Understanding brass extrusion terminology is crucial for procurement managers seeking quality metal components. This comprehensive guide breaks down the technical language, manufacturing processes, and quality considerations that impact your sourcing decisions. As global manufacturing evolves, having this specialized knowledge helps you communicate effectively with suppliers and ensure your specifications are met precisely.

What Is Brass Extrusion and Why It Matters

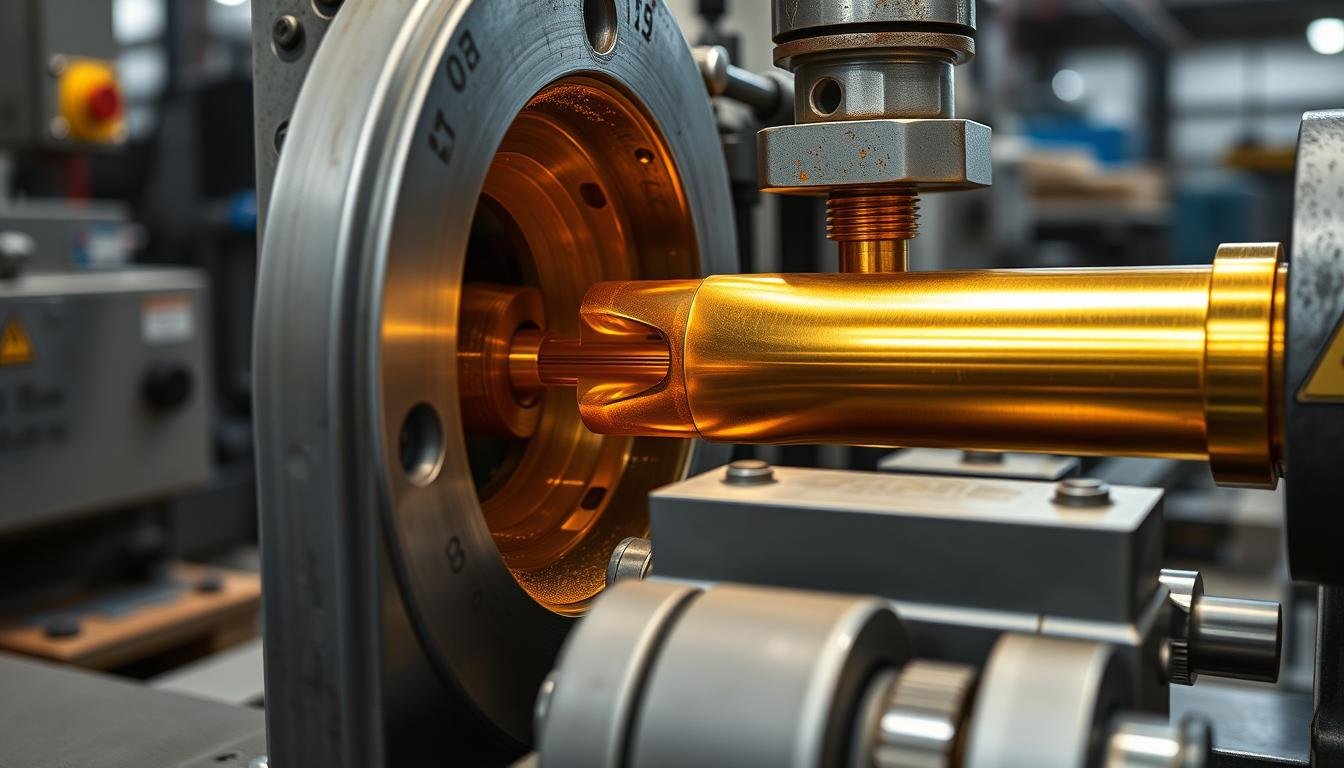

Modern brass extrusion manufacturing process at MAIKONG’s facility

Modern brass extrusion manufacturing process at MAIKONG’s facility

Brass extrusion is a metalworking technique where brass (an alloy of copper and zinc) is forced through a die with a specific cross-sectional profile. The process creates long, continuous pieces with consistent dimensions and properties. Unlike casting or machining, extrusion offers excellent surface quality, tight tolerances, and enhanced mechanical properties through grain alignment.

For procurement managers, brass extrusion provides several advantages: cost-effectiveness for medium to high-volume production, minimal material waste, excellent dimensional stability, and versatility in creating complex profiles that would be difficult to achieve through other manufacturing methods.

Need Expert Guidance on Brass Extrusion?

Our technical team can help you determine if brass extrusion is right for your application.

Request a Consultation

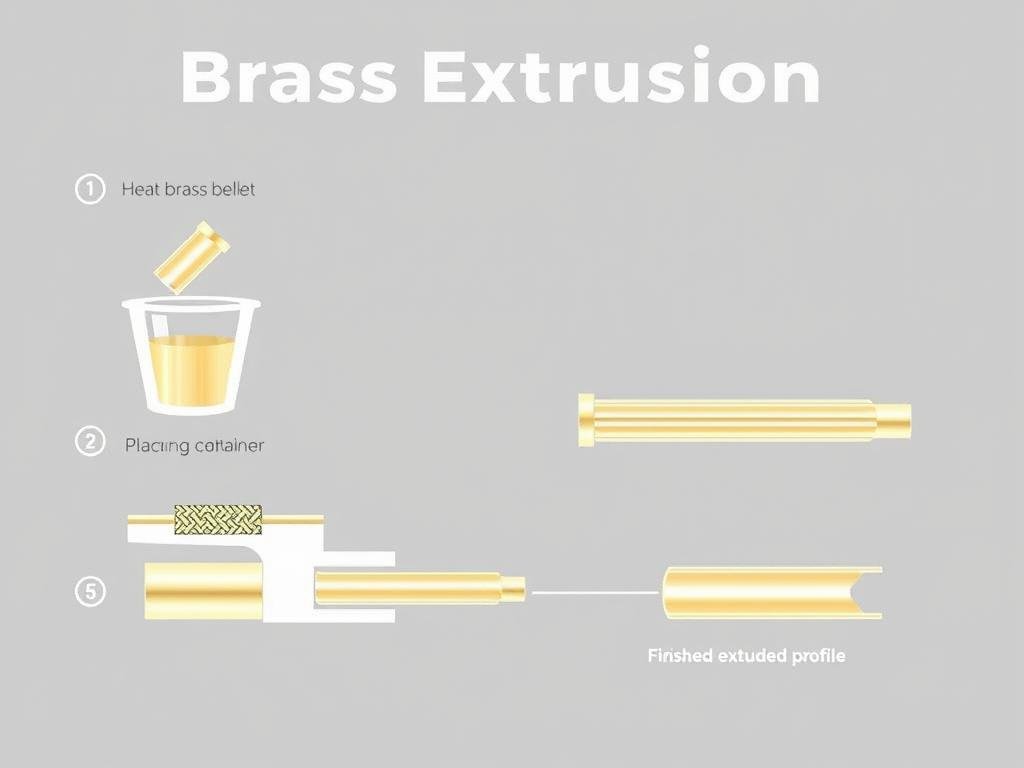

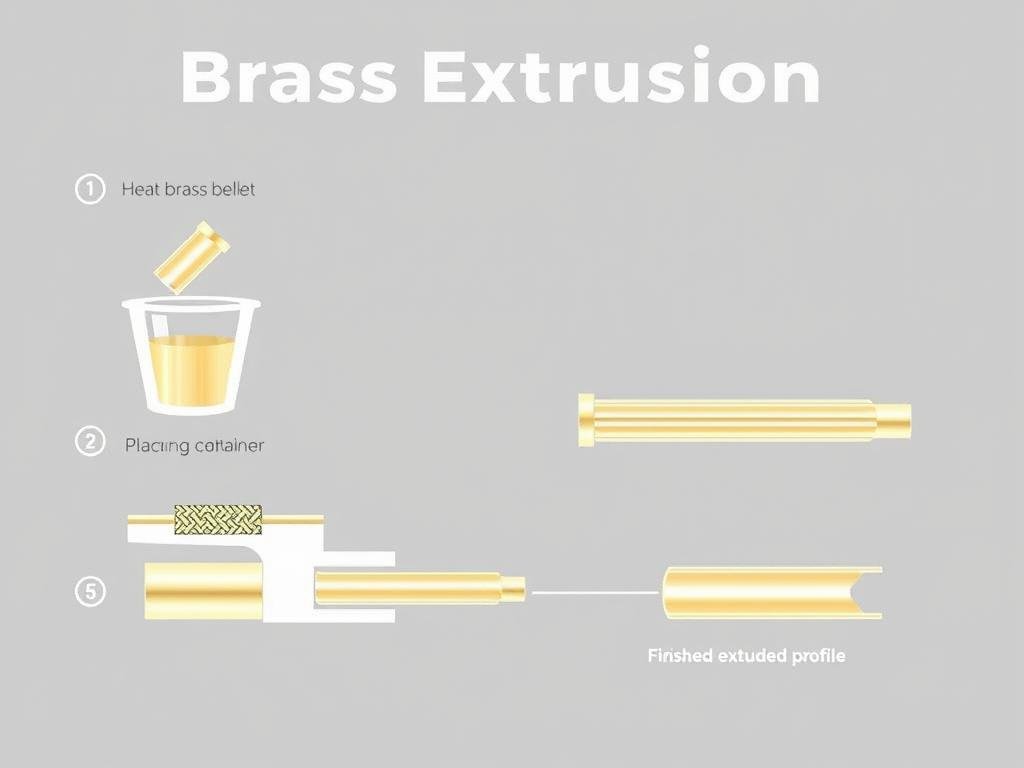

The Brass Extrusion Process Explained

Detailed breakdown of the brass extrusion manufacturing process

Understanding the brass extrusion process helps procurement managers make informed decisions about material selection, tolerances, and finishing requirements. The process consists of several key stages:

- Billet Preparation: Raw brass is cast into cylindrical billets and inspected for quality.

- Heating: Billets are heated to 650-850°C (1200-1560°F) to achieve optimal plasticity.

- Lubrication: The billet and die are lubricated to reduce friction and wear.

- Extrusion: Hydraulic pressure forces the heated brass through a die with the desired cross-sectional profile.

- Cooling: The extruded profile is cooled in a controlled manner to prevent warping.

- Stretching: The profile is stretched slightly to improve straightness and dimensional accuracy.

- Cutting: The continuous profile is cut to the required lengths.

- Heat Treatment: Optional annealing or tempering to achieve specific mechanical properties.

- Finishing: Surface treatments like polishing, brushing, or coating are applied as needed.

Hot vs. Cold Brass Extrusion: Key Differences

| Parameter |

Hot Extrusion |

Cold Extrusion |

| Working Temperature |

650-850°C (1200-1560°F) |

Room temperature to 200°C (390°F) |

| Surface Finish |

Good, may require finishing |

Excellent, minimal finishing needed |

| Dimensional Accuracy |

±0.2-0.5mm typical |

±0.05-0.2mm typical |

| Complexity of Shapes |

Complex profiles possible |

Limited to simpler profiles |

| Production Speed |

Faster for large volumes |

Slower process |

| Mechanical Properties |

Good strength, ductility |

Enhanced strength, work hardening |

| Ideal Applications |

Architectural, structural components |

Precision components, electrical parts |

At MAIKONG, we specialize in both hot and cold brass extrusion techniques, allowing us to recommend the optimal process based on your specific requirements for surface finish, dimensional accuracy, and mechanical properties.

Brass Alloys for Extrusion: Making the Right Selection

Different brass alloy compositions used in extrusion manufacturing

Selecting the appropriate brass alloy is critical for ensuring your extruded components meet performance requirements. Each alloy offers distinct characteristics that make it suitable for specific applications:

| Alloy Designation |

Composition |

Properties |

Typical Applications |

| C26000 (Cartridge Brass) |

70% Cu, 30% Zn |

Excellent ductility, good strength |

Ammunition casings, hardware, fasteners |

| C27000 (Yellow Brass) |

65% Cu, 35% Zn |

Good formability, moderate strength |

Plumbing components, decorative hardware |

| C36000 (Free-Cutting Brass) |

61.5% Cu, 35.5% Zn, 3% Pb |

Excellent machinability, moderate strength |

Gears, valves, fittings, hardware |

| C38500 (Architectural Bronze) |

57% Cu, 40% Zn, 3% Pb |

Good corrosion resistance, attractive finish |

Architectural trim, handrails, decorative elements |

| C46400 (Naval Brass) |

60% Cu, 39.2% Zn, 0.8% Sn |

Excellent corrosion resistance in marine environments |

Marine hardware, propeller shafts, valve stems |

| C67500 (Manganese Bronze) |

58.5% Cu, 39% Zn, 1.4% Fe, 1% Mn, 0.1% Sn |

High strength, good wear resistance |

Bearings, bushings, gear components |

MAIKONG’s metallurgical expertise ensures we can recommend the optimal brass alloy for your specific application requirements, balancing mechanical properties, corrosion resistance, and cost considerations.

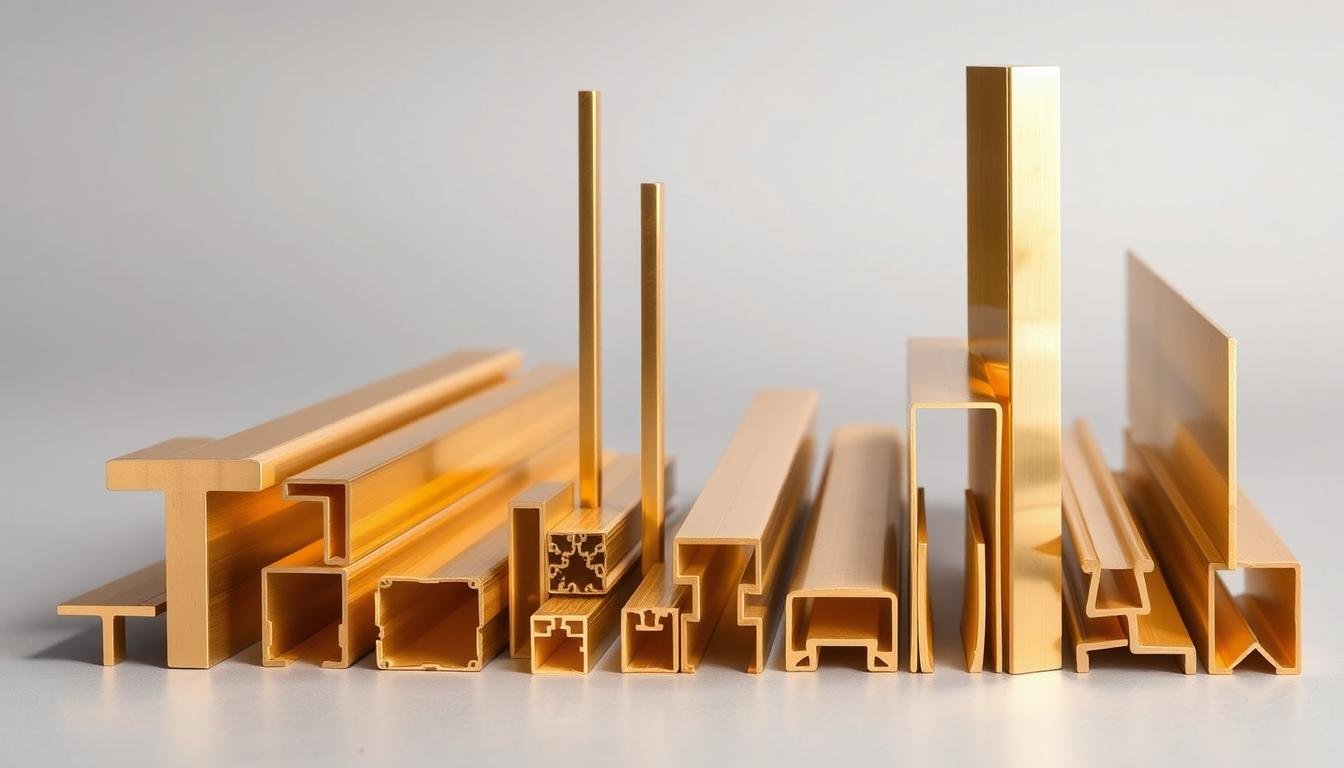

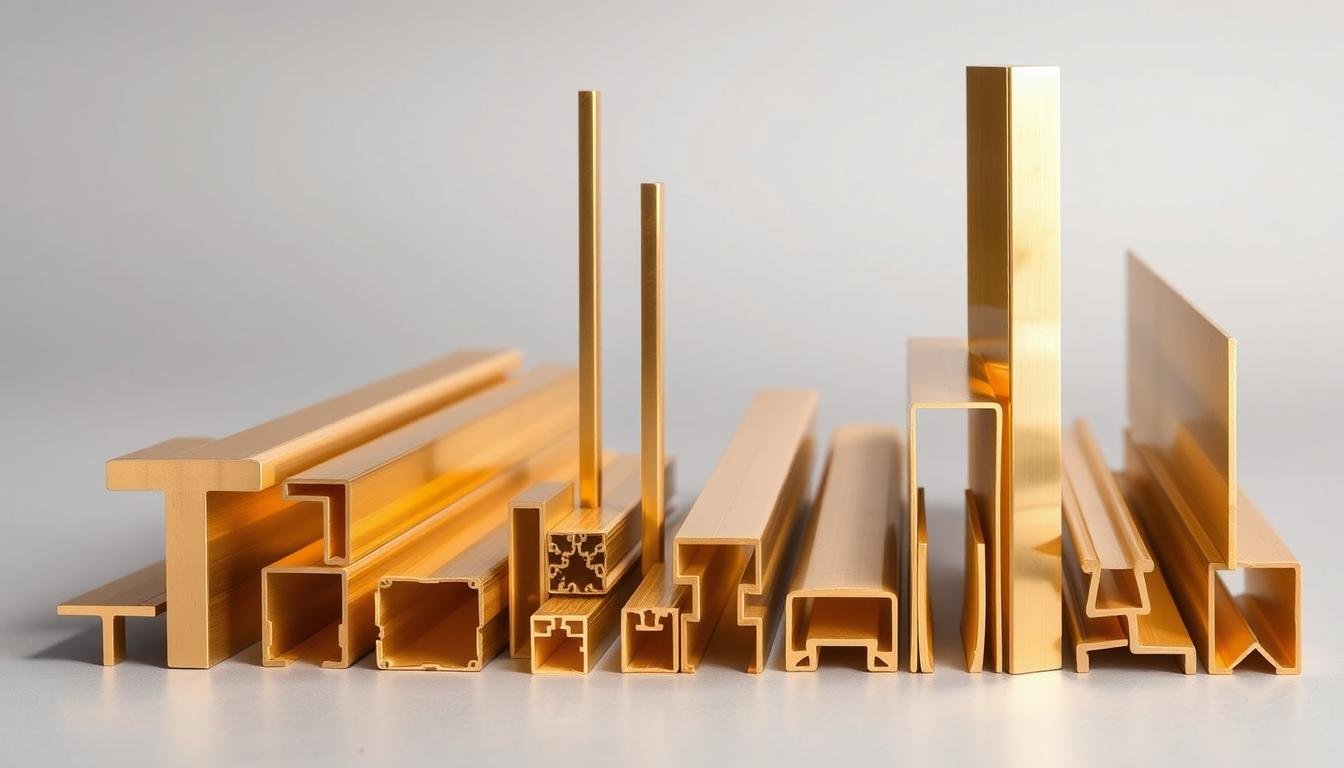

Common Brass Extrusion Profiles and Their Applications

Standard and custom brass extrusion profiles manufactured by MAIKONG

Brass extrusions are available in a wide range of standard and custom profiles to meet diverse application requirements. Understanding common profile types helps procurement managers specify the right components for their projects:

Structural Profiles

- Angles (L-shaped)

- Channels (C-shaped)

- T-sections

- I-beams

- H-sections

Applications: Architectural frameworks, support structures, decorative elements

Basic Shapes

- Round bars and rods

- Rectangular bars

- Square bars

- Hexagonal bars

- Flat bars

Applications: Machined components, electrical connectors, hardware

Specialized Profiles

- Tube and hollow sections

- Multi-cavity profiles

- Custom complex shapes

- Finned profiles

- Interlocking sections

Applications: Heat exchangers, electrical components, custom machinery parts

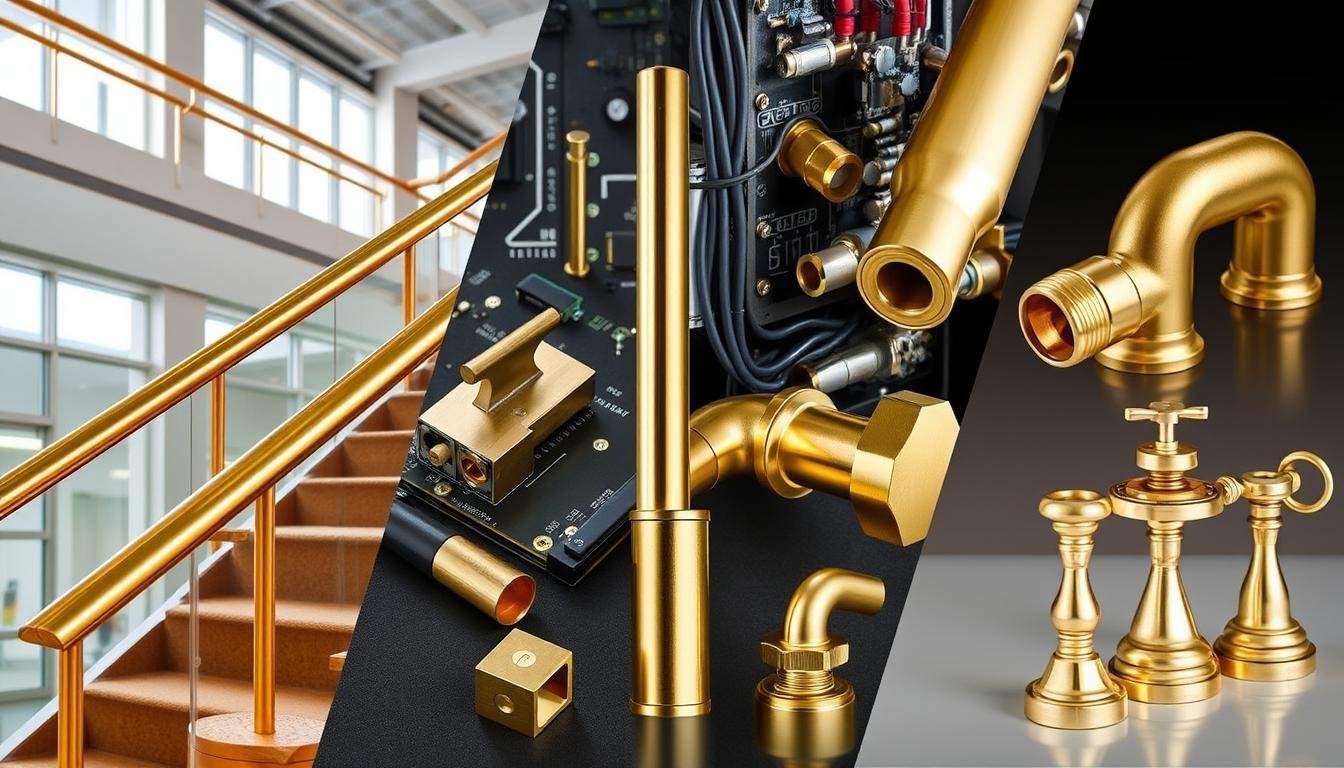

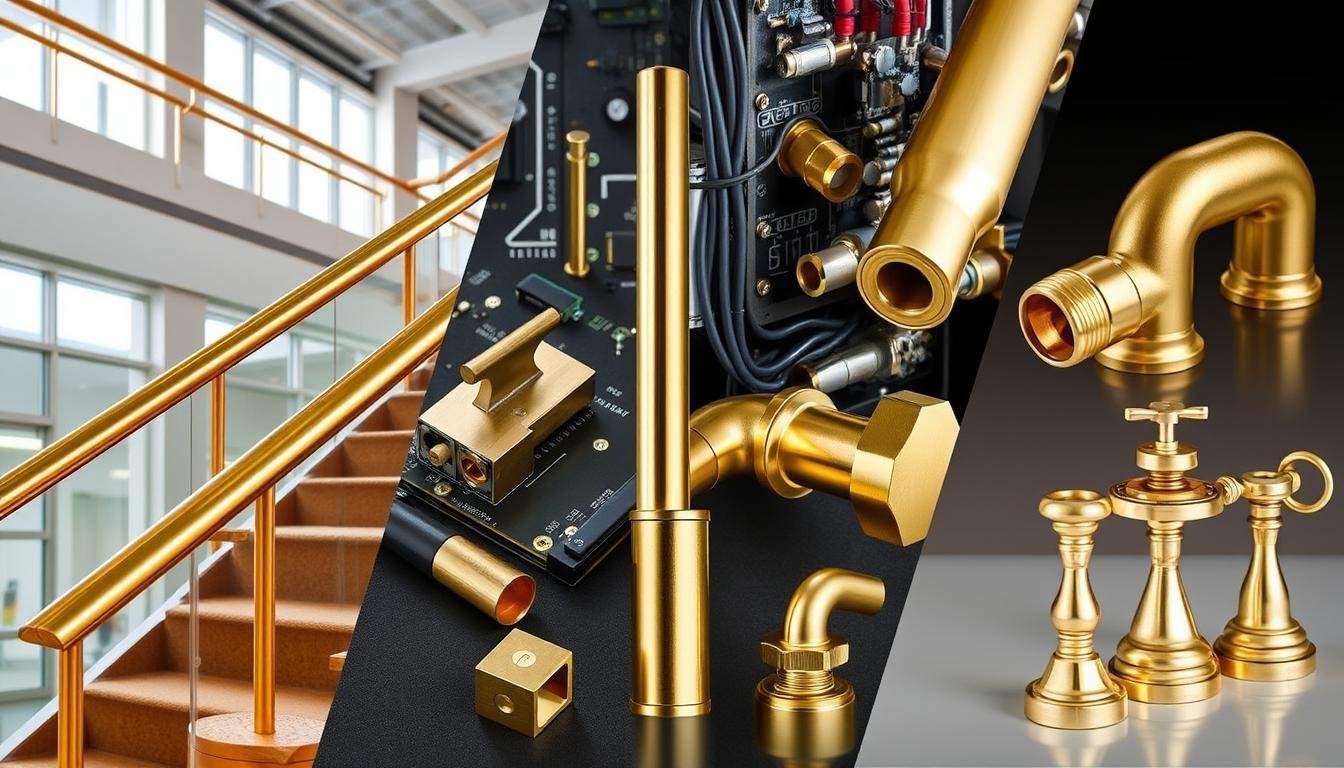

Industry-Specific Brass Extrusion Applications

Versatile applications of brass extrusion across multiple industries

- Architectural: Handrails, door frames, window trim, decorative moldings, and skirting

- Electrical: Terminals, connectors, busbars, and switch components

- Plumbing: Fittings, valve bodies, pipe connectors, and fixture components

- Automotive: Radiator components, electrical connectors, and decorative trim

- Furniture: Decorative elements, structural components, and hardware

- Industrial Equipment: Bearings, bushings, gears, and wear-resistant components

- Marine: Corrosion-resistant fittings, hardware, and structural elements

Need Custom Brass Extrusion Profiles?

MAIKONG specializes in custom brass extrusion manufacturing to your exact specifications.

Request a Quote

Quality Considerations for Brass Extrusion Procurement

Quality inspection of brass extrusion components at MAIKONG’s facility

When sourcing brass extrusions, procurement managers should consider several quality factors to ensure components meet performance requirements and manufacturing standards:

Dimensional Tolerances in Brass Extrusion

| Dimension Type |

Standard Tolerance |

Precision Tolerance |

| Cross-sectional dimensions |

±0.2-0.5mm |

±0.05-0.15mm |

| Wall thickness |

±10% |

±5% |

| Straightness (per meter) |

1.0mm |

0.5mm |

| Twist (per meter) |

2° max |

1° max |

| Length |

±3.0mm |

±1.0mm |

Surface Quality and Finish Options

Various surface finishes available for brass extrusion components

Common Surface Defects to Watch For:

- Die lines and scratches

- Surface porosity

- Inclusions and impurities

- Extrusion marks

- Inconsistent color or finish

Available Surface Finishes:

- Mill finish (as-extruded)

- Polished (mirror, semi-bright)

- Brushed (directional, non-directional)

- Sandblasted (matte texture)

- Chemical treatments (antiquing, patination)

- Protective coatings (lacquer, clear coat)

Mechanical Properties Testing

Quality brass extrusions should undergo testing to verify mechanical properties meet specifications:

- Tensile Testing: Measures strength, ductility, and elongation properties

- Hardness Testing: Verifies material hardness using Brinell, Rockwell, or Vickers scales

- Grain Structure Analysis: Ensures proper microstructure for optimal performance

- Chemical Composition Analysis: Confirms alloy meets specified requirements

- Corrosion Resistance Testing: Validates performance in intended environment

MAIKONG implements comprehensive quality control procedures throughout the brass extrusion manufacturing process, from raw material verification to final inspection, ensuring components meet or exceed your specifications.

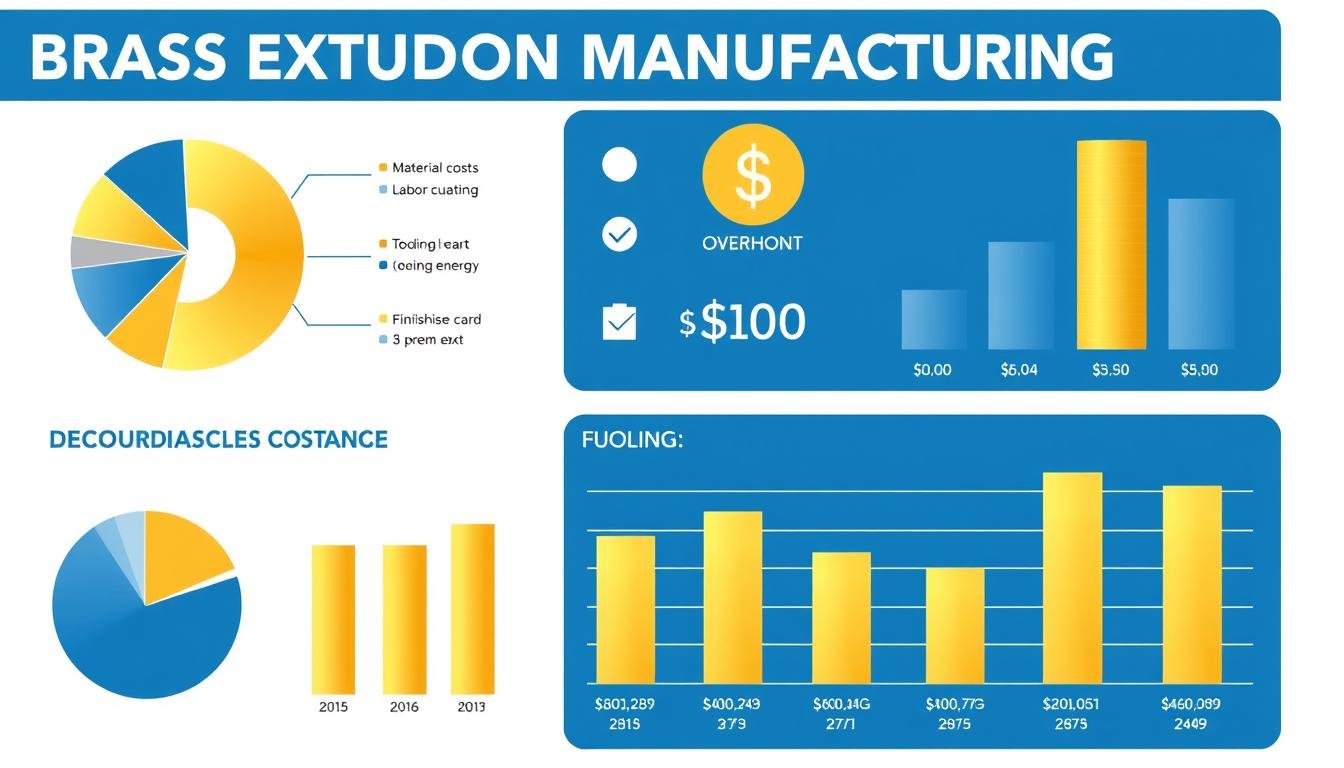

Cost Factors in Brass Extrusion Manufacturing

Key cost factors affecting brass extrusion pricing

Understanding the factors that influence brass extrusion costs helps procurement managers make informed decisions and identify opportunities for cost optimization:

- Material Costs: Brass alloy prices fluctuate with copper and zinc market prices, typically accounting for 50-70% of total component cost

- Tooling and Die Costs: One-time expenses for custom extrusion dies, ranging from $500-$5,000 depending on complexity

- Profile Complexity: Intricate shapes require more complex dies and slower extrusion speeds, increasing costs

- Dimensional Tolerances: Tighter tolerances require more precise tooling and additional quality control measures

- Surface Finish Requirements: Secondary finishing operations add to overall costs

- Order Volume: Larger quantities typically reduce per-unit costs through economies of scale

- Secondary Operations: Additional processes like cutting, machining, or heat treatment increase costs

Cost Optimization Strategies

Cost Reduction Opportunities

- Optimize profile design for efficient material usage

- Consider standard profiles instead of custom when possible

- Consolidate multiple components into single extrusions

- Order in economic batch quantities

- Specify appropriate tolerances (avoid over-specification)

- Minimize secondary operations through design optimization

- Consider alternative brass alloys with similar properties

Cost Increase Risks

- Frequent design changes requiring new tooling

- Unnecessarily tight tolerances

- Small, irregular order quantities

- Rush orders requiring production schedule changes

- Excessive surface finish requirements

- Complex profiles requiring slow extrusion speeds

- Specialized alloys with limited availability

MAIKONG’s engineering team works closely with clients to identify cost optimization opportunities without compromising quality or performance. Our experience in brass extrusion manufacturing allows us to recommend design and specification adjustments that can significantly reduce overall costs.

Looking for Cost-Effective Brass Extrusion Solutions?

Our engineering team can review your designs and suggest optimizations to reduce costs.

Email Our Engineering Team

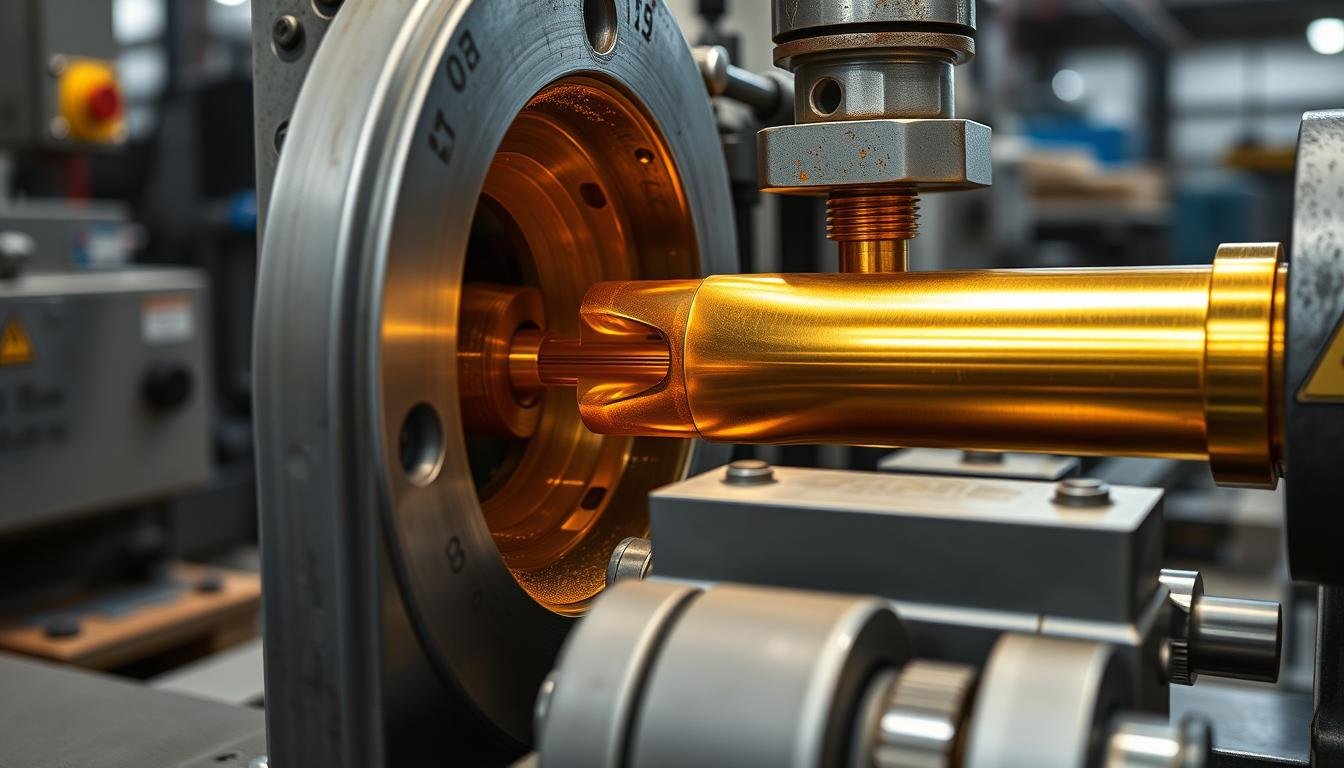

MAIKONG’s Brass Extrusion Manufacturing Capabilities

MAIKONG’s state-of-the-art brass extrusion manufacturing facility in GD, SZ

MAIKONG offers comprehensive brass extrusion manufacturing capabilities to meet diverse customer requirements:

Technical Capabilities

- Extrusion press capacity: 500-2500 tons

- Profile dimensions: 5mm to 300mm width

- Wall thickness: 0.5mm minimum

- Length capabilities: Up to 12 meters

- Tolerance capabilities: ±0.05mm (precision grade)

- Surface finish options: Mill, polished, brushed, sandblasted

- Secondary operations: Cutting, machining, bending, punching

Quality Assurance

- ISO 9001:2015 certified quality management system

- 100% dimensional inspection

- Material certification and traceability

- In-house metallurgical testing laboratory

- Comprehensive documentation packages

- Statistical process control (SPC)

- First article inspection reports (FAIR)

Integrated Manufacturing Services

MAIKONG’s end-to-end brass extrusion manufacturing process

Beyond basic extrusion capabilities, MAIKONG offers a complete suite of integrated manufacturing services:

- Design Assistance: Our engineering team provides design optimization recommendations for manufacturability and cost-effectiveness

- Tooling Design and Fabrication: In-house die design and manufacturing ensures optimal tooling for your specific requirements

- CNC Machining: Precision secondary operations for features that cannot be extruded directly

- Surface Finishing: Comprehensive finishing capabilities including polishing, brushing, anodizing, and coating

- Assembly Services: Integration of extrusions with other components to create finished assemblies

- Testing and Validation: Mechanical, dimensional, and performance testing to verify compliance with specifications

- Packaging and Logistics: Custom packaging solutions and global shipping capabilities

With over 20 years of experience in metal manufacturing, MAIKONG has established itself as a trusted partner for brass extrusion projects across diverse industries. Our commitment to quality, competitive pricing, and responsive customer service makes us an ideal supplier for US procurement managers seeking reliable manufacturing partners.

Getting Started with MAIKONG for Your Brass Extrusion Projects

MAIKONG’s streamlined project management process

Working with MAIKONG for your brass extrusion projects is straightforward and efficient. Our customer-focused approach ensures clear communication and reliable results:

- Initial Consultation: Discuss your project requirements, specifications, and timeline with our technical team

- Design Review: Our engineers review your designs and provide feedback on manufacturability, material selection, and cost optimization

- Quotation: Receive a detailed quotation including tooling, unit costs, and lead times

- Prototype Development: For new designs, we can produce prototype samples for validation before full production

- Production: Once approved, your project moves to full production with regular status updates

- Quality Verification: Comprehensive inspection and testing ensure components meet all specifications

- Delivery: Finished components are carefully packaged and shipped to your specified location

What information should I provide for an accurate brass extrusion quote?

To receive the most accurate quotation, please provide:

- Detailed drawings (CAD files preferred)

- Material specifications (brass alloy)

- Dimensional tolerances

- Surface finish requirements

- Annual quantity requirements

- Any secondary operations needed

- Packaging specifications

- Delivery location and timeline

What are typical lead times for brass extrusion projects?

Lead times vary based on project complexity, but typical timeframes are:

- New tooling development: 2-4 weeks

- First article samples: 1-2 weeks after tooling completion

- Production: 3-6 weeks after sample approval (quantity dependent)

- Expedited services available for urgent requirements

Does MAIKONG offer distributor partnerships in the US?

Yes, MAIKONG is actively seeking distributor partnerships throughout the United States. We offer competitive pricing, reliable quality, and comprehensive support for distributors of metal components. Our distributor program includes:

- Exclusive territorial rights

- Competitive pricing structures

- Marketing and technical support

- Customized inventory programs

- Joint development opportunities

Contact our partnership team to discuss distributor opportunities in your region.

Ready to Discuss Your Brass Extrusion Project?

Contact MAIKONG today to speak with our technical team about your requirements.

Why Choose MAIKONG for Your Brass Extrusion Needs

MAIKONG’s commitment to quality and customer satisfaction

MAIKONG combines technical expertise, manufacturing excellence, and customer-focused service to deliver superior brass extrusion solutions:

- Technical Expertise: Our engineering team has extensive experience in brass metallurgy and extrusion manufacturing

- Quality Focus: Comprehensive quality management system ensures consistent, reliable components

- Competitive Pricing: Efficient operations and strategic location in GD, SZ provide cost advantages

- Manufacturing Versatility: Integrated capabilities from extrusion to finishing and assembly

- Responsive Service: Dedicated account managers provide prompt communication and support

- Global Logistics: Experienced in international shipping and documentation requirements

- Long-term Partnership: Committed to building lasting relationships with US customers

As you navigate the complexities of brass extrusion procurement, MAIKONG stands ready as your trusted manufacturing partner. Our commitment to quality, competitive pricing, and responsive service makes us an ideal supplier for procurement managers seeking reliable brass extrusion solutions.

Contact MAIKONG Today

Discover how our brass extrusion expertise can support your manufacturing needs.

Modern brass extrusion manufacturing process at MAIKONG’s facility

Modern brass extrusion manufacturing process at MAIKONG’s facility