Brass extrusion stands as one of the most versatile metal forming processes in modern manufacturing. This sophisticated technique transforms brass alloys into precise, complex shapes with exceptional surface finish and mechanical properties. At MAIKONG, we’ve mastered the art and science of brass extrusion, delivering custom components that combine aesthetic appeal with outstanding performance across diverse industries.

Need Custom Brass Components?

Our engineering team is ready to discuss your project requirements and provide expert guidance.

Get A Quick Quote

Understanding Brass Extrusion: The Fundamentals

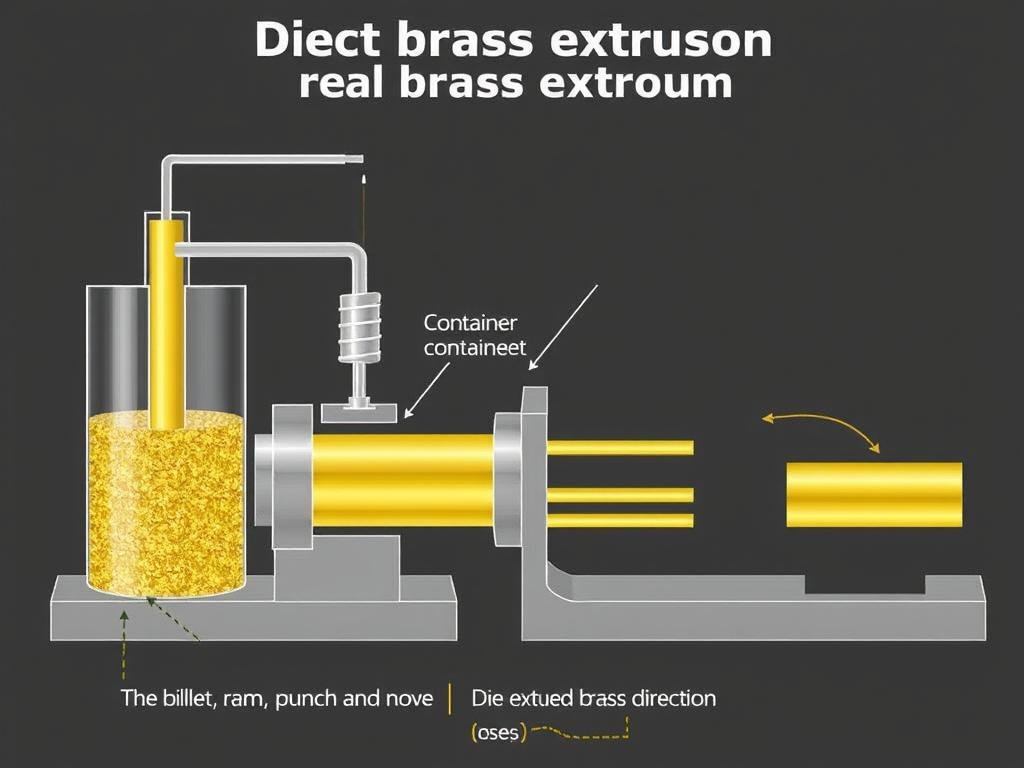

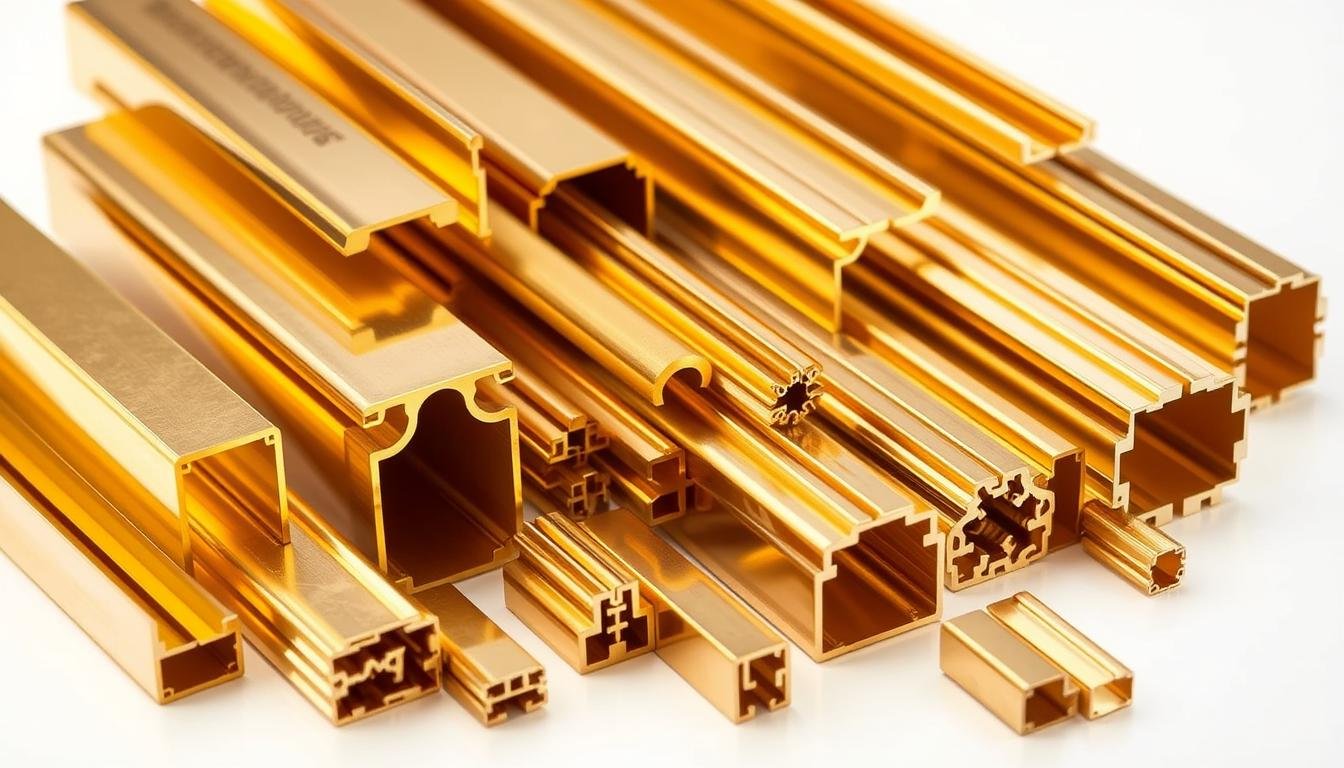

The brass extrusion process at MAIKONG’s state-of-the-art facility

The brass extrusion process at MAIKONG’s state-of-the-art facility

Brass extrusion is a metal working process where brass alloy is heated and forced through a specially designed die to create a fixed cross-sectional profile. This manufacturing method allows for the creation of complex shapes that would be difficult or impossible to achieve through other fabrication techniques. The resulting extruded brass components feature consistent dimensions and excellent surface finish.

Unlike casting or machining, brass extrusion creates products with enhanced grain structure and mechanical properties. The compression during extrusion results in parts with dense grain structure and superior mechanical traits, making them ideal for applications requiring durability and precision.

The Science Behind Brass Extrusion

The process begins with brass billets that are heated to increase ductility. The heated material is then forced through a die under high pressure, creating the desired cross-sectional profile. This technique can produce both simple shapes like rods and tubes as well as complex profiles with intricate details. The extruded material can be cut to specific lengths or produced continuously depending on application requirements.

Types of Brass Extrusion Processes

Direct Brass Extrusion

Also known as forward extrusion, this method involves the billet, ram, and punch moving in the same direction. The billet slides against the container wall, increasing friction. This process is simple, cost-effective, and ideal for manufacturing simple shapes with good surface finish.

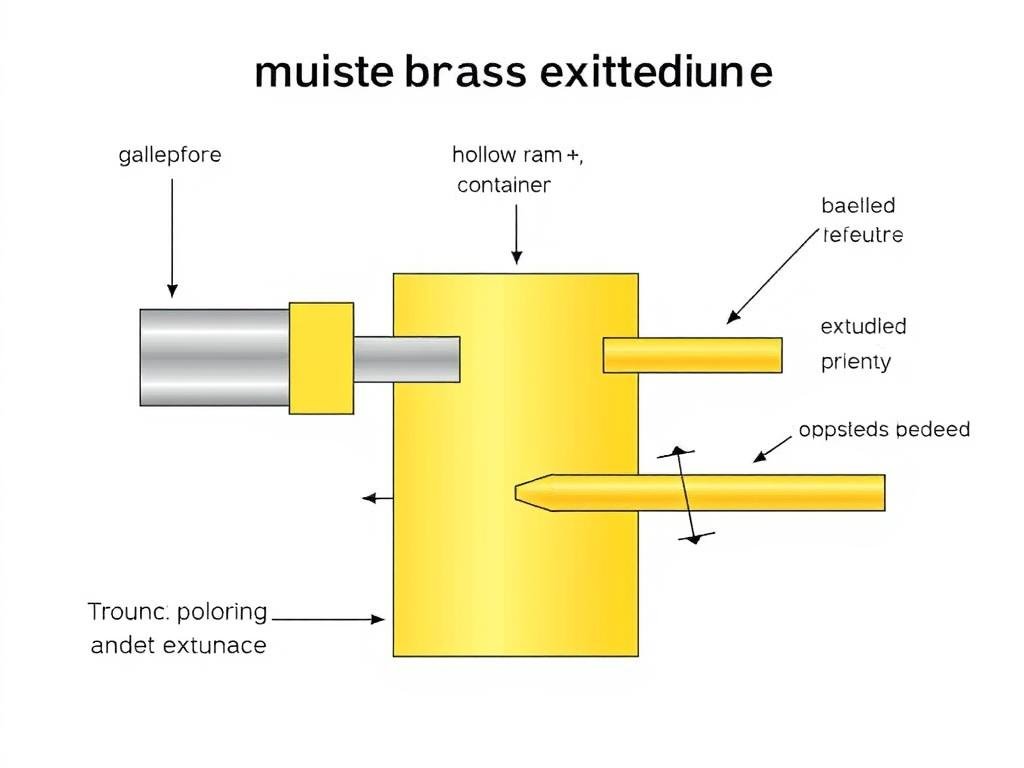

Indirect Brass Extrusion

Also called backward extrusion, this process features the punch and billet moving in opposite directions. With minimal relative motion between the container and billet, less friction is generated. This method requires less force than direct extrusion and experiences minimal container wear.

Impact Brass Extrusion

This specialized method is particularly suitable for creating hollow brass items like cups. The process is relatively simple to perform with low tooling costs, making it ideal for producing brass tubes with thin walls and specific dimensional requirements.

Hydrostatic Brass Extrusion

This advanced technique employs liquids as the medium through which pressure is transmitted during the extrusion process. Since the billet and container don’t make direct contact, no friction is generated, making this method suitable for creating brittle products at room temperature.

Advantages of Brass Extrusion Manufacturing

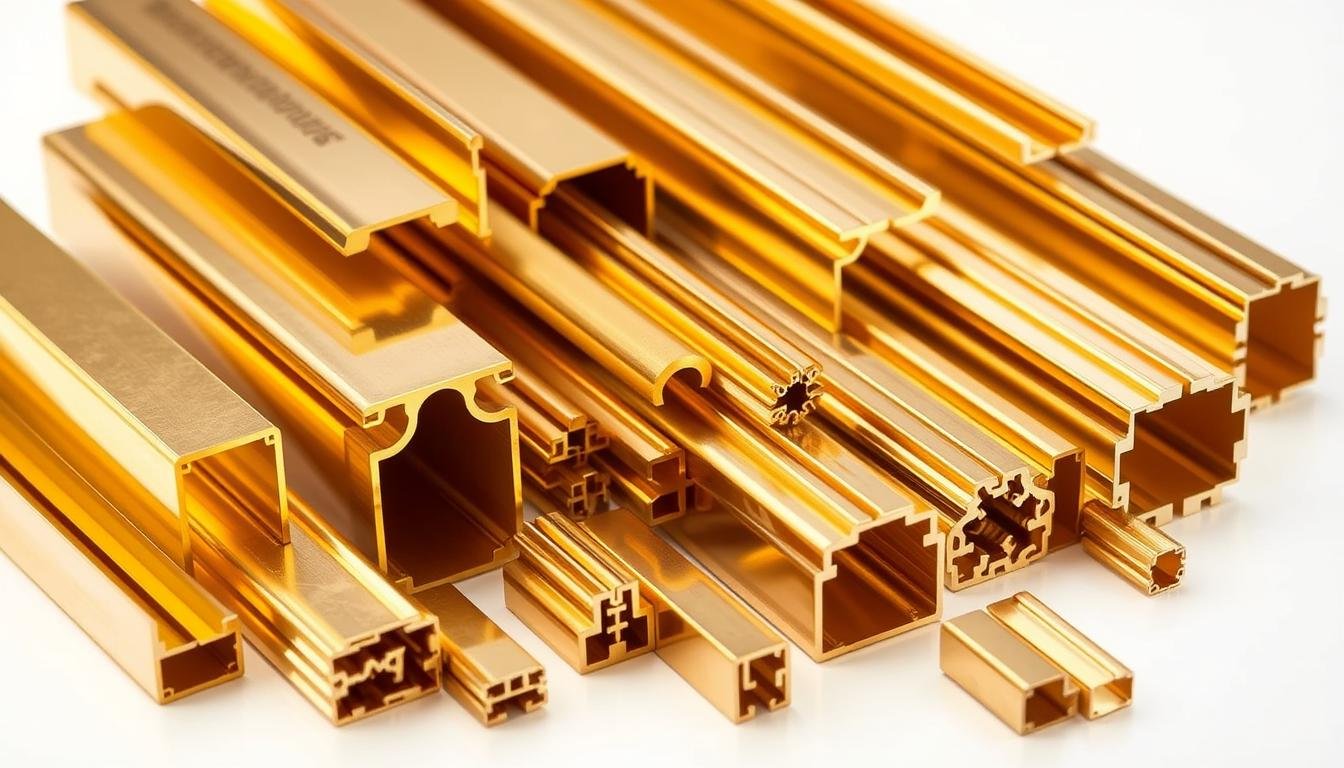

Complex brass extrusion profiles manufactured by MAIKONG

Advantages of Extruding Brass

- Efficient mass production with short cycle times

- Ability to create a wide range of cross-sectional profiles

- Superior corrosion resistance compared to cast components

- Enhanced mechanical properties due to compressed grain structure

- High dimensional accuracy for complex parts

- Excellent surface finish requiring minimal post-processing

- Cost-effective for medium to high volume production

- Consistent quality across production runs

Limitations to Consider

- Higher initial setup and tooling costs

- Requires significant force for material deformation

- Less economical for very small production runs

- Uniform cross-section throughout the product length

- Some design constraints compared to casting

Maximize Your Manufacturing Efficiency

Let MAIKONG’s engineering team help you determine if brass extrusion is the right process for your components.

Contact Our Experts

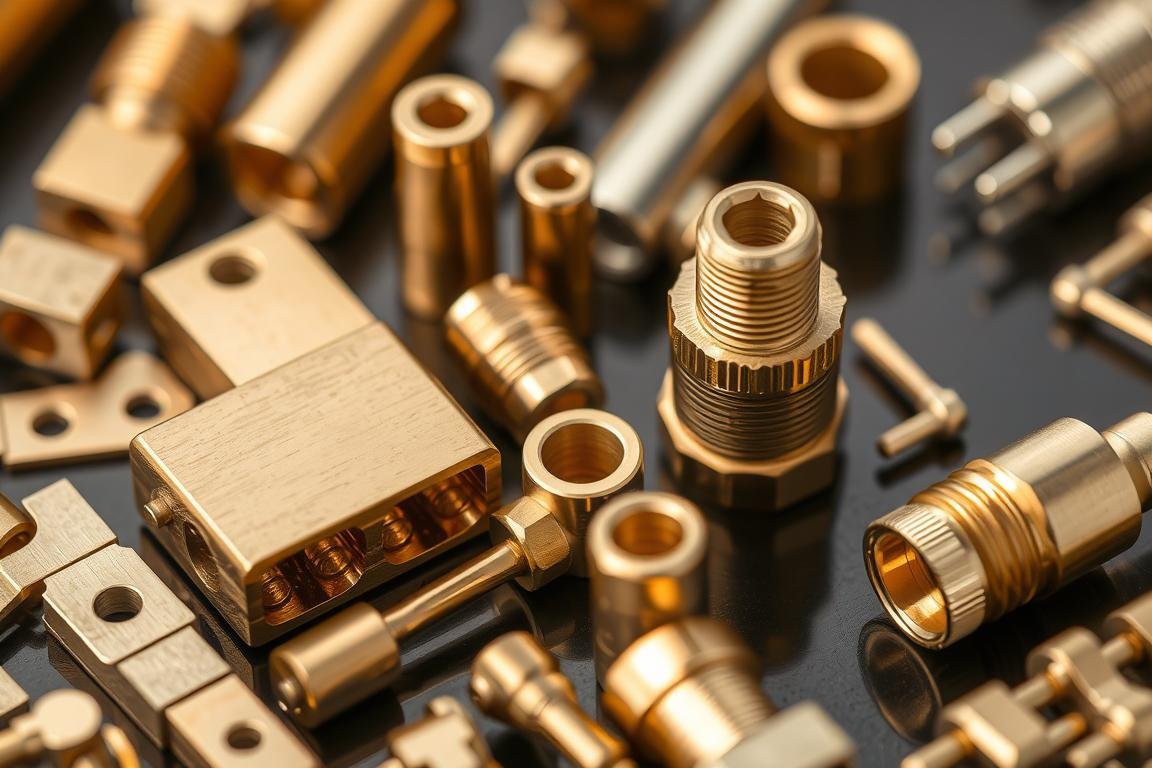

Applications of Extruded Brass Components

The versatility of brass extrusion allows for the creation of components used across numerous industries. From architectural elements to precision electrical components, extruded brass offers the perfect combination of aesthetic appeal, durability, and functionality.

Architectural Applications

- Decorative handrails and railings

- Door and window frames

- Curtain wall components

- Decorative moldings and trim

Electrical Components

- Electrical terminals and connectors

- Terminal blocks and fuse parts

- Cable clamps and spacers

- Conductive elements

Industrial Applications

- Valve components and fittings

- Gears and mechanical parts

- Bearings and bushings

- Plumbing fixtures and components

Additional applications include automotive components, musical instruments, marine hardware, and consumer products. The non-sparking nature of brass makes it particularly valuable in environments where safety is paramount, such as in the presence of flammable materials.

Optimal Brass Alloys for Extrusion

The success of a brass extrusion project largely depends on selecting the right brass alloy. At MAIKONG, we work with a variety of brass grades, each offering specific advantages for different applications.

| Brass Alloy |

Composition |

Properties |

Recommended Applications |

| C26000 (Cartridge Brass) |

70% Copper, 30% Zinc |

Excellent ductility, good strength |

Ammunition casings, hardware, fasteners |

| C27000 (Yellow Brass) |

65% Copper, 35% Zinc |

Good formability, moderate strength |

Plumbing components, decorative hardware |

| C35300 (Low Leaded Brass) |

62% Copper, 37% Zinc, 0.9% Lead |

Improved machinability, moderate strength |

Valves, fittings, gears |

| C38000 (Architectural Bronze) |

57% Copper, 40% Zinc, 3% Lead |

Good machinability, moderate strength |

Architectural components, decorative elements |

| C48500 (Naval Brass) |

60% Copper, 39% Zinc, 1% Tin |

Excellent corrosion resistance, high strength |

Marine hardware, corrosive environments |

Brass alloy samples at MAIKONG’s material testing laboratory

Surface Finishes for Extruded Brass

The appearance and functionality of brass extrusion products can be enhanced through various surface finishing techniques. At MAIKONG, we offer comprehensive finishing services to meet your specific requirements.

Polishing

Our precision polishing processes create a smooth, reflective surface that enhances the natural beauty of brass. This finish is particularly popular for architectural and decorative applications where aesthetic appeal is paramount.

Electroplating

We apply thin metallic layers to brass extrusions through electroplating, enhancing corrosion resistance and visual appeal. Common plating options include nickel, chrome, and gold, each offering unique benefits for different applications.

Anodizing

Though more commonly associated with aluminum, specialized anodizing processes can be applied to brass to create a protective oxide layer. This treatment enhances corrosion resistance while maintaining the material’s electrical conductivity.

Powder Coating

For applications requiring specific colors or enhanced durability, we offer powder coating services. This process applies a fine powder to the surface of brass extrusions, which is then heated to fuse into a protective coating with excellent adhesion and longevity.

Enhance Your Brass Components

Discuss your surface finish requirements with our finishing specialists.

Email Our Team

Quality Factors in Custom Brass Extrusion

At MAIKONG, we understand that the quality of extruded brass components depends on multiple factors throughout the manufacturing process. Our comprehensive quality control procedures ensure consistent excellence in every component we produce.

Quality inspection of brass extrusions at MAIKONG’s quality control laboratory

Material Quality

We source only premium brass alloys with optimal ductility and grain structure. Our material testing laboratory verifies the composition and properties of every batch to ensure consistency and performance.

Temperature Control

Precise temperature management during the extrusion process is critical for achieving optimal material flow and grain structure. Our advanced heating systems maintain exact temperatures for consistent results.

Extrusion Speed & Pressure

We carefully control extrusion speed and pressure parameters to achieve the ideal balance between productivity and quality. These factors significantly impact surface finish, dimensional accuracy, and mechanical properties.

Additional quality factors include die design and maintenance, cooling rate control, and comprehensive dimensional verification. Our ISO-certified quality management system ensures that every component meets or exceeds industry standards and customer specifications.

MAIKONG’s Brass Extrusion Capabilities

With over 60 CNC machines and a monthly metal processing capacity exceeding 100 tons, MAIKONG offers comprehensive brass extrusion and fabrication services. Our state-of-the-art facility in GD, SZ combines advanced technology with skilled craftsmanship to deliver exceptional results.

MAIKONG’s advanced manufacturing facility in GD, SZ

Our Comprehensive Services Include:

Design & Engineering

- CAD/CAM design optimization

- Material selection consultation

- Die design and simulation

- Prototype development

Manufacturing

- Custom brass extrusion

- CNC machining and finishing

- Surface treatment options

- Heat treatment services

Quality Assurance

- Material testing and verification

- Dimensional inspection

- Surface quality assessment

- Mechanical property testing

Additional Services

- Assembly and packaging

- Inventory management

- Global logistics support

- Technical documentation

Partner with MAIKONG for Superior Brass Extrusion Solutions

MAIKONG combines advanced technology, skilled craftsmanship, and rigorous quality control to deliver exceptional brass extrusion components. Our comprehensive capabilities and customer-focused approach make us the ideal partner for your custom brass manufacturing needs.

Whether you require architectural profiles, electrical components, or industrial parts, our team is ready to provide expert guidance and superior manufacturing services. With competitive pricing and a commitment to excellence, MAIKONG is actively seeking distribution partners throughout the United States.

The brass extrusion process at MAIKONG’s state-of-the-art facility

The brass extrusion process at MAIKONG’s state-of-the-art facility