In today’s competitive manufacturing landscape, the true value of metal forge parts extends far beyond their initial purchase price. Quality forged components deliver exceptional strength, durability, and performance that translate to significant long-term cost savings. At MAIKONG, we specialize in producing premium metal forge parts that combine advanced manufacturing techniques with superior materials to create components that stand the test of time.

MAIKONG’s Metal Forge Parts Manufacturing Capabilities

With over 60 CNC machines and a monthly processing capacity exceeding 100 tons, MAIKONG stands as a leading provider of precision metal forge parts. Our state-of-the-art facility in GD, SZ combines traditional forging expertise with cutting-edge technology to deliver components that meet the most demanding specifications.

Ready to Experience Superior Quality?

Discover how our precision metal forge parts can enhance your products’ performance while reducing lifetime costs.

Discover how our precision metal forge parts can enhance your products’ performance while reducing lifetime costs.

Get a Quick Quote

The Forging Advantage: Strength Through Structure

Unlike casting or machining from stock, the forging process aligns the grain structure of the metal, resulting in components with superior strength-to-weight ratios. This fundamental advantage makes metal forge parts the preferred choice for applications where reliability and durability are non-negotiable.

Key Benefits of Forged Components:

- Enhanced mechanical properties through grain refinement

- Superior strength-to-weight ratio for efficient designs

- Exceptional fatigue resistance for longer service life

- Improved impact toughness in demanding applications

- Consistent performance under variable loading conditions

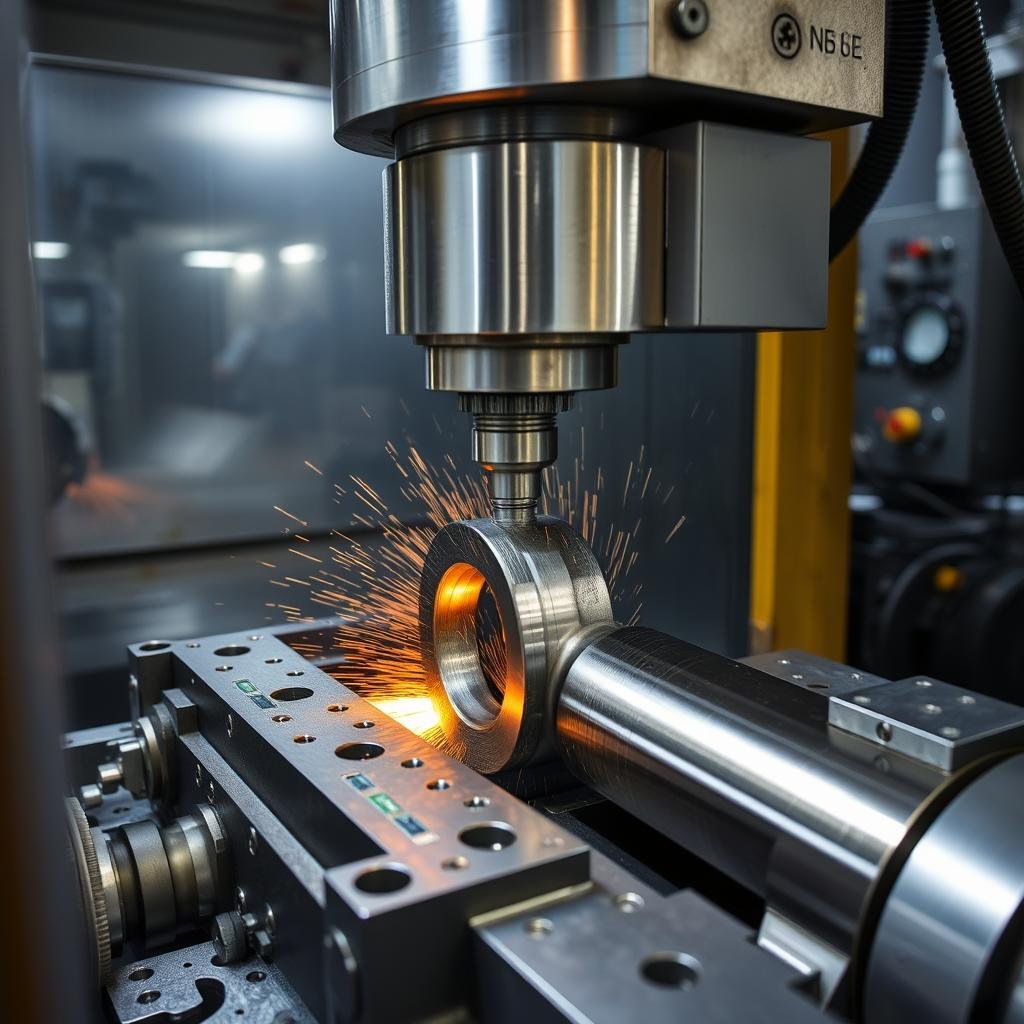

Comprehensive CNC Machining Services for Metal Forge Parts

At MAIKONG, we complement our forging capabilities with advanced CNC machining services to deliver fully finished metal forge parts ready for immediate integration into your products. Our comprehensive approach eliminates the need for multiple suppliers, streamlining your supply chain and ensuring consistent quality.

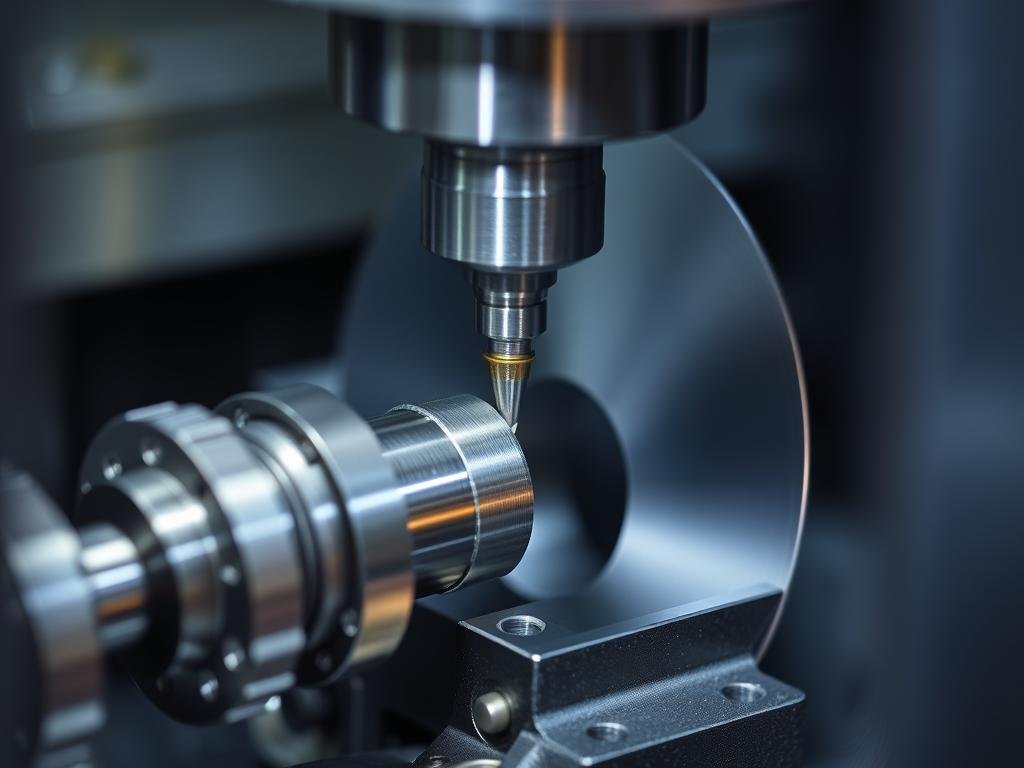

CNC Turning Services

Our CNC turning capabilities deliver superior surface finishes on cylindrical shapes, deep holes, and machined threads. This precision manufacturing process is ideal for creating metal forge parts with exceptional dimensional accuracy and consistency.

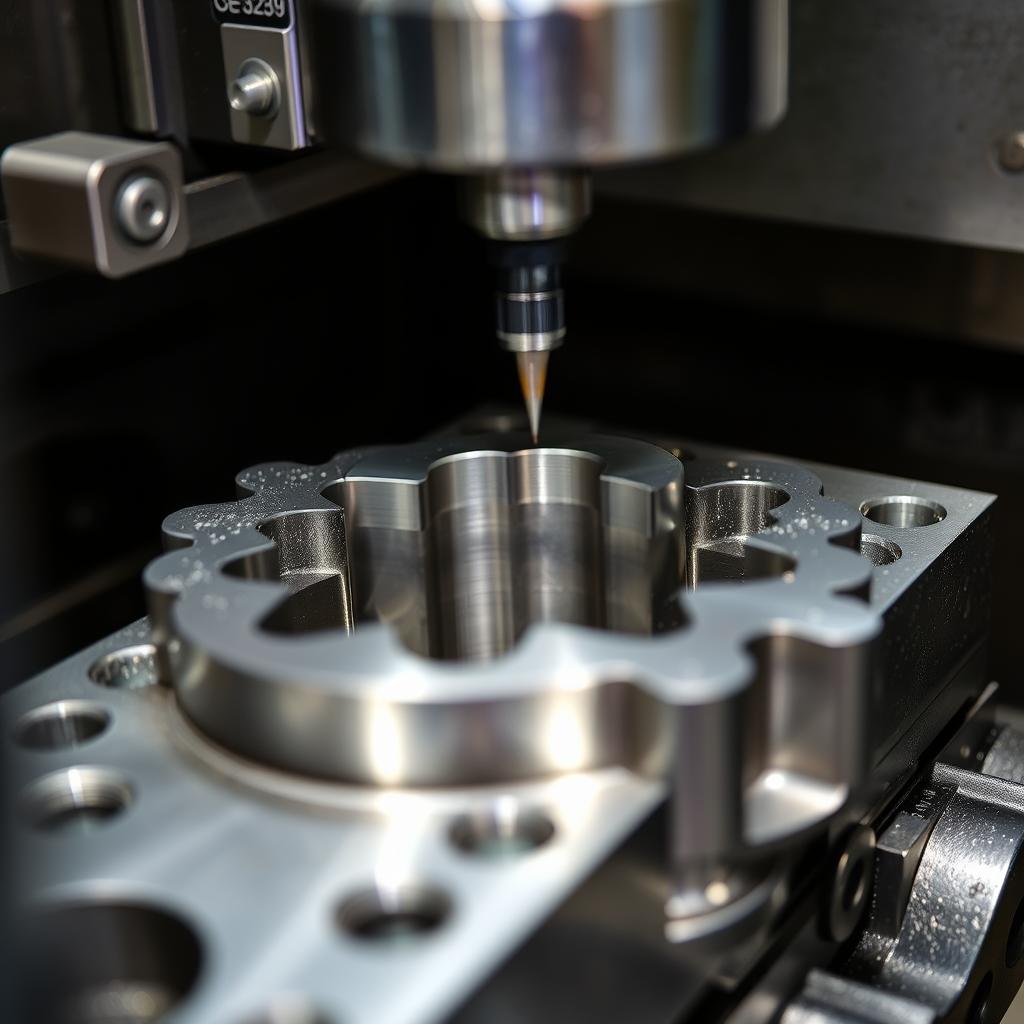

CNC Milling Services

For complex prismatic shapes and flat surfaces, our multi-axis CNC milling services provide the flexibility and accuracy needed for sophisticated metal forge parts. No fixed tooling requirements means faster turnaround and greater design freedom.

Swiss-Type Machining

Our Swiss-type machining specializes in small precision components and long shaft parts for metal forge parts. With dual spindles and multi-axis capabilities, we provide one-stop solutions for the most intricate components without sacrificing accuracy.

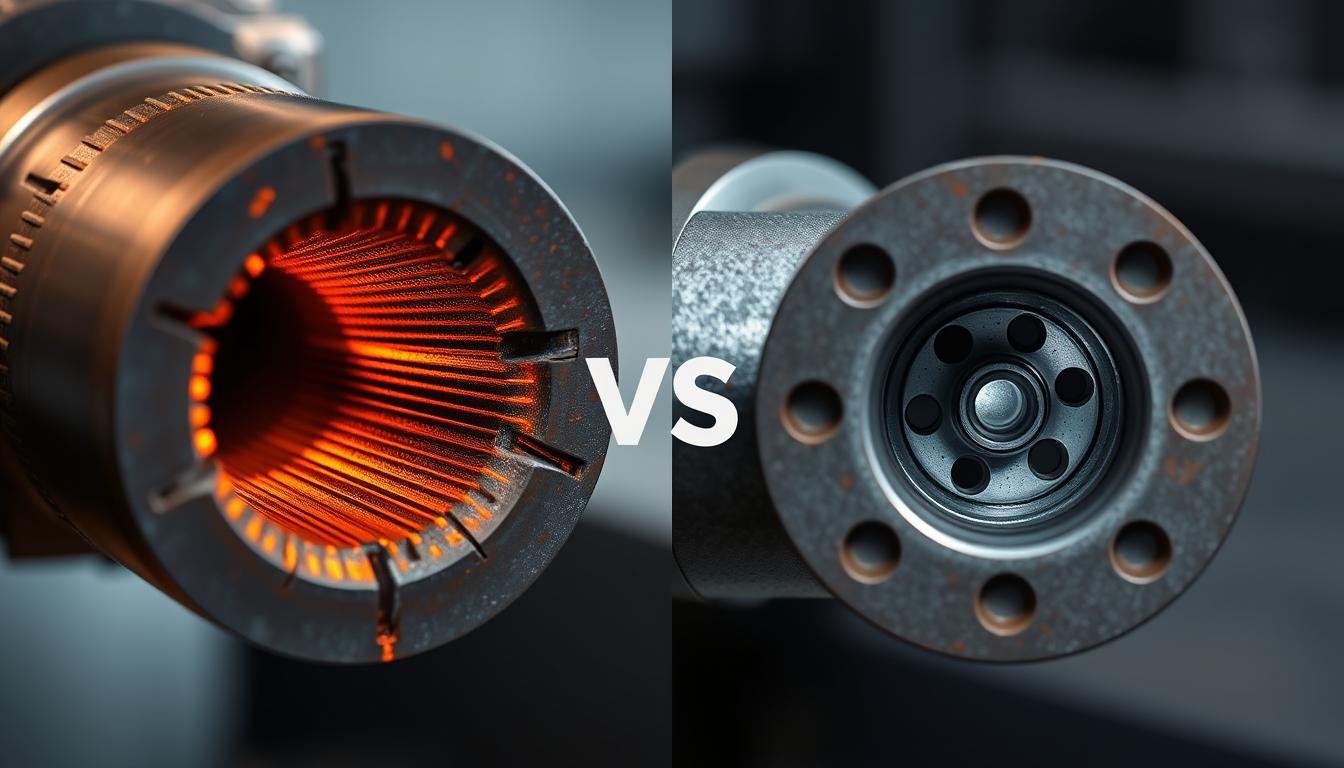

Why Choose Forged Over Cast Metal Forge Parts?

When evaluating manufacturing methods for metal components, understanding the fundamental differences between forging and casting is crucial for making cost-effective decisions. While casting may offer lower initial costs, metal forge parts provide superior long-term value through enhanced performance and extended service life.

| Comparison Criteria |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Lower due to potential air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Weight-to-Strength Ratio |

High strength-to-weight ratio |

Bulkier parts may be needed for equivalent strength |

| Ideal Applications |

Aerospace, automotive, medical devices |

Consumer goods, non-critical components |

Not Sure Which Process Is Right for Your Application?

Our engineering team can help determine the most cost-effective manufacturing approach for your specific requirements.

Discuss Your Project

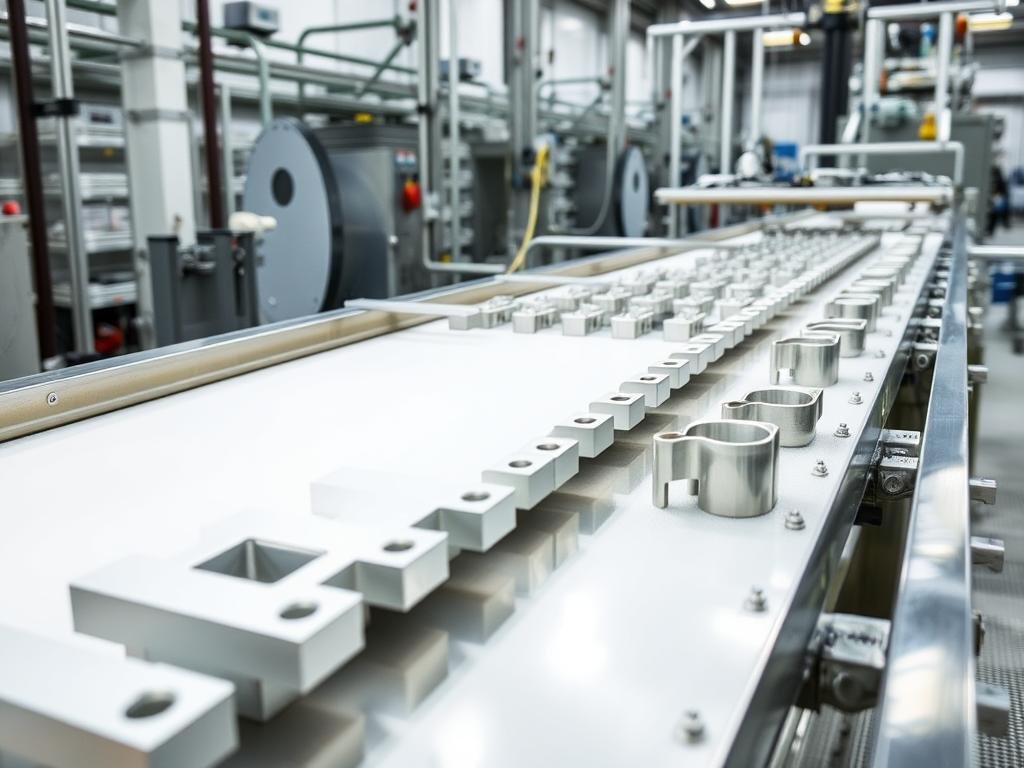

Full-Service Supply Chain for Premium Metal Forge Parts

MAIKONG offers a comprehensive end-to-end solution for metal forge parts, eliminating the complexity of managing multiple vendors. Our integrated approach ensures quality control at every stage of production, from initial design to final delivery.

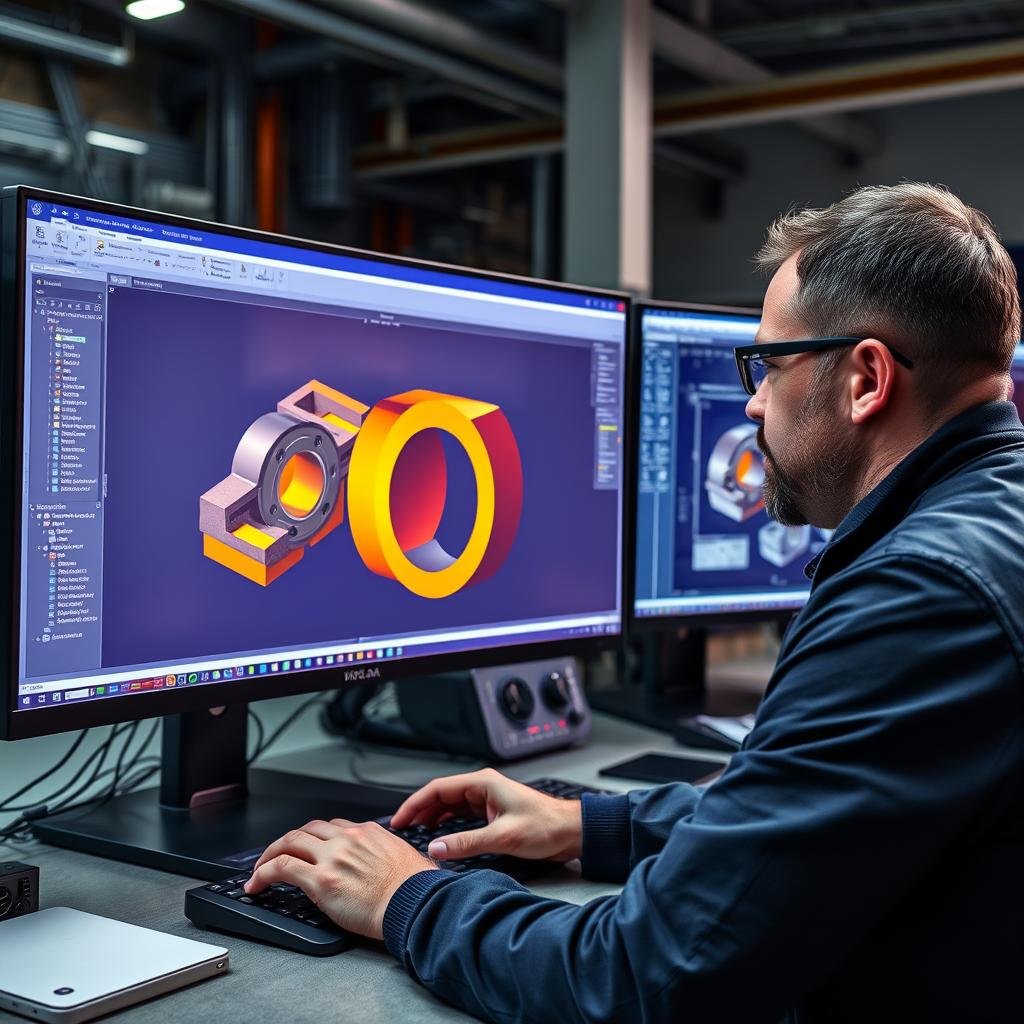

CAD/CAM Design

Advanced analysis software identifies potential issues early in the design process, optimizing both the part and the manufacturing approach.

Material Selection

We carefully evaluate mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness of each alloy.

Tooling Design

Precision tooling design ensures initial quality, while our regular maintenance program preserves consistency across production runs.

Forging Process

Our forging workshop accommodates diverse specifications, creating components with superior grain structure and mechanical properties.

Heat Treatment

In-house heat treatment with comprehensive statistical analysis ensures consistent material properties across all components.

CNC Machining

State-of-the-art CNC machines perform precise and intricate operations to achieve final dimensions and features.

Surface Treatment & Quality Control

Our comprehensive approach extends to surface treatments that enhance both appearance and performance. Options include:

- Anodizing for improved corrosion resistance

- Painting with precise color and gloss control

- Laser engraving for permanent identification

- Sand blasting for uniform surface preparation

Every metal forge part undergoes rigorous quality control procedures using advanced measurement tools and statistical process control to ensure consistent compliance with specifications.

Streamline Your Supply Chain

Eliminate the complexity of managing multiple vendors with our comprehensive metal forge parts solutions.

Contact Our Team

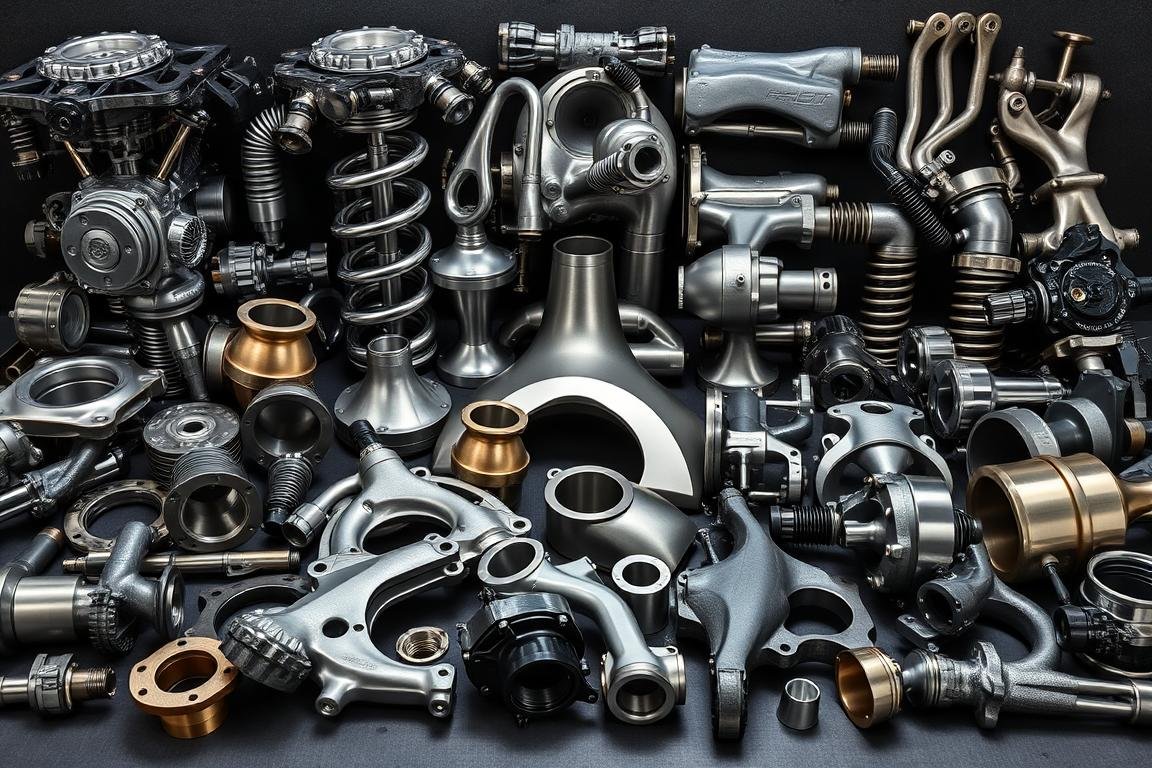

Industry Applications for MAIKONG Metal Forge Parts

Our precision metal forge parts serve critical functions across numerous industries where performance, reliability, and efficiency are paramount. Each application leverages the inherent advantages of the forging process to deliver components that outperform alternatives in demanding environments.

Aerospace

Our aerospace metal forge parts deliver the exceptional strength-to-weight ratio and reliability required for flight-critical applications. From structural components to engine parts, our forged solutions meet the industry’s stringent quality standards.

Automotive

Automotive manufacturers rely on our metal forge parts for components that must withstand extreme forces and temperatures. Our forged solutions provide the durability needed for engine, drivetrain, and suspension applications.

Medical Devices

The medical industry demands metal forge parts with uncompromising quality and biocompatibility. Our precision components meet these requirements for surgical instruments, implant hardware, and diagnostic equipment.

See How MAIKONG Can Support Your Industry

Explore our portfolio of industry-specific metal forge parts solutions.

View Our Portfolio

Our Commitment to Quality Metal Forge Parts

At MAIKONG, quality isn’t just a goal—it’s a fundamental aspect of our manufacturing philosophy. We understand that the true cost-effectiveness of metal forge parts depends on consistent performance and reliability throughout their service life.

Quality Management System

Our comprehensive quality management system addresses every aspect of production:

- ISO 9001:2015 certified processes

- Statistical process control for consistent quality

- Advanced measurement and testing equipment

- Documented quality procedures for traceability

- Continuous improvement initiatives

Material Verification

Our in-house material laboratory ensures that every metal forge part meets specified requirements:

- Chemical composition analysis

- Mechanical property testing

- Microstructure examination

- Heat treatment verification

- Comprehensive documentation

4.8

Customer Satisfaction

Become a US Distributor for MAIKONG Metal Forge Parts

MAIKONG is actively seeking distributor partnerships throughout the United States to expand our market presence and better serve local customers. Our comprehensive range of metal forge parts and machining services offers distributors a competitive advantage in the market.

Partnership Benefits

- Exclusive territorial rights

- Competitive pricing structure

- Technical training and support

- Marketing materials and assistance

- Reliable supply chain with consistent quality

- Diverse product portfolio to serve multiple industries

Partnership Requirements

- Established presence in industrial markets

- Technical sales capabilities

- Commitment to market development

- Inventory investment

- Regular performance reviews

- Adherence to brand standards

Ready to Discuss Distribution Opportunities?

Contact us today to explore how a partnership with MAIKONG can enhance your product portfolio with premium metal forge parts.

or

Connect on WhatsApp

Invest in Quality Metal Forge Parts for Long-Term Value

When evaluating metal forge parts suppliers, looking beyond the initial price reveals the true cost-effectiveness of quality components. MAIKONG’s commitment to excellence throughout the manufacturing process—from material selection to final inspection—ensures that our products deliver exceptional performance and longevity.

By choosing MAIKONG as your metal forge parts partner, you’re investing in components that will perform reliably under demanding conditions, reducing maintenance costs, minimizing downtime, and extending the service life of your products. Contact us today to discover how our precision forged components can enhance your competitive advantage through superior quality and long-term value.

Ready to Elevate Your Products with Premium Metal Forge Parts?

Take the first step toward enhancing your products’ performance and reliability.

Get Your Custom Quote Today

Discover how our precision metal forge parts can enhance your products’ performance while reducing lifetime costs.

Discover how our precision metal forge parts can enhance your products’ performance while reducing lifetime costs.