The landscape of metal manufacturing is evolving rapidly, with Forging Procedures at the forefront of innovation. As industries demand stronger, lighter, and more precise components, manufacturers must adapt with advanced techniques and comprehensive capabilities. MAIKONG leads this evolution by combining traditional forging expertise with cutting-edge technology, offering superior metal forming solutions that meet the exacting standards of modern manufacturing while maintaining cost-effectiveness.

Understanding Modern Forging Procedures and Their Evolution

Forging is a manufacturing process that shapes metal using localized compressive forces. These forces are delivered with hammers, presses, or specialized equipment to create components with exceptional strength and durability. Unlike casting or machining from stock, forging aligns the grain structure of the metal, resulting in superior mechanical properties and performance.

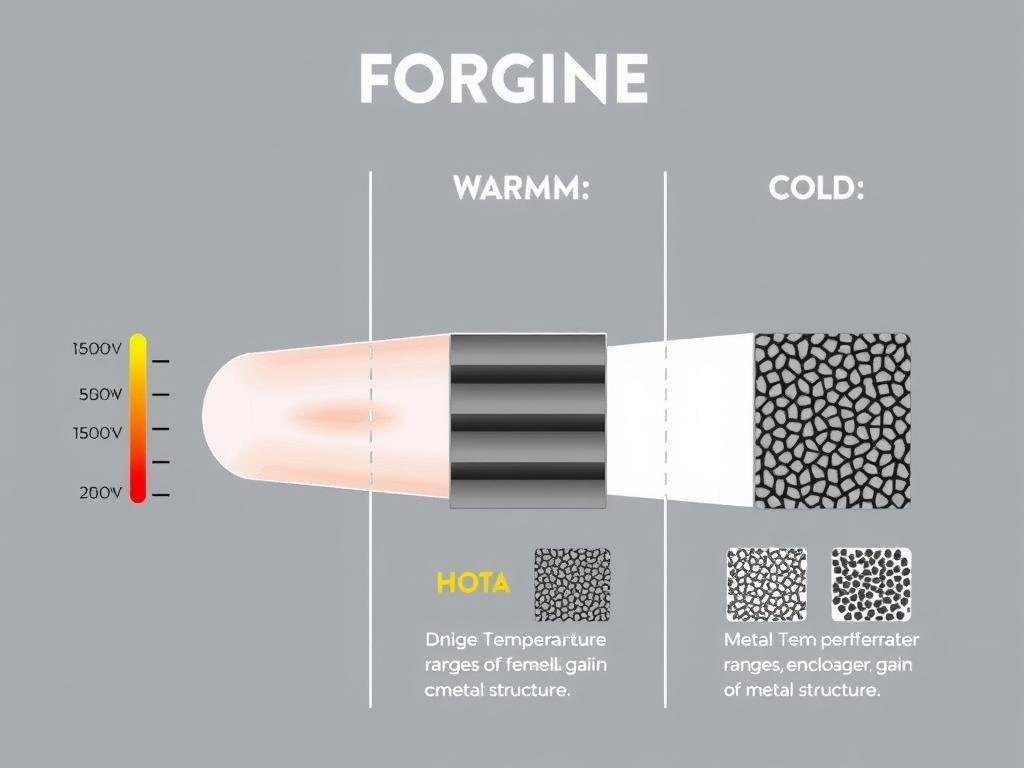

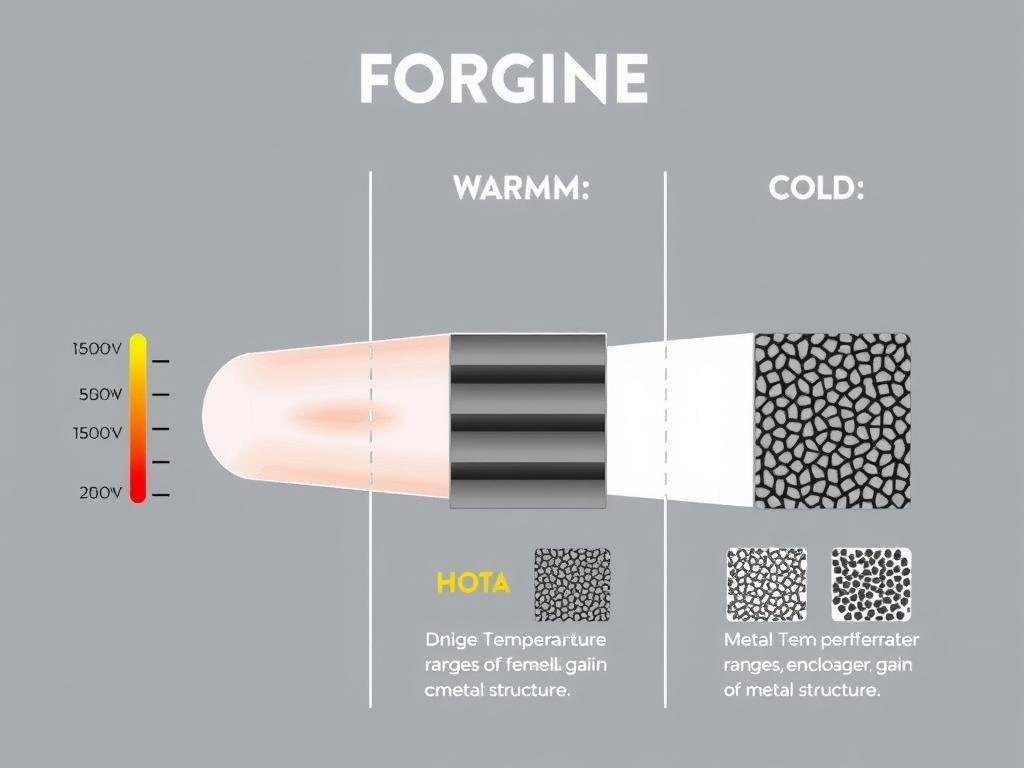

Advanced forging process aligning metal grain structure for superior strength

The origins of forging date back thousands of years, but today’s forging procedures have evolved dramatically. Modern forging combines traditional metallurgical knowledge with computer-aided design, precision-controlled equipment, and advanced material science to create components that meet increasingly demanding specifications.

Key Benefits of Advanced Forging Procedures

- Enhanced mechanical properties through refined grain structure

- Superior strength-to-weight ratio compared to cast or machined parts

- Improved fatigue resistance and structural integrity

- Elimination of internal defects like porosity and voids

- Greater dimensional accuracy and consistency

- Reduced material waste compared to machining from stock

Classification of Modern Forging Processes

Understanding the various forging methods is essential for selecting the right process for specific applications. Modern forging can be classified by temperature, equipment used, and the specific techniques employed.

Classification by Temperature

Hot Forging

Conducted at temperatures above the metal’s recrystallization point (typically 0.6 times the melting temperature), hot forging allows for significant deformation with relatively low force. This process results in excellent grain refinement but may have lower dimensional precision and surface finish compared to other methods.

Warm Forging

Performed at intermediate temperatures (between cold and hot forging), warm forging balances formability and precision. This approach requires moderate force and produces good surface finish with reasonable dimensional accuracy, making it ideal for complex parts that don’t require the highest precision.

Temperature comparison in forging procedures and their effect on metal structure

Cold Forging

Executed at room temperature or slightly elevated temperatures (below recrystallization), cold forging delivers excellent dimensional accuracy and surface finish. This method requires higher forces but produces parts with superior mechanical properties and often eliminates the need for additional finishing operations.

Isothermal Forging

In this specialized process, both the dies and workpiece are maintained at the same elevated temperature throughout forging. This technique allows for complex shapes with thin sections and is particularly valuable for difficult-to-forge materials like titanium and nickel-based superalloys.

Advanced Forging Methods and Techniques

The forging industry has developed numerous specialized techniques to address specific manufacturing challenges and requirements. Each method offers distinct advantages for particular applications and materials.

Open Die Forging

In open die forging, the metal is shaped between flat or simply shaped dies that don’t completely confine the workpiece. This versatile method is ideal for large components and custom shapes, allowing for excellent grain flow control and mechanical properties.

Closed Die Forging

Also known as impression die forging, this process shapes metal within dies containing a cavity that imparts the desired final shape. The method offers excellent repeatability and is ideal for medium to high-volume production of complex components.

Precision Forging

This near-net-shape process minimizes or eliminates the need for secondary machining operations. Precision forging delivers components with tight tolerances and excellent surface finish, reducing material waste and production costs.

Roll Forging

Roll forging uses rotating dies to progressively shape metal, typically to reduce thickness and increase length. This continuous process is excellent for producing elongated parts with varying cross-sections, such as axles, connecting rods, and leaf springs.

Upset Forging

This process increases the diameter of a workpiece by compressing its length. Upset forging is commonly used to form heads on bolts, rivets, and valves, creating localized features with excellent mechanical properties.

Ring Rolling

Specialized for producing seamless rings, this process starts with a pierced disk and progressively shapes it into a ring of larger diameter and reduced cross-section. The method creates exceptional grain flow and is ideal for bearings, gears, and aerospace components.

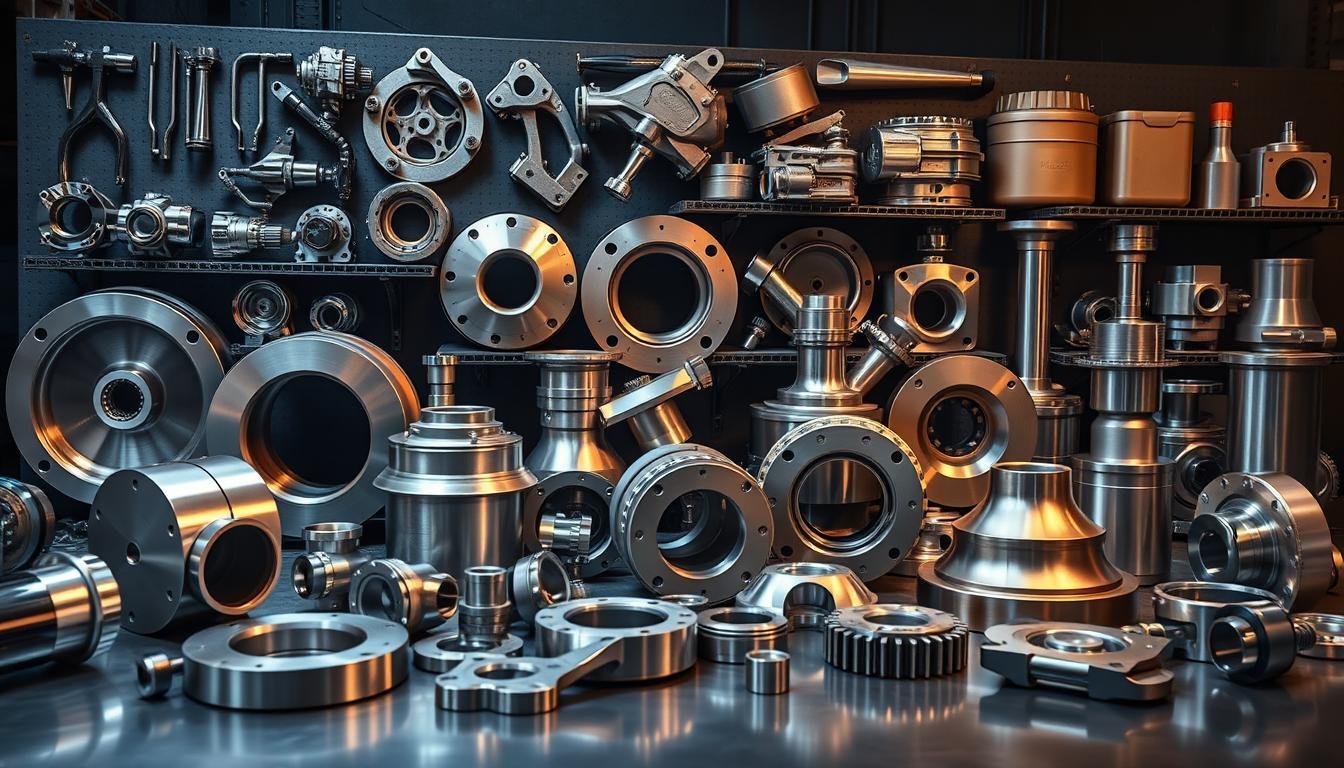

MAIKONG’s advanced forging facility utilizing multiple forging methods

MAIKONG’s Comprehensive Forging and Machining Services

At MAIKONG, we offer a complete range of metal forming and machining services, combining traditional expertise with cutting-edge technology to deliver superior components for demanding applications.

Experience the MAIKONG Advantage

Our integrated capabilities ensure quality, consistency, and cost-effectiveness across all your metal component needs.

Get a Quick Quote

Metal Forging Expertise

MAIKONG’s aluminum forging process ensuring optimal grain structure

Our forging capabilities span a wide range of materials and techniques, allowing us to produce components with exceptional mechanical properties and dimensional accuracy. From small precision parts to large structural components, our forging expertise delivers superior results.

- Aluminum forging services with optimized strength-to-weight ratio

- Steel forging for maximum durability and performance

- Brass forging for electrical and decorative applications

- Custom metal parts tailored to your exact specifications

Each forged component undergoes rigorous quality control to ensure it meets or exceeds industry standards and customer requirements.

Advanced CNC Machining Capabilities

MAIKONG operates over 60 CNC machines with a monthly capacity exceeding 100 tons of metal processing. Our comprehensive machining services complement our forging capabilities, allowing us to deliver fully finished components ready for assembly or use.

CNC Turning

Ideal for cylindrical components with superior surface finishes, deep holes, and machined threads. Our CNC turning services deliver precision parts with fast turnaround times.

CNC Milling

Perfect for complex prismatic shapes and flat surfaces. Our multi-axis CNC milling machines require no fixed tooling, offering flexibility and exceptional accuracy.

Swiss-Type Machining

Specialized for precision small parts and long shaft components. Our equipment features dual spindles and multi-axis capabilities for one-stop manufacturing solutions.

Multi-axis CNC machining center at MAIKONG facility

Our integrated approach to forging and machining allows us to optimize the entire manufacturing process, reducing lead times and ensuring consistent quality from raw material to finished component.

The Superior Advantages of Aluminum Forging

Comparison of grain structure: forged aluminum (left) vs. cast aluminum (right)

Aluminum forging represents one of our core specialties at MAIKONG. The forging process dramatically enhances aluminum’s inherent properties, creating components with an optimal balance of strength, weight, and performance.

Strength-to-Weight Ratio: Engineering Excellence

The strength-to-weight ratio is a fundamental engineering principle that addresses the balance between material strength and weight—an essential consideration in industries prioritizing performance, efficiency, and safety. Aluminum, recognized for its lightweight properties and robust mechanical characteristics, is enhanced through forging, refining its internal grain structure for increased resilience and strength.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

Can achieve complex shapes in one session |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Critical Applications |

Structural members and load-bearing components |

Limited suitability for critical applications |

Need High-Performance Aluminum Components?

MAIKONG’s aluminum forging services deliver superior strength, durability, and precision for your most demanding applications.

Contact Our Experts

Full-Service Metal Manufacturing Capabilities

MAIKONG offers a comprehensive suite of services that cover every aspect of metal component manufacturing, from initial design to final finishing. Our integrated approach ensures quality, consistency, and cost-effectiveness throughout the production process.

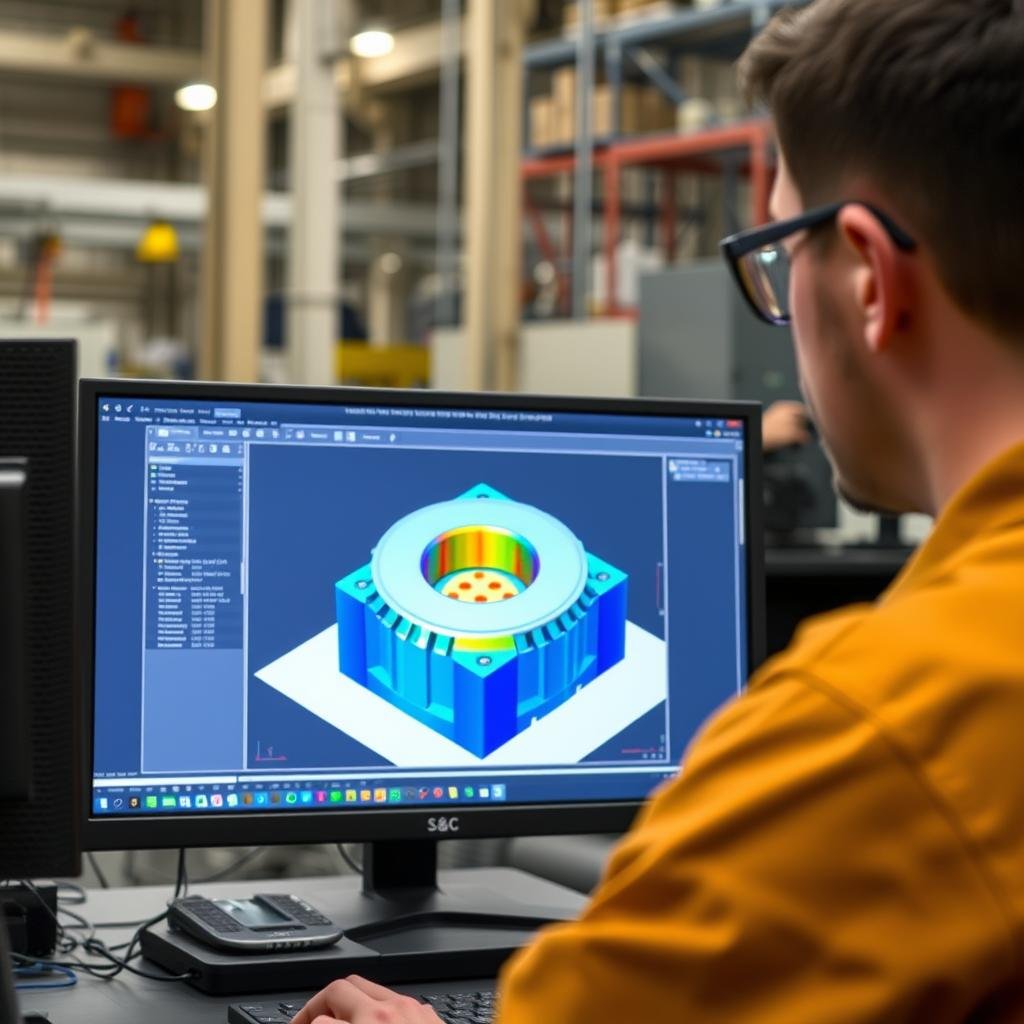

CAD/CAM Engineering

Our engineering team utilizes advanced CAD/CAM tools to optimize component design and manufacturing processes. This technology allows us to identify and address potential issues early, saving time and resources while ensuring superior results.

Material Selection

We carefully consider mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness when selecting materials. Our material expertise ensures optimal performance for your specific application requirements.

Tooling Design

Our tooling design ensures initial quality, while regular maintenance preserves consistency—both critical for producing high-quality forgings. We invest in superior tooling to deliver exceptional components with consistent quality.

Heat Treatment

We conduct comprehensive statistical analysis and documentation for our in-house heat treatment processes. This critical step optimizes the mechanical properties of forged components, ensuring they meet or exceed performance requirements.

Precision Grinding

Automated grinding with specialized robots is employed to remove parting lines and achieve precise dimensions. This technology ensures consistent quality and superior surface finish across production runs of any size.

Surface Treatment

Surface treatments enhance appearance, performance, and competitiveness. Our capabilities include anodizing, painting, laser engraving, and sand blasting, all monitored with advanced quality control equipment.

MAIKONG’s integrated manufacturing facility ensures consistent quality from forging to finishing

Quality Assurance and Certification

At MAIKONG, quality is not just a department—it’s a fundamental aspect of our entire operation. Our comprehensive quality management system ensures that every component we produce meets or exceeds the most demanding specifications and standards.

Quality Control Procedures

Our quality control procedures are essential to ensure that forged components meet stringent standards. We employ a variety of testing and inspection methods throughout the production process:

- Dimensional inspection using precision measurement equipment

- Non-destructive testing including ultrasonic, magnetic particle, and dye penetrant inspection

- Mechanical property testing for hardness, tensile strength, and impact resistance

- Metallurgical analysis to verify grain structure and material composition

- Visual inspection for surface defects and finishing quality

Precision quality control inspection at MAIKONG facility

Certifications and Standards

MAIKONG maintains ISO 9001:2015 certification, demonstrating our commitment to quality management and continuous improvement. Our quality management system ensures consistent results and customer satisfaction across all our manufacturing processes.

Industry Applications for Forged Components

Forged components play critical roles across numerous industries where strength, reliability, and performance are non-negotiable. MAIKONG’s forging and machining capabilities serve diverse sectors with custom solutions tailored to specific requirements.

Automotive

Forged components are essential in automotive applications where safety and reliability are paramount. Our forged parts are used in critical systems including:

- Crankshafts and connecting rods

- Steering and suspension components

- Transmission gears and shafts

- Wheel hubs and axle components

Aerospace

The aerospace industry demands the highest levels of quality and performance. Our forged components deliver the exceptional reliability required for:

- Landing gear components

- Engine mounts and structural parts

- Control system linkages

- Turbine and compressor discs

Industrial Equipment

Heavy industrial applications rely on forged components to withstand extreme conditions and loads. Our forgings are used in:

- Hydraulic cylinders and valves

- Heavy machinery components

- Mining and construction equipment

- Material handling systems

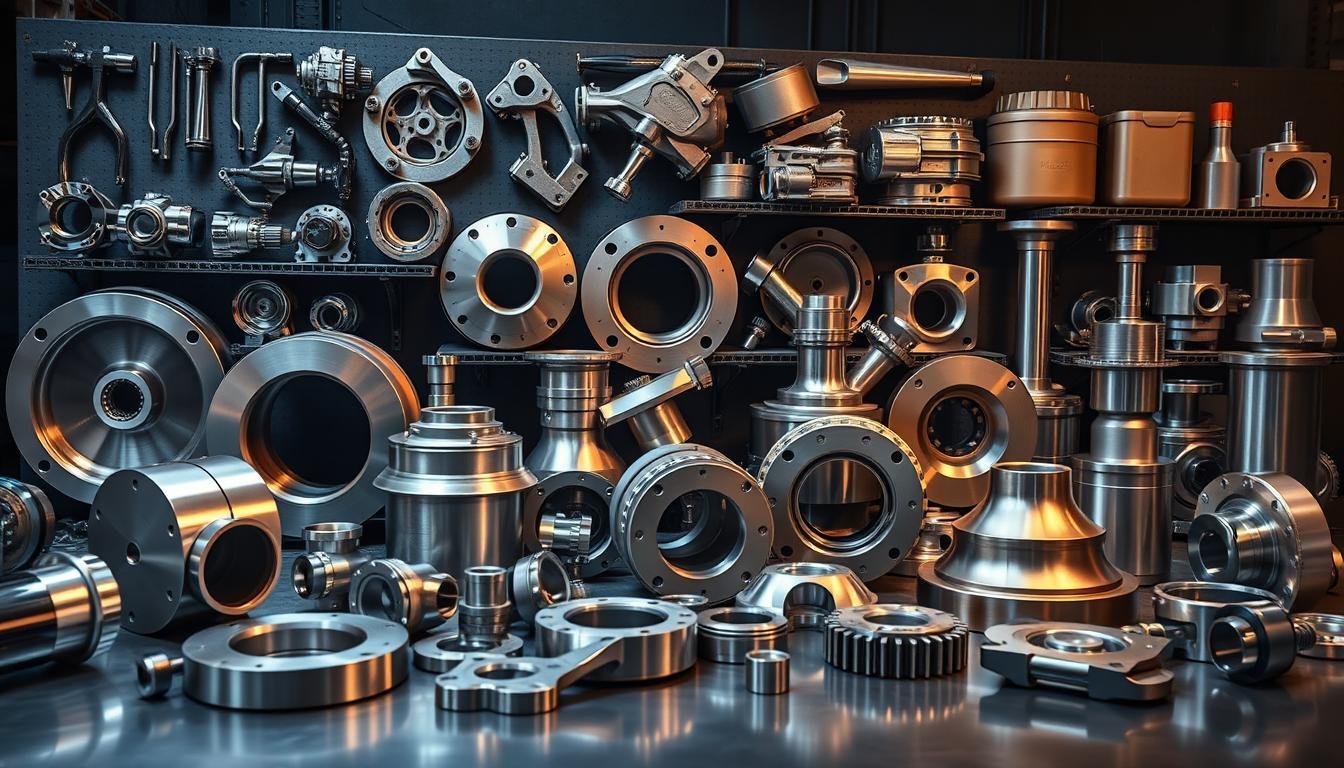

Diverse forged components manufactured by MAIKONG for various industries

Other industries served by MAIKONG include oil and gas, power generation, medical equipment, and consumer products. Our versatile capabilities allow us to meet the unique requirements of virtually any application where metal components are needed.

Partner with MAIKONG for Your Metal Component Needs

As both a producer and consumer of our customers’ products, we recognize the crucial importance of consistency, strength, and weight in each forged part for the final product. With a dedicated focus on crafting superior forged parts, we can fulfill your requirements for heat treating, machining, and testing.

Why Choose MAIKONG?

- Comprehensive capabilities from forging to finishing

- Superior quality with competitive pricing

- Advanced technology and equipment

- Experienced engineering and production teams

- Rigorous quality control procedures

- Flexible production capacity for any volume

- Responsive customer service and support

MAIKONG engineering team collaborating on custom solutions

Our material laboratory plays a vital role in our production process, enabling us to achieve the precise results you demand. Our team is committed to delivering optimal outcomes by possessing a profound understanding of materials, their properties, and their interactions. We are devoted to ensuring that our products consistently meet the highest standards of quality and performance.

Ready to Discuss Your Project?

Contact MAIKONG today to explore how our forging and machining expertise can deliver superior components for your application.

Advancing the Future of Forging Procedures

As manufacturing continues to evolve, MAIKONG remains at the forefront of innovation in forging procedures and metal forming technologies. Our commitment to quality, efficiency, and customer satisfaction drives us to continuously improve our processes and capabilities.

By combining traditional forging expertise with advanced technology and comprehensive manufacturing capabilities, we deliver superior components that meet the most demanding requirements across industries. Whether you need aluminum forgings, steel components, or precision-machined parts, MAIKONG has the expertise and resources to exceed your expectations.

Contact us today to discuss your metal component needs and discover how MAIKONG can help you achieve your manufacturing goals with superior quality and cost-effectiveness.

Start Your Project with MAIKONG

Email us for detailed information or to request a quote for your specific requirements.

Email: Lucy@maikongforge.us