Metal Forge

- Enhanced Grain Structure: A Key Benefit of Professional Metal Forge Techniques

- MAIKONG: Your Expert Partner in Precision Metal Forge Solutions

- The Ultimate Guide to Metal Forge Manufacturing: Strength & Durability

- Why Metal Forging is Superior: Unlocking Performance for Industrial Applications

- Cost-Effectiveness in the Long Run: Investing in Quality Metal Forge Parts

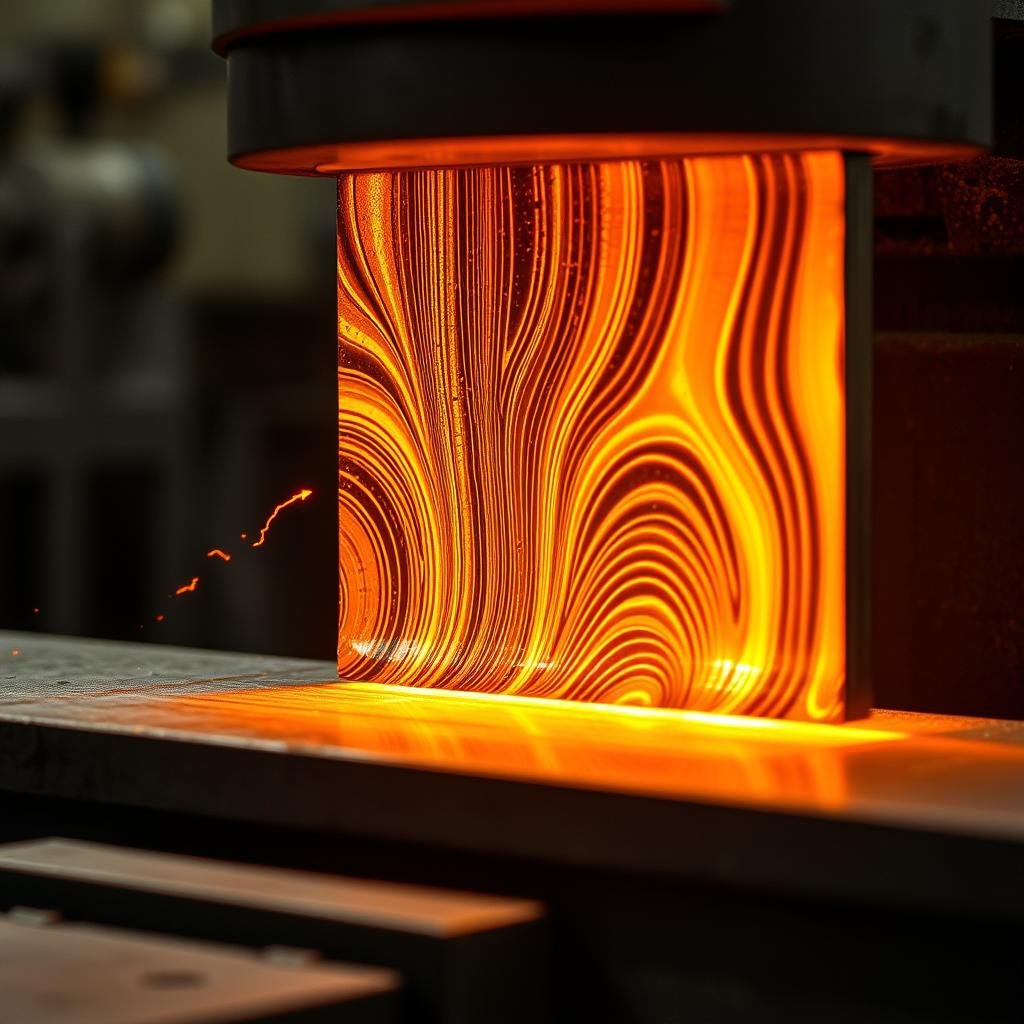

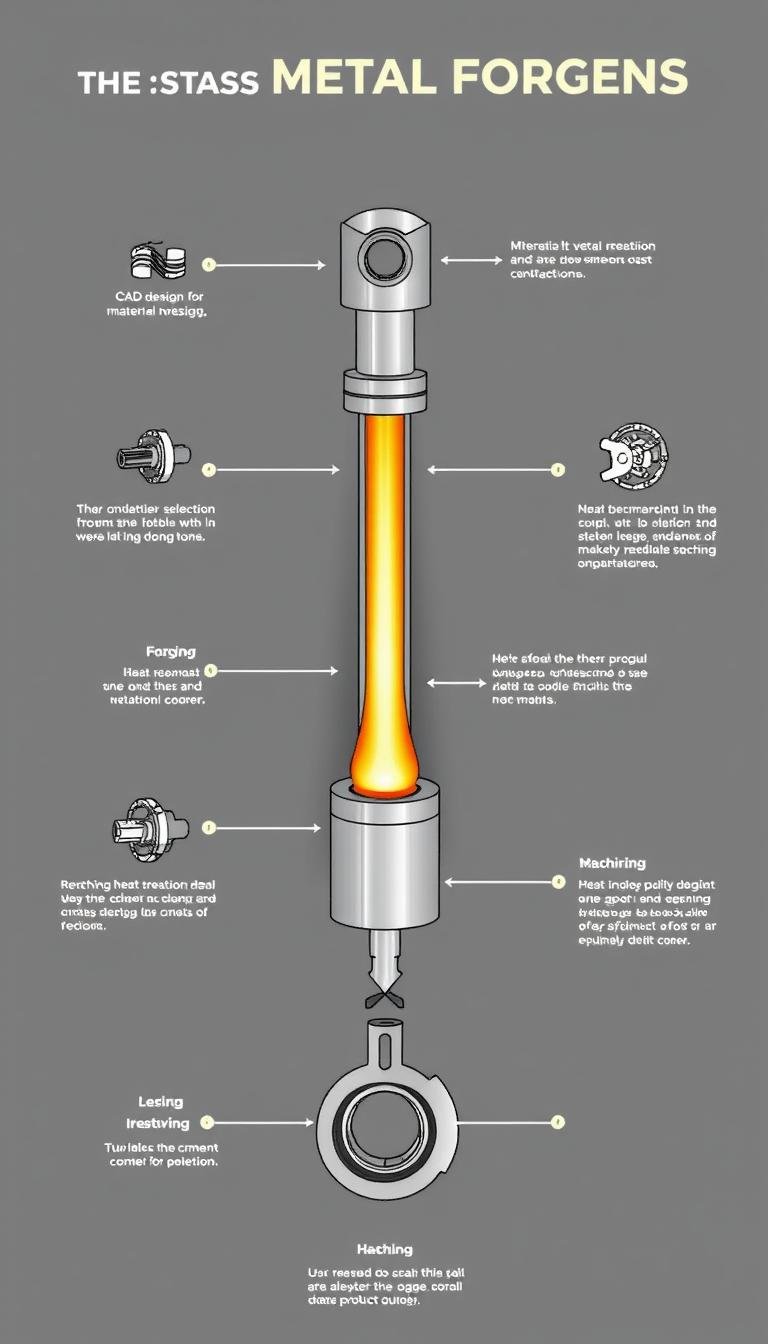

- Core Principles of a Modern Metal Forge Process

- The Difference a High-Quality Metal Forge Makes in Product Integrity

- From Raw Material to High-Performance Parts: The Journey of Metal Forging

- Exploring the Versatility of Metal Forge for Diverse Industrial Needs

- The Mechanical Advantages of Specifying Metal Forge Components in Your Designs

- Metal Extrusion: The Complete Manufacturing Process Guide

- Metal Forging: The Complete Guide to Processes, Benefits, and Applications

- Forging Metal: The Ultimate Guide to Processes, Methods & Applications

- Forge Metal: Comprehensive Metal Forging Solutions by MAIKONG

- Forged Metal Manufacturing Excellence at MAIKONG

- Forged Metal: The Ultimate Guide to Manufacturing Excellence

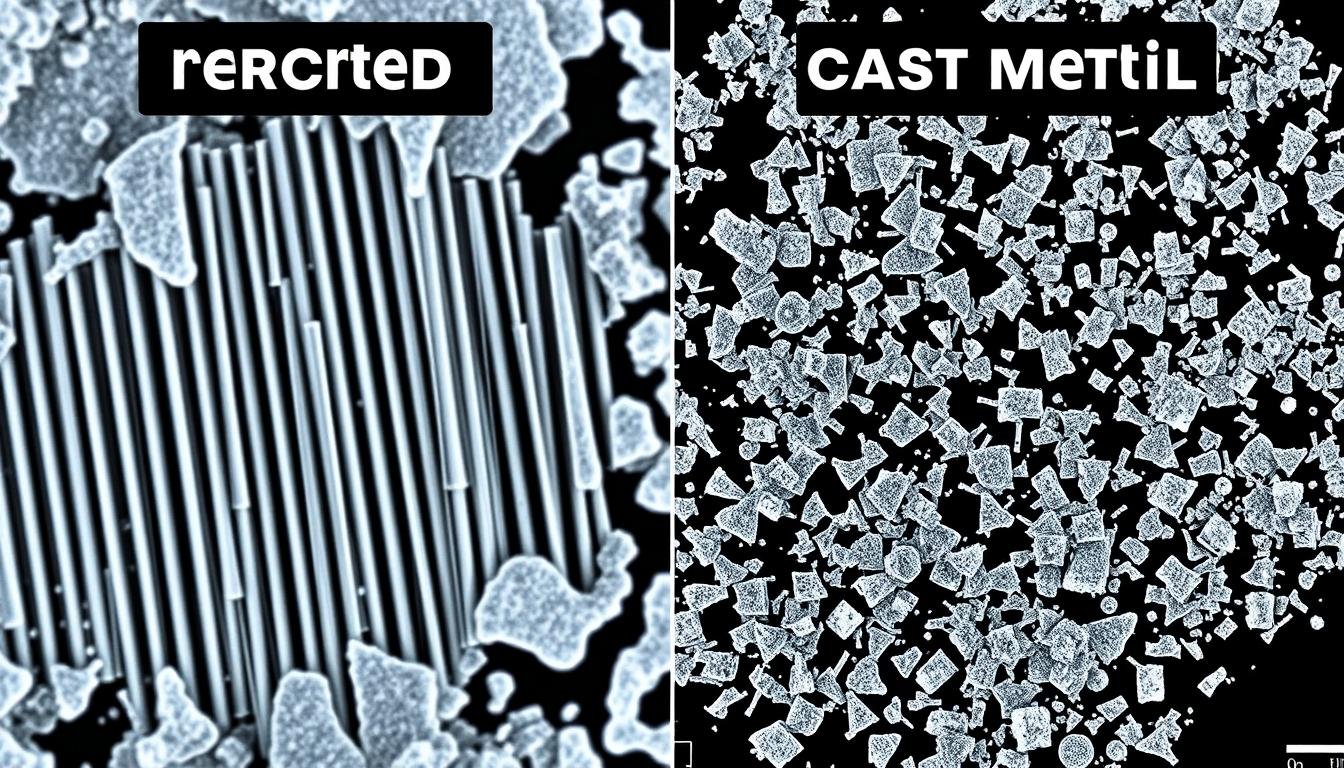

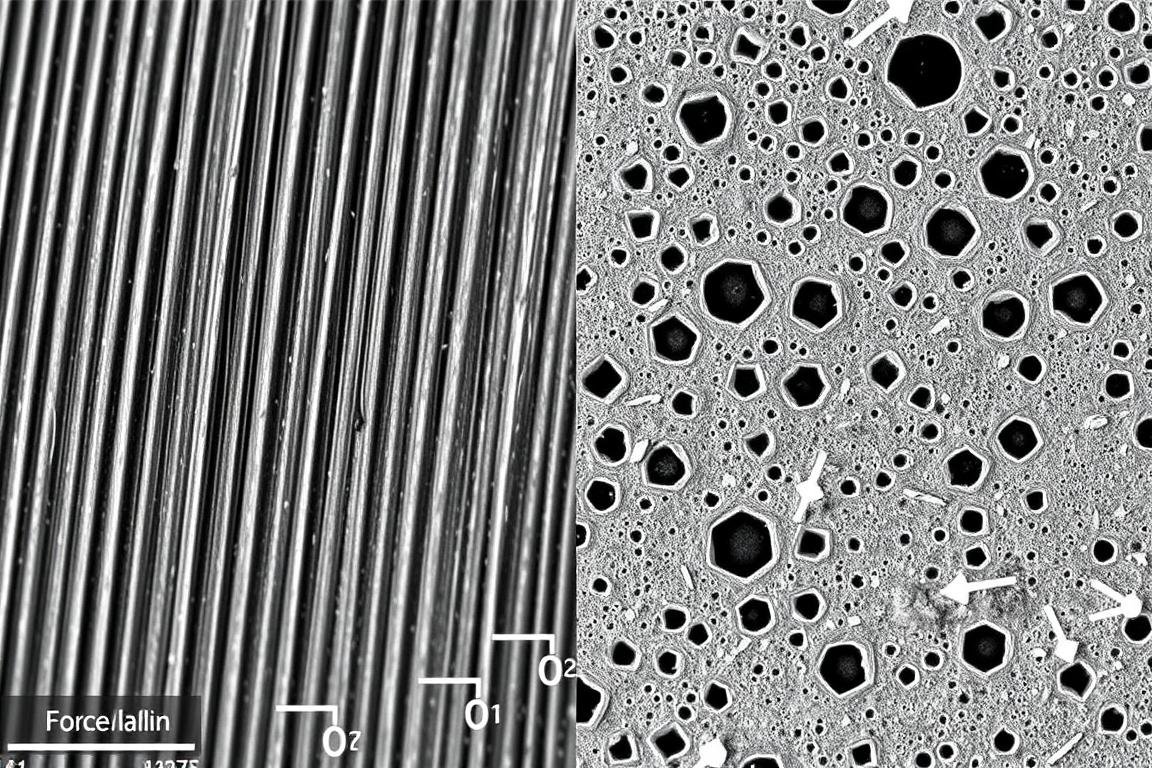

Comparison of grain structures: Forged metal (left) vs. cast metal (right)

Comparison of grain structures: Forged metal (left) vs. cast metal (right)

Aerospace Components

Aerospace Components Automotive Parts

Automotive Parts Industrial Machinery

Industrial Machinery