Understanding the complex language of forge tooling is crucial for procurement professionals seeking quality metal components. In an industry where precision matters, knowing the difference between a die block and a bolster plate can mean the difference between project success and costly mistakes. This comprehensive guide to Decoding Forge Tooling Terminology will equip you with the essential knowledge needed to communicate effectively with manufacturers, evaluate capabilities, and make informed procurement decisions.

Why Decoding Forge Tooling Terminology Matters for Procurement Success

For procurement professionals in manufacturing industries, the ability to accurately interpret forge tooling terminology directly impacts your ability to source high-quality components. Without this specialized knowledge, you risk miscommunication, specification errors, and ultimately, receiving products that fail to meet your requirements.

The forging industry uses a specialized vocabulary that has evolved over centuries of metalworking practice. When sourcing forged components, understanding this terminology allows you to:

- Communicate precise requirements to manufacturers

- Evaluate supplier capabilities more accurately

- Compare quotes with a clear understanding of what’s included

- Identify potential quality issues before they arise

- Make more informed decisions about manufacturing processes

Partner with Forging Experts Who Speak Your Language

At MAIKONG, we understand the importance of clear communication in the procurement process. Our team of forging specialists can help you navigate the complex world of forge tooling terminology.

Get Expert Guidance

Fundamental Forge Tooling Terms Every Procurement Professional Should Know

Before diving into the more specialized terminology, let’s establish a foundation with the essential terms that form the basis of forge tooling vocabulary. Mastering these concepts will provide you with the framework needed to understand more complex forging processes.

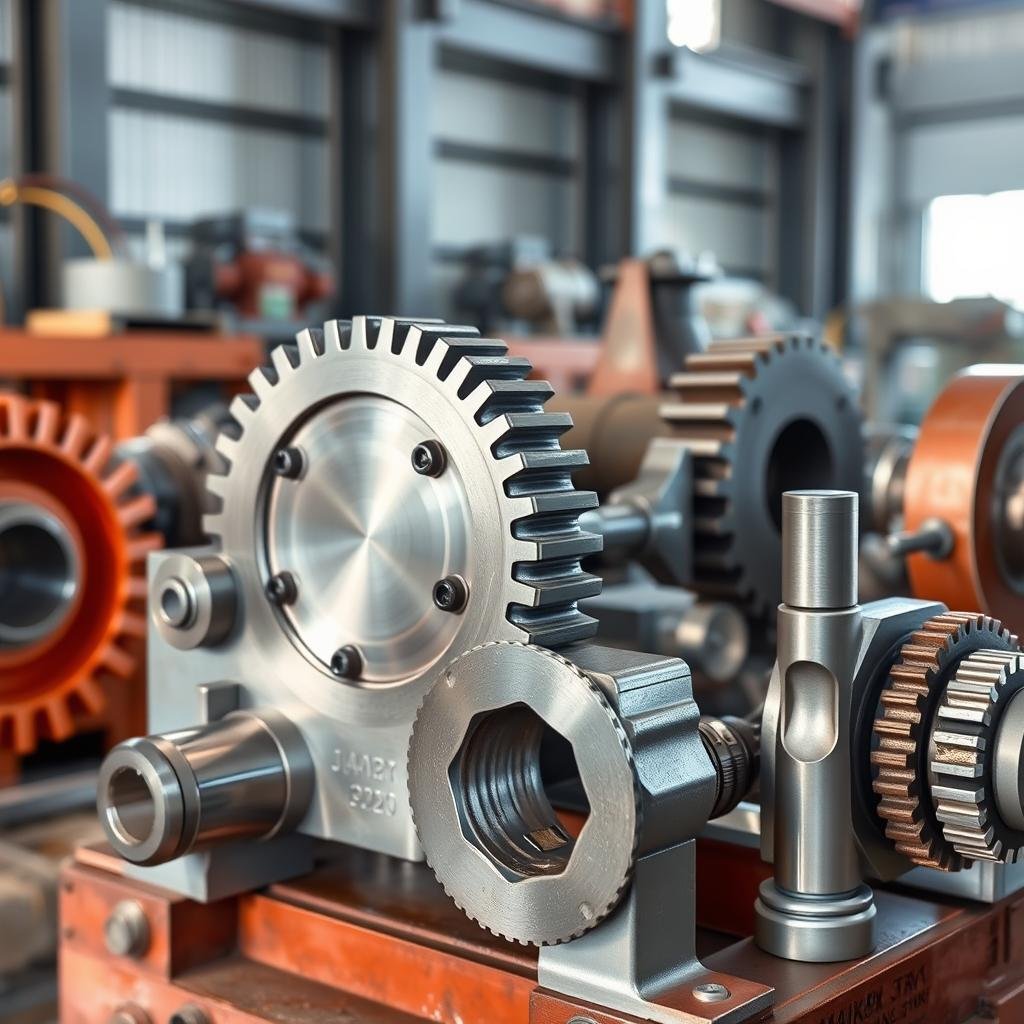

Dies & Tooling

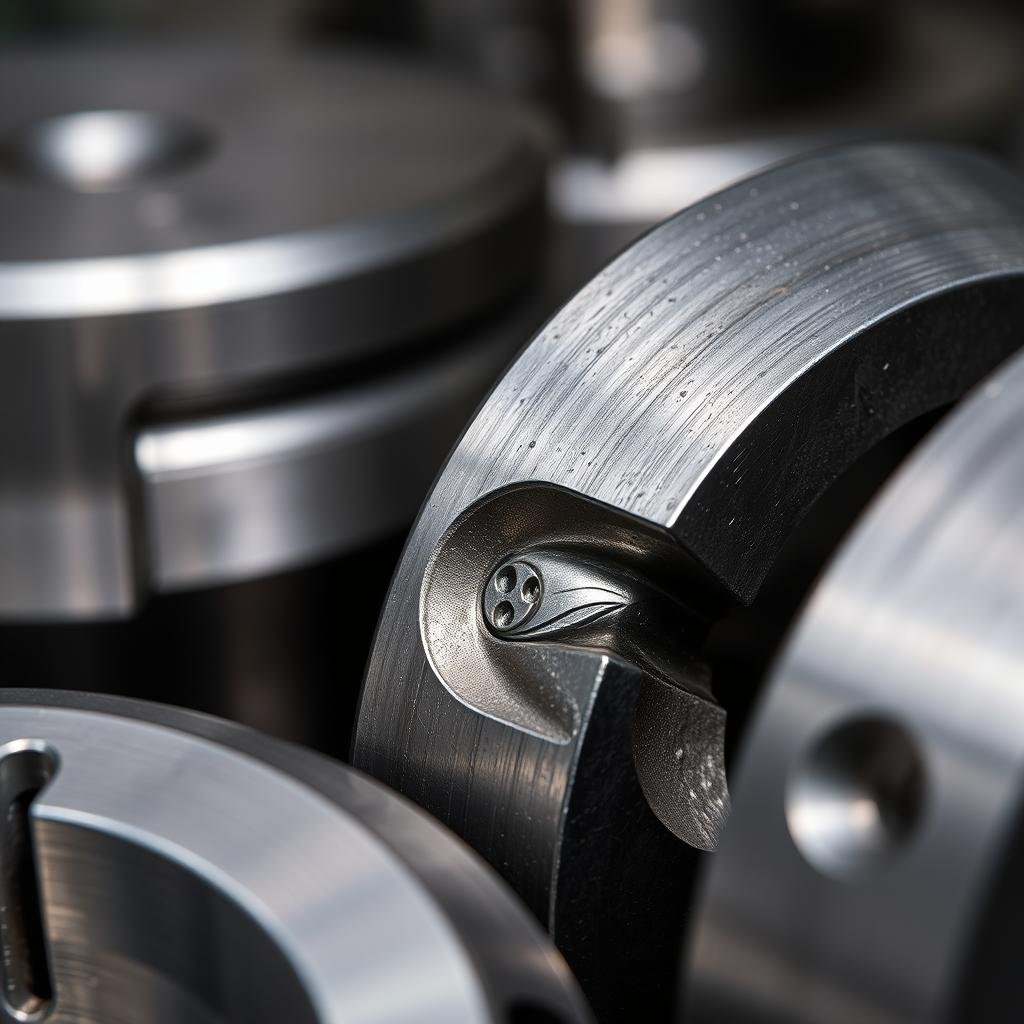

The metal blocks into which forging impressions are machined. Dies contain the cavities that give forgings their shape and are typically made from tool steel. Key components include:

- Die blocks – The primary metal forms containing impressions

- Die cavity – The recessed area that shapes the forging

- Die impression – The portion that determines the final shape

- Insert dies – Smaller dies fitted to master die blocks

Forging Equipment

The machinery used to shape metal through compressive force. Common types include:

- Forging hammer – Delivers impact force to shape metal

- Forging press – Uses continuous pressure rather than impact

- Mechanical press – Uses a crankshaft to operate the ram

- Hydraulic press – Uses hydraulic fluid pressure for force

Forging Processes

The methods used to shape metal into desired forms. Primary approaches include:

- Open die forging – Metal worked between flat or simple dies

- Closed die forging – Metal formed in impression dies

- Impression die forging – Metal shaped in cavities with flash

- Precision forging – Near-net-shape with minimal machining

Understanding these fundamental categories provides the foundation for more detailed exploration of forge tooling terminology. As a procurement professional, recognizing these basic concepts will significantly enhance your ability to evaluate forging capabilities and communicate requirements effectively.

Essential Die Terminology for Decoding Forge Tooling

Dies are the heart of the forging process, directly determining the quality and characteristics of the finished product. Procurement professionals must understand the various types of dies and their components to effectively evaluate manufacturing capabilities.

Die Components and Structure

Modern forging dies are sophisticated tools with multiple components working together to create precise metal forms:

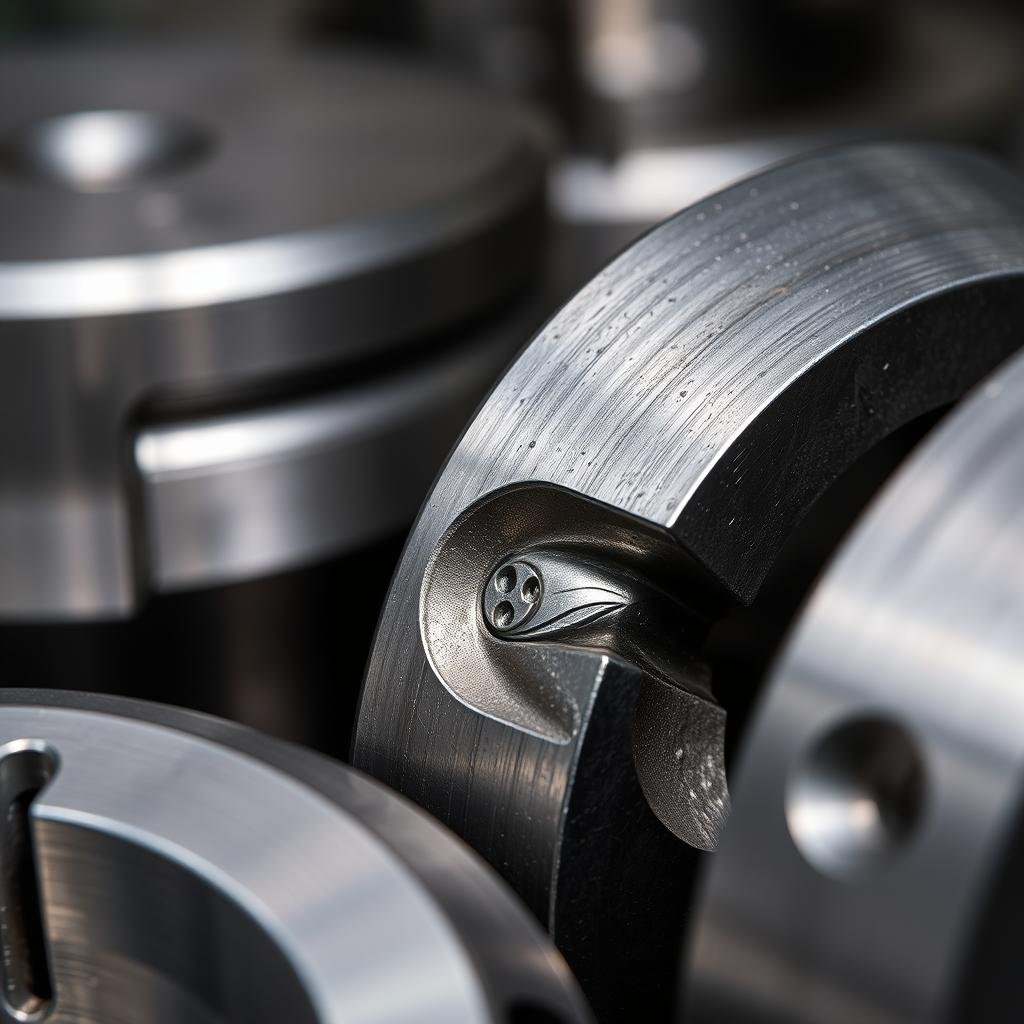

- Die block – The main body of the die, typically made from tool steel

- Die cavity – The recessed area that forms the shape of the forging

- Flash land – The area where excess metal (flash) flows during forging

- Gutter – A reservoir around the die impression for excess metal

- Parting line – Where the upper and lower dies meet

- Draft angle – The taper on vertical walls to allow part removal

- Die match – The alignment of upper and lower die impressions

- Knockout pins – Mechanisms to release workpieces from the die

Types of Dies in Forging Operations

Different forging operations require specialized die types, each serving a specific purpose in the metal forming process:

| Die Type |

Description |

Primary Application |

Key Characteristics |

| Blocker Dies |

Preliminary dies that give the forging its general shape |

Initial forming before finishing dies |

Generous radii, draft angles, and material allowances |

| Finisher Dies |

Dies that impart the final shape to the forging |

Final forming operation |

Precise dimensions, tighter tolerances |

| Impression Dies |

Dies with cavities that shape the workpiece |

Closed die forging |

Complete 3D control of workpiece shape |

| Open Dies |

Flat or simply contoured dies |

Open die forging, preforming |

Allow free metal flow, require manipulation |

| Insert Dies |

Smaller dies fitted to master die blocks |

Complex or high-wear areas |

Replaceable, often made of premium materials |

| Trimming Dies |

Dies used to remove flash from forgings |

Post-forging flash removal |

Sharp cutting edges, precise alignment |

Die Design Considerations for Quality Forgings

When evaluating a forging supplier, understanding these key die design factors can help you assess their capability to produce quality components:

Material Flow

Proper die design ensures optimal metal flow during forging, preventing defects like laps, folds, and cold shuts. Dies must be designed to promote uniform material displacement and grain flow.

Thermal Management

Dies must withstand extreme temperature cycles. Thermal management features like cooling channels and proper preheating procedures extend die life and maintain dimensional stability.

Wear Resistance

High-quality dies incorporate wear-resistant materials and treatments in high-stress areas. This ensures consistent part quality over longer production runs and reduces tooling costs.

Expert Die Design for Superior Forgings

MAIKONG’s engineering team specializes in advanced die design for optimal material flow and extended tool life. Our expertise ensures your components are produced with precision and consistency.

Discuss Your Die Requirements

Forging Equipment Terminology: Key to Decoding Forge Tooling

The type of equipment used in the forging process significantly impacts the characteristics and quality of the final product. Understanding the capabilities and limitations of different forging equipment helps procurement professionals make informed decisions about supplier selection.

Forging Hammers

Hammers deliver impact energy to shape metal through repeated blows. They’re particularly effective for creating complex shapes with deep impressions.

- Board hammers – Gravity-drop hammers where the ram is raised by friction boards

- Air-lift hammers – Use air cylinders to raise the ram, allowing variable stroke control

- Power-driven hammers – Use steam or air to both raise the ram and augment the downward blow

- Counterblow hammers – Feature two opposed rams striking simultaneously

Forging Presses

Presses apply continuous pressure rather than impact force, offering more precise control over the forging process.

- Mechanical presses – Use a crankshaft, eccentric, or toggle mechanism to operate the ram

- Hydraulic presses – Employ hydraulic fluid pressure for more controlled force application

- Screw presses – Drive a ram up or down on a screw shaft for precision forming

- Forging machines (upsetters) – Apply horizontal force to gripped workpieces

Specialized Forging Equipment

Beyond standard hammers and presses, specialized equipment serves particular forging applications:

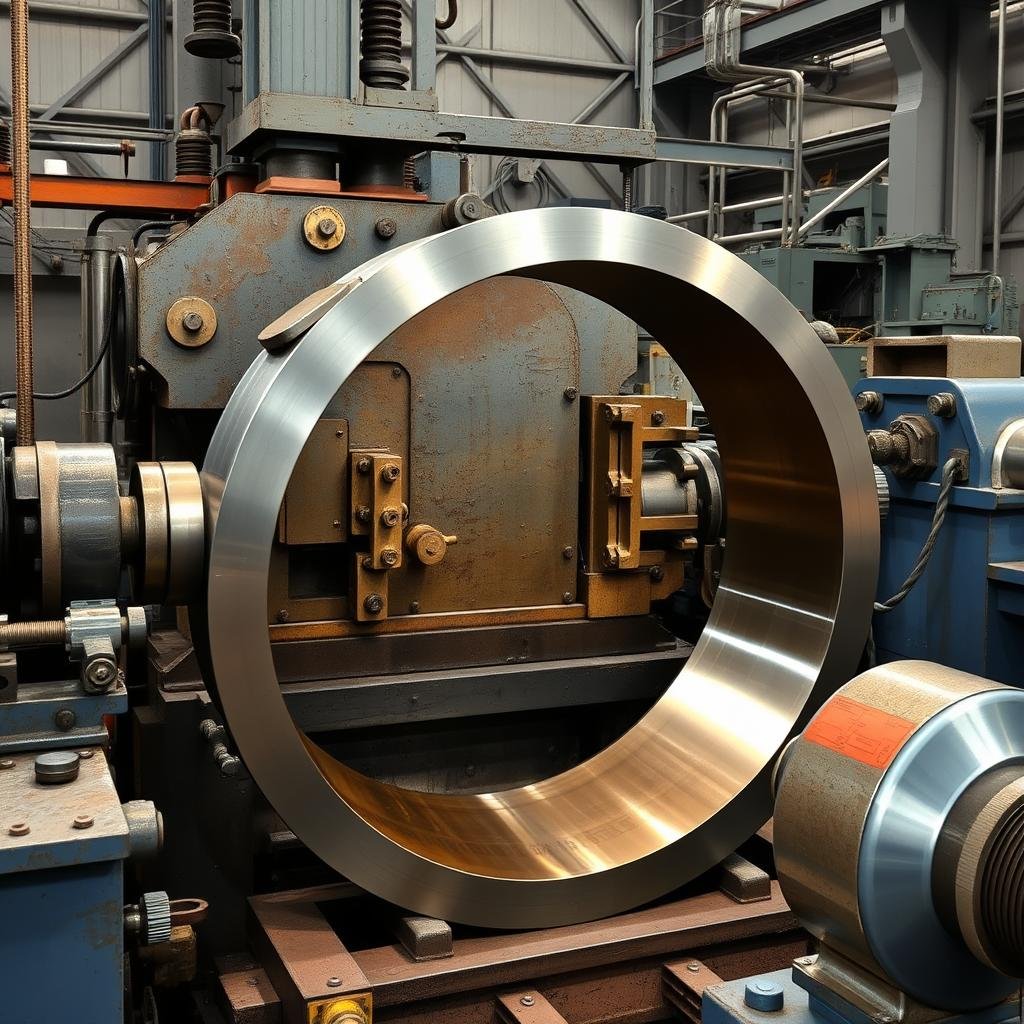

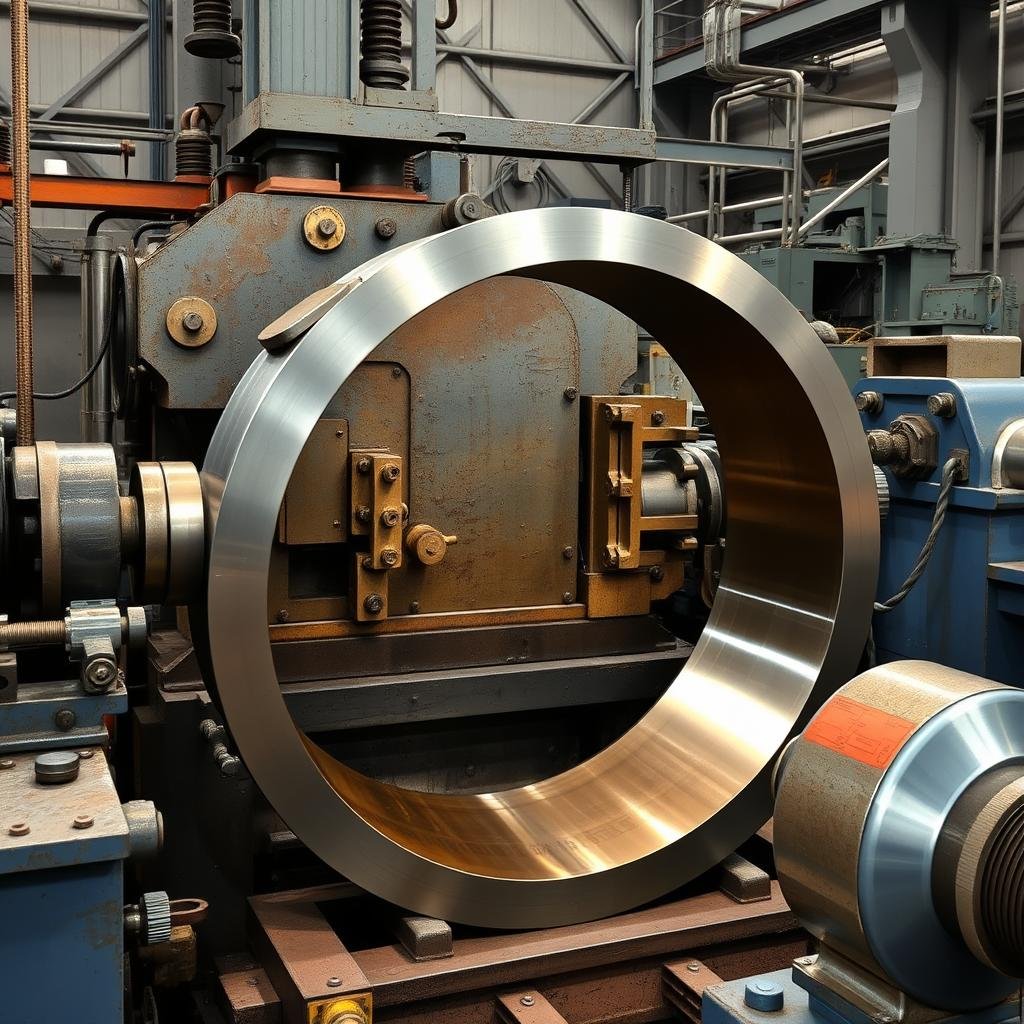

Ring Rolling Mills

Specialized equipment for producing seamless rolled rings. These mills use a combination of rollers to gradually form ring-shaped components from pierced blanks.

Manipulators

Mechanical devices for handling and positioning large forgings during the forming process. These provide precise control over workpiece orientation and movement.

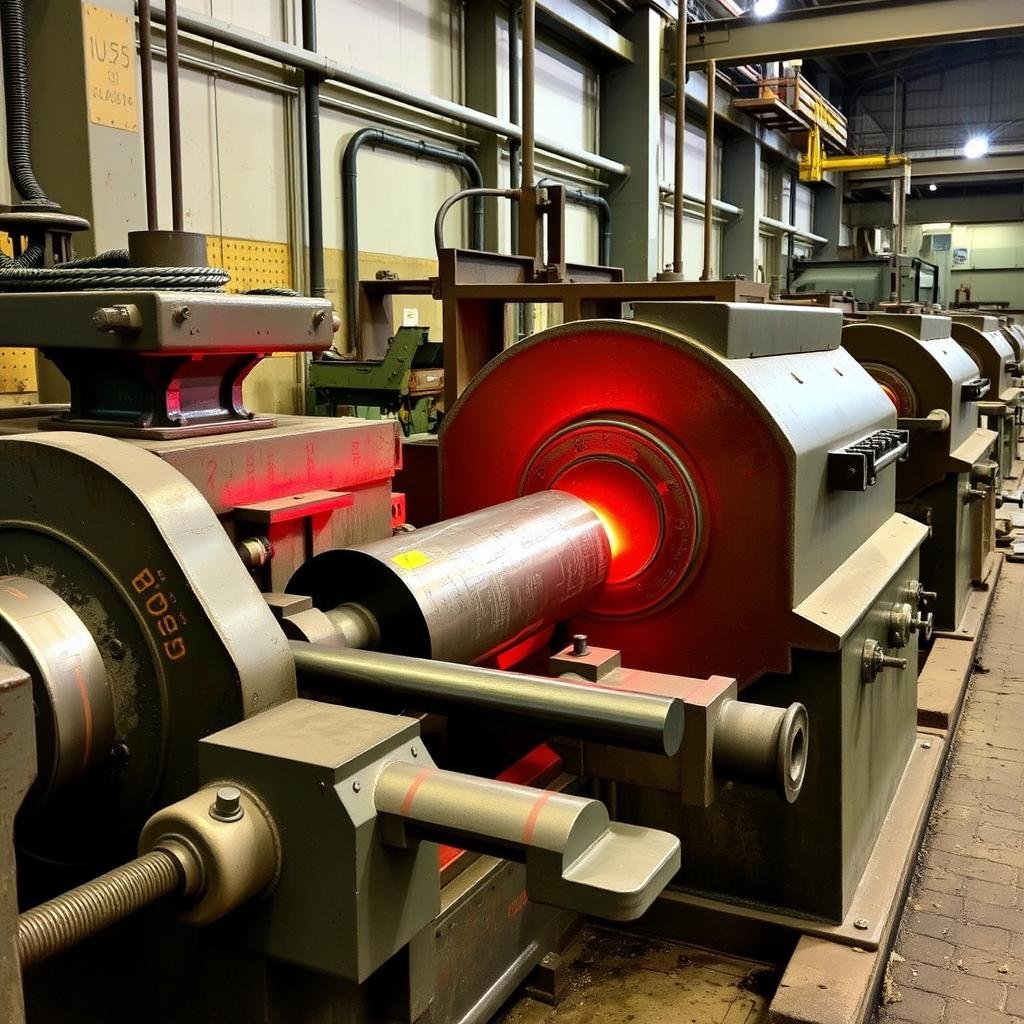

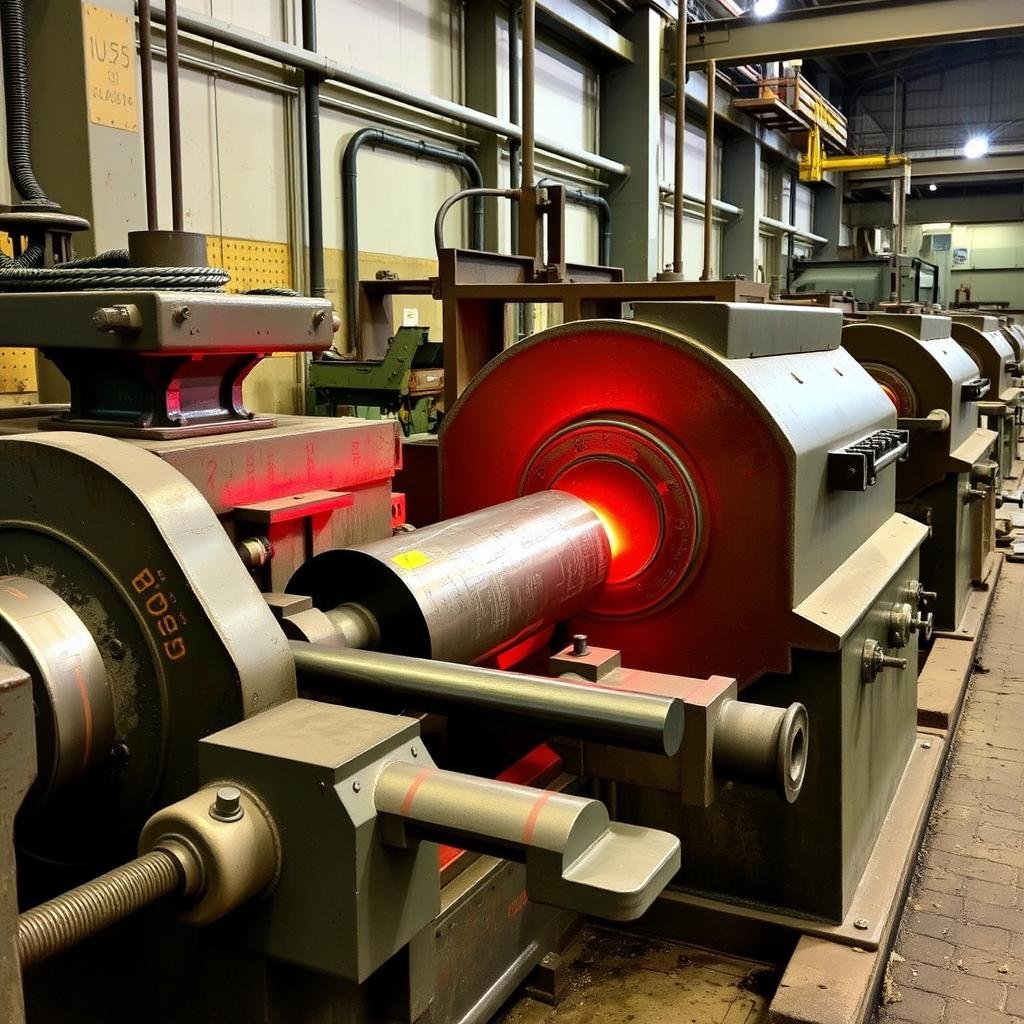

Forging Rolls

Power-driven rolls used to preform bar or billet stock before final forging. These create initial shapes that optimize material distribution for subsequent operations.

Equipment Selection Impact on Forging Quality

The choice of forging equipment directly affects several key aspects of the finished product:

| Equipment Type |

Strain Rate |

Deformation Control |

Part Complexity |

Production Volume |

Typical Applications |

| Hammers |

High |

Moderate |

High |

Low to Medium |

Complex shapes, deep impressions |

| Mechanical Presses |

Medium |

Good |

Medium to High |

High |

Automotive components, hardware |

| Hydraulic Presses |

Low |

Excellent |

Medium |

Medium |

Large forgings, aerospace components |

| Screw Presses |

Medium |

Very Good |

Medium to High |

Medium |

Precision components, hand tools |

| Upsetters |

Medium |

Good |

Limited |

High |

Headed parts, fasteners |

MAIKONG’s Advanced Forging Equipment

With over 60 CNC machines and 100+ tons of monthly metal processing capacity, MAIKONG offers comprehensive forging solutions for your most demanding applications.

Explore Our Capabilities

Forging Process Terminology: A Critical Component of Decoding Forge Tooling

Understanding the various forging processes is essential for procurement professionals to select the most appropriate manufacturing method for their specific requirements. Each process offers distinct advantages and limitations that directly impact component quality, cost, and lead time.

Open Die Forging

Also known as free forging or hand forging, this process involves shaping metal between flat or simply contoured dies through repeated strokes and workpiece manipulation.

Key Characteristics:

- Minimal material waste

- Suitable for large components

- Requires skilled operators

- Excellent grain flow control

- Limited to simpler shapes

Closed Die Forging

Also called impression die forging, this process shapes metal completely within the walls or cavities of two dies that come together to enclose the workpiece.

Key Characteristics:

- Complex shapes possible

- Excellent dimensional control

- Optimized grain flow

- Higher tooling costs

- Flash formation requires trimming

Precision Forging

A specialized form of closed die forging that produces components to near-net shape with minimal flash and tight tolerances, reducing or eliminating the need for machining.

Key Characteristics:

- Minimal material waste

- Reduced machining requirements

- Tight dimensional tolerances

- Higher tooling complexity

- Ideal for high-performance components

Specialized Forging Processes

Beyond the three primary methods, several specialized processes address specific manufacturing challenges:

Roll Forging

A process where round or flat bar stock is reduced in thickness and increased in length by passing it between two rotating rolls with shaped grooves. This process is often used to preform stock for subsequent forging operations.

Upset Forging

A process that increases the cross-sectional area of a portion of a bar, rod, or other product form by compressing it between dies. Commonly used for bolt and fastener heads, valves, and similar components.

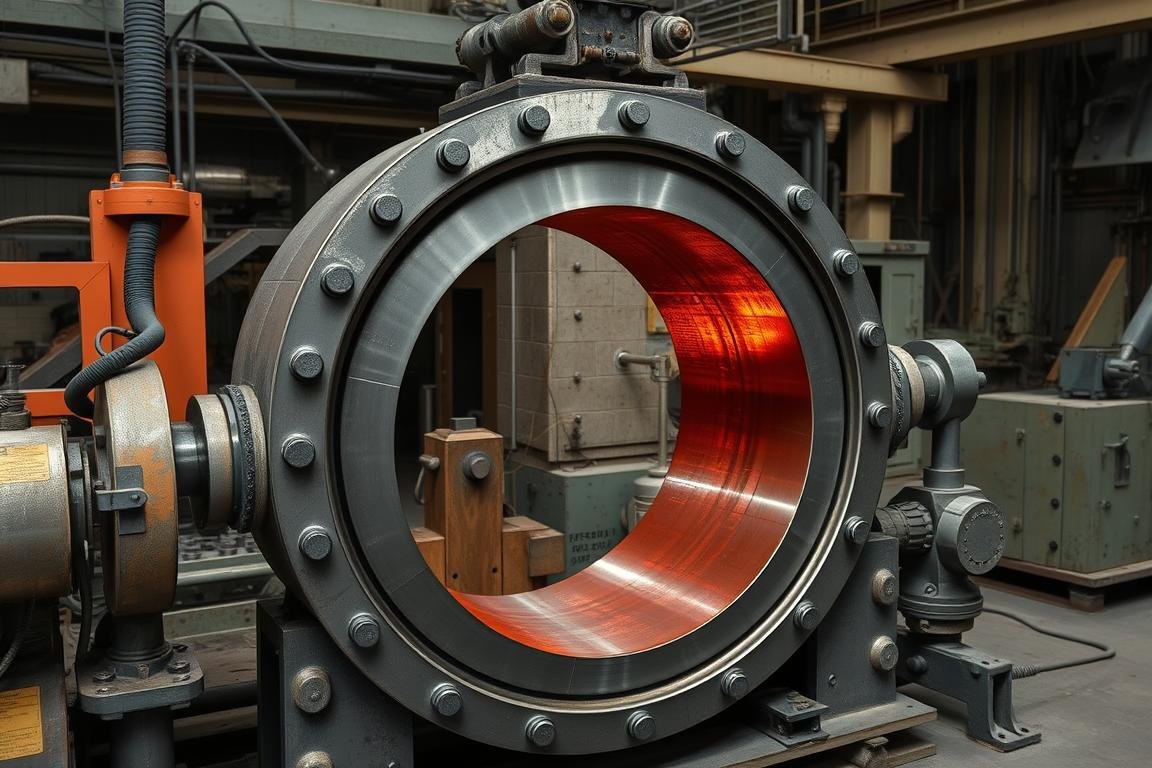

Ring Rolling

A specialized process for creating seamless rings by piercing a thick circular blank and then rolling it between rotating rolls to increase diameter while reducing wall thickness.

Temperature Classification in Forging

Forging processes are also classified by the temperature at which they are performed, each offering distinct advantages:

| Process |

Temperature Range |

Advantages |

Limitations |

Typical Applications |

| Hot Forging |

Above recrystallization temperature |

Lower force requirements, complex shapes possible, improved grain structure |

Lower dimensional precision, surface oxidation, shorter die life |

Structural components, large parts, complex geometries |

| Warm Forging |

Between room temperature and recrystallization |

Better precision than hot forging, less force than cold forging |

More complex heating control, specialized lubricants required |

Automotive components, hardware, medium-complexity parts |

| Cold Forging |

Room temperature |

Excellent dimensional accuracy, superior surface finish, improved strength |

Higher force requirements, limited complexity, work hardening |

Fasteners, small precision components, high-volume parts |

| Isothermal Forging |

Material-specific controlled temperature |

Precise control of material flow, reduced forming loads |

Expensive equipment, slower process, complex temperature control |

Superalloy components, aerospace parts, critical applications |

Find the Optimal Forging Process for Your Components

MAIKONG’s engineering team can help you select the most appropriate forging process to optimize quality, cost, and performance for your specific application.

Consult Our Forging Experts

Material Terminology in Decoding Forge Tooling

The materials used in both tooling and workpieces significantly impact forging quality, tool life, and component performance. Procurement professionals must understand material terminology to make informed decisions about forging specifications.

Die Materials and Properties

Forging dies must withstand extreme conditions, including high temperatures, pressures, and cyclic loading. The selection of appropriate die materials is critical for tool life and part quality:

- Tool steels – High-alloy steels designed for tooling applications, offering hardness, wear resistance, and toughness

- Hot-work tool steels – Specialized grades (H11, H13) that maintain properties at elevated temperatures

- Die blocks – The primary material from which dies are manufactured

- Insert materials – Often premium alloys used for high-wear areas

- Surface treatments – Nitriding, PVD coatings, and other treatments to enhance die performance

Workpiece Materials in Forging

Different materials respond uniquely to the forging process, requiring specific temperature ranges, equipment, and techniques:

| Material Category |

Common Alloys |

Forging Temperature Range |

Special Considerations |

Typical Applications |

| Carbon Steel |

1018, 1045, 1095 |

2100-2300°F (1150-1260°C) |

Decarburization control, scaling |

Structural components, tools, automotive parts |

| Alloy Steel |

4140, 4340, 8620 |

2000-2250°F (1090-1230°C) |

Narrower temperature window, grain growth control |

High-strength components, gears, shafts |

| Stainless Steel |

304, 316, 17-4PH |

2000-2200°F (1090-1200°C) |

Higher forging forces, die wear, narrow temperature range |

Corrosion-resistant parts, food processing, medical |

| Aluminum |

6061, 7075, 2024 |

750-950°F (400-510°C) |

Narrow temperature window, sticking to dies |

Aerospace components, lightweight structures |

| Titanium |

Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo |

1650-1750°F (900-950°C) |

Oxidation control, specialized lubricants, isothermal forging |

Aerospace, medical implants, high-performance components |

| Brass/Bronze |

C36000, C83600 |

1300-1650°F (700-900°C) |

Zinc volatilization in brass, hot shortness |

Valves, fittings, decorative hardware |

Material Terminology Related to Forging Properties

Understanding these key material terms helps in evaluating forging quality and specifications:

Grain Flow

The directional alignment of the material’s internal structure during forging. Proper grain flow enhances mechanical properties and is a key advantage of forged components over cast or machined parts.

Flow Stress

The resistance of a material to deformation during forging, affected by temperature, strain rate, and material composition. Understanding flow stress helps optimize forging parameters.

Forgeability

A material’s ability to deform without fracturing during forging. Materials with good forgeability can be formed into complex shapes with minimal risk of defects.

The Advantage of Aluminum Forging vs. Casting

Understanding the differences between forging and casting helps procurement professionals make informed decisions about manufacturing processes:

| Comparison Categories |

Aluminum Forging |

Cast Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Weight-to-Strength Ratio |

High strength-to-weight ratio |

Bulkier parts may be needed |

Expert Material Selection for Your Forging Needs

MAIKONG’s metallurgical expertise ensures the optimal material selection for your specific application requirements, balancing performance, cost, and manufacturability.

Consult Our Materials Experts

Forging Defects Terminology: Critical Knowledge for Decoding Forge Tooling

Understanding the terminology related to forging defects is essential for procurement professionals to effectively communicate quality requirements and evaluate supplier capabilities. Recognizing these terms helps in specifying appropriate inspection methods and acceptance criteria.

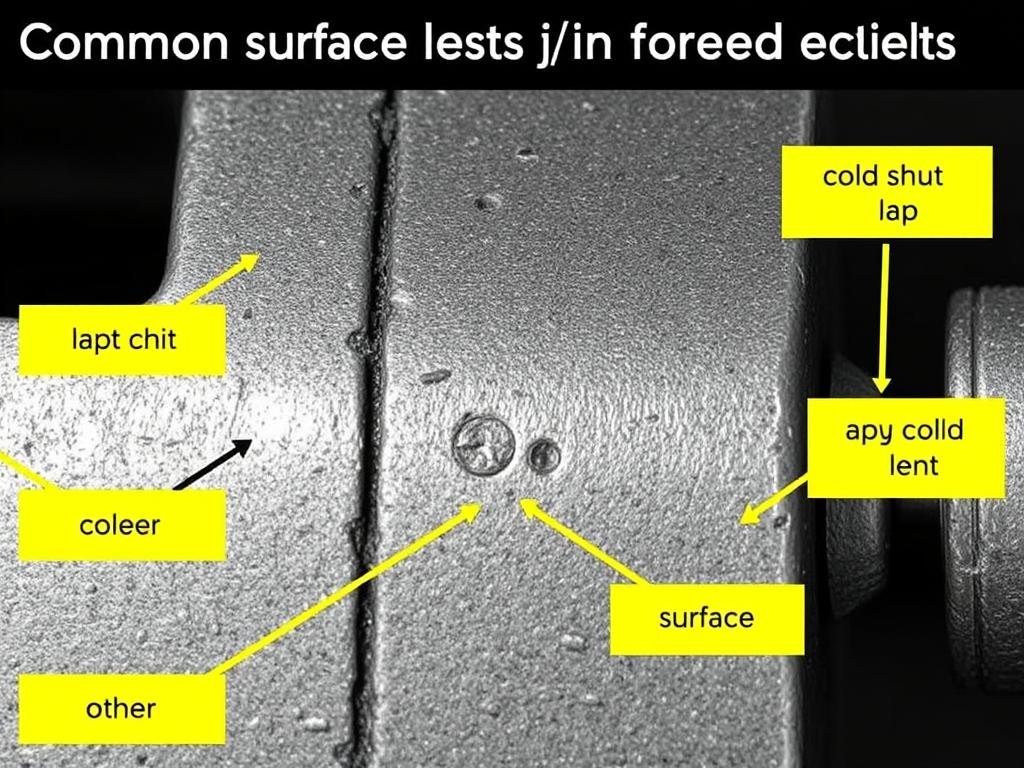

Surface Defects

Defects visible on the component surface that may affect appearance, function, or structural integrity:

- Laps – Surface irregularities caused by folding of metal during forging

- Cold shuts – Similar to laps, occurring when metal fails to fill the die cavity properly

- Scale pits – Surface depressions caused by scale (oxide) embedded in the surface

- Die wear – Dimensional variations or surface imperfections due to worn dies

- Flakes – Small surface cracks caused by hydrogen embrittlement

- Seams – Linear defects originating from raw material defects

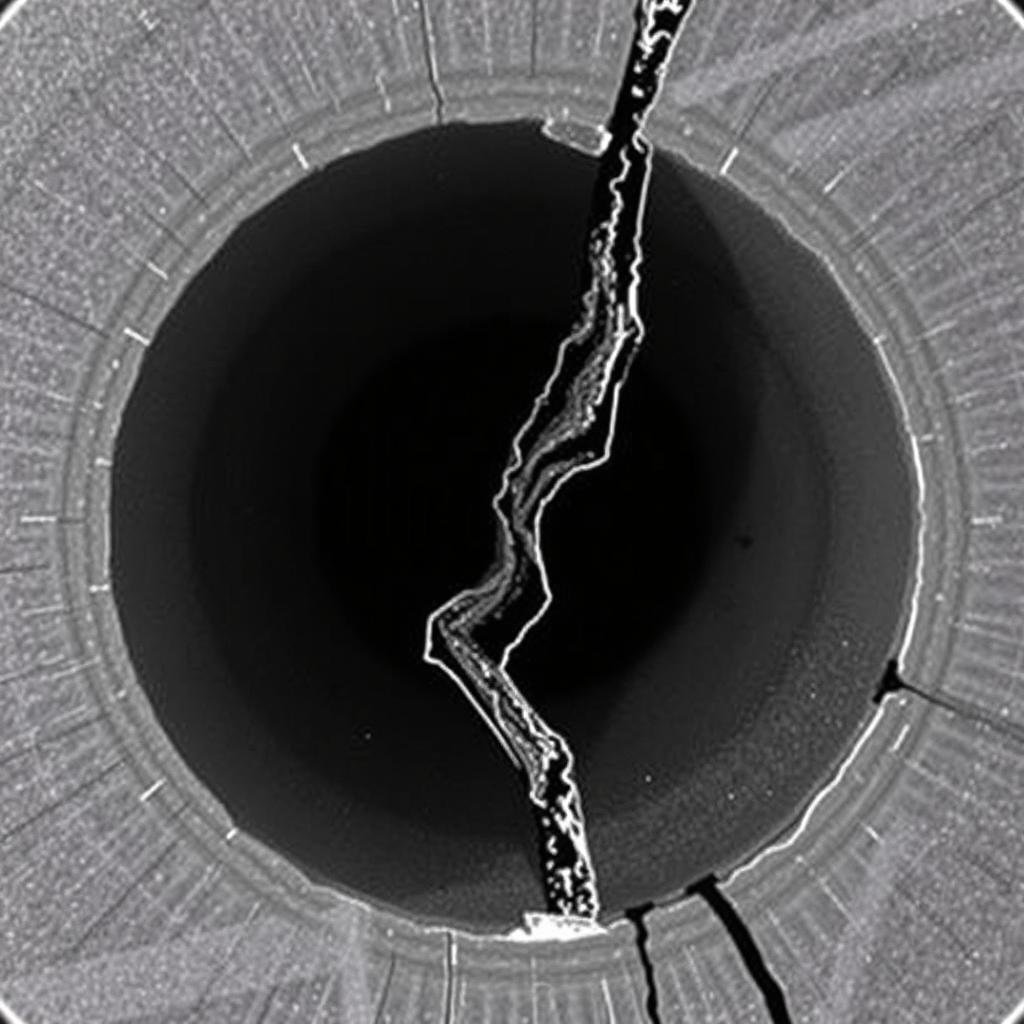

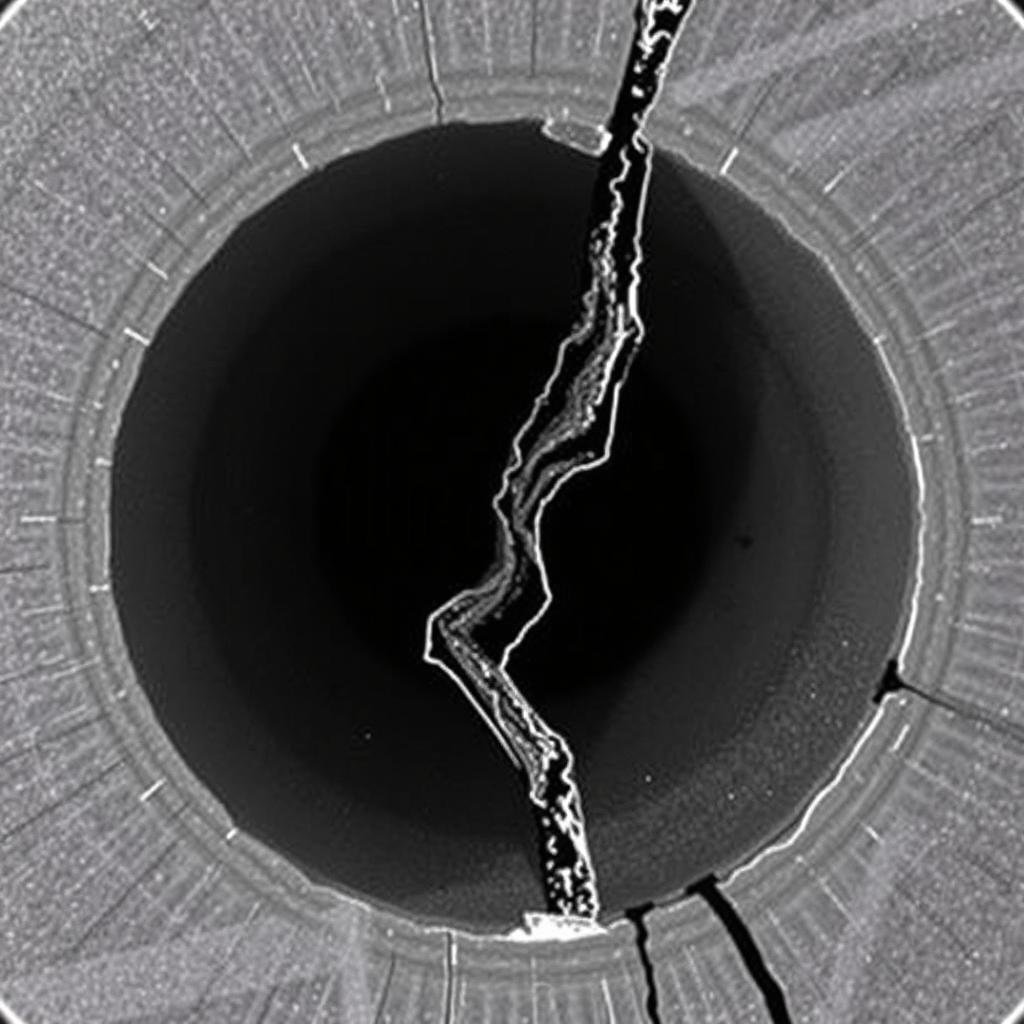

Internal and Structural Defects

Defects within the forged component that may not be visible but can affect performance and reliability:

Flow-Through

A defect caused by metal flow past the base of a rib with consequent rupture of the grain structure, compromising structural integrity.

Improper Grain Flow

Suboptimal directional properties due to improper metal flow during forging, potentially reducing strength and fatigue resistance.

Internal Bursts

Internal cracks or voids caused by excessive forging pressure or improper temperature control during the forging process.

Dimensional and Geometric Defects

Defects related to the dimensional accuracy and geometric characteristics of forged components:

| Defect Type |

Description |

Common Causes |

Detection Methods |

Prevention Strategies |

| Mismatch |

Misalignment between upper and lower die impressions |

Improper die setup, worn guides, excessive side thrust |

Visual inspection, dimensional measurement |

Proper die alignment, regular maintenance, guide adjustment |

| Underfill |

Incomplete filling of the die cavity |

Insufficient material, low temperature, inadequate pressure |

Visual inspection, dimensional measurement |

Proper billet sizing, temperature control, adequate forging force |

| Warpage |

Unintended deformation after forging |

Uneven cooling, residual stresses, improper handling |

Dimensional measurement, flatness checks |

Controlled cooling, stress relief, proper support during cooling |

| Draft Errors |

Incorrect taper on vertical surfaces |

Die design errors, wear, improper machining |

Dimensional measurement, visual inspection |

Proper die design, regular die maintenance |

| Die Shift |

Movement of dies during forging causing dimensional errors |

Inadequate clamping, excessive forging force |

Dimensional measurement, pattern analysis |

Proper die securing, balanced force distribution |

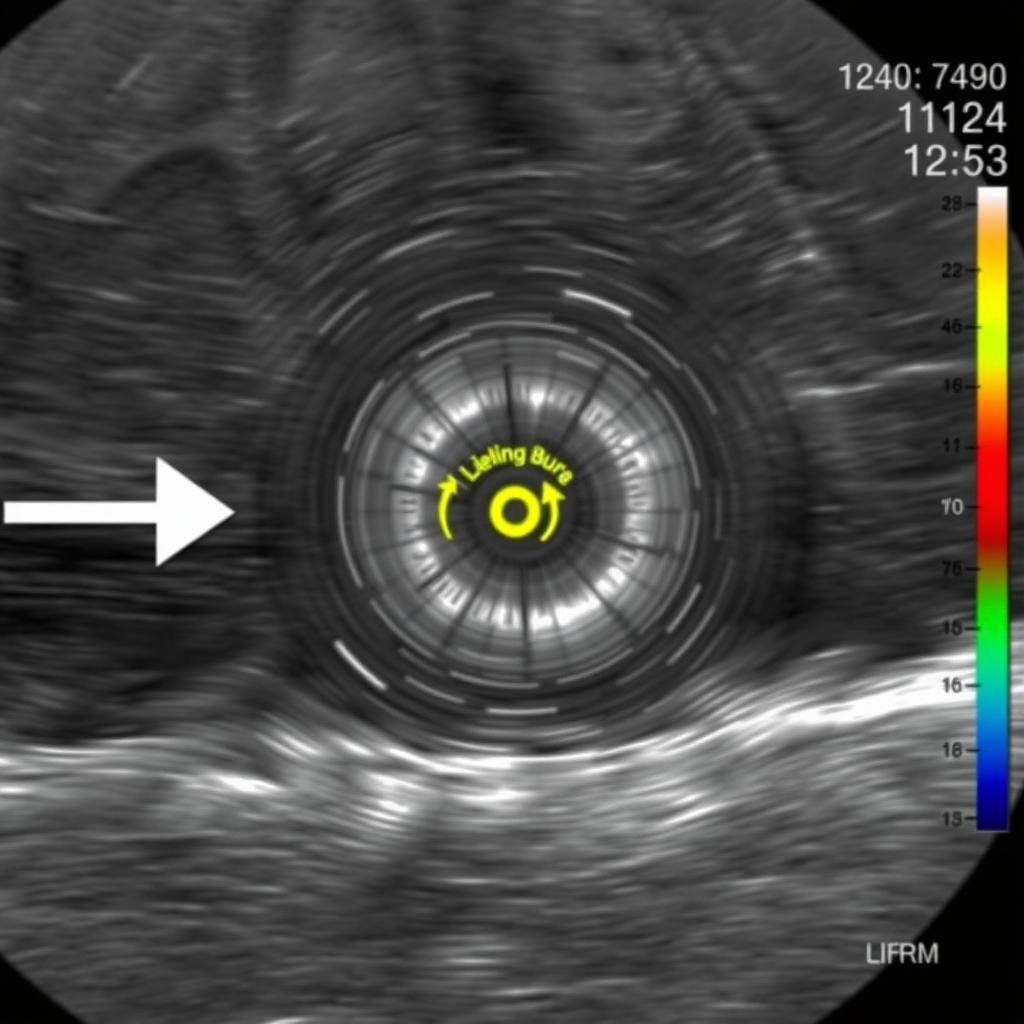

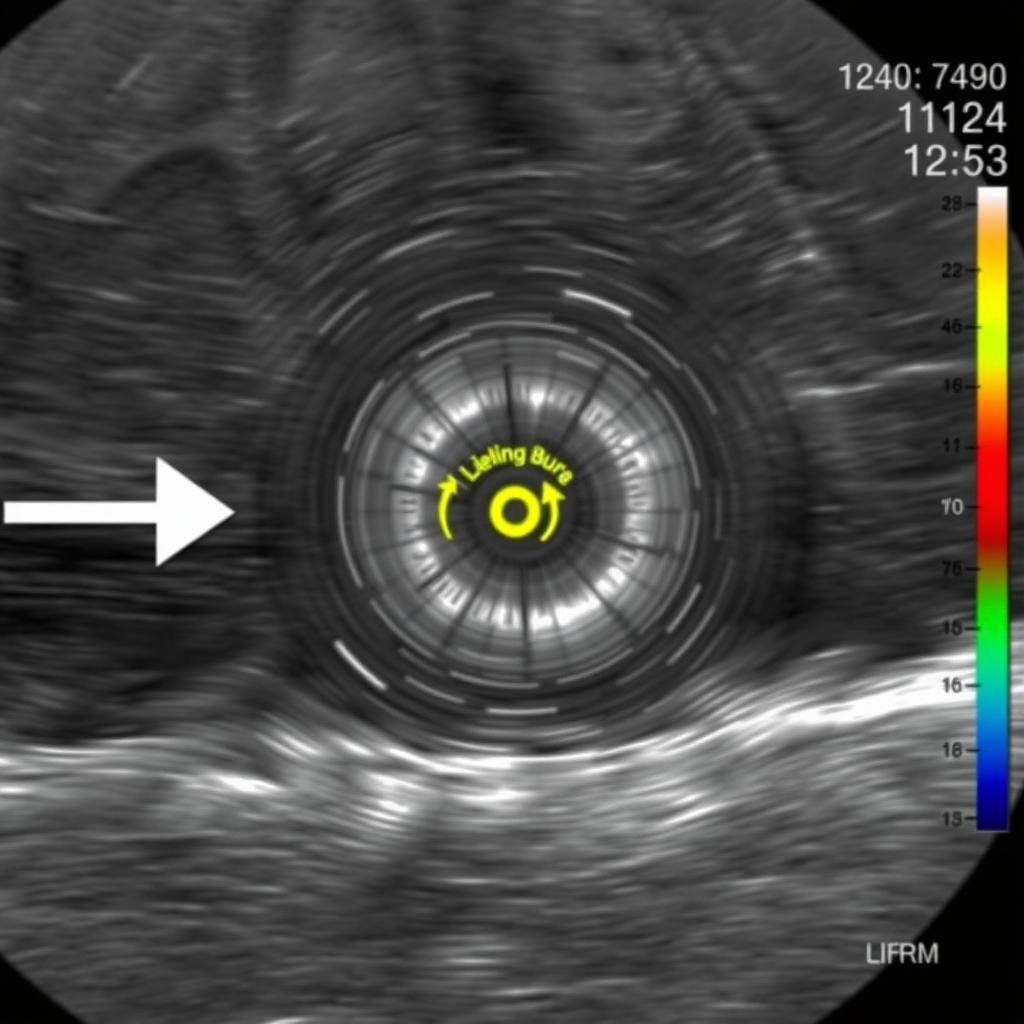

Inspection Terminology for Forged Components

Understanding inspection methods and terminology is crucial for specifying quality requirements:

- Magnetic particle inspection – Non-destructive testing method for detecting surface and near-surface discontinuities in ferromagnetic materials

- Ultrasonic testing – Non-destructive method using sound waves to detect internal flaws

- Dye penetrant testing – Surface inspection method using colored dye to reveal surface defects

- Macroetch testing – Destructive test that reveals grain flow and internal structure

- Dimensional inspection – Measurement of critical dimensions against specifications

- Hardness testing – Measurement of material hardness (Brinell, Rockwell, etc.)

Ensure Defect-Free Forgings with MAIKONG’s Quality Assurance

Our comprehensive quality control system employs advanced inspection technologies and rigorous processes to deliver forgings that meet or exceed your specifications.

Learn About Our Quality Systems

Auxiliary Operations in Decoding Forge Tooling Terminology

Beyond the core forging process, numerous auxiliary operations contribute to the final quality and characteristics of forged components. Understanding these operations helps procurement professionals specify complete manufacturing requirements and evaluate supplier capabilities.

Trimming and Finishing

Operations that remove excess material and improve the appearance and dimensional accuracy of forgings:

- Trimming – Removal of flash (excess material) from the forging

- Coining – Secondary pressing operation to improve dimensional accuracy

- Sizing – Operation to bring forgings to final dimensions

- Straightening – Correction of warpage or distortion

- Grinding – Removal of parting lines or surface imperfections

Heat Treatment

Thermal processes that modify the mechanical properties of forged components:

- Normalizing – Heating and air cooling to refine grain structure

- Annealing – Softening through controlled heating and cooling

- Quenching – Rapid cooling to increase hardness

- Tempering – Reheating after quenching to reduce brittleness

- Stress relief – Heating to reduce residual stresses

Surface Treatment

Processes that modify the surface characteristics of forgings:

- Shot blasting – Cleaning and surface preparation using metal shot

- Pickling – Chemical cleaning to remove scale and oxides

- Tumbling – Mechanical finishing in rotating drums

- Coating – Application of protective or decorative finishes

- Case hardening – Surface hardening through carbon diffusion

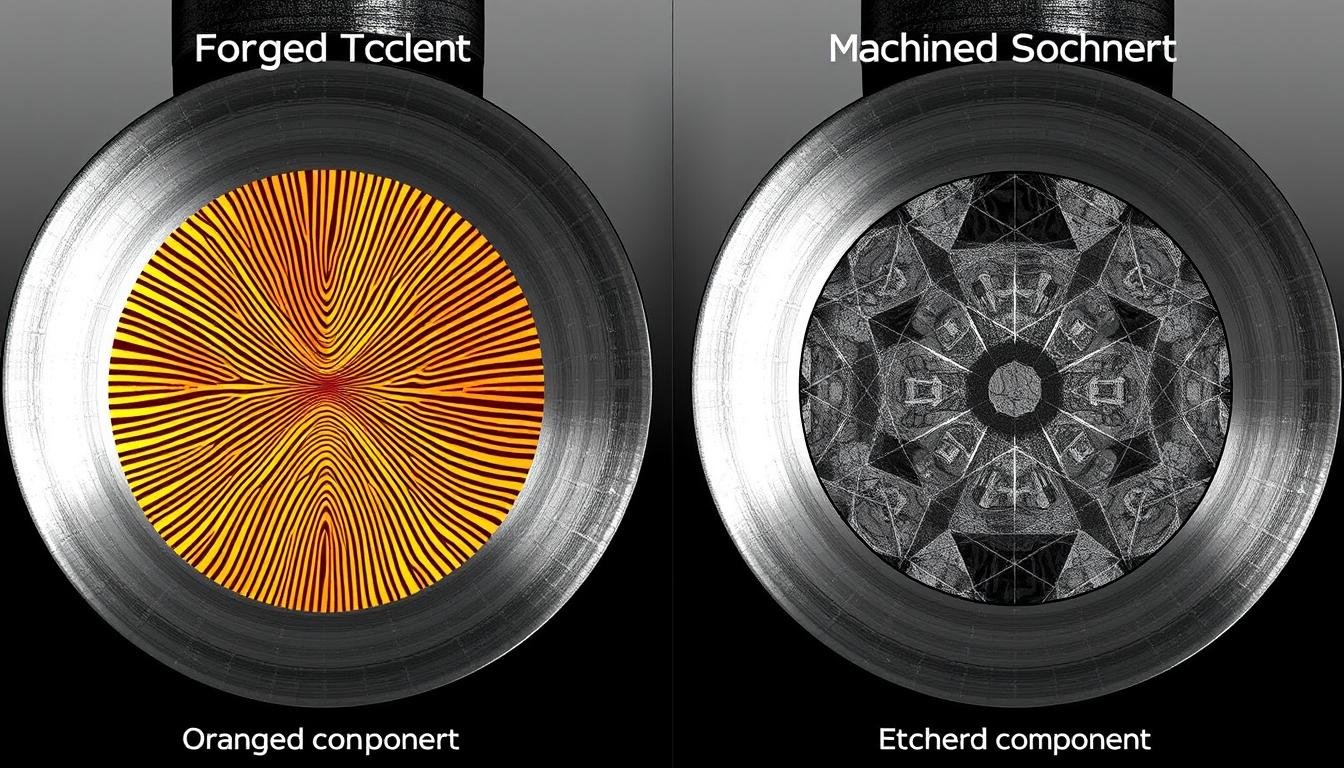

Machining Operations

Many forged components require additional machining to achieve final dimensions and features:

MAIKONG’s integrated manufacturing capabilities include comprehensive CNC machining services with over 60 CNC machines providing 100+ tons of metal processing capacity per month. Our machining operations include:

- CNC Turning – Ideal for cylindrical shapes, deep holes, and machined threads with superior surface finishes

- CNC Milling – Creates complex prismatic shapes and flat surfaces with high accuracy

- CNC Swiss-Type Machining – Specializes in precision small parts and long shaft components

- Surface Grinding – Produces extremely flat surfaces with tight tolerances

- Laser Engraving – Adds permanent markings and identification

Our multi-axis machining centers allow for complex geometries to be produced in a single setup, reducing handling and improving dimensional accuracy. All machining operations are supported by our comprehensive quality control system.

Testing and Inspection Operations

Quality assurance operations verify that forged components meet specified requirements:

| Testing Category |

Methods |

Properties Evaluated |

Typical Requirements |

| Mechanical Testing |

Tensile testing, impact testing, hardness testing, fatigue testing |

Strength, ductility, toughness, hardness, fatigue resistance |

Minimum tensile strength, yield strength, elongation, impact energy |

| Non-Destructive Testing |

Ultrasonic, magnetic particle, dye penetrant, radiography |

Internal and surface discontinuities, flaws, cracks |

Acceptance criteria based on relevant standards (ASTM, etc.) |

| Dimensional Inspection |

CMM, gauges, optical measurement, 3D scanning |

Dimensions, geometrical tolerances, surface finish |

Conformance to drawing specifications and tolerances |

| Metallurgical Testing |

Microstructure analysis, chemical analysis, grain flow evaluation |

Material composition, grain structure, inclusions |

Specified material composition, absence of detrimental inclusions |

Complete Manufacturing Solutions from MAIKONG

From forging to finishing, MAIKONG offers comprehensive manufacturing capabilities to deliver fully finished components that meet your exact specifications.

Explore Our Full-Service Capabilities

Advanced Technologies in Decoding Forge Tooling

Modern forging operations increasingly incorporate advanced technologies to improve quality, efficiency, and capabilities. Understanding these technologies helps procurement professionals evaluate supplier capabilities and potential for innovation.

CAD/CAM Integration

Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems have revolutionized forge tooling design and production:

- Die design optimization – Advanced software allows for optimized die designs that improve material flow and reduce defects

- Simulation-based validation – Virtual testing of die designs before physical production

- CNC die machining – Precise, computer-controlled machining of die components

- Digital process planning – Comprehensive digital workflow from design to production

- Reduced lead times – Faster development cycles through digital integration

Forging Simulation and Analysis

Advanced simulation tools provide insights into the forging process before physical production:

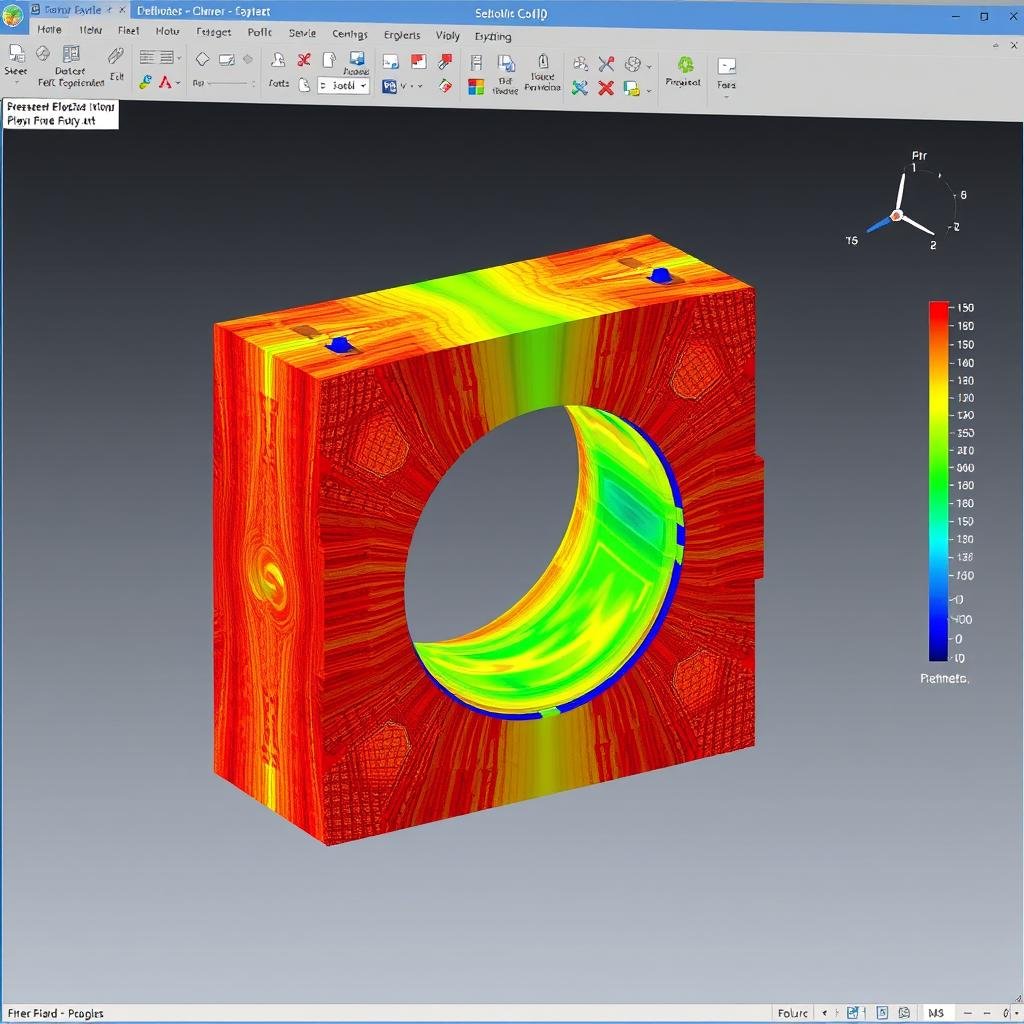

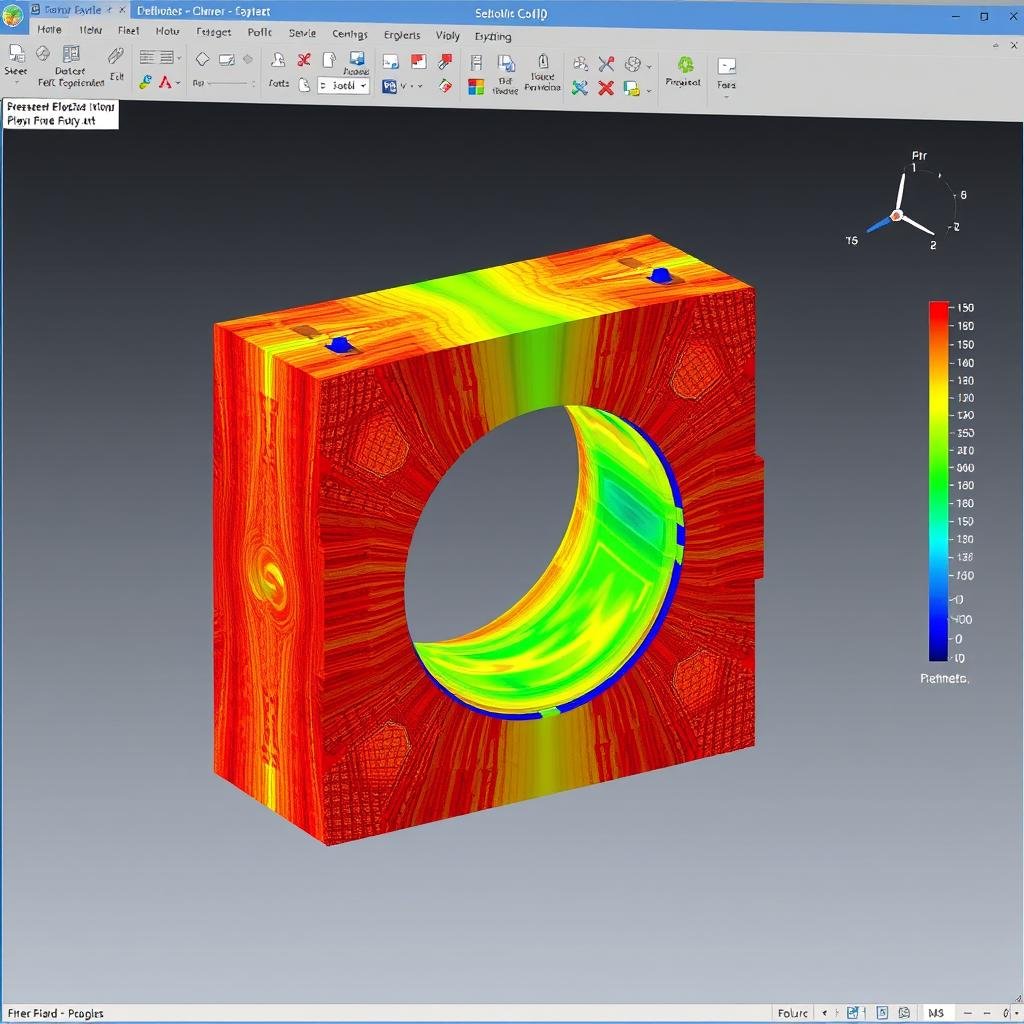

Finite Element Analysis (FEA)

Computational technique that predicts material behavior during forging, allowing engineers to optimize die design, process parameters, and material utilization.

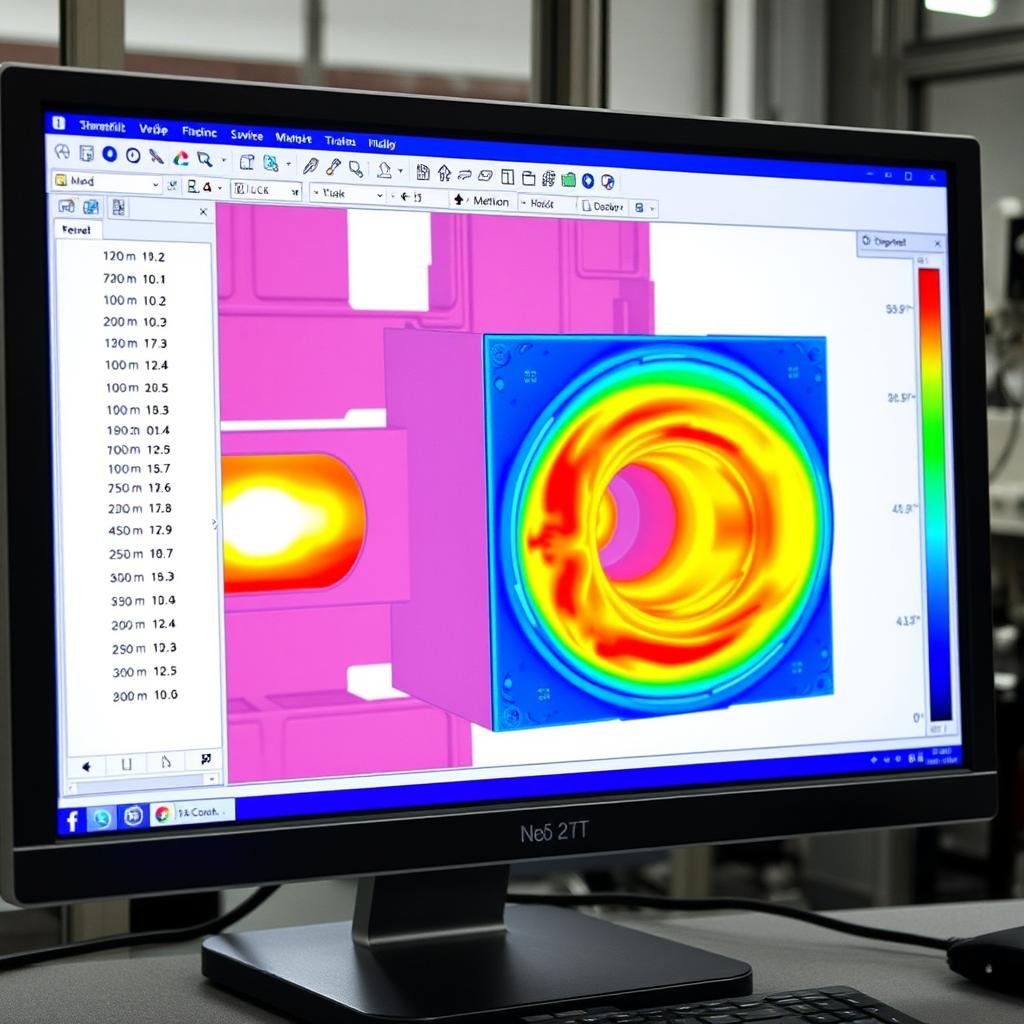

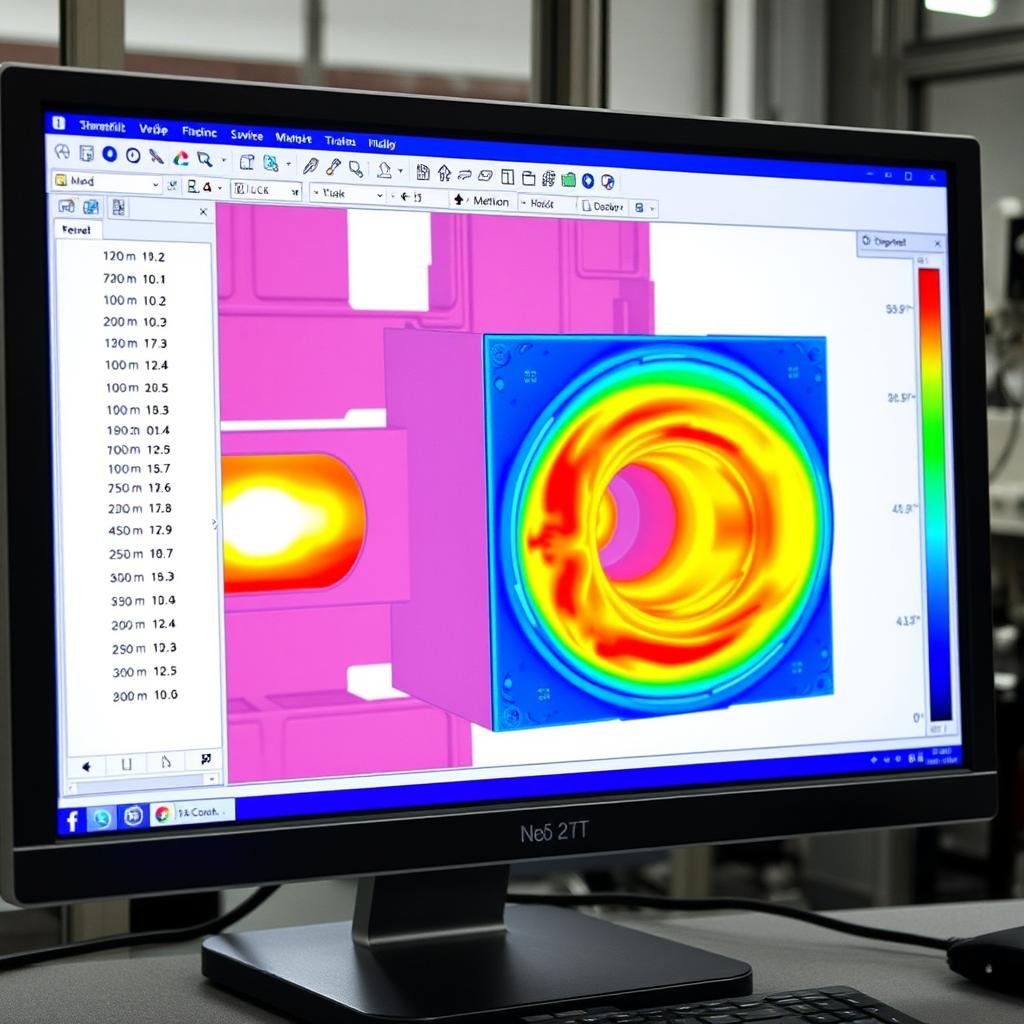

Material Flow Simulation

Specialized simulation that visualizes how metal flows during the forging process, helping identify potential defects and optimize die design for proper grain flow.

Thermal Analysis

Simulation of temperature distribution and heat transfer during forging, critical for understanding how temperature affects material properties and die life.

Advanced Manufacturing Technologies

Innovative technologies are transforming traditional forging operations:

Process Monitoring and Control

Real-time monitoring systems track critical parameters during forging, allowing for immediate adjustments and consistent quality:

- Force and energy monitoring – Ensures consistent forging pressure

- Temperature monitoring – Verifies proper heating and cooling

- Die wear tracking – Predicts maintenance needs

- Statistical process control – Identifies trends and variations

- Quality documentation – Provides traceability and verification

Automation and Robotics

Automated systems improve consistency, safety, and efficiency in forging operations:

- Robotic material handling – Consistent positioning and movement

- Automated lubrication – Precise application of die lubricants

- Integrated inspection – In-line quality verification

- Automated cell control – Coordinated operation of multiple systems

MAIKONG’s Advanced Manufacturing Capabilities

At MAIKONG, we’ve invested in cutting-edge technologies to deliver superior forged components:

| Technology Area |

MAIKONG Capabilities |

Customer Benefits |

| Design & Engineering |

Advanced CAD/CAM systems, FEA simulation, collaborative engineering |

Optimized designs, reduced development time, virtual validation before production |

| Forging Equipment |

State-of-the-art presses and hammers with precision control systems |

Consistent quality, capability for complex geometries, efficient production |

| CNC Machining |

60+ CNC machines with multi-axis capabilities, 100+ tons monthly capacity |

Precision finishing, complete component manufacturing, reduced lead times |

| Quality Control |

Advanced measurement systems, non-destructive testing, material analysis |

Verified quality, comprehensive documentation, reduced inspection costs |

| Process Integration |

Seamless workflow from forging through heat treatment to finishing |

Single-source responsibility, consistent quality, reduced logistics costs |

Experience MAIKONG’s Advanced Manufacturing Capabilities

Our investment in cutting-edge technologies ensures superior quality, efficiency, and innovation in every forged component we produce.

Discover Our Technological Advantage

Industry Applications: Putting Decoding Forge Tooling Knowledge to Work

Understanding forge tooling terminology becomes particularly valuable when applied to specific industry contexts. Different sectors have unique requirements and priorities that influence forging specifications and processes.

Aerospace

The aerospace industry demands the highest levels of quality and reliability in forged components:

- Critical structural components

- Landing gear components

- Engine disks and shafts

- Airframe structural elements

- Fastening systems

Key requirements: Superior strength-to-weight ratio, excellent fatigue resistance, precise dimensional control, comprehensive documentation.

Automotive

Automotive applications balance performance requirements with cost efficiency:

- Crankshafts and connecting rods

- Transmission components

- Steering and suspension parts

- Wheel hubs and axles

- Engine valves and camshafts

Key requirements: Cost-effective production, consistent quality, good fatigue properties, appropriate material selection.

Oil & Gas

The oil and gas industry requires components that can withstand extreme conditions:

- Valve bodies and bonnets

- Pressure vessel components

- Flanges and fittings

- Wellhead components

- Subsea equipment

Key requirements: Pressure containment capability, corrosion resistance, material traceability, certification to industry standards.

Specialized Industry Applications

Beyond the major sectors, forged components play critical roles in numerous specialized industries:

Power Generation

The power generation industry relies on forged components for critical applications in turbines, generators, and nuclear systems:

- Turbine rotors and disks – High-temperature, high-stress applications

- Generator components – Require excellent electrical and mechanical properties

- Pressure boundary parts – Must meet strict regulatory requirements

- Valve bodies and stems – Control critical system functions

- Structural supports – Provide long-term stability and safety

Key requirements: Long service life, resistance to creep and fatigue, strict material certification, non-destructive testing.

Medical

The medical industry requires exceptionally high-quality forged components for implants and surgical instruments:

- Orthopedic implants – Hip and knee replacements, bone plates, spinal devices

- Surgical instruments – Forceps, retractors, scissors, clamps

- Dental implements – Specialized tools and implant components

- Medical device components – Structural elements for medical equipment

Key requirements: Biocompatibility, corrosion resistance, fatigue strength, precise dimensions, exceptional surface finish, full traceability.

MAIKONG’s Industry Expertise

At MAIKONG, we’ve developed specialized expertise across multiple industries, allowing us to deliver forged components that meet the specific requirements of each sector:

Industry-Specific Forging Solutions from MAIKONG

Our team understands the unique requirements of your industry and can deliver forged components that meet your specific performance, quality, and regulatory needs.

Discuss Your Industry Requirements

Procurement Guide: Applying Decoding Forge Tooling Knowledge

Armed with a solid understanding of forge tooling terminology, procurement professionals can more effectively specify requirements, evaluate suppliers, and manage forging projects. This section provides practical guidance for applying this knowledge in the procurement process.

Specification Development

Creating clear, comprehensive specifications is essential for successful forging procurement:

- Material requirements – Specify alloy, condition, and any special requirements

- Dimensional tolerances – Define critical dimensions and acceptable variations

- Surface finish – Specify requirements for appearance and function

- Mechanical properties – Define strength, hardness, and other performance criteria

- Testing and inspection – Specify methods and acceptance criteria

- Process requirements – Define any specific forging methods or controls

- Documentation – Specify required certifications and records

Supplier Evaluation Criteria

When evaluating forging suppliers, consider these key factors:

| Evaluation Category |

Key Considerations |

Questions to Ask |

| Technical Capability |

Equipment specifications, process capabilities, engineering expertise |

What types of forging equipment do you operate? What are your size and weight capabilities? Do you have in-house engineering support? |

| Quality Systems |

Certifications, inspection capabilities, process controls |

What quality certifications do you hold? What inspection methods do you use? How do you ensure process consistency? |

| Material Expertise |

Experience with required alloys, material sourcing, heat treatment capabilities |

What experience do you have with our required materials? Do you perform heat treatment in-house? How do you verify material properties? |

| Production Capacity |

Available capacity, lead times, lot size flexibility |

What are your typical lead times? Can you handle our volume requirements? What is your minimum order quantity? |

| Value-Added Services |

Machining capabilities, finishing operations, assembly services |

What secondary operations can you perform? Do you offer complete component manufacturing? Can you provide assembly services? |

Cost Considerations in Forging Procurement

Understanding the factors that influence forging costs helps in budget planning and supplier negotiation:

Material Factors

- Alloy type and market price

- Material availability and lead time

- Material certification requirements

- Material utilization efficiency

- Scrap value and recycling

Tooling Factors

- Die complexity and size

- Required die materials

- Expected production volume

- Die maintenance requirements

- Tooling amortization approach

Process Factors

- Required forging equipment

- Number of operations

- Heat treatment requirements

- Secondary operations

- Inspection and testing scope

Common Procurement Pitfalls to Avoid

Being aware of these common challenges can help procurement professionals navigate the forging sourcing process more effectively:

- Incomplete specifications – Leads to misunderstandings and quality issues

- Unrealistic tolerances – Increases costs without functional benefit

- Ignoring material considerations – Can result in performance problems

- Overlooking secondary operations – May require additional suppliers

- Focusing solely on unit price – Misses total cost of ownership

- Inadequate quality requirements – Can lead to field failures

- Poor communication – Causes delays and misunderstandings

Partner with MAIKONG for Successful Forging Procurement

Our experienced team works closely with procurement professionals to ensure clear specifications, realistic expectations, and successful outcomes for your forging projects.

Or contact us via WhatsApp at the same number: https://wa.me/861351090701

Request a Consultation

Conclusion: Mastering Decoding Forge Tooling Terminology

Understanding forge tooling terminology is a valuable asset for procurement professionals in the manufacturing sector. This knowledge enables more effective communication with suppliers, better specification development, and more informed decision-making throughout the procurement process.

By mastering the language of forge tooling, you can:

- Communicate more precisely with forging suppliers

- Develop more comprehensive and accurate specifications

- Evaluate supplier capabilities more effectively

- Identify potential quality issues before they occur

- Make more informed decisions about manufacturing processes

- Optimize component design for manufacturability

- Reduce costs through improved process selection

As the manufacturing landscape continues to evolve with new technologies and materials, staying current with forge tooling terminology will remain an important skill for procurement professionals seeking to secure high-quality forged components.

Why Choose MAIKONG for Your Forging Needs

MAIKONG combines technical expertise, advanced manufacturing capabilities, and customer-focused service to deliver superior forged components:

Technical Excellence

- Comprehensive engineering support

- Advanced simulation and analysis

- Optimized process development

- Material expertise across alloys

- Continuous innovation focus

Manufacturing Capability

- 60+ CNC machines

- 100+ tons monthly capacity

- Comprehensive forging equipment

- In-house heat treatment

- Complete finishing operations

Customer Focus

- Responsive communication

- Collaborative problem-solving

- Transparent project management

- Competitive global pricing

- Commitment to quality and delivery

Begin Your Partnership with MAIKONG Today

Experience the MAIKONG difference in forged component manufacturing. Our team is ready to support your procurement needs with expertise, quality, and value.