In today’s manufacturing landscape, sustainability isn’t just a buzzword—it’s a business imperative. Aluminum forging stands at the forefront of sustainable manufacturing practices, offering exceptional strength-to-weight ratios, durability, and recyclability. At MAIKONG, we’re pioneering advanced aluminum forging techniques that not only deliver superior performance but also contribute to a more sustainable manufacturing ecosystem across America.

The Sustainable Advantages of Aluminum Forging

The aluminum forging process represents a significant advancement in sustainable manufacturing practices. By utilizing precise pressure and temperature control, we create components with exceptional structural integrity while minimizing material waste and energy consumption.

Environmental Benefits of Aluminum Forging

- Infinite recyclability without property degradation

- 75% of all aluminum ever produced is still in use today

- Energy requirements for new aluminum production reduced by 25% since 1995

- Carbon footprint reduced by nearly 40% in modern forging processes

- Lightweight properties reduce transportation emissions

When compared to traditional manufacturing methods, aluminum forging offers superior performance with a significantly lower environmental impact. The process aligns perfectly with America’s growing emphasis on sustainable manufacturing practices and reduced carbon emissions across industrial sectors.

MAIKONG’s Advanced Aluminum Forging Process

At MAIKONG, we’ve refined our aluminum forging process to maximize both performance and sustainability. Our comprehensive approach ensures optimal results from initial design through final delivery.

Material Selection

We carefully select aluminum alloys based on mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness for each application.

CAD/CAM Design

Our advanced analysis software facilitates early-stage issue identification and optimization, ensuring efficient production and superior results.

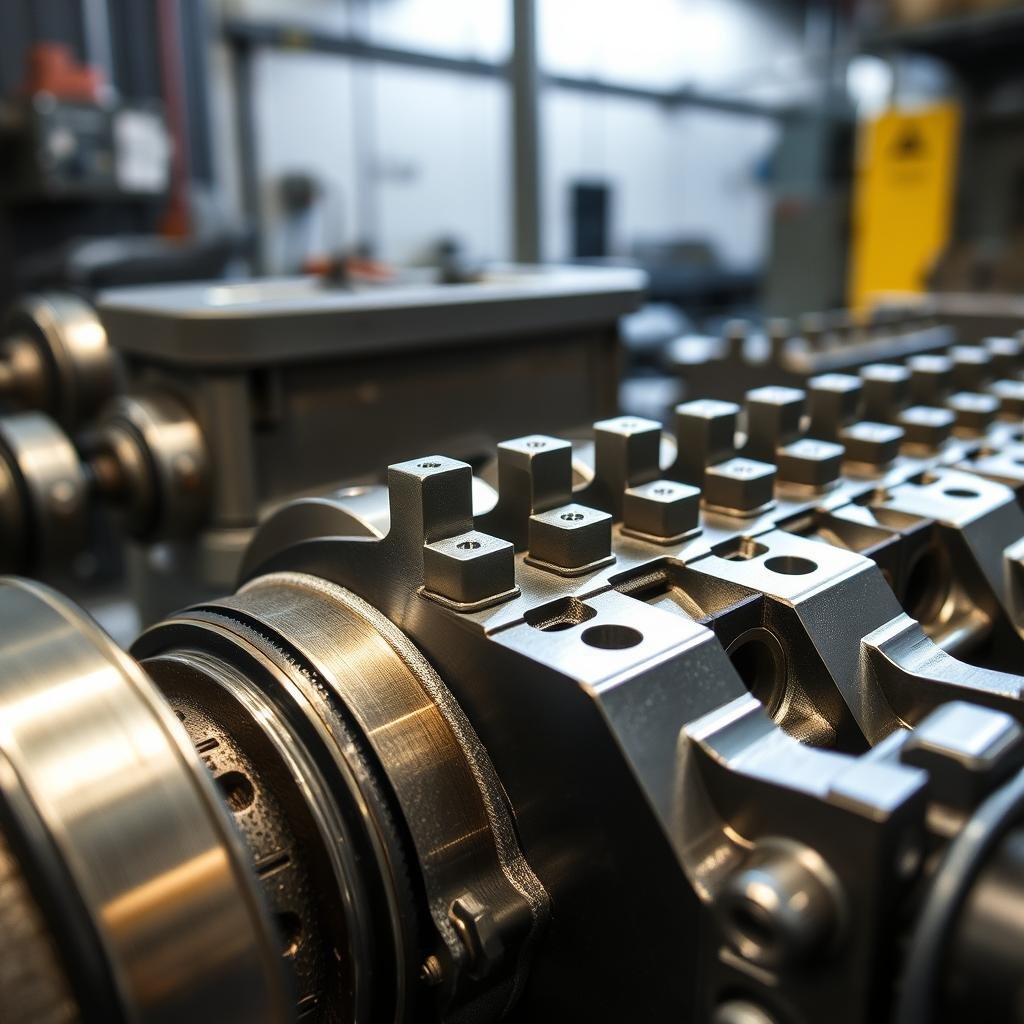

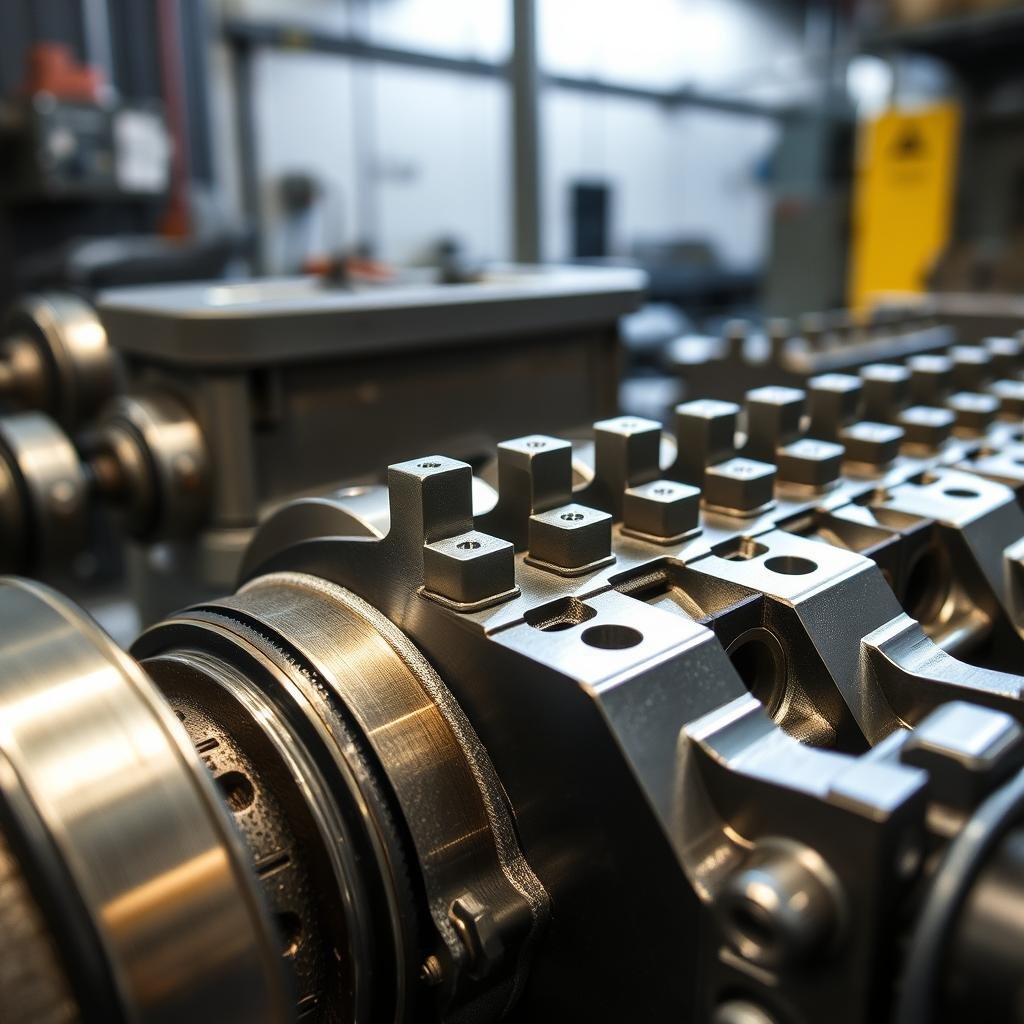

Precision Tooling

Our tooling design ensures initial quality, while regular maintenance preserves consistency—both critical for producing high-quality forgings.

Forging Process

Our forging workshop is equipped to accommodate diverse aluminum forging specifications with precision hydraulic presses and temperature control systems.

Heat Treatment

We conduct comprehensive statistical analysis and documentation for our in-house heat treatment to ensure optimal material properties.

Quality Control

Our rigorous quality control procedures ensure that every forged component meets stringent standards for dimensional accuracy and material integrity.

Aluminum Forging vs. Casting: The Sustainable Choice

Understanding the differences between aluminum forging and casting is crucial for making informed manufacturing decisions. The following comparison highlights why forging is often the superior choice for critical applications requiring strength, durability, and sustainability.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Weight-to-Strength Ratio |

High strength-to-weight ratio |

Bulkier parts may be needed for equivalent strength |

| Sustainability Impact |

Lower energy consumption, reduced waste |

Higher energy requirements, more material waste |

The superior grain structure alignment achieved through aluminum forging results in components that not only perform better but also contribute to sustainability through longer service life and reduced material requirements.

Experience the MAIKONG Difference

With 60+ CNC machines and 100+ tons monthly capacity, we deliver precision and quality at competitive prices.

Get a Quote Today

Or contact us directly: Lucy@maikongforge.us

Comprehensive Aluminum Forging Capabilities

MAIKONG offers a complete range of services to support your aluminum component needs from concept to completion. Our integrated approach ensures quality, consistency, and cost-effectiveness.

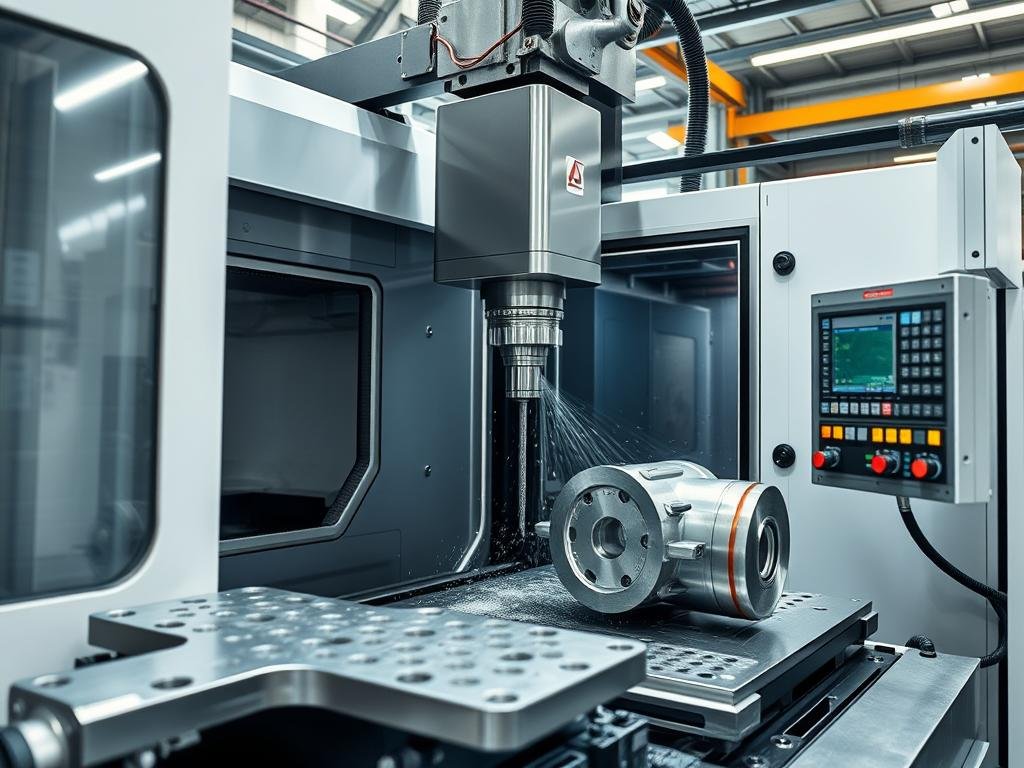

CNC Machining Services

MAIKONG operates 60+ CNC machines providing 100+ tons of metal processing capacity monthly. Our precision fabrication services include:

- CNC Turning for cylindrical shapes with superior surface finishes

- CNC Milling for complex prismatic shapes and flat surfaces

- Swiss-Type Machining for precision small parts and long shaft components

- Multi-axis machining for intricate geometries

- Surface grinding for exceptional finish quality

Surface Treatment Excellence

Our comprehensive surface finishing capabilities enhance both aesthetics and performance:

- Anodizing for improved corrosion resistance and appearance

- Precision painting with spectrophotometer color verification

- Laser engraving for permanent marking and identification

- Controlled sand blasting for optimal surface preparation

- Quality verification using adhesion testers and inspection equipment

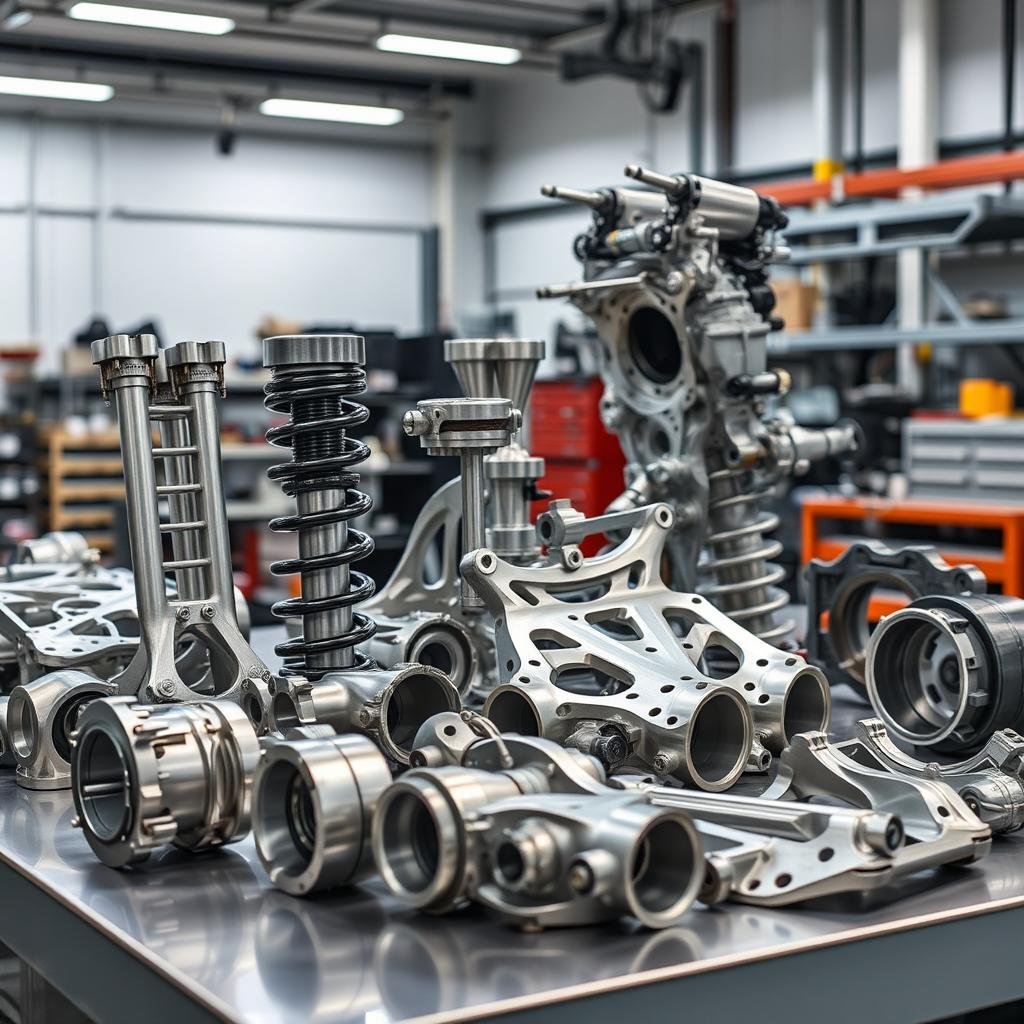

Industries Transformed by Aluminum Forging

The exceptional properties of forged aluminum make it ideal for applications where performance, safety, and sustainability are paramount. MAIKONG serves diverse industries with specialized aluminum forging solutions.

Aerospace

Forged aluminum components withstand harsh environmental conditions while providing the lightweight properties essential for fuel efficiency and performance in aerospace applications.

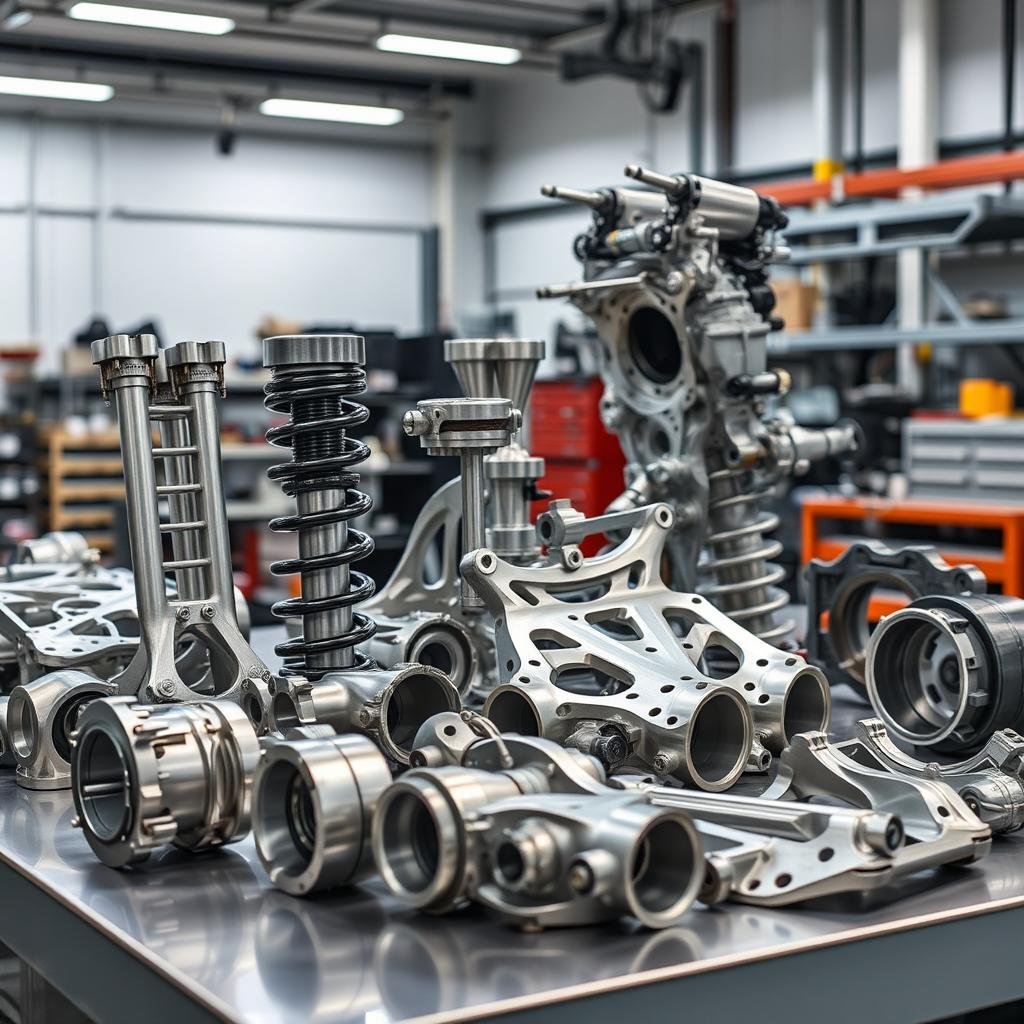

Automotive

From pistons to suspension components, forged aluminum delivers the strength, durability, and weight reduction that modern automotive manufacturers demand for improved efficiency and performance.

Defense

The exceptional reliability and performance of forged aluminum make it ideal for critical defense applications where failure is not an option and sustainability goals must be met.

Quality Assurance in Aluminum Forging

At MAIKONG, quality isn’t just a department—it’s a core value embedded in every aspect of our operation. Our comprehensive quality management system ensures consistent excellence in all our aluminum forging products.

Our Quality Commitment

- ISO 9001:2015 certified quality management system

- Comprehensive material testing and verification laboratory

- Statistical process control throughout production

- Systematic root cause analysis using advanced techniques

- 100% inspection of critical dimensions and properties

- Complete traceability from raw material to finished product

Our integrated approach to quality, from material selection through final inspection, ensures that every component we produce meets or exceeds the most demanding specifications while supporting sustainable manufacturing practices.

Advancing Sustainable Manufacturing Through Aluminum Forging

As America continues to prioritize sustainable manufacturing practices, aluminum forging stands as a proven technology that delivers exceptional performance with reduced environmental impact. At MAIKONG, we’re committed to pushing the boundaries of what’s possible in aluminum component manufacturing.

Our comprehensive capabilities—from advanced CAD/CAM design through precision forging, heat treatment, CNC machining, and surface finishing—provide a complete solution for your most demanding applications. By choosing MAIKONG as your aluminum forging partner, you’re not just getting superior components; you’re contributing to a more sustainable manufacturing future.

Our experts are standing by to discuss your aluminum forging needs and provide customized solutions.

Our experts are standing by to discuss your aluminum forging needs and provide customized solutions.