In today’s competitive manufacturing landscape, the integrity of metal components can make or break a product’s success. At MAIKONG, we understand that a high-quality metal forge process is the foundation of exceptional product performance. Our state-of-the-art forging techniques create components with superior strength, durability, and precision that simply cannot be matched by alternative manufacturing methods.With over 60 CNC machines and a monthly capacity exceeding 100 tons, MAIKONG has established itself as a leading provider of premium metal forge and machining services. Our expertise spans across aluminum, steel, brass, and other alloys, delivering custom solutions that meet the most demanding specifications.

Ready to Experience Superior Metal Components?

Our team is standing by to discuss your project requirements and provide a detailed quote.

Our team is standing by to discuss your project requirements and provide a detailed quote.

Get a Quick Quote

Understanding the Metal Forge Advantage

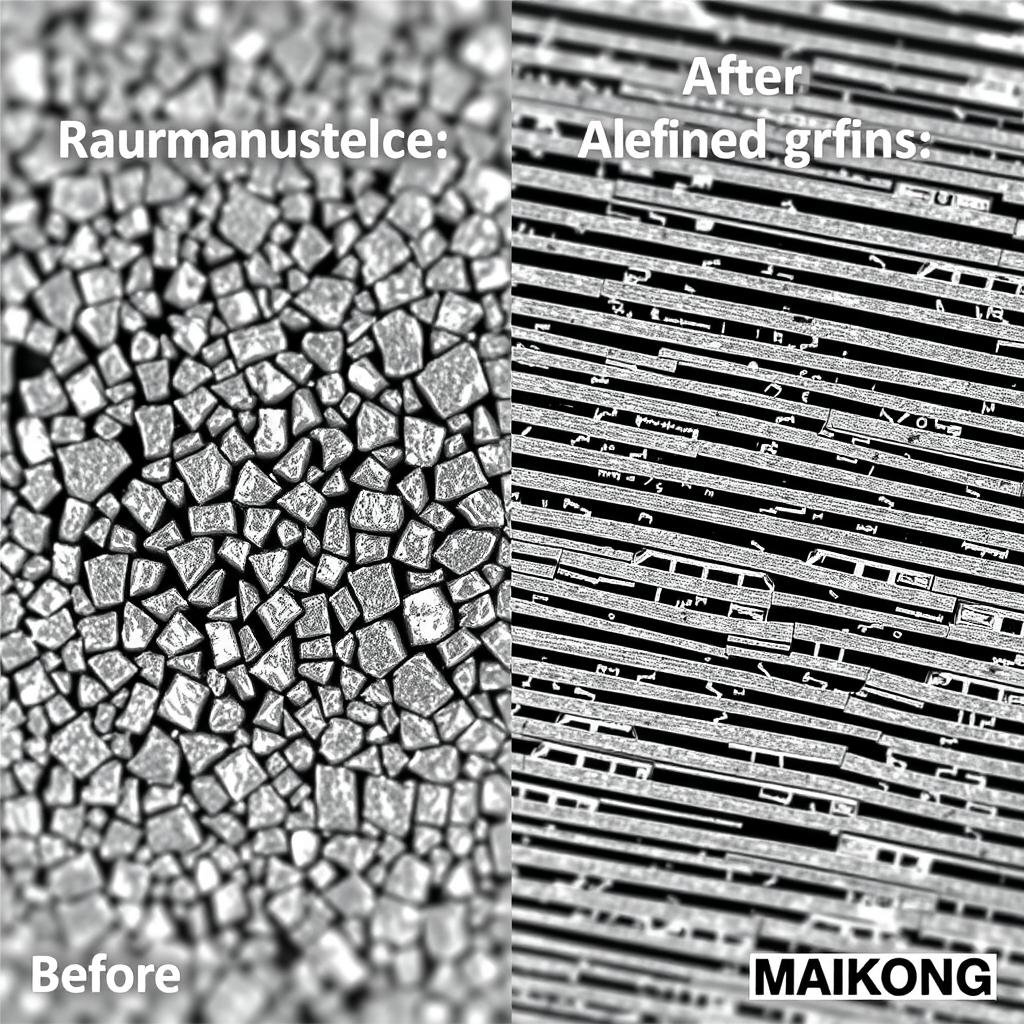

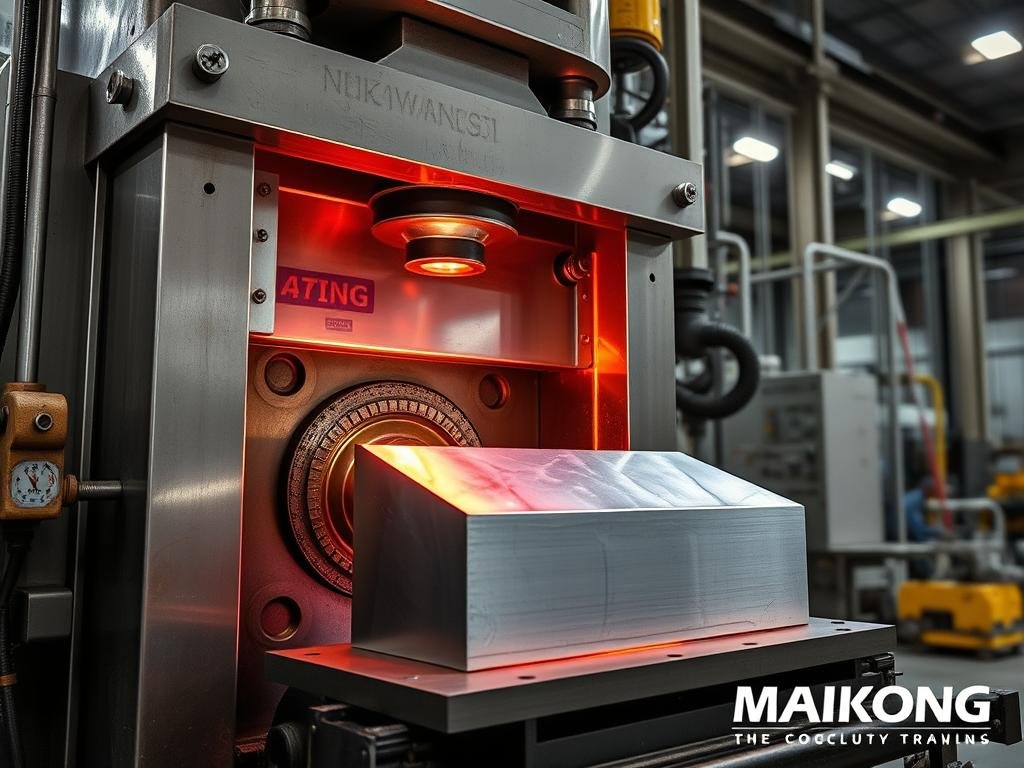

The metal forge process involves shaping metal through compressive forces, fundamentally altering its internal structure to create components with exceptional mechanical properties. Unlike casting or machining alone, forging aligns the grain structure of the metal, resulting in superior strength, improved fatigue resistance, and enhanced durability.

At MAIKONG, we’ve perfected our metal forge techniques through years of experience and continuous innovation. Our processes ensure that each component we produce meets the highest standards of quality and performance, providing our clients with a competitive edge in their respective markets.

How the Metal Forge Process Enhances Material Properties

The forging process fundamentally transforms metal at a microstructural level. By applying controlled pressure to heated metal, we create a refined, directional grain structure that significantly enhances mechanical properties. This results in components that can withstand greater stress, resist fatigue, and maintain dimensional stability under extreme conditions.

Our engineers carefully control temperature, pressure, and cooling rates to optimize the material properties for each specific application. This level of precision ensures that your components will perform reliably in even the most demanding environments.

Forged Metal vs. Cast Metal: A Comprehensive Comparison

Understanding the differences between forged and cast metal components is crucial when selecting the right manufacturing process for your application. The table below highlights the key advantages of metal forge processes compared to casting:

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Heat Treatment Response |

Responsive for controlled material properties |

Less predictable response |

| Weight-to-Strength Ratio |

High strength-to-weight ratio |

Bulkier parts may be needed |

| Critical Applications |

Ideal for structural members and load-bearing components |

Limited suitability for critical applications |

Need High-Performance Metal Components?

Let our forging experts help you select the optimal process for your specific requirements.

Contact Our Technical Team

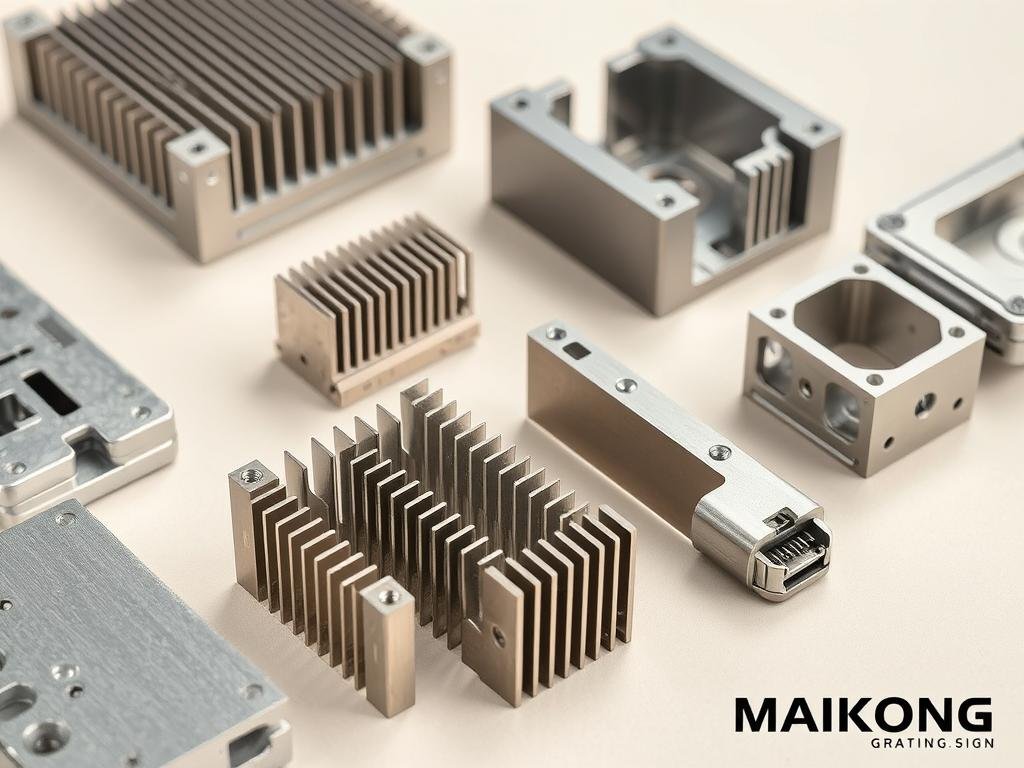

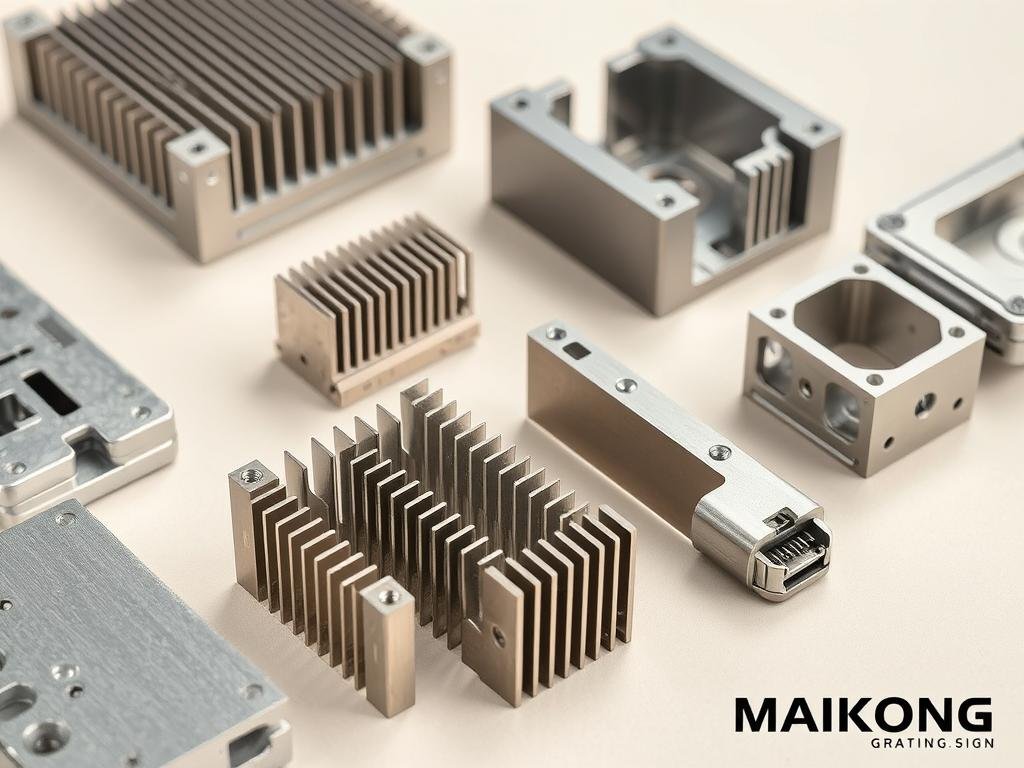

MAIKONG’s Comprehensive Metal Forge and Machining Services

At MAIKONG, we offer a complete range of metal manufacturing services, from initial design consultation to final finishing and quality control. Our integrated approach ensures seamless production and consistent quality across all your components.

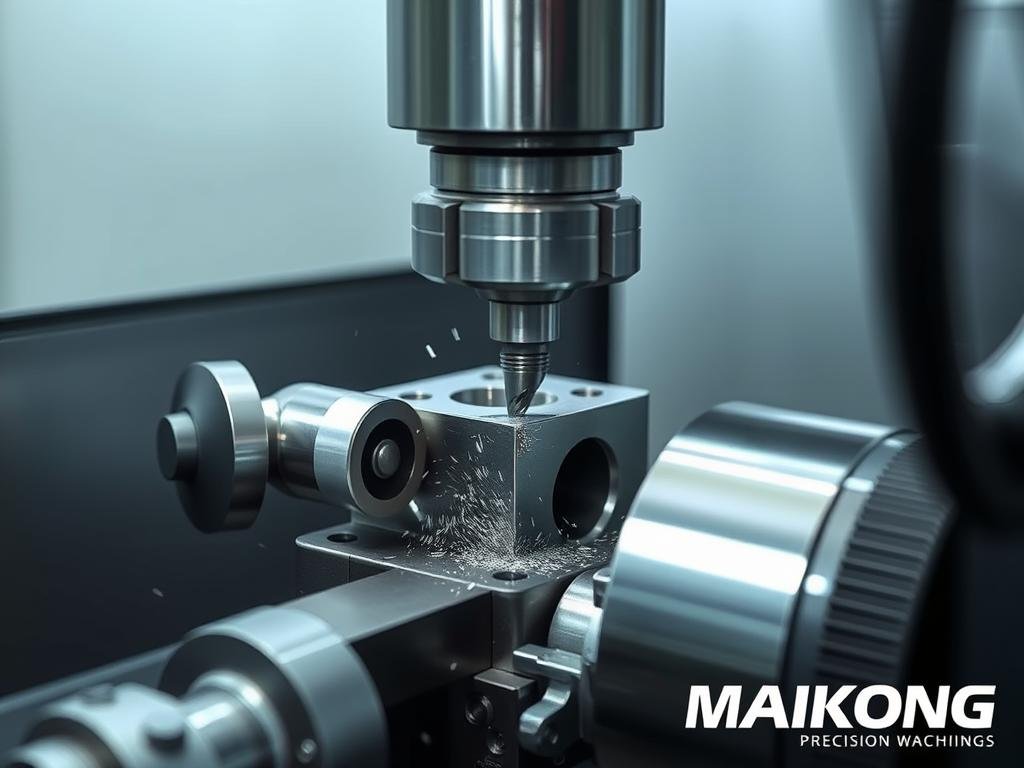

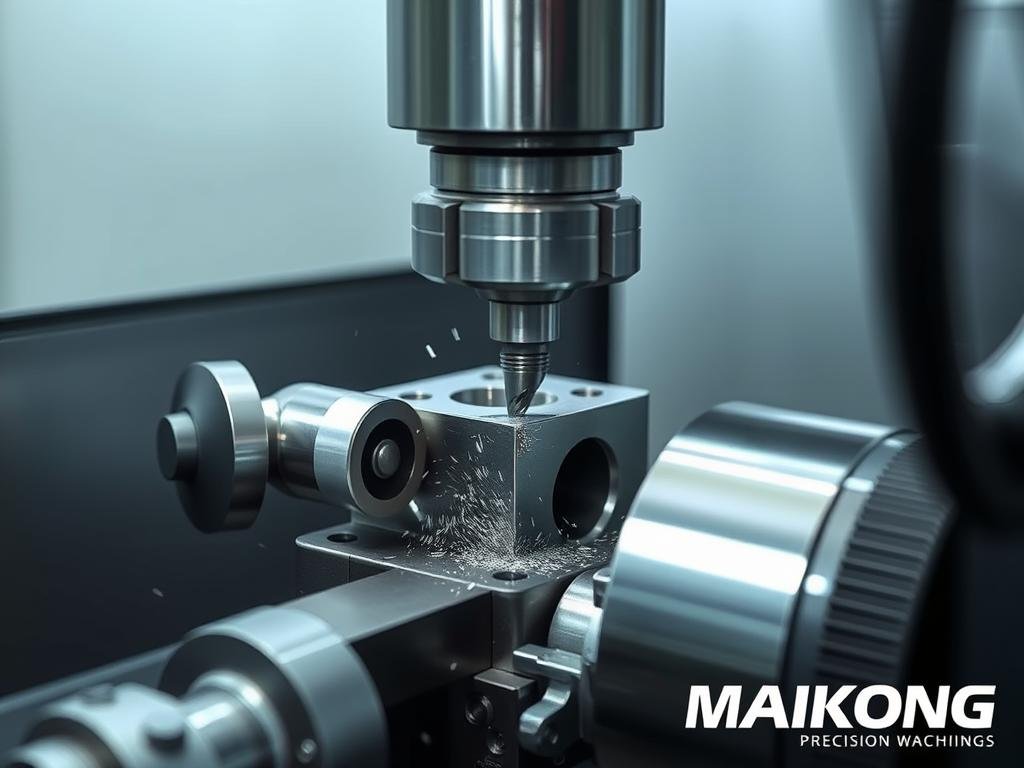

CNC Machining Services

Our advanced CNC machining centers provide precision fabrication of metal parts in any volume. With 60+ CNC machines, we deliver exceptional accuracy and surface finishes for even the most complex components.

Metal Forging

Our metal forge facilities utilize advanced techniques to create components with superior strength and durability. We specialize in aluminum, steel, and brass forging for critical applications.

Precision Machining

When tolerances are critical, our precision machining capabilities deliver components with exceptional dimensional accuracy and surface quality, ensuring perfect fit and function.

Specialized Metal Forge Capabilities

Aluminum Forging Services

Our aluminum forging expertise creates lightweight, high-strength components for aerospace, automotive, and consumer applications, with exceptional strength-to-weight ratios.

Steel Forging

For maximum strength and durability, our steel forging processes create components that can withstand extreme conditions, perfect for industrial and heavy equipment applications.

Brass Forging

Our brass forging capabilities deliver components with excellent corrosion resistance and electrical conductivity, ideal for plumbing, electrical, and decorative applications.

Our Advanced Metal Forge Technical Process

At MAIKONG, we’ve developed a comprehensive technical process that ensures consistent quality and optimal performance for all forged components. Our integrated approach combines cutting-edge technology with traditional forging expertise.

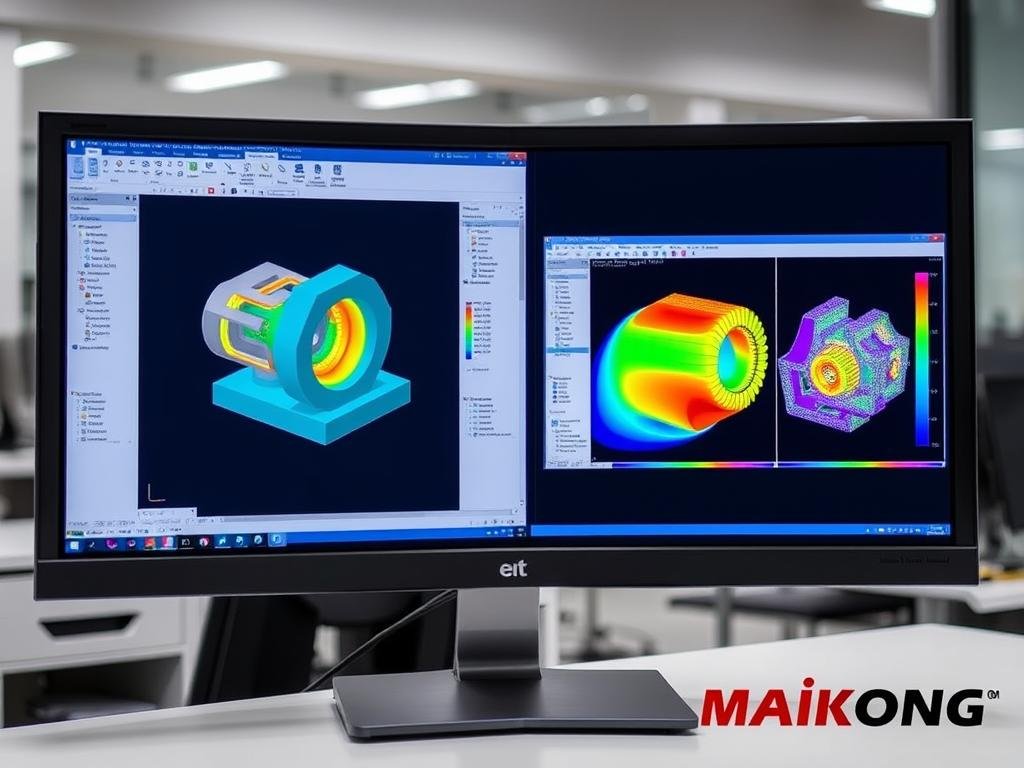

CAD/CAM Integration

Our engineering team utilizes advanced CAD/CAM software to design and simulate the forging process before production begins. This allows us to identify potential issues early and optimize the process for efficiency and quality.

By analyzing material flow, stress distribution, and cooling patterns, we can predict how the metal will behave during forging and make adjustments to achieve the desired properties. This digital-first approach saves time and resources while ensuring consistent results.

Material Selection and Preparation

The foundation of a superior forged component begins with proper material selection. Our metallurgists carefully evaluate the mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness of each alloy to determine the optimal choice for your application.

Once selected, the material undergoes rigorous testing and preparation to ensure it meets our strict quality standards. This includes chemical composition analysis, mechanical property testing, and careful inspection for any defects or inconsistencies.

Our material laboratory plays a vital role in this process, enabling us to achieve the precise results you demand. By understanding the properties and behavior of each material, we can optimize the forging process to enhance its natural strengths and mitigate any weaknesses.

Tooling Design and Maintenance

The quality of forged components is directly influenced by the design and condition of the forging tools. Our tooling engineers create custom dies that ensure optimal material flow and precise dimensions. Regular maintenance and inspection of these tools preserve consistency across production runs.

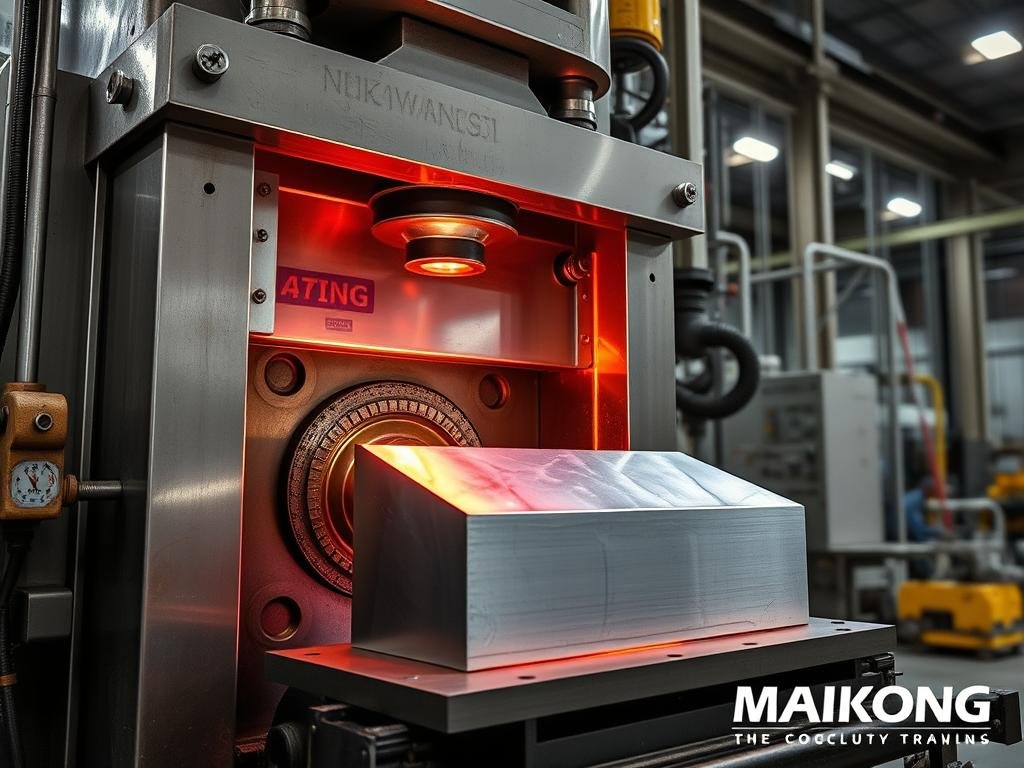

Heat Treatment Expertise

Heat treatment is critical for developing the optimal mechanical properties in forged components. Our in-house heat treatment facilities allow us to precisely control temperature profiles, ensuring consistent results. We conduct comprehensive statistical analysis and documentation for all heat treatment processes, guaranteeing that your components meet or exceed specifications.

Need Technical Guidance for Your Project?

Our engineering team can help you select the right materials and processes for optimal performance.

Email Our Technical Team

Quality Assurance in Metal Forge Manufacturing

At MAIKONG, quality is not just a department—it’s a core value that permeates every aspect of our operation. Our comprehensive quality management system ensures that each component we produce meets or exceeds the most stringent industry standards.

ISO 9001:2015 Certification

MAIKONG proudly maintains ISO 9001:2015 certification, demonstrating our commitment to quality management and continuous improvement. This internationally recognized standard ensures that our processes are consistent, efficient, and focused on customer satisfaction.

Comprehensive Inspection Protocols

Our quality control team employs a variety of testing and inspection methods to verify that each component meets specifications. This includes dimensional inspection, material testing, non-destructive evaluation, and performance testing under simulated operating conditions.

By implementing rigorous inspection at every stage of production, we can identify and address any issues before they affect the final product. This proactive approach ensures that you receive components that perform reliably in your application.

“Quality expresses a component’s capacity for fully satisfying the customer’s needs and expectations. At MAIKONG, we let the numbers speak for themselves.”

The advantages of our in-house production, from raw material processing to forging, heat treatment, CNC milling, and surface treatment, allow our quality engineering staff to monitor the production process at all times. This integrated approach ensures the consistency and quality of every component we produce.

Industries Served by MAIKONG Metal Forge

Our advanced forging and machining capabilities serve a wide range of industries with demanding requirements for strength, precision, and reliability. MAIKONG’s components can be found in applications where failure is not an option.

Aerospace

Our high-strength, lightweight forged components meet the rigorous standards of the aerospace industry, where safety and reliability are paramount.

Automotive

From engine components to chassis parts, our forged products deliver the performance and durability required in modern automotive applications.

Medical

Precision forged components for medical devices and surgical instruments, where exacting standards and biocompatibility are essential.

Construction

Durable, high-strength components that can withstand the rigors of construction equipment and structural applications.

Electronics

Precision forged components for electronic enclosures, heat sinks, and structural elements where thermal management and EMI shielding are critical.

Energy

Reliable components for power generation, oil and gas, and renewable energy applications where failure is not an option.

Working in a Specialized Industry?

Our engineers have experience with a wide range of industry-specific requirements and standards.

Discuss Your Industry Needs

Become a MAIKONG Metal Forge Agent in the USA

MAIKONG is actively seeking representatives and agents throughout the United States to help bring our high-quality forging and machining services to more customers. As a MAIKONG agent, you’ll have the opportunity to represent a leading manufacturer with a reputation for excellence and reliability.

Why Partner with MAIKONG?

- Represent a manufacturer with 60+ CNC machines and 100+ tons monthly capacity

- Offer customers high-quality forged components at competitive prices

- Access to our technical expertise and support for your clients

- Comprehensive marketing materials and product information

- Attractive commission structure and growth opportunities

Interested in Becoming a MAIKONG Agent?

Contact us today to discuss partnership opportunities in your region.

WhatsApp: +86 13510907401

Experience the MAIKONG Metal Forge Difference

At MAIKONG, we believe that the quality of your components directly impacts the success of your products. Our advanced metal forge processes, combined with precision machining and comprehensive quality control, ensure that you receive components that meet the highest standards of performance and reliability.

From material selection to final inspection, our integrated approach delivers consistent quality and exceptional value. Whether you need aluminum, steel, or brass components, our team has the expertise and capabilities to exceed your expectations.

Ready to Elevate Your Product Quality?

Contact MAIKONG today to discuss your metal forging and machining requirements.

Get a Quick Quote

Our team is standing by to discuss your project requirements and provide a detailed quote.

Our team is standing by to discuss your project requirements and provide a detailed quote.