| Strength and Durability |

✅Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps of effort to achieve complex shape |

✅Can achieve complex shape in one session |

| Dimensional Accuracy |

✅Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅Smoother surfaces, reduced post-processing |

Might require more machining due to air pocket |

| Heat Treatment Response |

✅Responsive for controlled material properties |

Less predictable response |

| Grain Structure |

✅Directional grain flow for improved properties |

No directional grain structure |

| Weight-to-Strength Ratio |

✅High strength-to-weight ratio |

Bulkier parts may be needed |

| Resistance to Corrosion |

✅Improved due to denser structure |

Naturally forming oxide layer for resistance |

| Engineering Consistency |

✅Controlled material characteristics |

Variability in material properties |

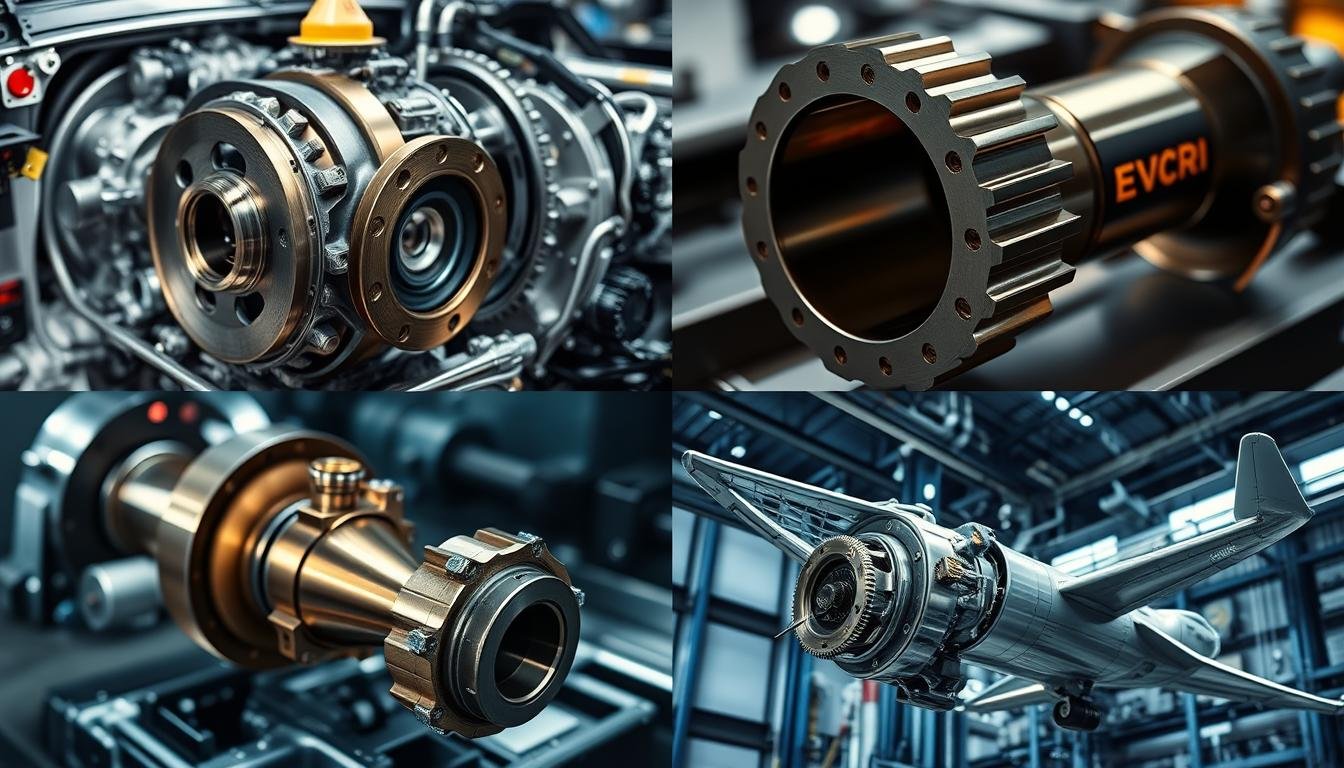

| Critical Applications |

✅Structural Members and load-bearing capabilities |

Limited suitability for critical applications |

| Focus Usage |

Enhanced mechanical performance and precision |

Less demanding applications and complex shapes |

| Ideal Industry |

Aerospace, automotive, medical devices, etc. |

Consumer goods, simple parts, non-critical sectors |