In today’s competitive manufacturing landscape, aluminum forging stands as a cornerstone technology for industries demanding high-performance, lightweight components with superior structural integrity. As US industries continue to evolve, the demand for advanced aluminum forging solutions that balance quality, cost-effectiveness, and innovation has never been greater.At MAIKONG, we’re pioneering the next generation of aluminum forging technologies while providing comprehensive manufacturing solutions that help American businesses thrive in an increasingly competitive global market. This article explores the cutting-edge trends shaping the future of aluminum forging and how our expertise can benefit your specific industry needs.

MAIKONG’s Advanced Aluminum Forging Capabilities

With decades of specialized experience in aluminum forging, MAIKONG has established itself as a leading provider of premium forged components for diverse industrial applications. Our state-of-the-art facilities in GD, SZ combine traditional craftsmanship with cutting-edge technology to deliver exceptional results.

MAIKONG’s state-of-the-art aluminum forging facility in GD, SZ

MAIKONG’s state-of-the-art aluminum forging facility in GD, SZ

Core Aluminum Forging Processes

Our comprehensive aluminum forging capabilities include:

- Open die forging for large components

- Closed die forging for precision parts

- Upset forging for specialized applications

- Roll forging for cylindrical components

- Precision forging for tight tolerances

Each process is optimized through:

- Advanced simulation software

- Precision temperature control

- Automated handling systems

- Real-time quality monitoring

- Statistical process control

Equipment and Technical Specifications

Our facility houses 60+ CNC machines with a monthly capacity exceeding 100 tons of metal processing. Our aluminum forging equipment includes hydraulic presses ranging from 800 to 8,000 tons, providing versatility for components of various sizes and complexities.

| Equipment Type |

Specifications |

Capabilities |

Applications |

| Hydraulic Presses |

800-8,000 tons |

Precision forming, high pressure |

Structural components, engine parts |

| Heat Treatment Furnaces |

Precision ±5°C control |

Solution, aging, annealing |

Strength enhancement, stress relief |

| CNC Machining Centers |

3-5 axis capability |

Secondary operations, finishing |

Precision surfaces, complex features |

| Testing Equipment |

Advanced metallurgical lab |

Material verification, quality assurance |

Certification, performance validation |

Ready to Explore Custom Aluminum Forging Solutions?

Our engineering team is available to discuss your specific requirements and provide expert guidance on the most suitable forging processes for your application.

Request a Quote

Contact via WhatsApp

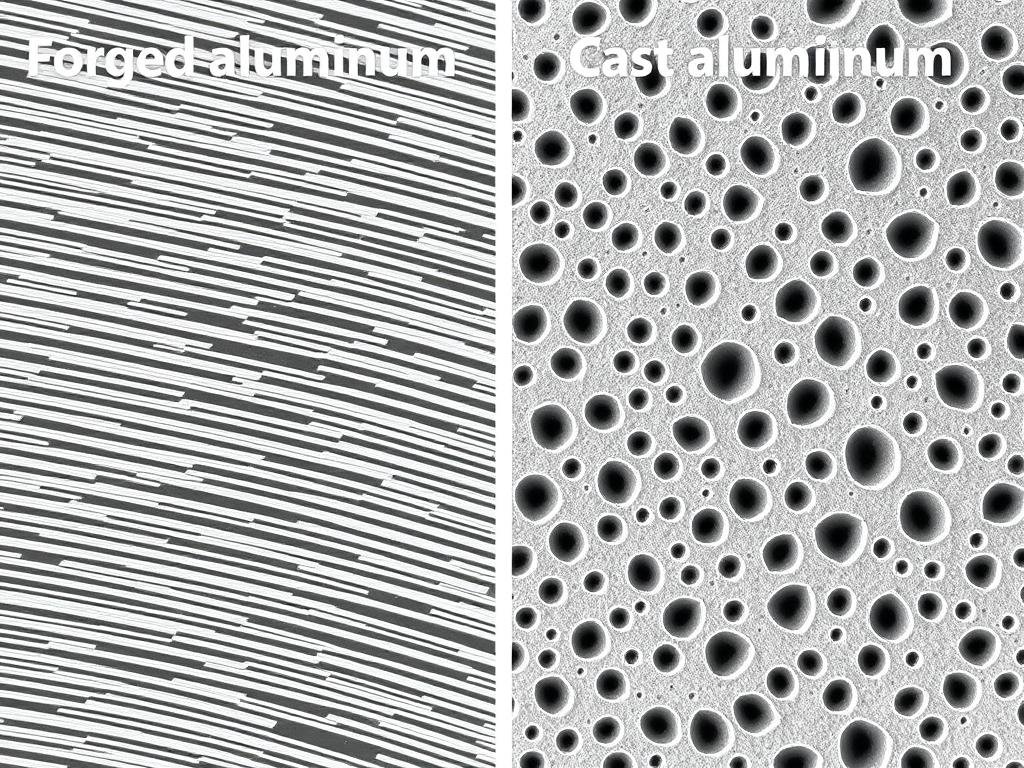

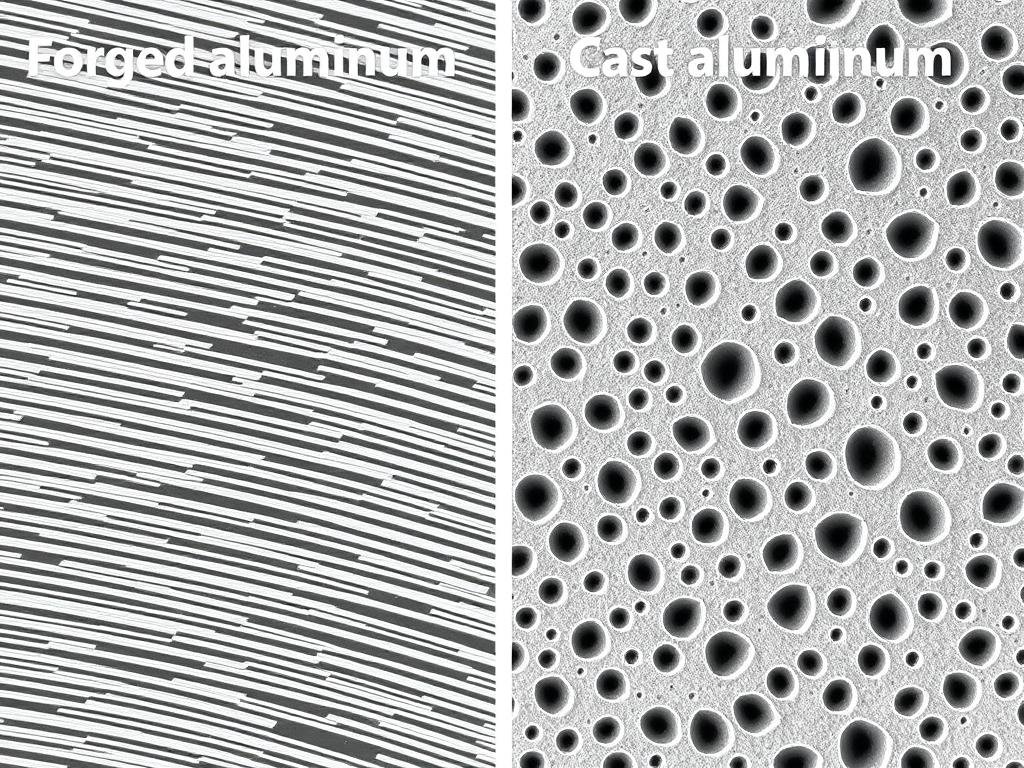

Technical Advantages of Aluminum Forging

Understanding the technical superiority of aluminum forging compared to alternative manufacturing methods is crucial for making informed production decisions. The forging process fundamentally transforms aluminum’s microstructure, resulting in components with exceptional mechanical properties.

Microscopic comparison: Forged aluminum (left) vs. cast aluminum (right) grain structure

Aluminum Forging vs. Casting: Comprehensive Comparison

When evaluating manufacturing methods for aluminum components, the differences between forging and casting are significant and can substantially impact performance, durability, and cost-effectiveness.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Heat Treatment Response |

✅ Responsive for controlled material properties |

Less predictable response |

| Grain Structure |

✅ Directional grain flow for improved properties |

No directional grain structure |

| Weight-to-Strength Ratio |

✅ High strength-to-weight ratio |

Bulkier parts may be needed |

| Ideal Applications |

Aerospace, automotive, critical structural components |

Consumer goods, decorative elements, complex shapes |

Optimal Strength-to-Weight Ratio

Aluminum forging delivers an exceptional balance of strength and weight, making it the preferred choice for applications where performance and efficiency are paramount. The forging process aligns the grain structure of aluminum, enhancing its mechanical properties without adding weight.

How the forging process aligns aluminum grain structure for enhanced strength

Overall Material Performance Rating

4.8

Forged Aluminum Excellence

Strength-to-Weight Ratio

4.8/5

Dimensional Stability

4.5/5

Corrosion Resistance

4.4/5

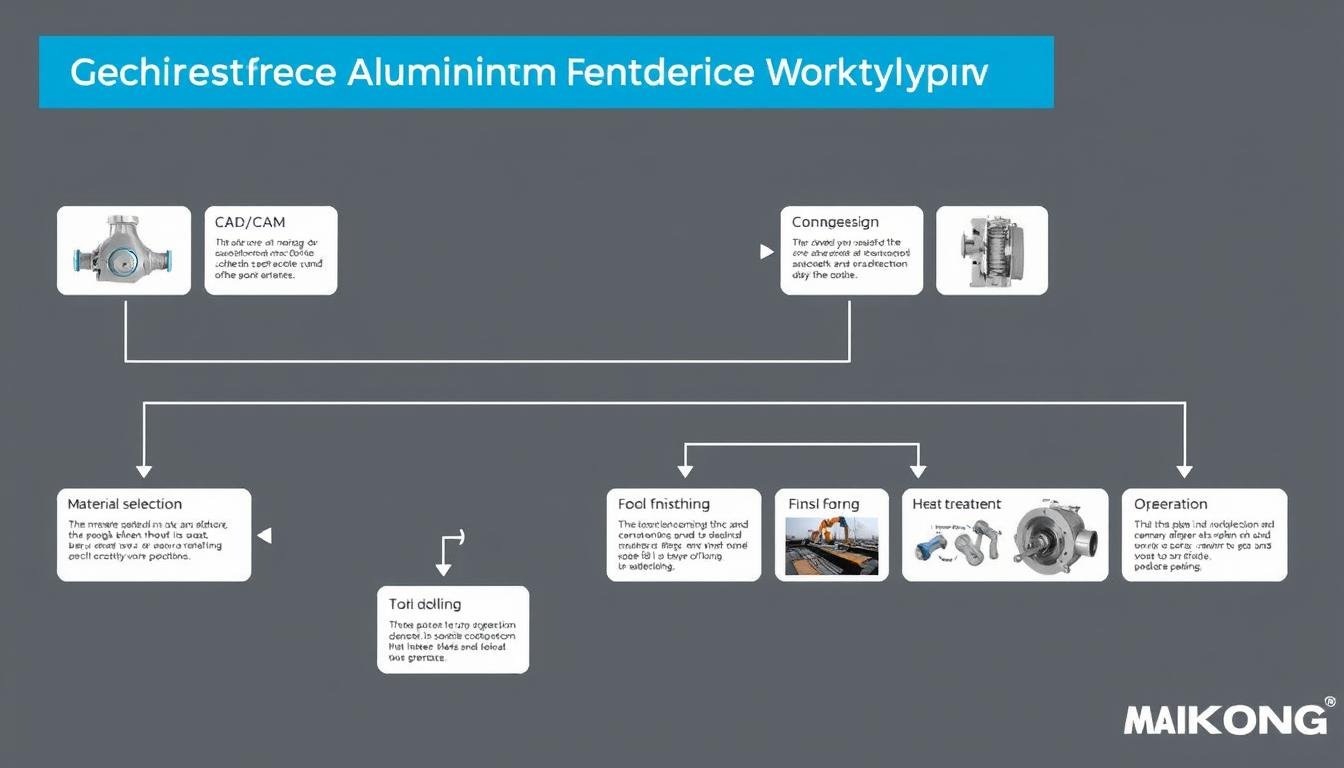

MAIKONG’s Full-Service Aluminum Forging Approach

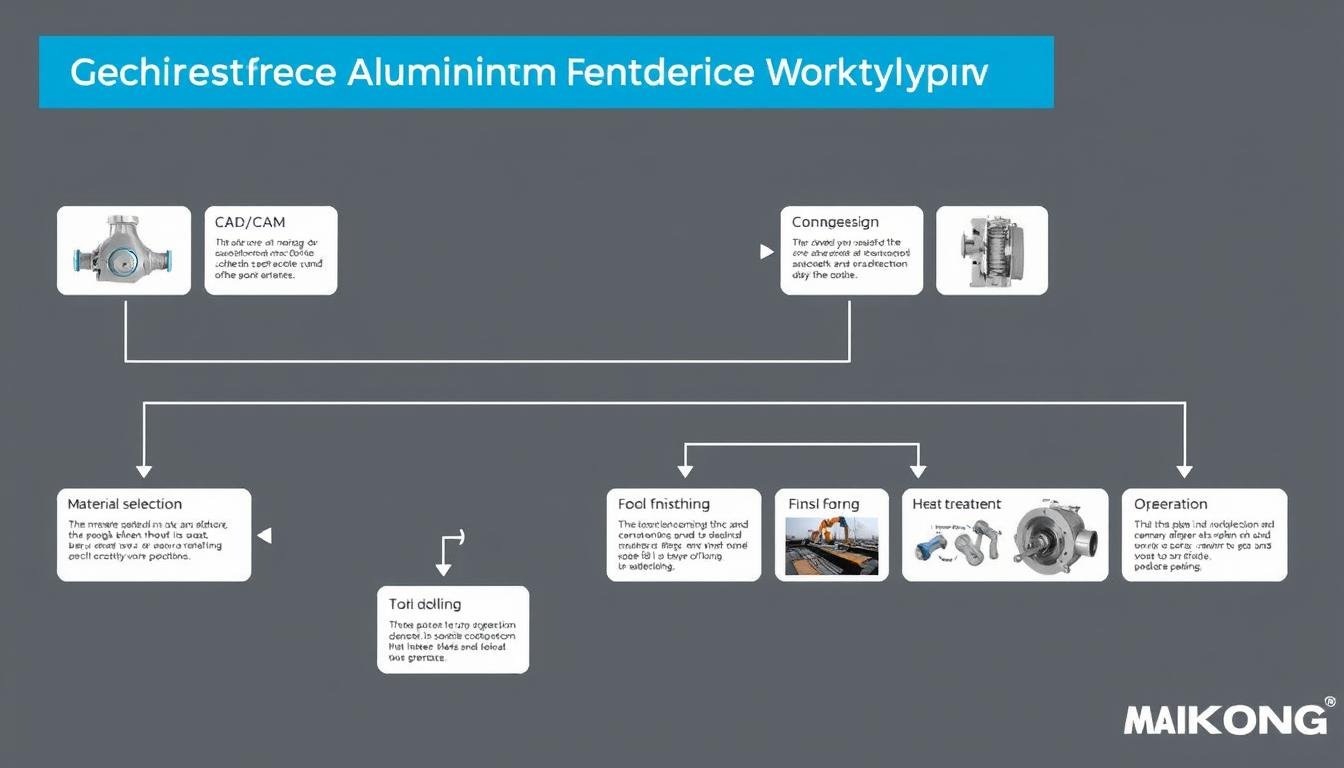

At MAIKONG, we’ve developed a comprehensive end-to-end approach to aluminum forging that addresses every aspect of component production. Our integrated services ensure quality, consistency, and cost-effectiveness throughout the manufacturing process.

MAIKONG’s end-to-end aluminum forging workflow

Design & Engineering

Our engineering team utilizes advanced CAD/CAM systems to optimize component design for the aluminum forging process. Through simulation and analysis, we identify potential issues early, ensuring manufacturability and performance.

- 3D modeling and simulation

- Finite element analysis

- Design for manufacturability

- Material optimization

Material Selection

Selecting the right aluminum alloy is crucial for component performance. Our metallurgists evaluate mechanical properties, machinability, heat treatment characteristics, and cost-effectiveness to recommend the optimal material for your application.

- Alloy 2014, 2219, 2618

- Alloy 5083, 5086, 5383

- Alloy 6061, 7050, 7075

- Custom alloy formulations

Tooling & Die Design

Precision tooling is the foundation of quality aluminum forging. Our tool design team creates custom dies that ensure dimensional accuracy, optimal material flow, and extended tool life, reducing your overall production costs.

- Computer-aided die design

- Flow simulation analysis

- Tool steel selection

- Preventive maintenance programs

Forging Process

Our aluminum forging workshop accommodates diverse specifications, with precision temperature control and automated handling systems ensuring consistency across production runs of any size.

- Closed die forging

- Open die forging

- Precision forging

- Custom process development

Heat Treatment

In-house heat treatment capabilities allow us to precisely control the mechanical properties of forged aluminum components. Our statistical analysis and documentation ensure consistent results that meet or exceed industry standards.

- Solution heat treatment

- Artificial aging

- Annealing processes

- Property verification testing

Precision Machining

Our state-of-the-art CNC machining centers provide secondary operations for aluminum forging, ensuring dimensional accuracy and surface finish requirements are met with precision and efficiency.

- 3-axis, 4-axis, 5-axis machining

- Swiss-type precision turning

- Surface grinding

- Laser engraving

MAIKONG’s advanced CNC machining center for secondary operations

Surface Treatment

We offer comprehensive surface finishing options to enhance the appearance, performance, and corrosion resistance of aluminum forging components, tailored to your specific application requirements.

- Anodizing (Type I, II, III)

- Powder coating

- Painting and laser engraving

- Sand blasting and polishing

Quality Assurance

Our rigorous quality control procedures ensure that every aluminum forging component meets stringent standards. From material verification to final inspection, we maintain comprehensive documentation for full traceability.

- Dimensional inspection

- Non-destructive testing

- Mechanical property testing

- ISO 9001:2015 certified processes

Logistics & Support

MAIKONG provides complete logistics solutions for your aluminum forging components, including inventory management, just-in-time delivery, and comprehensive technical support throughout the product lifecycle.

- Global shipping capabilities

- Inventory management

- Just-in-time delivery

- Technical documentation

Experience Our Comprehensive Aluminum Forging Services

From design to delivery, MAIKONG provides end-to-end solutions for your most demanding applications. Let our experts help you optimize your components for performance and cost-effectiveness.

Get a Custom Quote

Email Our Team

Future Trends in Aluminum Forging Technology

The aluminum forging industry continues to evolve with technological advancements that enhance efficiency, quality, and sustainability. At MAIKONG, we’re at the forefront of these innovations, implementing cutting-edge solutions that deliver superior results for our customers.

Advanced simulation software optimizing aluminum forging processes at MAIKONG

Emerging Technologies in Aluminum Forging

Digital Twin Technology

Digital twin technology creates virtual replicas of physical aluminum forging processes, enabling real-time monitoring, predictive maintenance, and process optimization without disrupting production.

Precision Temperature Control

Advanced temperature monitoring and control systems ensure optimal material flow during the aluminum forging process, resulting in enhanced grain structure and superior mechanical properties.

AI-Driven Process Optimization

Artificial intelligence algorithms analyze vast amounts of production data to identify patterns and optimize aluminum forging parameters, reducing defects and improving consistency.

Sustainable Manufacturing Practices

Energy-efficient furnaces, closed-loop cooling systems, and recycling programs minimize the environmental impact of aluminum forging operations while reducing production costs.

Material Innovations for Enhanced Performance

The development of new aluminum alloys specifically designed for forging applications continues to expand the capabilities and performance of forged components. These innovations enable lighter, stronger, and more durable parts for demanding applications.

MAIKONG’s metallurgical laboratory developing advanced aluminum alloys

“The future of aluminum forging lies in the integration of digital technologies, advanced materials, and sustainable practices. At MAIKONG, we’re committed to pioneering these innovations to deliver superior components for our customers’ most demanding applications.”

– MAIKONG Engineering Team

Industry Applications for Aluminum Forging

Aluminum forging delivers exceptional performance across a wide range of industries, each benefiting from the unique properties of forged aluminum components. MAIKONG specializes in providing tailored solutions for these diverse applications.

MAIKONG’s aluminum forged components for diverse industry applications

Aerospace

The aerospace industry demands the highest standards of performance and reliability, making aluminum forging the ideal manufacturing method for critical components.

- Structural components

- Landing gear parts

- Engine mounts

- Control system components

Automotive

Automotive manufacturers rely on aluminum forging to reduce vehicle weight while maintaining structural integrity and safety, improving fuel efficiency and performance.

- Suspension components

- Steering knuckles

- Connecting rods

- Wheel hubs and pistons

Medical

The medical industry benefits from the precision and reliability of aluminum forging for equipment components that require strength, lightweight properties, and corrosion resistance.

- Surgical instruments

- Imaging equipment components

- Medical device housings

- Rehabilitation equipment

Defense

Military and defense applications demand the exceptional reliability and performance that aluminum forging provides, particularly in mission-critical components.

- Weapons systems components

- Vehicle armor supports

- Communication equipment housings

- Tactical gear components

Energy

The energy sector relies on aluminum forging for components that can withstand extreme conditions while providing excellent thermal and electrical conductivity.

- Solar mounting systems

- Wind turbine components

- Oil and gas equipment

- Power transmission parts

Sports & Recreation

Sporting goods and recreational equipment benefit from the lightweight strength and durability of aluminum forging, enhancing performance and user experience.

- Bicycle components

- Golf club heads

- Climbing equipment

- Marine hardware

Precision aluminum forged components for automotive applications

Find the Perfect Aluminum Forging Solution for Your Industry

Our industry specialists understand the unique requirements of your application and can recommend the optimal forging solution to meet your performance and cost objectives.

Discuss Your Industry Needs

Why Choose MAIKONG for Your Aluminum Forging Needs

Selecting the right partner for your aluminum forging requirements is a critical decision that impacts product quality, cost-effectiveness, and overall success. MAIKONG offers a unique combination of technical expertise, manufacturing capabilities, and customer service that sets us apart in the industry.

MAIKONG’s quality control team ensuring excellence in every component

The MAIKONG Advantage

- Comprehensive in-house capabilities from design to delivery

- Advanced equipment and technology for superior quality

- Experienced engineering team with industry-specific expertise

- Competitive pricing with exceptional value

- Flexible production capacity for both small and large orders

- Rigorous quality control and material verification

- Global logistics and supply chain management

- Responsive customer service and technical support

Challenges of Other Suppliers

- Limited in-house capabilities requiring multiple vendors

- Outdated equipment leading to quality inconsistencies

- Generic solutions lacking industry-specific knowledge

- Hidden costs and unexpected charges

- Inflexible minimum order requirements

- Inconsistent quality control processes

- Logistics complications and delivery delays

- Poor communication and limited technical support

Our Commitment to Quality and Service

At MAIKONG, quality isn’t just a department—it’s a core value that permeates every aspect of our operation. Our ISO 9001:2015 certified processes ensure consistent quality across all aluminum forging components, backed by comprehensive documentation and traceability.

MAIKONG’s quality management system and certifications

How does MAIKONG ensure consistent quality across production runs?

MAIKONG implements a comprehensive quality management system that includes statistical process control, regular equipment calibration, and thorough inspection protocols. Every aluminum forging batch undergoes material verification, dimensional inspection, and performance testing to ensure consistency across all production runs, regardless of volume.

What makes MAIKONG’s aluminum forging services cost-effective?

Our integrated manufacturing approach eliminates the need for multiple vendors, reducing logistics costs and production time. Advanced simulation and process optimization minimize material waste and tooling wear, while our efficient operations in GD, SZ provide competitive labor rates without sacrificing quality. The result is superior aluminum forging components at highly competitive prices.

How does MAIKONG handle international shipping and logistics?

MAIKONG has established reliable global logistics networks to ensure timely delivery of aluminum forging components worldwide. We handle all aspects of international shipping, including documentation, customs clearance, and tracking. Our logistics team works closely with customers to determine the most cost-effective shipping methods while maintaining product integrity throughout transit.

Become a MAIKONG Distribution Partner in the US

We’re actively seeking US distribution partners to represent our high-quality aluminum forging services. Join our network and offer your customers access to premium forged components at competitive prices.

Explore Partnership Opportunities

Email: Lucy@maikongforge.us

Embracing the Future of Aluminum Forging with MAIKONG

As industries continue to evolve and demand higher-performance components, aluminum forging remains at the forefront of manufacturing technology, delivering unmatched strength, durability, and efficiency. MAIKONG is committed to advancing these capabilities through continuous innovation, investment in cutting-edge equipment, and development of our technical expertise.

By choosing MAIKONG as your aluminum forging partner, you gain access to comprehensive manufacturing solutions that optimize performance, reduce costs, and accelerate time-to-market. Our customer-centric approach ensures that your specific requirements are met with precision and reliability, backed by responsive service and technical support throughout the product lifecycle.

Contact us today to discover how MAIKONG’s advanced aluminum forging capabilities can enhance your products and streamline your manufacturing processes. Together, we’ll forge a path to success in today’s competitive global market.

Start Your Aluminum Forging Journey with MAIKONG

Take the first step toward superior components with our expert team. We’re ready to discuss your requirements and provide tailored solutions for your most demanding applications.

Request a Consultation

Call Us: +86 13-51090-74-01

MAIKONG’s state-of-the-art aluminum forging facility in GD, SZ

MAIKONG’s state-of-the-art aluminum forging facility in GD, SZ