The exceptional performance of steel forgings in demanding industrial applications is no accident—it’s the result of precise metallurgical science and advanced manufacturing processes. At MAIKONG, we’ve mastered the art and science of creating superior steel forgings that deliver unmatched strength, durability, and performance. This comprehensive guide explores the fundamental metallurgy that makes steel forgings the preferred choice for critical components across aerospace, oil and gas, power generation, and heavy equipment industries.

Steel Grades and Alloys for Premium Steel Forgings

The selection of appropriate steel grades is crucial for achieving specific performance characteristics in steel forgings. At MAIKONG, we work with a comprehensive range of carbon and alloy steels to meet diverse application requirements.

Selection of steel alloy billets ready for the forging process – https://maikongforge.us

Carbon Steel Categories for Steel Forgings

| Category |

Carbon Content |

Key Properties |

Common Applications |

| Low Carbon Steel |

0.05% – 0.25% |

High ductility, good machinability, excellent formability |

Structural components, shafts, pins |

| Medium Carbon Steel |

0.29% – 0.54% |

Balanced strength and ductility, good wear resistance |

Gears, crankshafts, connecting rods |

| High Carbon Steel |

0.55% – 0.95% |

High strength, excellent wear resistance, good shape memory |

Springs, high-strength wire, cutting tools |

| Very High Carbon Steel |

0.96% – 2.1% |

Extreme hardness, high wear resistance, limited ductility |

Specialized cutting tools, high-wear components |

Alloy Steel Options for Enhanced Steel Forgings

Alloy steels incorporate additional elements to enhance specific properties, making them ideal for specialized steel forgings applications:

Chromium-Molybdenum Steels

- 4130: Excellent strength-to-weight ratio, widely used in aerospace

- 4140: Superior toughness and wear resistance for heavy equipment

- 4340: High hardenability and fatigue resistance for critical components

Nickel-Based Alloy Steels

- 8620: Excellent case hardening properties for gears and shafts

- 9310: Superior fatigue strength for aerospace applications

- 3310: Exceptional impact resistance for high-stress environments

Heat treatment process enhancing the mechanical properties of steel forgings – https://maikongforge.us

Why Choose Steel Forgings Over Alternative Manufacturing Methods

When comparing manufacturing methods for steel components, steel forgings consistently outperform alternatives in critical applications where strength and reliability are paramount.

| Performance Criteria |

Steel Forgings |

Cast Steel |

Machined Steel |

| Structural Integrity |

Superior – Continuous grain flow follows part contour |

Moderate – Potential for porosity and inclusions |

Limited – Grain flow is interrupted |

| Tensile Strength |

Excellent – Enhanced by compressed grain structure |

Good – Limited by casting defects |

Moderate – Compromised by machining |

| Fatigue Resistance |

Exceptional – Directional grain flow enhances durability |

Fair – Susceptible to crack initiation |

Good – Dependent on base material |

| Impact Toughness |

Superior – Refined grain structure absorbs energy |

Moderate – Varies with casting quality |

Limited – Lacks directional strength |

| Material Utilization |

Efficient – Near-net shape reduces waste |

Very Efficient – Minimal material waste |

Poor – Significant material removal |

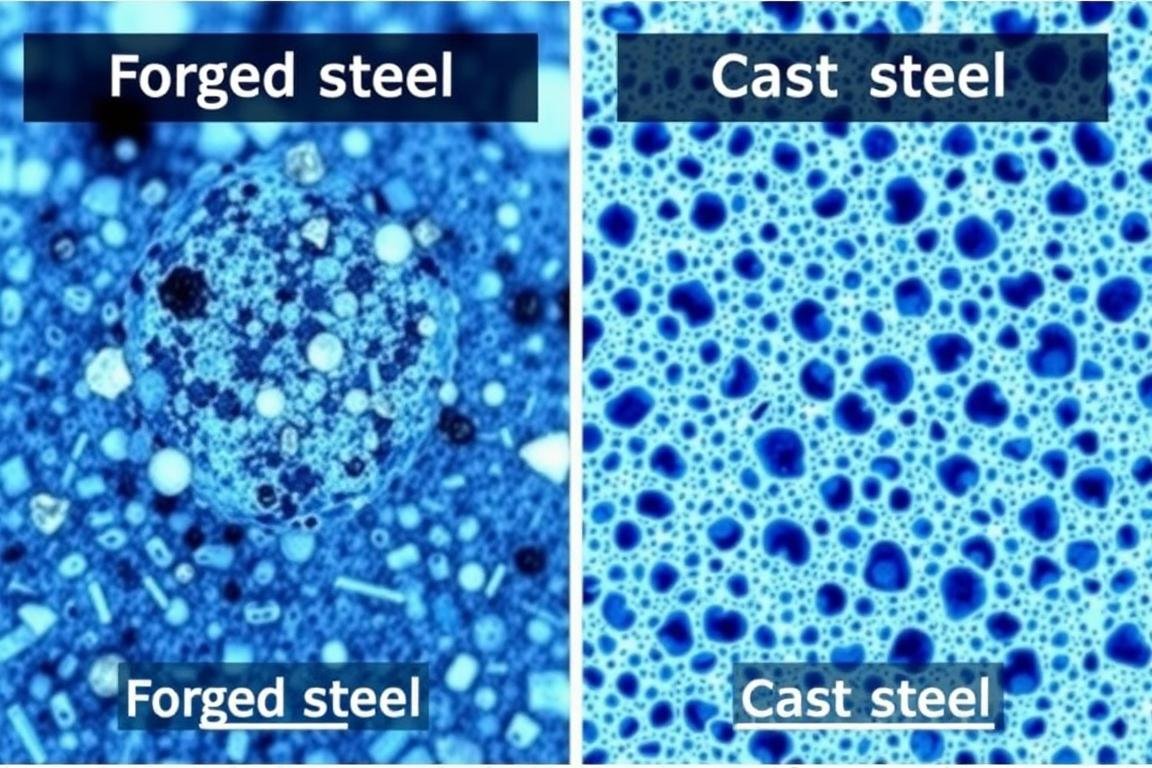

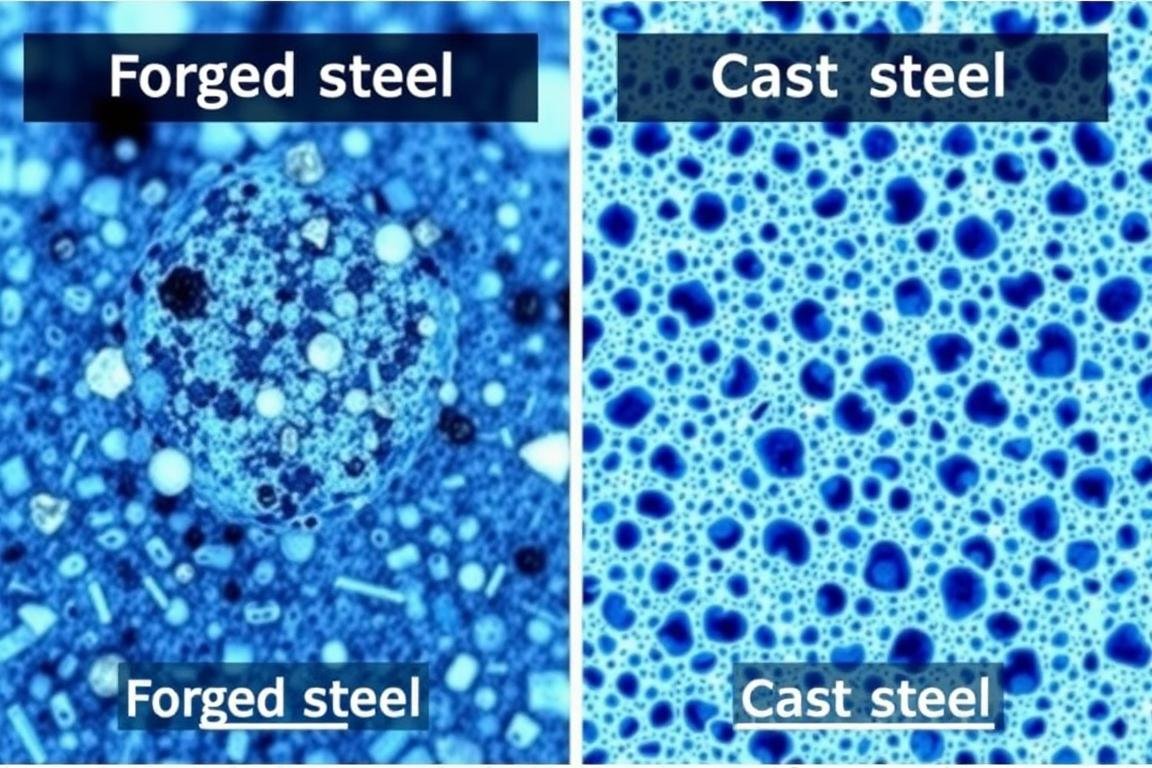

Microscopic comparison: Forged steel (left) vs. cast steel (right) showing density differences – https://maikongforge.us

Experience the MAIKONG Difference in Steel Forgings

Our metallurgical expertise ensures superior quality and performance in every forged component. Contact our engineering team to discuss your specific requirements.

Get A Quick Quote

The Comprehensive Manufacturing Process for Premium Steel Forgings

At MAIKONG, we employ a rigorous multi-stage process to create steel forgings that consistently exceed industry standards. Each step is carefully controlled to ensure optimal metallurgical properties and dimensional accuracy.

Industrial forging press forming a precision steel component – https://maikongforge.us

Key Stages in MAIKONG’s Steel Forgings Production

- Material Selection and Testing – Rigorous verification of chemical composition and mechanical properties before processing begins

- CAD/CAM Design and Simulation – Advanced computer modeling to optimize part geometry and forging parameters

- Die Design and Fabrication – Precision-engineered tooling created specifically for each component

- Preheating and Billet Preparation – Controlled heating to achieve optimal forging temperature

- Forging Operation – Application of precisely controlled pressure to shape the metal

- Heat Treatment – Specialized thermal processing to enhance mechanical properties

- Precision Machining – CNC operations to achieve final dimensions and tolerances

- Surface Treatment – Application of protective finishes for enhanced performance

- Comprehensive Quality Inspection – Multi-stage testing to verify conformance to specifications

Advanced Heat Treatment for Enhanced Steel Forgings

Heat treatment is critical for developing optimal mechanical properties in steel forgings. Our state-of-the-art heat treatment facilities enable precise control of microstructure development:

Common Heat Treatment Processes

- Normalizing – Refines grain structure and improves uniformity

- Quenching – Rapidly cools steel to increase hardness

- Tempering – Reduces brittleness while maintaining strength

- Annealing – Enhances ductility and machinability

Quality Assurance Measures

- Computerized temperature monitoring and control

- Uniform heat distribution verification

- Precise cooling rate management

- Post-treatment hardness and microstructure testing

Precision CNC machining operations on a forged steel component – https://maikongforge.us

Quality Assurance in MAIKONG Steel Forgings

Our comprehensive quality management system ensures that every steel forging meets or exceeds the most demanding industry specifications. We employ both destructive and non-destructive testing methods to verify material integrity and dimensional accuracy.

Advanced non-destructive testing of steel forgings for quality assurance – https://maikongforge.us

Comprehensive Testing Protocols for Steel Forgings

Non-Destructive Testing

- Ultrasonic Testing – Detects internal flaws and discontinuities

- Magnetic Particle Inspection – Identifies surface and near-surface defects

- Dye Penetrant Testing – Reveals surface imperfections

- Radiographic Inspection – Provides internal imaging of critical components

Destructive Testing

- Tensile Testing – Measures strength and elongation properties

- Impact Testing – Evaluates toughness and energy absorption

- Hardness Testing – Verifies surface and core hardness

- Metallographic Analysis – Examines microstructure characteristics

Our ISO-certified quality management system ensures complete traceability from raw material to finished product, giving our customers confidence in the integrity of every steel forging we produce.

Industry Applications for High-Performance Steel Forgings

The superior mechanical properties of steel forgings make them indispensable across numerous industries where reliability and performance are critical. MAIKONG provides specialized forging solutions for diverse applications.

Diverse steel forged components manufactured by MAIKONG for various industries – https://maikongforge.us

Critical Applications for MAIKONG Steel Forgings

Oil & Gas Industry

- Valve bodies for high-pressure environments

- Wellhead components with superior corrosion resistance

- Pump shafts designed for continuous operation

- Flanges engineered for extreme pressure conditions

Aerospace & Defense

- Landing gear components with exceptional fatigue resistance

- Structural airframe parts with optimized weight-to-strength ratio

- Engine mounting brackets designed for thermal stability

- Critical fasteners for high-stress applications

Power Generation

- Turbine shafts engineered for high-temperature environments

- Generator components with superior electrical properties

- Pressure vessel parts with enhanced safety factors

- Connection fittings designed for thermal cycling resistance

Heavy Equipment

- Gears and transmission components with wear resistance

- Hydraulic cylinder components for high-pressure systems

- Structural connectors with impact resistance

- Drive train components engineered for torque transmission

Automotive Industry

- Crankshafts with optimized fatigue properties

- Connecting rods designed for high-performance engines

- Steering components with precision tolerances

- Suspension parts engineered for durability

Marine Applications

- Propeller shafts with corrosion resistance

- Hull fittings designed for watertight integrity

- Rudder components engineered for directional stability

- Anchor chain components with superior wear properties

MAIKONG steel forged components in operation at an oil and gas facility – https://maikongforge.us

MAIKONG’s Advanced Steel Forgings Capabilities

With state-of-the-art facilities in GD, SZ, MAIKONG offers comprehensive steel forging solutions from concept to completion. Our technical expertise and manufacturing capabilities ensure superior quality and performance in every component we produce.

MAIKONG’s state-of-the-art steel forging facility in GD, SZ – https://maikongforge.us

Our Comprehensive Steel Forgings Services

Forging Capabilities

- Open die forging for large components

- Closed die forging for precision parts

- Ring rolling for seamless circular components

- Custom-designed dies for specialized geometries

- Capacity for components up to 2000kg

Value-Added Services

- Precision CNC machining for tight tolerances

- Specialized heat treatment for enhanced properties

- Surface treatments for corrosion protection

- Comprehensive testing and certification

- Engineering consultation and design optimization

Industries We Serve with Premium Steel Forgings

MAIKONG provides specialized steel forging solutions for diverse industries with demanding requirements:

Oil & Gas

Oil & Gas

Aerospace

Aerospace

Power Generation

Power Generation

Partner with MAIKONG for Premium Steel Forgings

The metallurgical science behind steel forgings is what makes them indispensable for critical applications across industries. At MAIKONG, we combine advanced metallurgical knowledge with state-of-the-art manufacturing processes to deliver steel forgings of exceptional quality and performance.

Our commitment to excellence extends from material selection through final inspection, ensuring that every component meets the most demanding specifications. Whether you require standard or custom steel forgings, our team of experts is ready to provide the perfect solution for your application.

MAIKONG is actively seeking distribution partners and agents across the United States to represent our premium steel forgings and precision machining services. Contact us today to discuss partnership opportunities or to request a quote for your specific requirements.

Microscopic view of grain structure in forged steel showing directional flow – https://maikongforge.us

Microscopic view of grain structure in forged steel showing directional flow – https://maikongforge.us

Oil & Gas

Oil & Gas Aerospace

Aerospace Power Generation

Power Generation