In today’s competitive manufacturing landscape, the quality and performance of forge tooling drives significant improvements in operational efficiency, product quality, and bottom-line results. At MAIKONG, we’ve spent decades perfecting our forge tooling technology to help American forging operations maximize productivity while minimizing costs. Our innovative approach combines precision engineering, advanced materials science, and state-of-the-art manufacturing processes to deliver forge tooling solutions that consistently outperform industry standards.

Key Benefits of MAIKONG’s Advanced Forge Tooling Drives

Our innovative approach to forge tooling design and manufacturing delivers measurable advantages for American forging operations seeking to improve efficiency and competitiveness.

Extended Tool Life

Our proprietary heat treatment processes and surface treatments extend die life by up to 40% compared to industry standards, reducing tooling costs and minimizing production interruptions.

Improved Part Quality

Precision-engineered tooling ensures consistent part geometry, superior surface finish, and optimal grain flow in forged components, resulting in stronger parts with fewer defects.

Reduced Production Costs

Our optimized tooling designs minimize material waste, reduce energy consumption, and decrease the need for secondary operations, delivering significant cost savings throughout the production process.

Ready to Enhance Your Forging Operation?

Our forge tooling experts can analyze your current processes and recommend customized solutions to improve efficiency and reduce costs.

Get a Quick Quote

Advanced Technology Behind Our Forge Tooling Drives

MAIKONG leverages cutting-edge technology throughout our design and manufacturing processes to create forge tooling that delivers superior performance and longevity.

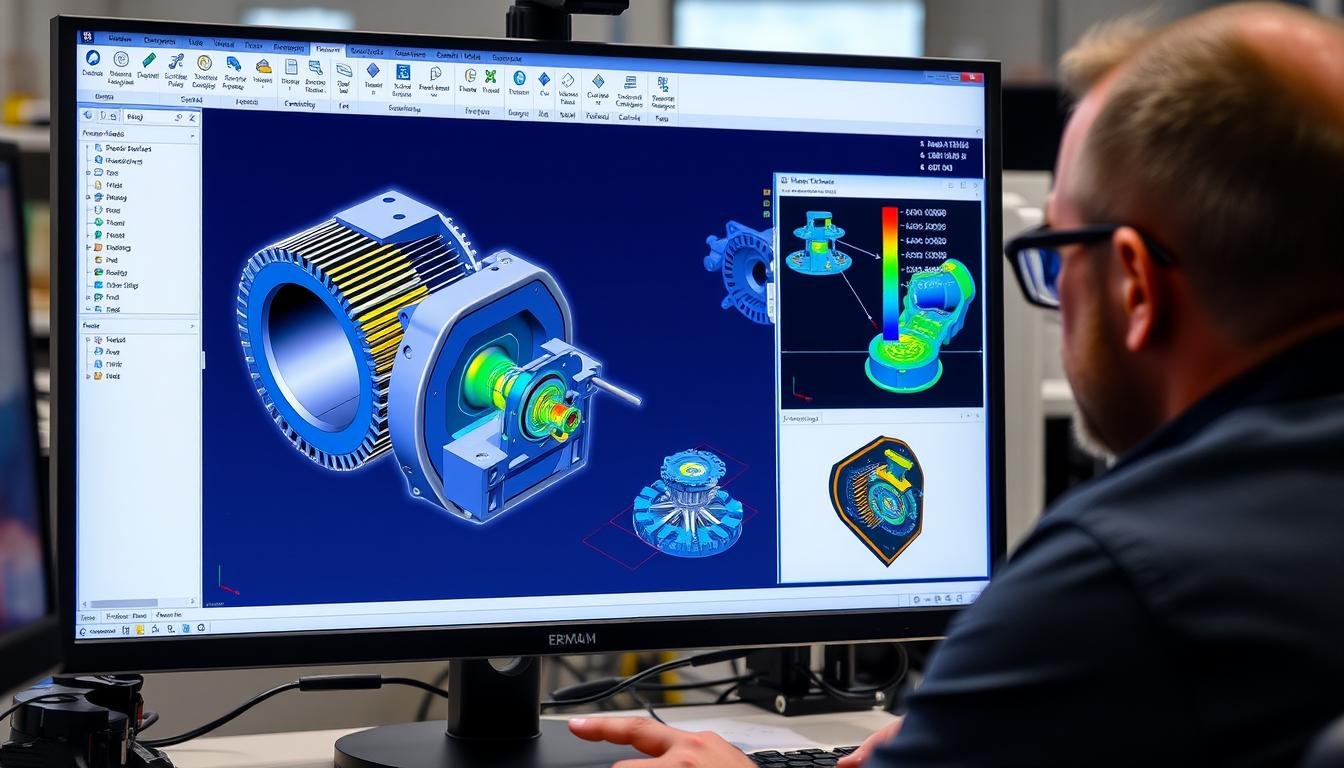

CAD/CAM Integration

Our integrated CAD/CAM systems enable seamless transition from design to manufacturing, ensuring that complex tooling geometries are accurately translated into finished products. Advanced simulation capabilities allow us to optimize designs before production, identifying and addressing potential issues before they impact your operations.

Precision CNC Machining

With over 60 advanced CNC machines in our facility, MAIKONG offers exceptional precision in tooling production. Our multi-axis machining centers can achieve tolerances of ±0.001 inches, ensuring that your forge tooling performs exactly as designed. This precision translates directly into improved part quality and consistency in your forging operations.

Surface Treatment Technologies

MAIKONG employs advanced surface treatment processes to enhance the performance and durability of our forge tooling. These treatments include:

| Treatment Type |

Benefits |

Ideal Applications |

| Nitriding |

Increased surface hardness, improved wear resistance, reduced friction |

Hot forging dies, punches, and mandrels |

| PVD Coating |

Extreme hardness, low friction coefficient, thermal barrier properties |

High-stress applications, precision forming tools |

| Cryogenic Treatment |

Enhanced microstructure, improved wear resistance, stress relief |

Tool steels for critical applications, high-precision tooling |

| Shot Peening |

Improved fatigue resistance, compressive stress layer, crack prevention |

Tooling subject to cyclic loading and thermal fatigue |

Industry Applications for MAIKONG Forge Tooling Drives

Our advanced forge tooling solutions serve diverse industries across the American manufacturing landscape, each with unique requirements and challenges.

Automotive

MAIKONG provides precision forge tooling for critical automotive components including crankshafts, connecting rods, steering knuckles, and transmission gears. Our tooling ensures the structural integrity and performance required for modern vehicle safety and efficiency standards.

Aerospace

The aerospace industry demands the highest levels of precision and reliability. Our forge tooling produces critical components for aircraft engines, landing gear, and structural elements where failure is not an option. MAIKONG tooling meets rigorous aerospace certification requirements.

Heavy Equipment

Construction and agricultural equipment rely on robust forged components to withstand extreme conditions. MAIKONG forge tooling produces excavator teeth, bulldozer track links, hydraulic cylinder components, and other critical parts that deliver reliability in demanding environments.

Specialized Forge Tooling for Your Industry

Whether you’re in automotive, aerospace, energy, or heavy equipment manufacturing, our engineers can design custom forge tooling solutions for your specific applications.

Contact Our Experts

How MAIKONG Forge Tooling Drives Outperform Competitors

When evaluating forge tooling providers, it’s important to consider multiple factors that impact your operation’s efficiency and profitability. Here’s how MAIKONG compares to typical industry standards:

MAIKONG Advantage

- Proprietary heat treatment processes extending die life by 30-40%

- Advanced surface treatments reducing friction and wear

- Integrated design and manufacturing for faster delivery

- Comprehensive material testing and certification

- Custom solutions tailored to specific applications

- Direct technical support from forge tooling engineers

Industry Standard

- Conventional heat treatment with average die life

- Basic surface treatments with limited performance

- Separated design and production processes

- Limited material testing capabilities

- Standard catalog offerings with minimal customization

- General customer service without specialized expertise

“After switching to MAIKONG forge tooling, we’ve seen a 35% increase in die life and a significant reduction in downtime. Their engineering support has been invaluable in optimizing our forging processes.”

– Manufacturing Director, Leading US Automotive Supplier

Our Comprehensive Forge Tooling Drives Development Process

MAIKONG follows a systematic approach to forge tooling development that ensures optimal performance for your specific applications.

- Requirement Analysis – We begin by thoroughly understanding your forging process, part geometry, material, and production volume requirements.

- Design Engineering – Our engineers utilize advanced CAD/CAM systems to design tooling that optimizes material flow, minimizes wear, and ensures dimensional accuracy.

- Material Selection – Based on your application, we select the optimal tool steel grade and determine the appropriate heat treatment and surface treatments.

- Simulation and Validation – We use finite element analysis to simulate the forging process, identifying and addressing potential issues before manufacturing.

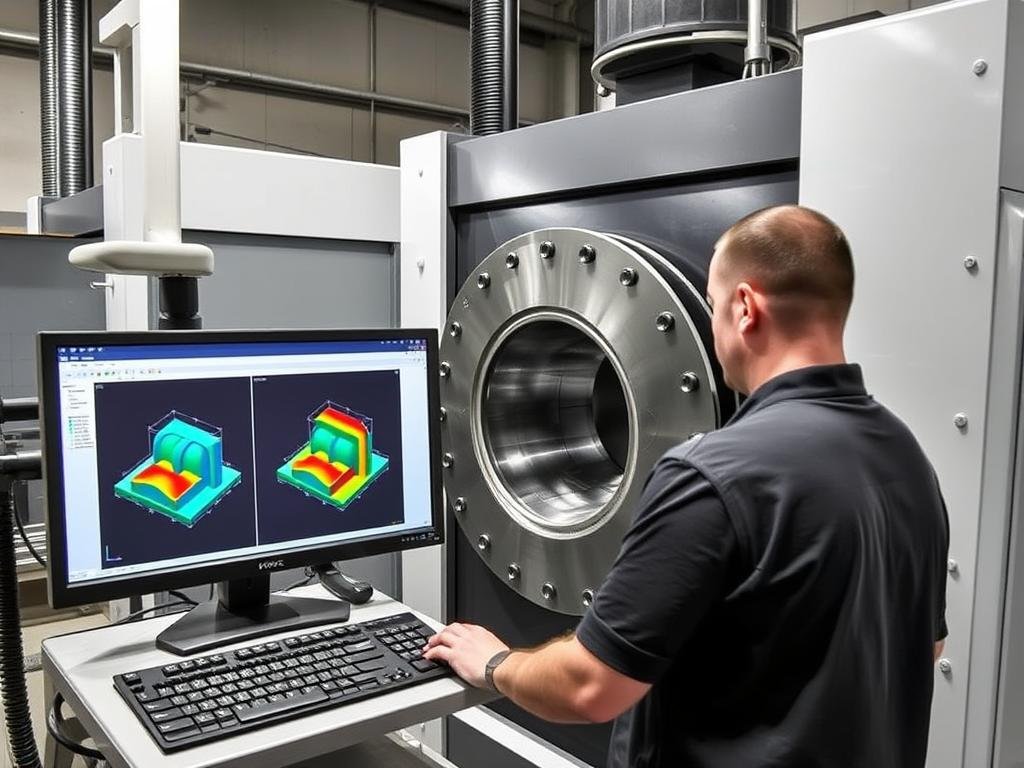

- Precision Manufacturing – Our state-of-the-art CNC machining centers produce tooling to exact specifications with tight tolerances.

- Heat Treatment – Proprietary heat treatment processes optimize the microstructure and properties of the tooling for maximum performance and longevity.

- Surface Treatment – Advanced surface treatments are applied to enhance wear resistance, reduce friction, and extend tool life.

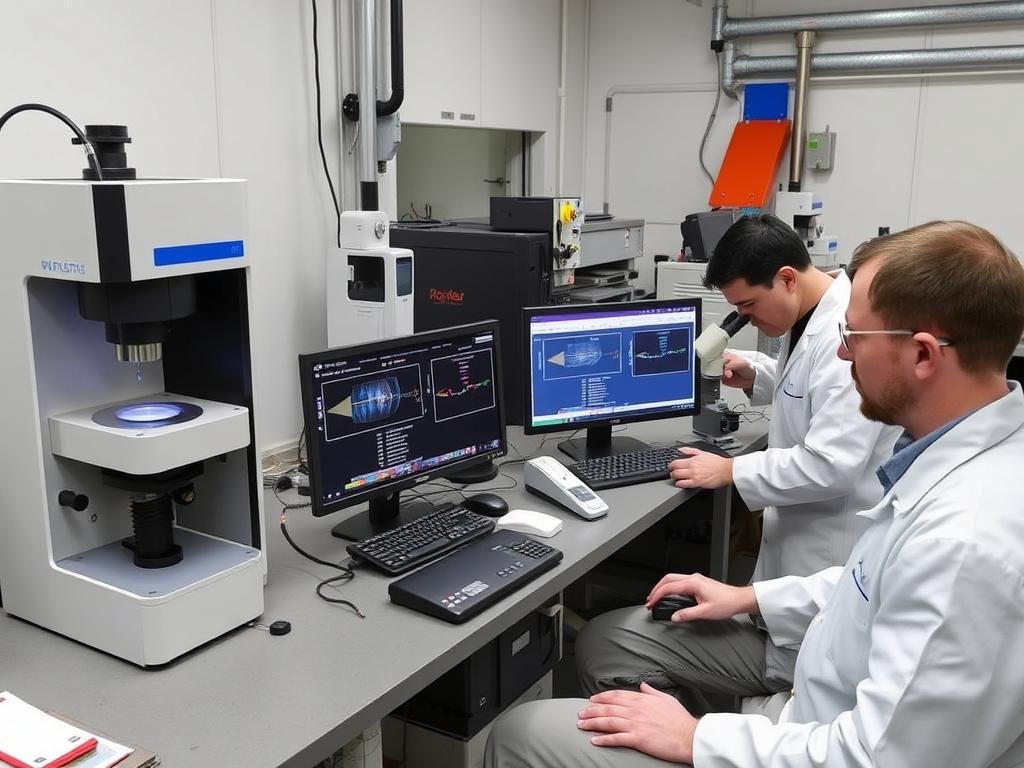

- Quality Verification – Comprehensive inspection using coordinate measuring machines and other advanced equipment ensures conformance to specifications.

- Performance Testing – We can perform simulated production runs to validate tooling performance before delivery.

Quality Assurance for Superior Forge Tooling Drives

At MAIKONG, quality is built into every step of our forge tooling manufacturing process. Our comprehensive quality management system ensures that every tool we produce meets or exceeds your specifications and performance requirements.

Material Certification

All tool steels undergo rigorous testing and certification to verify chemical composition, microstructure, and mechanical properties. Our in-house materials laboratory enables us to maintain strict quality control from raw material to finished product.

Dimensional Inspection

We utilize advanced coordinate measuring machines (CMMs) and laser scanning technology to verify that all tooling dimensions meet specified tolerances. This ensures proper fit and function in your forging equipment and consistent part production.

MAIKONG Quality Rating

4.9

Based on customer satisfaction surveys

Dimensional Accuracy

4.9/5

Partner with MAIKONG for Superior Forge Tooling Drives

MAIKONG is actively seeking distribution partners and direct customers throughout the United States. Our combination of technical expertise, manufacturing capability, and competitive pricing makes us an ideal partner for American forging operations looking to improve efficiency and reduce costs.

Become a Distributor

We offer attractive partnership opportunities for distributors serving the forging industry. With our comprehensive product range, competitive pricing, and technical support, you can provide exceptional value to your customers while growing your business.

Direct Manufacturing Partnership

For forging operations seeking a direct relationship with a tooling manufacturer, MAIKONG offers customized solutions tailored to your specific requirements. Our engineering team works closely with you to optimize tooling for your unique applications.

Elevate Your Forging Operations with MAIKONG Forge Tooling Drives

In today’s competitive manufacturing environment, the quality and performance of your forge tooling directly impact your operational efficiency, product quality, and bottom-line results. MAIKONG combines advanced engineering, precision manufacturing, and comprehensive quality assurance to deliver forge tooling solutions that consistently outperform industry standards.

With our extensive capabilities in CNC machining, metal forging, precision machining, and custom metal fabrication, we offer a complete range of solutions for all your forging tooling needs. Whether you’re looking to improve tool life, enhance part quality, or reduce production costs, MAIKONG has the expertise and manufacturing capability to help you achieve your goals.

Ready to Transform Your Forging Operations?

Contact MAIKONG today to discuss your forge tooling requirements and discover how our advanced solutions can drive efficiency and profitability in your operations.

Get Started Today