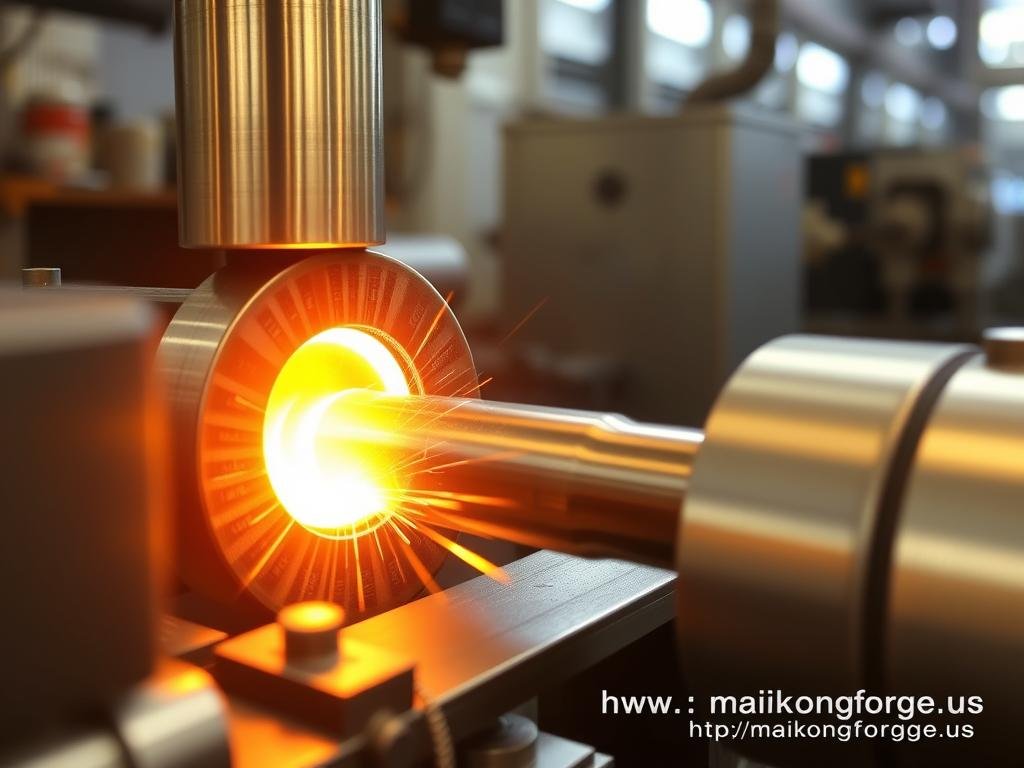

Early 20th century brass extrusion equipment showcasing the technological foundations of modern processes

Early 20th century brass extrusion equipment showcasing the technological foundations of modern processes

The Evolution of Brass Extrusion Technology

The journey of brass extrusion begins in the late 18th century, though the fundamental concept dates back to ancient civilizations. The industrial revolution brought mechanical innovations that made commercial brass extrusion viable. By forcing heated brass through specially designed dies, manufacturers could create consistent shapes with superior mechanical properties compared to casting methods.

Early Brass Extrusion Techniques

The earliest commercial brass extrusion operations in America emerged in the mid-19th century, primarily serving the growing demand for standardized brass components in the plumbing and hardware industries. These early processes were labor-intensive and limited in the complexity of profiles they could produce. Horizontal extrusion presses dominated the landscape, with most operations requiring significant manual intervention.

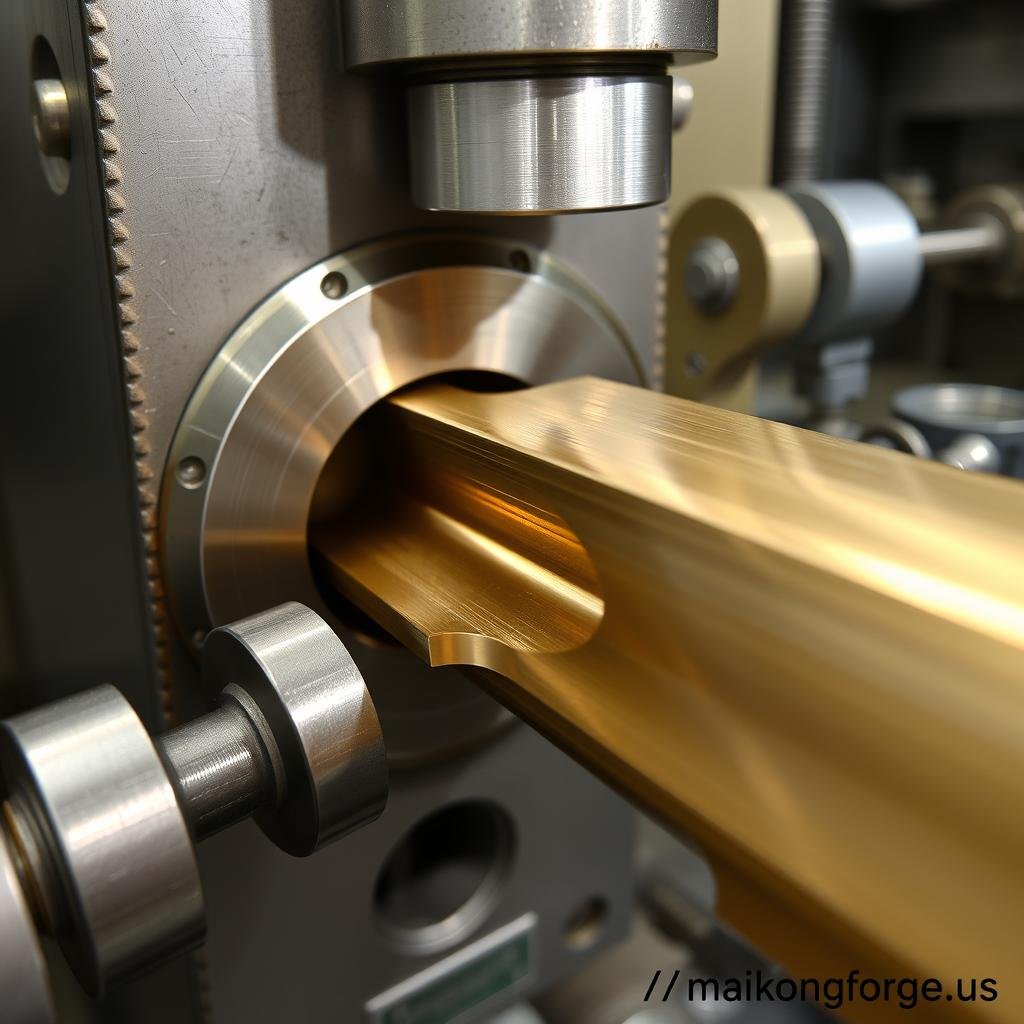

Modern brass extrusion process showcasing advanced die technology and precision control

Technological Breakthroughs in the 20th Century

The 20th century witnessed remarkable advancements in brass extrusion technology. The introduction of hydraulic presses in the early 1900s dramatically increased production capabilities, allowing for greater force application and more complex profile creation. By mid-century, continuous extrusion processes emerged, enabling higher production volumes while maintaining consistent quality.

The post-war industrial boom in America saw brass extrusion become a cornerstone manufacturing technique across multiple sectors. Innovations in metallurgy improved the workability of brass alloys, while advancements in die design expanded the range of achievable profiles. The introduction of computer-controlled systems in the latter half of the century brought unprecedented precision to the extrusion process.

MAIKONG’s Advanced Brass Extrusion Capabilities

Discover how our cutting-edge technology and expertise can deliver superior brass extrusion solutions for your specific requirements.

Request a Quote Today

MAIKONG’s state-of-the-art brass extrusion facility in GD, SZ

At MAIKONG, we’ve established ourselves as industry leaders in brass extrusion technology, combining traditional craftsmanship with cutting-edge innovation. Our comprehensive approach encompasses every aspect of the extrusion process, from initial design consultation through production and finishing.

Our Brass Extrusion Process Excellence

Advanced Equipment

Our facility in GD, SZ houses the latest generation of extrusion equipment, including hydraulic presses ranging from 800 to 2,500 tons. This diverse capacity allows us to handle projects of any scale, from small precision components to large architectural profiles. Our CNC-controlled systems ensure consistent quality across production runs of any size.

Material Expertise

MAIKONG works with a comprehensive range of brass alloys, including C26000 (Cartridge Brass), C36000 (Free-Cutting Brass), C38500 (Architectural Bronze), and many others. Our metallurgists can recommend the optimal alloy based on your application’s specific requirements for strength, machinability, corrosion resistance, and aesthetic appearance.

Custom Profile Design

Our engineering team excels in designing custom extrusion profiles that optimize performance while minimizing material usage. Using advanced CAD/CAM systems, we can develop profiles that perfectly match your specifications, often suggesting refinements that improve functionality or reduce production costs without compromising quality.

Comprehensive Quality Control

Quality assurance is integrated throughout our brass extrusion process. From raw material verification to final dimensional inspection, every step is monitored and documented. Our quality control laboratory is equipped with state-of-the-art testing equipment, ensuring that all products meet or exceed industry standards and customer specifications.

Quality Assurance in Brass Extrusion

MAIKONG’s comprehensive quality control process ensures exceptional brass extrusion products

At MAIKONG, quality is not just a department—it’s a core philosophy that permeates every aspect of our brass extrusion operations. Our comprehensive quality assurance system combines rigorous testing protocols with continuous process improvement to deliver products that consistently exceed customer expectations.

Our Quality Control Process

- Material Verification: Every batch of brass alloy undergoes chemical composition analysis to ensure it meets specified standards before entering our production process.

- Die Inspection: Extrusion dies are regularly inspected and maintained to prevent defects and ensure consistent profile dimensions across production runs.

- In-Process Monitoring: Advanced sensors and monitoring systems track critical parameters throughout the extrusion process, allowing for real-time adjustments to maintain optimal quality.

- Dimensional Verification: Extruded profiles undergo comprehensive dimensional inspection using precision measuring equipment, ensuring adherence to specified tolerances.

- Surface Quality Assessment: Trained inspectors examine surface finish and appearance, identifying and addressing any imperfections before products advance to finishing operations.

- Mechanical Testing: Random samples undergo mechanical testing to verify physical properties such as tensile strength, hardness, and ductility meet required specifications.

- Final Inspection: Completed products receive a final inspection before packaging and shipping to ensure they meet all quality requirements and customer specifications.

Certifications and Standards

MAIKONG maintains rigorous quality management systems certified to international standards. Our brass extrusion processes comply with relevant ASTM, ISO, and industry-specific standards, ensuring our products meet or exceed global quality requirements. Detailed quality documentation, including material certifications and inspection reports, is available upon request for all orders.

The Future of Brass Extrusion Technology

As we look to the future, brass extrusion technology continues to evolve with advancements in automation, material science, and sustainable manufacturing practices. MAIKONG remains at the forefront of these developments, continuously investing in research and equipment upgrades to maintain our position as industry leaders.

The enduring popularity of brass as an engineering and architectural material ensures that extrusion will remain a vital manufacturing process for decades to come. With its unique combination of properties and the precision afforded by modern extrusion techniques, brass continues to find new applications across diverse industries.

At MAIKONG, we’re proud to contribute to this rich industrial heritage while pushing the boundaries of what’s possible in brass extrusion technology. Our commitment to innovation, quality, and customer satisfaction drives everything we do, positioning us as your ideal partner for all brass extrusion needs.

Early 20th century brass extrusion equipment showcasing the technological foundations of modern processes

Early 20th century brass extrusion equipment showcasing the technological foundations of modern processes