In today’s competitive manufacturing landscape, implementing efficient Forging Procedures is crucial for creating high-quality, durable metal components while minimizing environmental impact. At MAIKONG, we’ve refined our forging techniques to deliver exceptional strength, precision, and sustainability across diverse applications. Our optimized processes not only enhance product performance but also reduce material waste, energy consumption, and overall environmental footprint—making us your ideal partner for sustainable metal manufacturing solutions.

Understanding Metal Forging Procedures: The Foundation of Sustainable Manufacturing

Metal forging is a manufacturing process that shapes metals through localized compressive forces. These forces are delivered with hammers, presses, or rollers. No other metal working process can match forging in terms of strength, durability, and structural integrity.

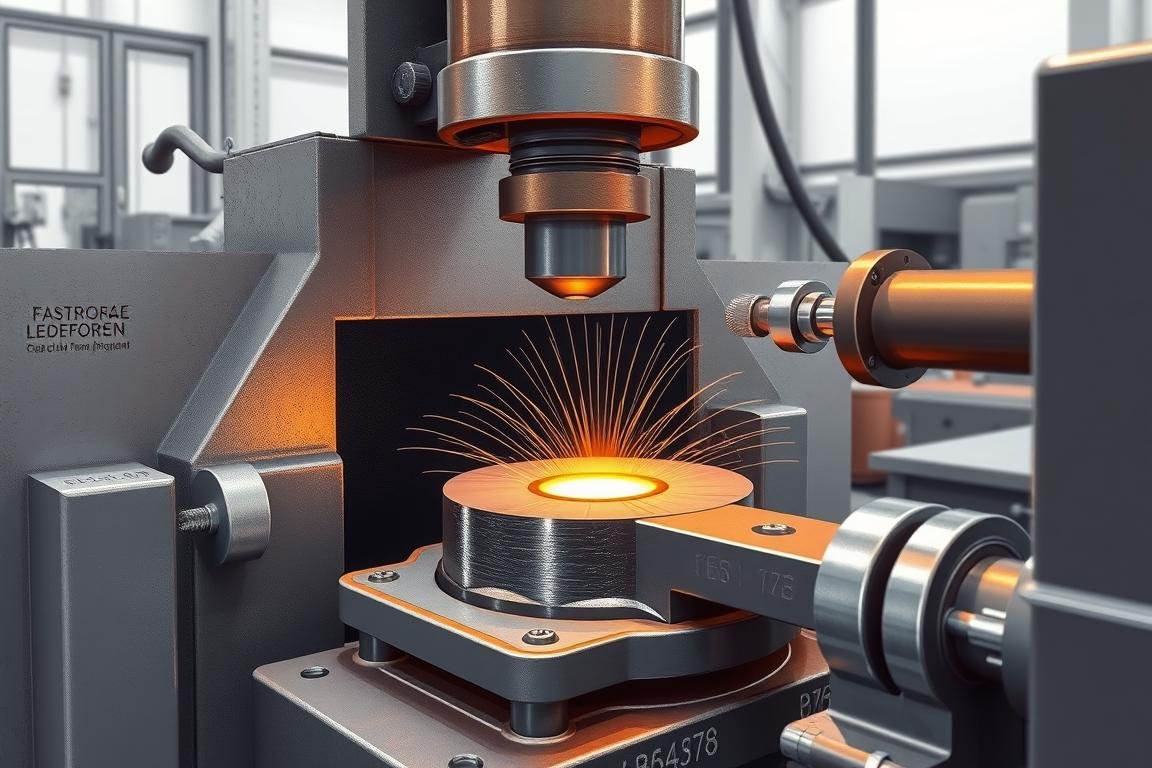

MAIKONG’s advanced forging facility implementing sustainable

Forging Procedures

The origins of forging date back thousands of years, but modern Forging Procedures have evolved significantly. Today’s techniques combine traditional methods with advanced technology to create precision components that meet strict specifications while minimizing environmental impact.

The Science Behind Sustainable Forging Procedures

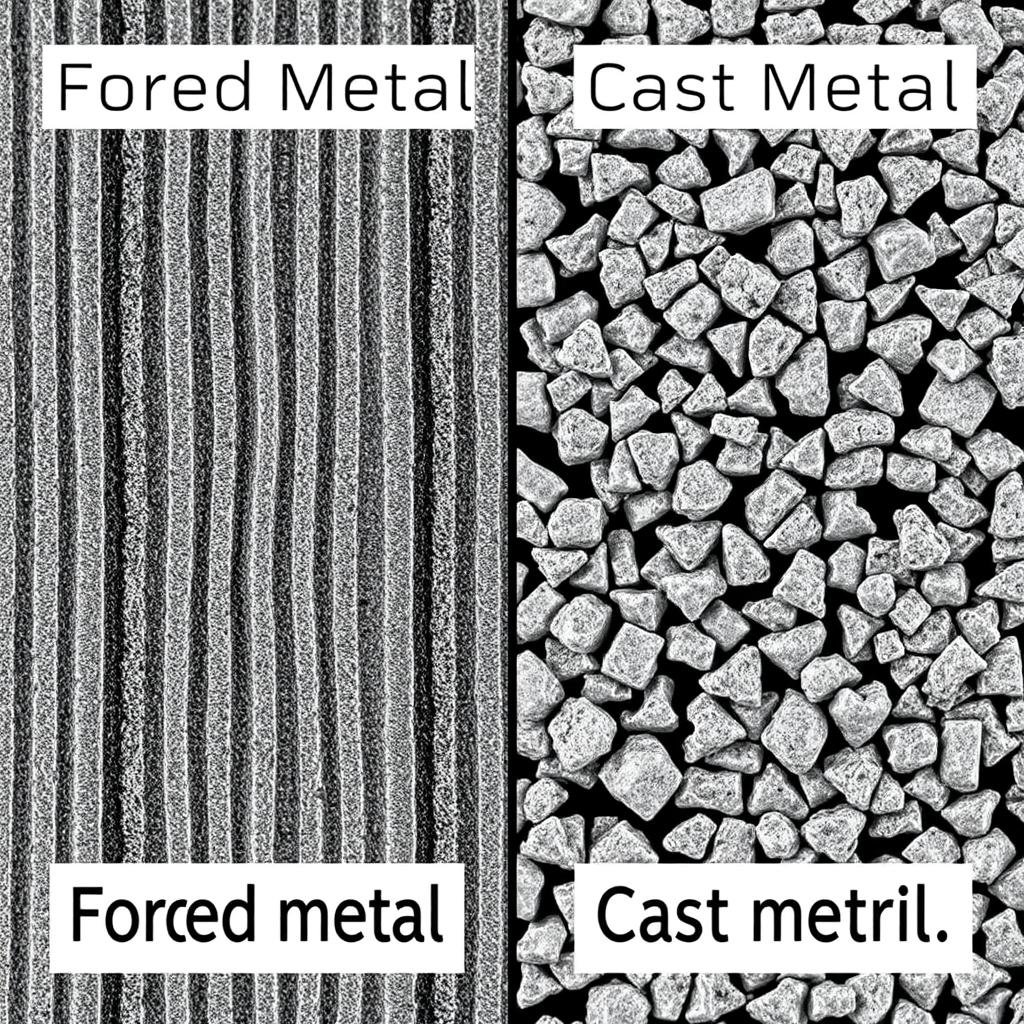

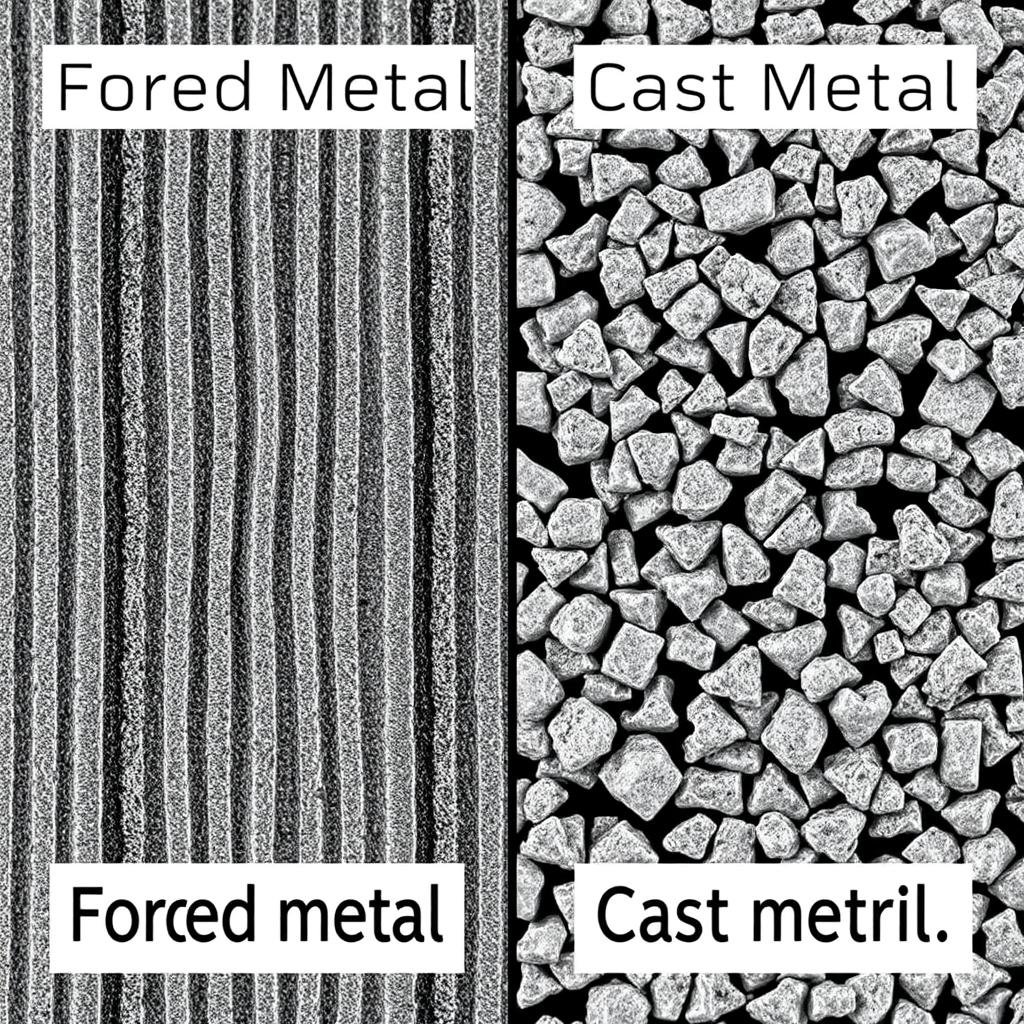

At MAIKONG, our Forging Procedures enhance material properties through controlled deformation. When metal is properly forged, its grain structure aligns with the part’s shape, significantly improving strength and durability compared to casting or machining alone. This grain refinement results in components that can withstand higher stresses with less material—a key aspect of sustainable manufacturing.

Key Benefits of Optimized Forging

- Enhanced mechanical properties through refined grain structure

- Superior strength-to-weight ratio, especially in aluminum components

- Improved fatigue resistance and structural integrity

- Elimination of internal defects like porosity and voids

- Reduced material waste compared to subtractive manufacturing

Grain structure comparison: Forged (left) vs. Cast (right)

Classification of Forging Procedures for Sustainable Manufacturing

Understanding the various types of forging processes is essential for selecting the most sustainable approach for your specific application. At MAIKONG, we classify our Forging Procedures based on temperature, equipment, and techniques to optimize both performance and environmental impact.

Temperature-Based Forging Procedures

Cold Forging

Performed at room temperature, cold forging delivers superior surface finish and dimensional accuracy. This process requires higher press forces but eliminates heating energy, making it more environmentally friendly for suitable applications.

- Excellent dimensional precision

- Superior surface finish

- No energy required for heating

- Ideal for small to medium parts

Warm Forging

Conducted at temperatures between cold and hot forging (typically 750-950°C for steel), warm forging balances energy efficiency with formability. This middle-ground approach offers an excellent compromise for sustainable manufacturing.

- Reduced energy consumption vs. hot forging

- Better formability than cold forging

- Good balance of precision and flow

- Moderate tool wear

Hot Forging

Performed at temperatures above the metal’s recrystallization point (typically 1100-1250°C for steel), hot forging requires more energy but allows for complex shapes with less force, extending die life and reducing material waste.

- Maximum material formability

- Ability to create complex geometries

- Lower press force requirements

- Ideal for large or complex components

Equipment-Based Forging Procedures

Open Die Forging

In open die forging, metal is shaped between flat or simply contoured dies that don’t completely constrain the material. This versatile process is ideal for large components and custom shapes, offering excellent grain flow with minimal tooling costs.

Closed Die Forging

Also known as impression die forging, this process shapes metal within two or more dies that contain a pre-cut profile. The metal fills the die cavity under pressure, creating complex shapes with excellent dimensional control and minimal material waste.

Experience MAIKONG’s Advanced Forging Capabilities

With 60+ CNC machines and 100+ tons of monthly metal processing capacity, we deliver precision-forged components that meet your exact specifications. Our optimized Forging Procedures ensure superior quality while minimizing environmental impact.

Get a Free Quote

Sustainable Forging Procedures at MAIKONG

At MAIKONG, sustainability is integrated into every aspect of our forging operations. Our optimized Forging Procedures are designed to maximize resource efficiency while delivering superior components.

Material Optimization in Forging Procedures

Selecting the right material for forging is crucial for both performance and sustainability. Different metals respond differently to forging processes, affecting energy requirements, tool life, and final properties.

| Metal Type |

Sustainability Benefits |

Ideal Forging Temperature |

Applications |

| Aluminum Alloys |

Lightweight, recyclable, low forging temperature |

350-500°C |

Aerospace, automotive, sporting goods |

| Carbon Steel |

Durable, widely available, excellent strength |

1100-1250°C |

Industrial equipment, tools, structural components |

| Stainless Steel |

Corrosion resistant, long service life |

1150-1200°C |

Food processing, medical, marine applications |

| Brass |

Excellent formability, lower energy requirements |

700-800°C |

Plumbing, electrical components, decorative hardware |

| Titanium |

Exceptional strength-to-weight ratio, corrosion resistance |

870-980°C |

Aerospace, medical implants, high-performance applications |

Energy-Efficient Forging Procedures

MAIKONG implements several strategies to reduce energy consumption in our forging operations:

- Optimized heating cycles to minimize energy waste

- Induction heating for precise temperature control

- Heat recovery systems to capture and reuse thermal energy

- Efficient furnace insulation to reduce heat loss

- Strategic batch processing to maximize furnace efficiency

Waste Reduction in Modern Forging Procedures

Our sustainable approach to forging minimizes waste through several key strategies:

- Near-net-shape forging to reduce machining requirements

- Precision die design to minimize flash and excess material

- Recycling of flash and scrap material back into the production cycle

- Advanced simulation tools to optimize material usage before production

- Integrated quality control to reduce defects and rework

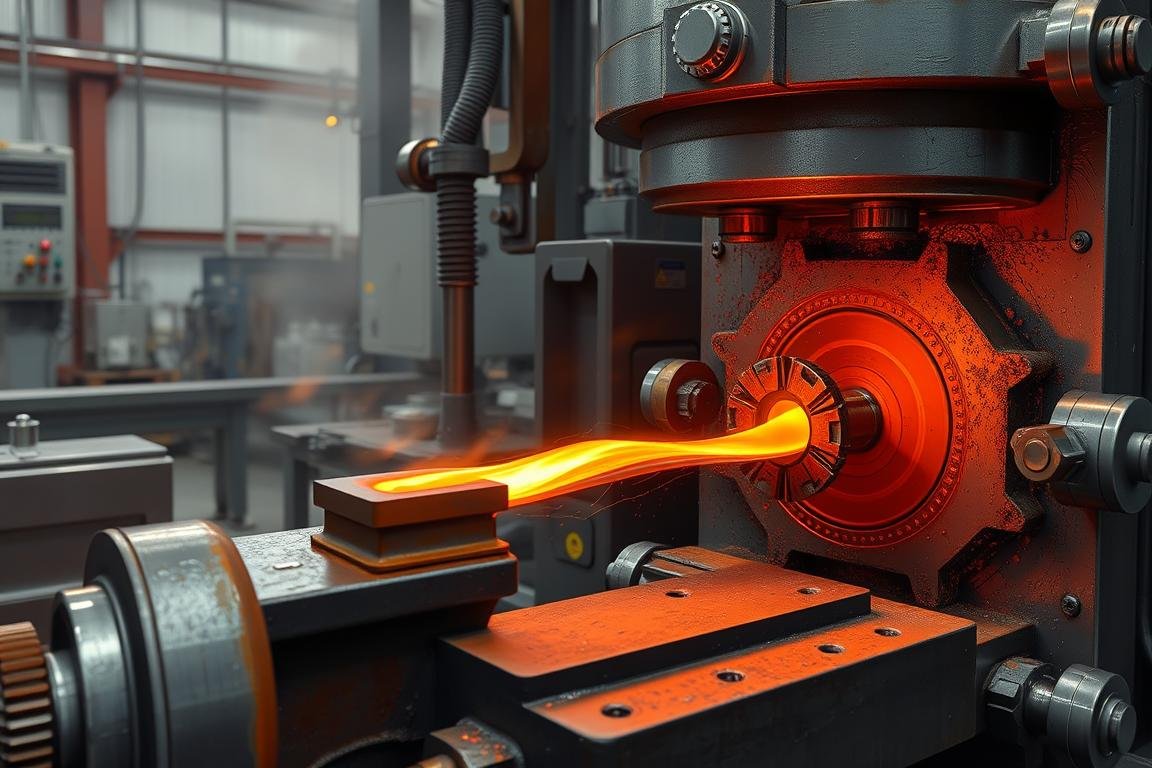

Near-net-shape forging significantly reduces material waste compared to traditional methods

Optimized Forging Procedures: Step-by-Step Process

At MAIKONG, we follow a comprehensive approach to forging that ensures both quality and sustainability. Our optimized Forging Procedures involve several critical steps:

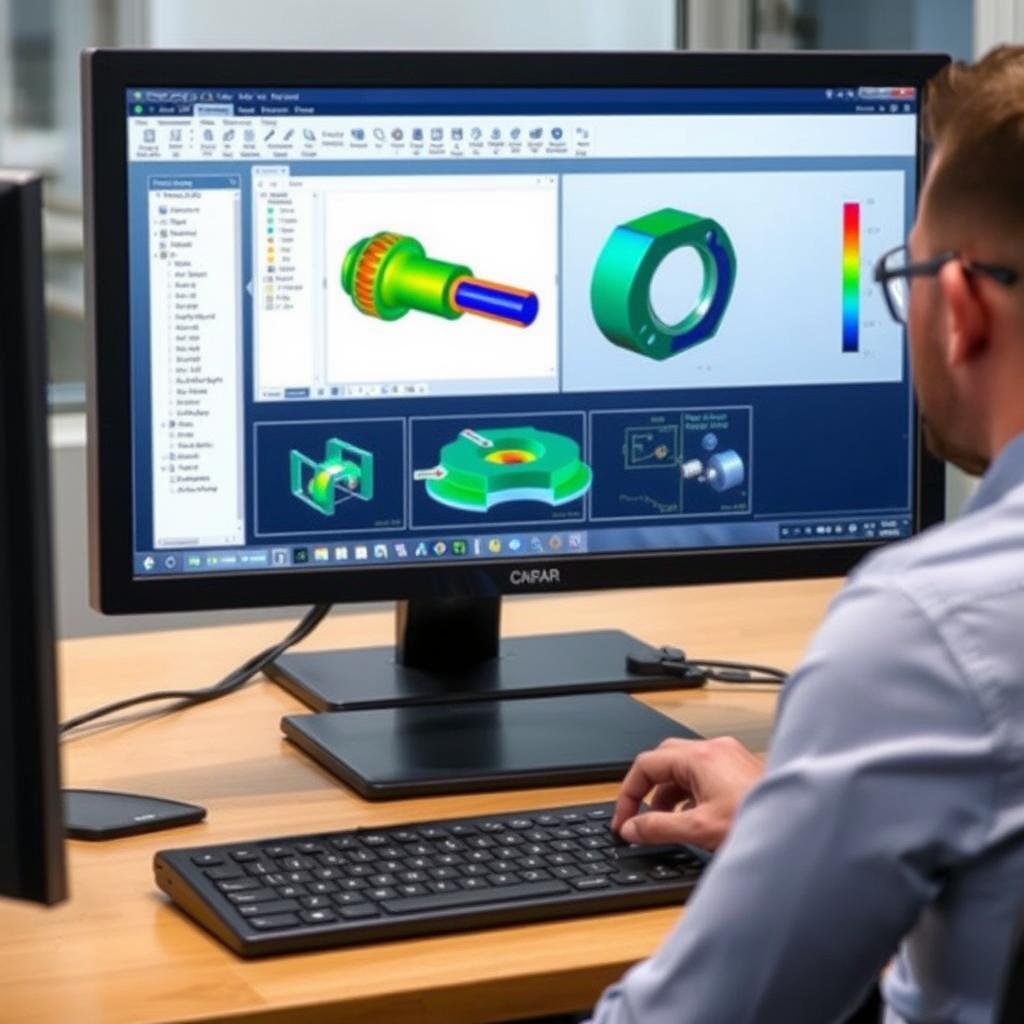

1. Design & Simulation

We begin with advanced CAD/CAM design and simulation to optimize the forging process before production. This crucial step identifies potential issues and ensures efficient material flow, reducing waste and energy consumption.

2. Material Selection

Selecting the right material is critical for sustainable forging. We analyze mechanical properties, machinability, heat treatment characteristics, and cost-effectiveness to determine the optimal alloy for your application.

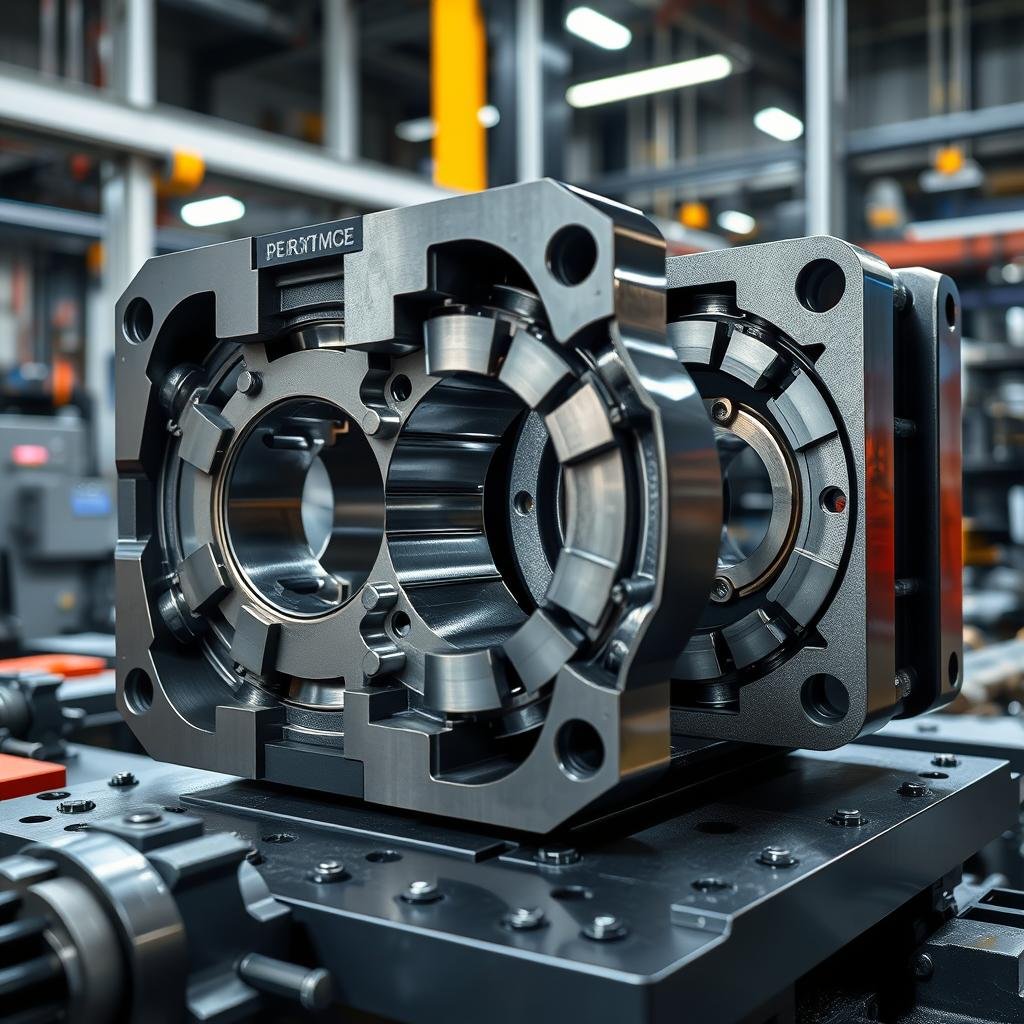

3. Tooling Design

Our tooling design ensures initial quality while minimizing material waste. Precision dies are engineered for optimal material flow, reduced flash, and extended tool life—all contributing to more sustainable operations.

4. Forging Operation

Our forging workshop is equipped to accommodate diverse specifications. We carefully control temperature, pressure, and deformation rates to ensure optimal grain flow and mechanical properties while minimizing energy consumption.

5. Heat Treatment

We conduct comprehensive statistical analysis and documentation for our in-house heat treatment. This critical step enhances mechanical properties while being carefully optimized to reduce energy usage and environmental impact.

6. Finishing Operations

From precision CNC machining to surface treatments, our finishing operations are designed for efficiency and sustainability. We minimize waste while ensuring components meet exact specifications.

Quality Control in Sustainable Forging Procedures

Quality control is integrated throughout our forging process, ensuring components meet stringent standards while minimizing rework and waste:

- Non-destructive testing to verify internal integrity

- Dimensional inspection to ensure precise tolerances

- Material verification to confirm proper composition

- Mechanical testing to validate performance characteristics

- Surface inspection to identify and address any defects

Rigorous quality control ensures our forged components meet exact specifications

Aluminum Forging: A Sustainable Manufacturing Solution

Aluminum forging represents one of the most sustainable metal forming processes available today. At MAIKONG, we specialize in aluminum forging services that deliver exceptional performance with minimal environmental impact.

Aluminum Forging vs. Casting: Sustainability Comparison

Understanding the differences between forging and casting is crucial for making sustainable manufacturing decisions:

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Energy Efficiency |

✅ More efficient for high-performance parts |

More efficient for complex, non-critical parts |

| Material Waste |

✅ Less waste with near-net-shape techniques |

Potential for higher rejection rates |

Leverage MAIKONG’s Aluminum Forging Expertise

Our specialized aluminum forging services deliver superior strength-to-weight ratio, excellent durability, and precise dimensional control—all with sustainable manufacturing practices.

Request Custom Aluminum Forging

Strength-to-Weight Ratio: The Sustainable Advantage

Aluminum’s exceptional strength-to-weight ratio makes it ideal for sustainable manufacturing. Through our optimized Forging Procedures, we enhance this natural advantage:

- Lighter components reduce transportation energy and emissions

- Enhanced strength allows for material reduction without compromising performance

- Improved fatigue resistance extends product lifespan

- Excellent corrosion resistance minimizes maintenance and replacement

- 100% recyclability supports circular economy principles

Sustainable Applications of Advanced Forging Procedures

MAIKONG’s optimized Forging Procedures deliver sustainable solutions across numerous industries. Our precision-forged components contribute to efficiency, durability, and environmental performance in various applications.

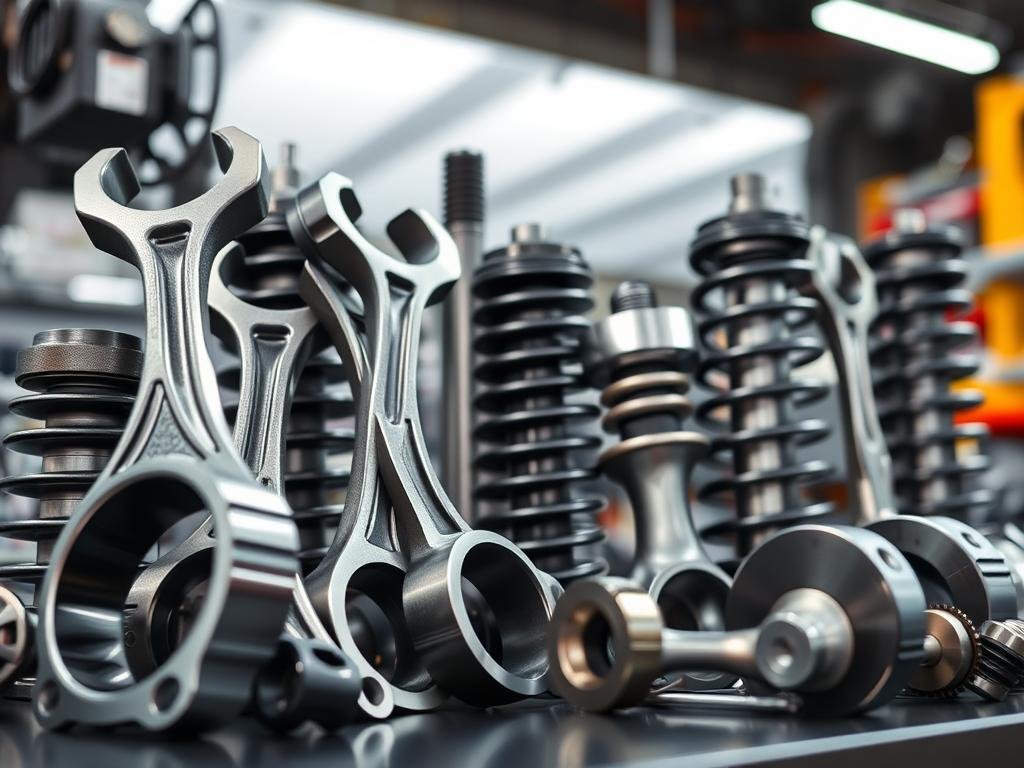

Automotive Components

Our forged automotive components—including connecting rods, crankshafts, and suspension parts—contribute to vehicle lightweighting, improved fuel efficiency, and extended service life.

Aerospace Applications

Our aerospace forged components deliver the exceptional reliability and performance required for flight-critical applications while minimizing weight and environmental impact.

Industrial Equipment

From gears and shafts to structural components, our industrial forgings provide superior durability and performance in demanding environments, reducing replacement frequency and resource consumption.

MAIKONG’s Comprehensive Metal Solutions

Beyond our advanced Forging Procedures, MAIKONG offers a complete range of metal manufacturing services to support your sustainable production needs:

CNC Machining Services

With 60+ CNC machines and 100+ tons of monthly capacity, our precision machining services complement our forging capabilities:

- CNC Turning for cylindrical components

- CNC Milling for complex prismatic shapes

- Swiss-Type Machining for small precision parts

- Multi-axis machining for complex geometries

- Surface grinding for precise finishes

Additional Manufacturing Services

Our comprehensive capabilities ensure we can meet all your metal component needs:

- Heat Treatment for optimized material properties

- Surface Treatments including anodizing and painting

- Quality Testing and Certification

- Prototyping and Small-Batch Production

- Assembly and Finishing Services

Quality Assurance in Sustainable Forging Procedures

At MAIKONG, quality is never compromised in our pursuit of sustainability. Our comprehensive quality management system ensures that our forged components consistently meet the highest standards while minimizing environmental impact.

Certifications and Standards

Our commitment to quality and sustainability is validated through rigorous certification:

- ISO 9001:2015 Quality Management System

- Strict adherence to international material standards

- Comprehensive testing and documentation

- Regular third-party audits and verification

- Continuous improvement processes

Our Commitment to Continuous Improvement

Sustainability in forging is an ongoing journey. At MAIKONG, we continuously refine our Forging Procedures to enhance both quality and environmental performance:

- Regular process audits to identify optimization opportunities

- Investment in energy-efficient equipment and technologies

- Employee training on sustainable manufacturing practices

- Collaboration with customers to develop eco-friendly solutions

- Research and development of innovative forging techniques

Partner with MAIKONG for Sustainable Metal Solutions

Experience the perfect balance of quality, performance, and sustainability with MAIKONG’s advanced Forging Procedures and comprehensive manufacturing capabilities.

Conclusion: Advancing Sustainability Through Optimized Forging Procedures

As manufacturing continues to evolve, the importance of sustainable Forging Procedures becomes increasingly evident. At MAIKONG, we’re committed to leading this transformation by delivering high-performance forged components that minimize environmental impact while maximizing performance and value.

Our comprehensive approach—combining advanced forging techniques, precision machining, and rigorous quality control—ensures that every component we produce meets the highest standards for both performance and sustainability. By partnering with MAIKONG, you gain access to cutting-edge manufacturing capabilities, extensive material expertise, and a dedicated team committed to your success.

Whether you need aluminum forged components, precision CNC machined parts, or comprehensive metal manufacturing solutions, MAIKONG is your trusted partner for sustainable, high-quality metal components. Contact us today to discover how our optimized Forging Procedures can contribute to your sustainable manufacturing goals.

MAIKONG’s advanced forging facility implementing sustainable Forging Procedures

MAIKONG’s advanced forging facility implementing sustainable Forging Procedures