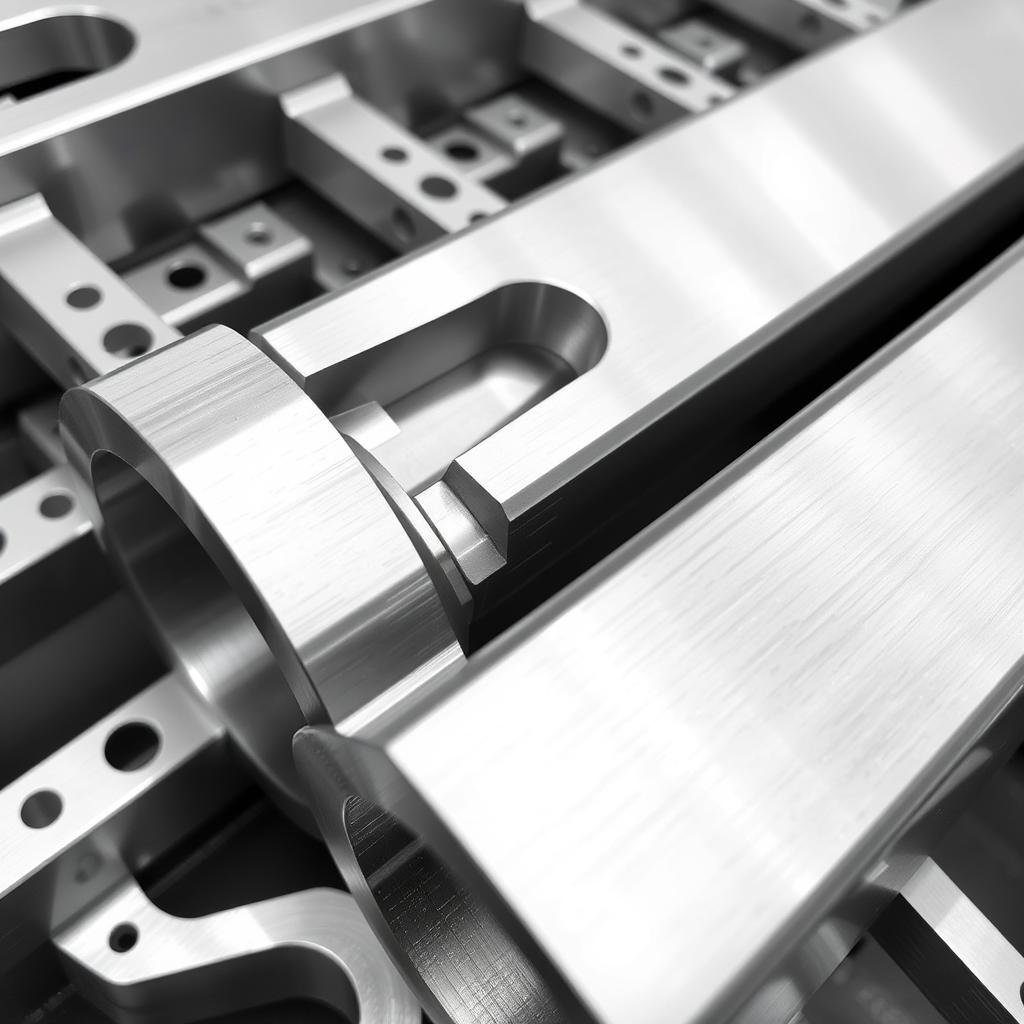

MAIKONG’s 7050 Aluminum Forgings Manufacturing Process

At MAIKONG, we’ve developed a comprehensive manufacturing process that ensures the highest quality 7050 aluminum forgings with consistent properties and precise dimensions. Our end-to-end capabilities allow us to control every aspect of production.

Design & Engineering

Our engineering team utilizes advanced CAD/CAM systems to optimize forging designs for manufacturability and performance. We collaborate closely with customers to ensure specifications are met precisely.

Material Selection

We source premium 7050 aluminum billets with certified chemical composition and properties. Our material laboratory verifies all incoming materials to ensure they meet specifications.

Forging Process

Our state-of-the-art forging equipment applies precise pressure and temperature control to create optimal grain flow and mechanical properties in each component.

Heat Treatment

Our in-house heat treatment facilities provide precise control over the T7451, T7452, and T736 tempers commonly specified for 7050 aluminum components.

Precision Machining

With over 60 CNC machines, we provide comprehensive machining capabilities to achieve final dimensions and surface finishes to exact specifications.

Quality Assurance

Comprehensive testing including dimensional inspection, mechanical testing, and non-destructive evaluation ensures every component meets or exceeds requirements.

Ready to Discuss Your Forging Requirements?

Our engineering team is available to review your specifications and provide expert guidance.

Email Our Team

Technical Specifications for 7050 Aluminum Forgings

MAIKONG produces 7050 aluminum forgings to meet a wide range of industry standards and specifications, ensuring compliance with the most demanding requirements.

Available Tempers

T7451 Temper

Solution heat treated, stress relieved by stretching, then artificially aged. Offers optimal balance of strength and stress corrosion resistance for most aerospace applications.

T7452 Temper

Solution heat treated, stress relieved by compression, then artificially aged. Provides enhanced properties for complex shapes where stretching is not feasible.

Mechanical Properties

| Property |

Metric |

Imperial |

| Tensile Strength, Ultimate |

524 MPa |

76,000 psi |

| Tensile Strength, Yield |

469 MPa |

68,000 psi |

| Elongation at Break |

11% |

11% |

| Modulus of Elasticity |

71.7 GPa |

10,400 ksi |

| Shear Strength |

303 MPa |

44,000 psi |

| Hardness, Brinell |

140 |

140 |

Manufacturing Capabilities

| Forging Type |

Maximum Dimensions |

Maximum Weight |

| Open Die Forging – Cube |

Length ≤ 7000mm, Width ≤ 2000mm, Height ≤ 500mm |

≤ 9T |

| Open Die Forging – Disk |

Diameter ≤ 2500mm |

≤ 5T |

| Open Die Forging – Ring |

Outer diameter ≤ 2500mm, Height ≤ 500mm |

≤ 5T |

| Closed Die Forging |

PVA ≤ 3.0 m² (Diameter ≤ 1950mm) |

Based on dimensions |

The MAIKONG Advantage for 7050 Aluminum Forgings

When you partner with MAIKONG for your 7050 aluminum forgings, you gain access to comprehensive capabilities that ensure quality, consistency, and value.

Quality Assurance

- ISO 9001:2015 certified processes

- Comprehensive material testing

- Advanced non-destructive testing

- 100% dimensional inspection

- Full traceability documentation

Engineering Support

- Design for manufacturability

- Material selection assistance

- Process optimization

- Prototyping capabilities

- Value engineering services

Value-Added Services

- Precision CNC machining

- Heat treatment

- Surface finishing

- Assembly services

- Global logistics support

Experience the MAIKONG Difference

Contact us today to discuss your 7050 aluminum forgings requirements and discover how our comprehensive capabilities can benefit your projects.

Get A Quick Quote

Call/WhatsApp: +86-13-51090-74-01

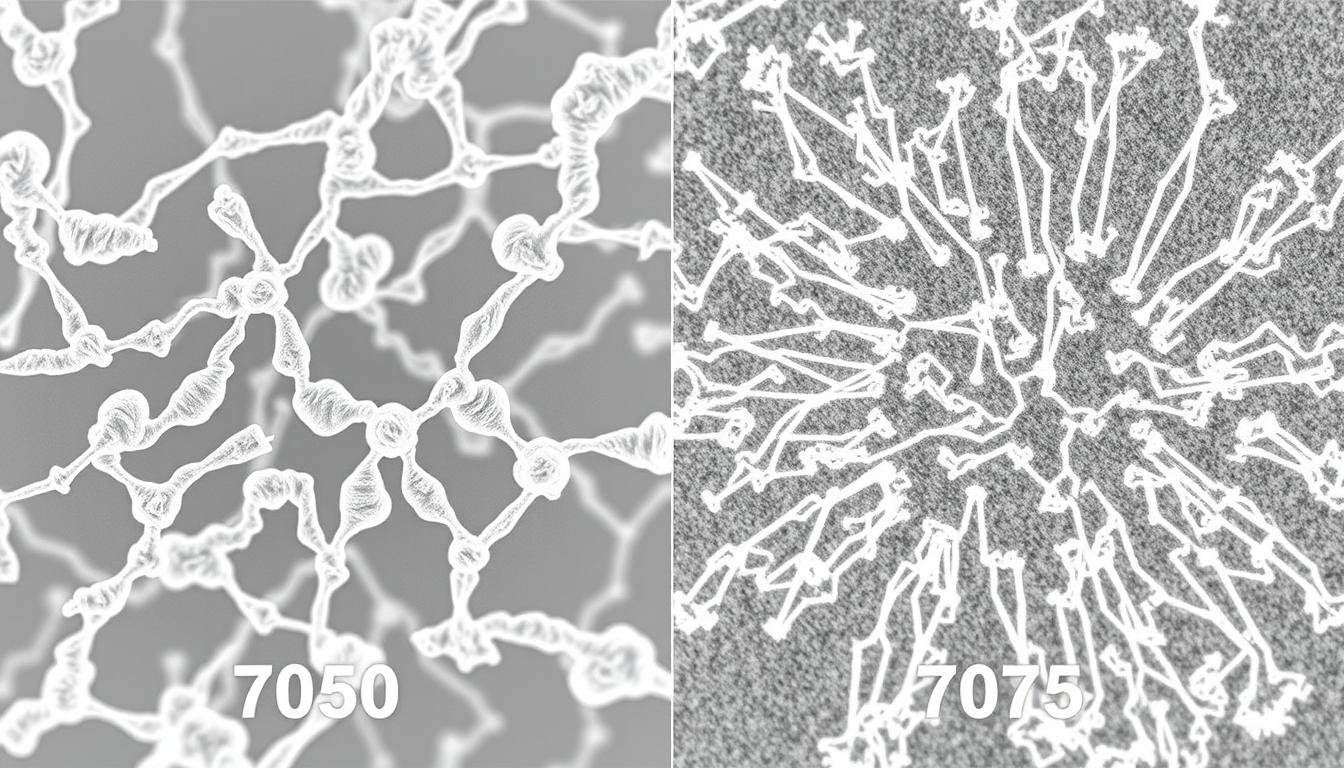

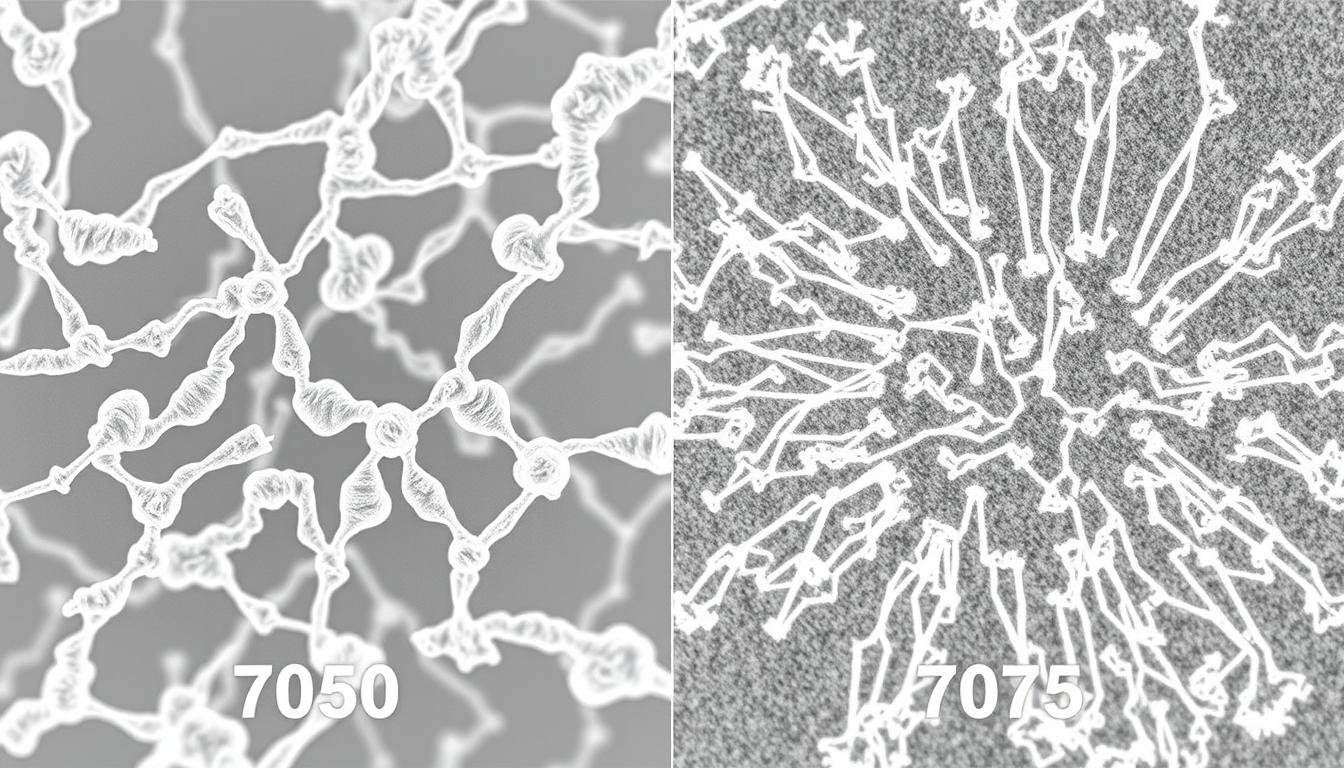

7050 vs. 7075 Aluminum Forgings: Key Differences

While both 7050 and 7075 are high-strength aluminum alloys used in aerospace applications, there are important differences that make each suitable for specific applications.

7050 Aluminum Advantages

- Superior stress corrosion cracking resistance

- Better fracture toughness

- Lower quench sensitivity (maintains properties in thick sections)

- Excellent exfoliation corrosion resistance

- Better performance in thick sections (3-6 inches)

7075 Aluminum Advantages

- Slightly higher overall strength

- More widely available

- Often lower cost

- Better suited for thinner sections

- Longer history of use in aerospace

For applications requiring the highest combination of strength, fracture toughness, and corrosion resistance, especially in thicker sections, 7050 aluminum forgings are typically the superior choice. MAIKONG can help you determine which alloy best meets your specific requirements.