The History of Aluminum Forging represents one of the most significant technological developments in metallurgy. From its humble beginnings as a precious metal more valuable than gold to becoming an essential material in modern manufacturing, aluminum’s journey has transformed industries worldwide. At MAIKONG, we combine centuries of forging tradition with cutting-edge technology to deliver exceptional aluminum forging solutions. Join us as we explore the fascinating evolution of aluminum forging technology and how it continues to shape our world today.

The Early History of Aluminum Forging: From Precious Metal to Industrial Material

Early aluminum extraction using the Hall-Héroult process, circa 1886

Early aluminum extraction using the Hall-Héroult process, circa 1886

Before 1886, aluminum was considered a semi-precious metal, comparable in price to silver despite being the most abundant metallic element in the earth’s crust. The challenge wasn’t finding aluminum—it was extracting it from its ore in a cost-effective manner.

Ancient civilizations unknowingly used aluminum compounds for thousands of years. Persians made pottery from clay containing aluminum oxide over 7,000 years ago, while ancient Egyptians used aluminum compounds in medicines, dyes, and cosmetics. However, pure aluminum metal remained elusive due to its high affinity for oxygen.

The Breakthrough: Hall-Héroult Process

The turning point in the History of Aluminum Forging came in 1886 when two young inventors—Charles Martin Hall in the United States and Paul Héroult in France—independently discovered an economical method to extract aluminum using electrolysis. Their process, now known as the Hall-Héroult process, involved dissolving aluminum oxide in molten cryolite and passing an electric current through the solution.

This revolutionary discovery dramatically reduced the cost of aluminum production. What was once a precious metal became an industrial material available for widespread use. By 1888, Hall had founded the Pittsburgh Reduction Company (later renamed Alcoa) to commercialize his process, marking the birth of the aluminum industry in North America.

Evolution of Aluminum Forging Techniques in the United States

Early aluminum forging workshop in the United States, early 1900s

As aluminum became more accessible, forging techniques evolved rapidly. Early forging methods were adapted from those used with other metals like iron and steel, but aluminum’s unique properties required specialized approaches.

From World War I to Industrial Revolution

World War I accelerated aluminum forging development as the material’s lightweight properties made it ideal for aircraft components. During this period, open-die forging was the primary technique, where aluminum was hammered between flat or simply shaped dies.

By the 1920s and 1930s, closed-die forging techniques became more sophisticated, allowing for more complex shapes with tighter tolerances. The Great Depression, while economically devastating, ironically boosted aluminum’s popularity as manufacturers sought less expensive alternatives to silver and other precious metals for consumer goods.

Aircraft production utilizing aluminum forged parts during World War II

World War II: The Catalyst for Advanced Forging

World War II represented a watershed moment in the History of Aluminum Forging. The urgent need for lightweight, strong materials for aircraft and military equipment drove unprecedented innovation in aluminum forging techniques. Production capacity expanded dramatically, and new alloys were developed specifically for forging applications.

During this period, precision forging emerged, allowing manufacturers to create near-net-shape components that required minimal machining. This advancement significantly reduced production time and material waste, making aluminum forging more economical for mass production.

Modern Aluminum Forging Processes and Technologies

State-of-the-art aluminum forging facility with computer-controlled equipment

Today’s aluminum forging processes have evolved far beyond their historical origins. Modern techniques combine traditional metallurgical knowledge with cutting-edge technology to produce components with unprecedented precision and performance.

Types of Modern Aluminum Forging Processes

Open Die Forging

This traditional method involves shaping aluminum between multiple dies that don’t completely enclose the material. It’s ideal for producing large, simple shapes and remains valuable for certain applications.

Closed Die Forging

Also known as impression die forging, this process uses two or more dies containing the shape of the final product. It allows for more complex geometries and tighter tolerances, making it the most common forging method today.

Ring Rolling

A specialized forging technique used to produce seamless rings with high strength-to-weight ratios, commonly used in aerospace and automotive applications.

Precision Forging

This advanced technique achieves near-net shapes with minimal machining requirements, essential for manufacturing high-precision components with complex geometries.

Expert Aluminum Forging Solutions from MAIKONG

With decades of experience in aluminum forging, MAIKONG offers comprehensive solutions for your most demanding applications. Our state-of-the-art facilities in GD, SZ combine traditional craftsmanship with modern technology.

Get A Quick Quote

MAIKONG’s Comprehensive Aluminum Forging Services

MAIKONG’s advanced aluminum forging production line

At MAIKONG, we’ve built upon the rich History of Aluminum Forging to develop comprehensive manufacturing capabilities that meet the most demanding requirements. Our one-stop solution encompasses every stage of the aluminum forging process.

Our Full-Service Aluminum Forging Process

Design & Engineering

Our engineering team utilizes advanced CAD/CAM software to optimize designs for manufacturability, identifying potential issues early in the development process.

Material Selection

We carefully select aluminum alloys based on mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness for each application.

Tooling Design

Our precision tooling ensures initial quality, while regular maintenance preserves consistency—both critical for producing high-quality aluminum forgings.

Forging Process

Our forging workshop is equipped to accommodate diverse aluminum forging specifications, from small precision components to larger structural parts.

Heat Treatment

In-house heat treatment capabilities allow us to precisely control material properties, with comprehensive statistical analysis and documentation.

Surface Finishing

We offer various surface treatments including anodizing, painting, laser engraving, and sand blasting to enhance appearance, performance, and durability.

MAIKONG’s quality control laboratory for aluminum forged parts

CNC Machining Capabilities

MAIKONG offers extensive CNC machining services to complement our aluminum forging capabilities. With over 60 CNC machines providing 100+ tons of metal processing capacity monthly, we deliver precision fabrication for any volume requirement.

CNC Turning Services

Ideal for deep holes, machined threads, and cylindrical shapes with superior surface finishes, our CNC turning delivers precisely manufactured parts with fast turnaround.

CNC Milling Services

Our multi-axis CNC milling creates complex prismatic shapes and flat surfaces without fixed tooling, offering flexibility and extreme accuracy.

CNC SWISS Type Machining

Specializing in precision small parts and long shaft components, our equipment features dual spindles and multi-axis capabilities for one-stop solutions.

Advantages of Aluminum Forging Over Other Manufacturing Methods

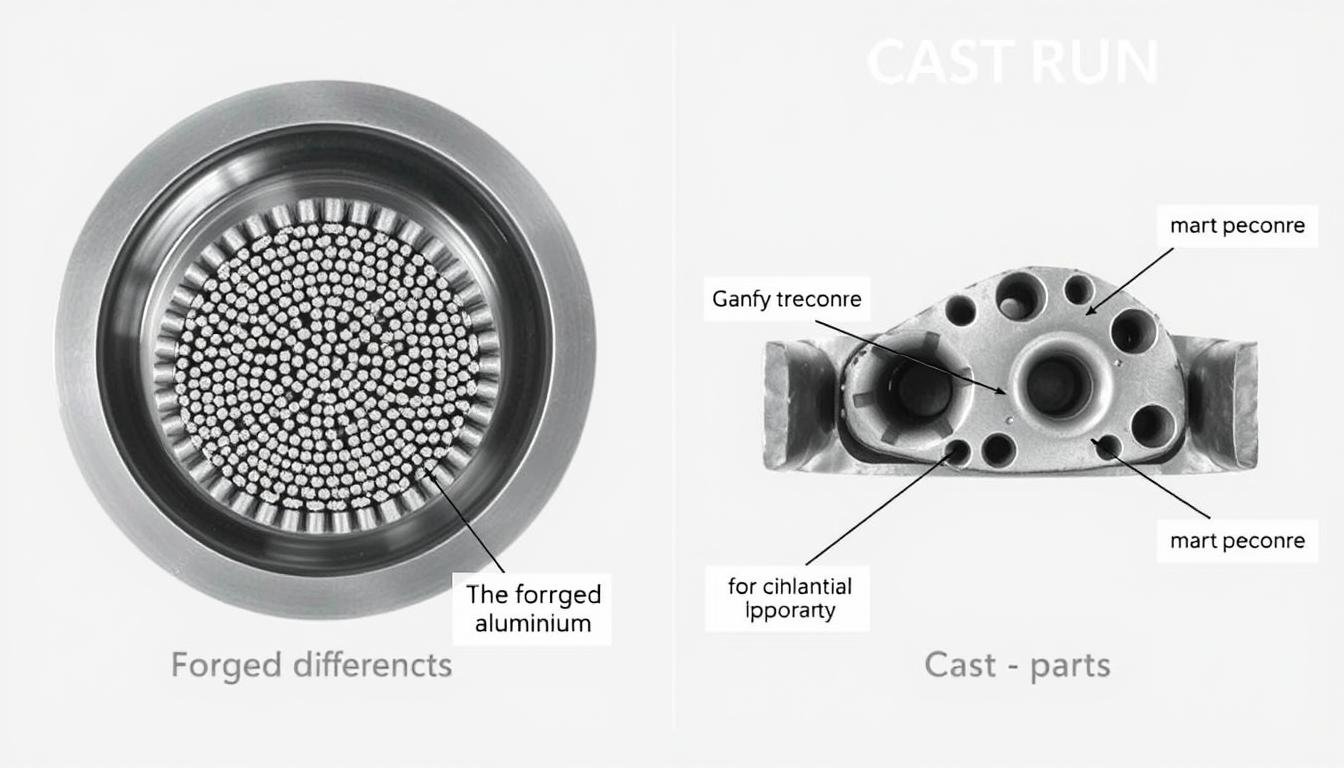

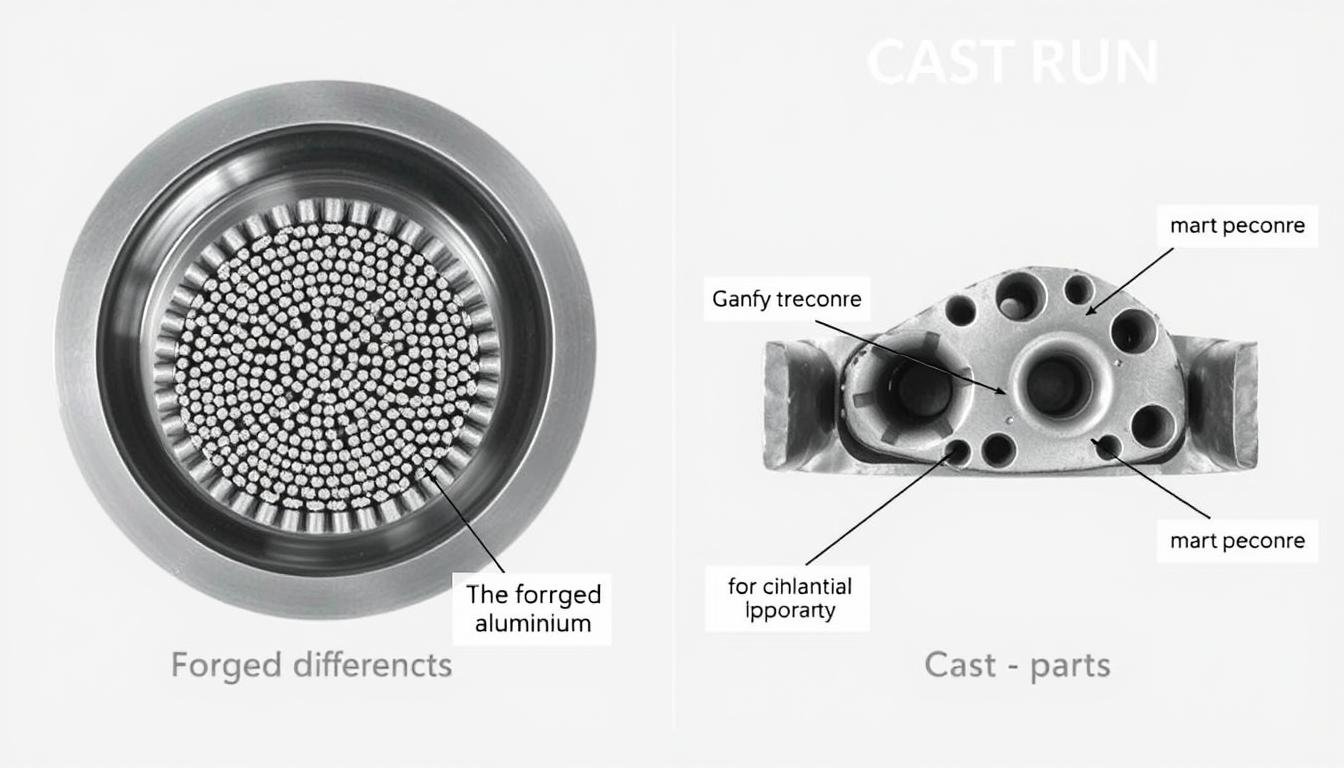

Comparison of grain structure: forged aluminum (left) vs. cast aluminum (right)

Throughout the History of Aluminum Forging, the process has consistently demonstrated significant advantages over alternative manufacturing methods like casting and machining from solid stock.

Forging vs. Casting: The MAIKONG Advantage

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Weight-to-Strength Ratio |

High strength-to-weight ratio |

Bulkier parts may be needed |

| Ideal Applications |

Aerospace, automotive, medical devices |

Consumer goods, simple parts, non-critical sectors |

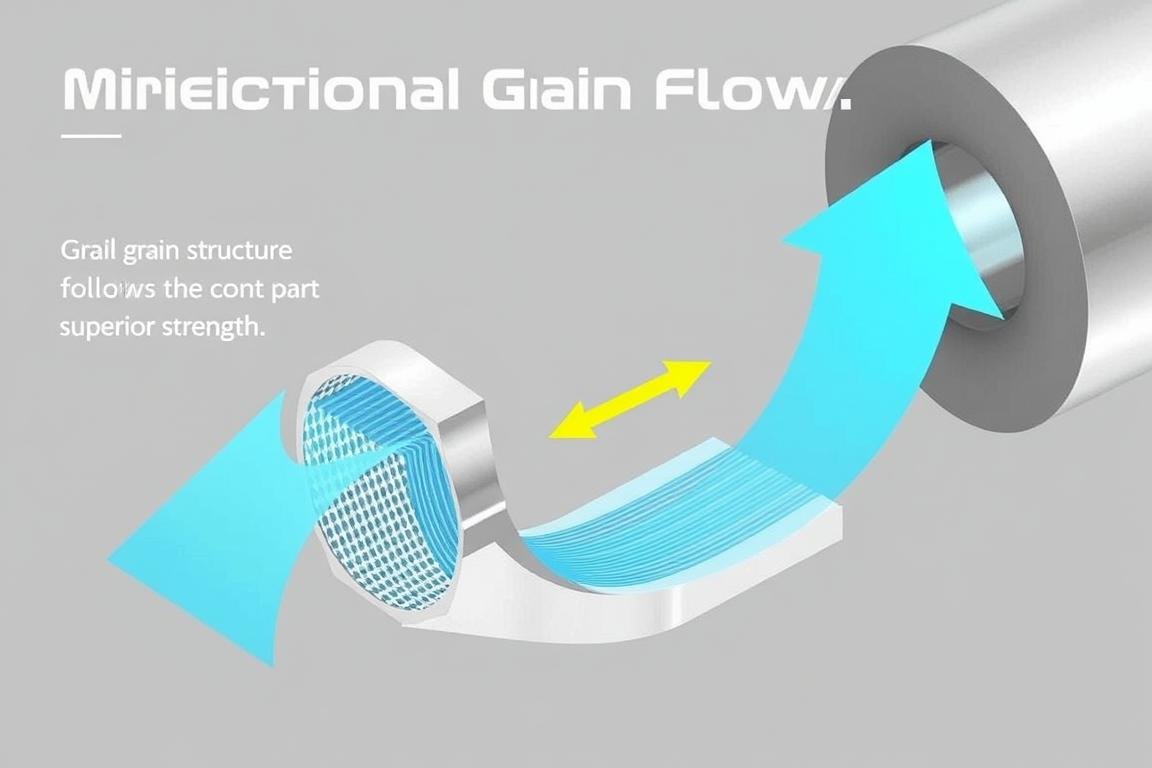

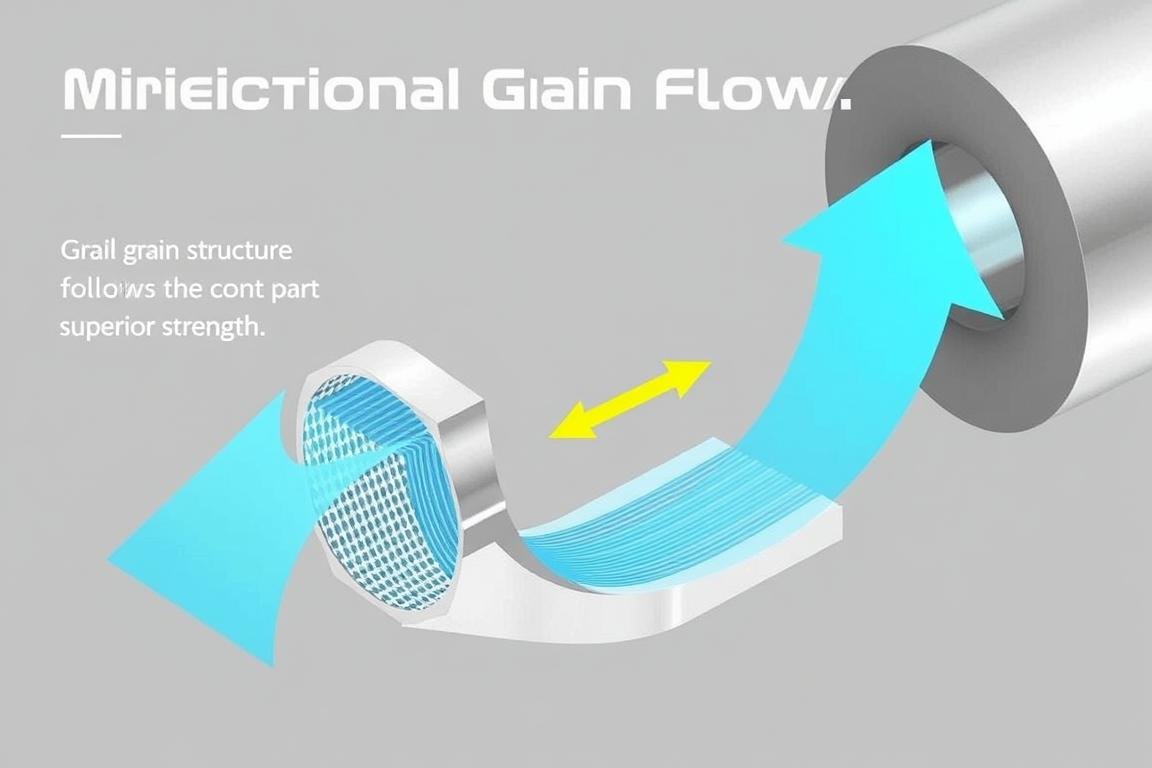

Optimal Strength-to-Weight Ratio

The forging process aligns the grain structure of aluminum, enhancing its mechanical properties. This results in components with an optimal strength-to-weight ratio—a critical consideration in industries prioritizing performance, efficiency, and safety.

Visualization of directional grain flow in forged aluminum components

At MAIKONG, we leverage these inherent advantages of aluminum forging to deliver components that consistently outperform alternatives in demanding applications. Our engineering team works closely with clients to optimize designs specifically for the forging process, maximizing the benefits of this superior manufacturing method.

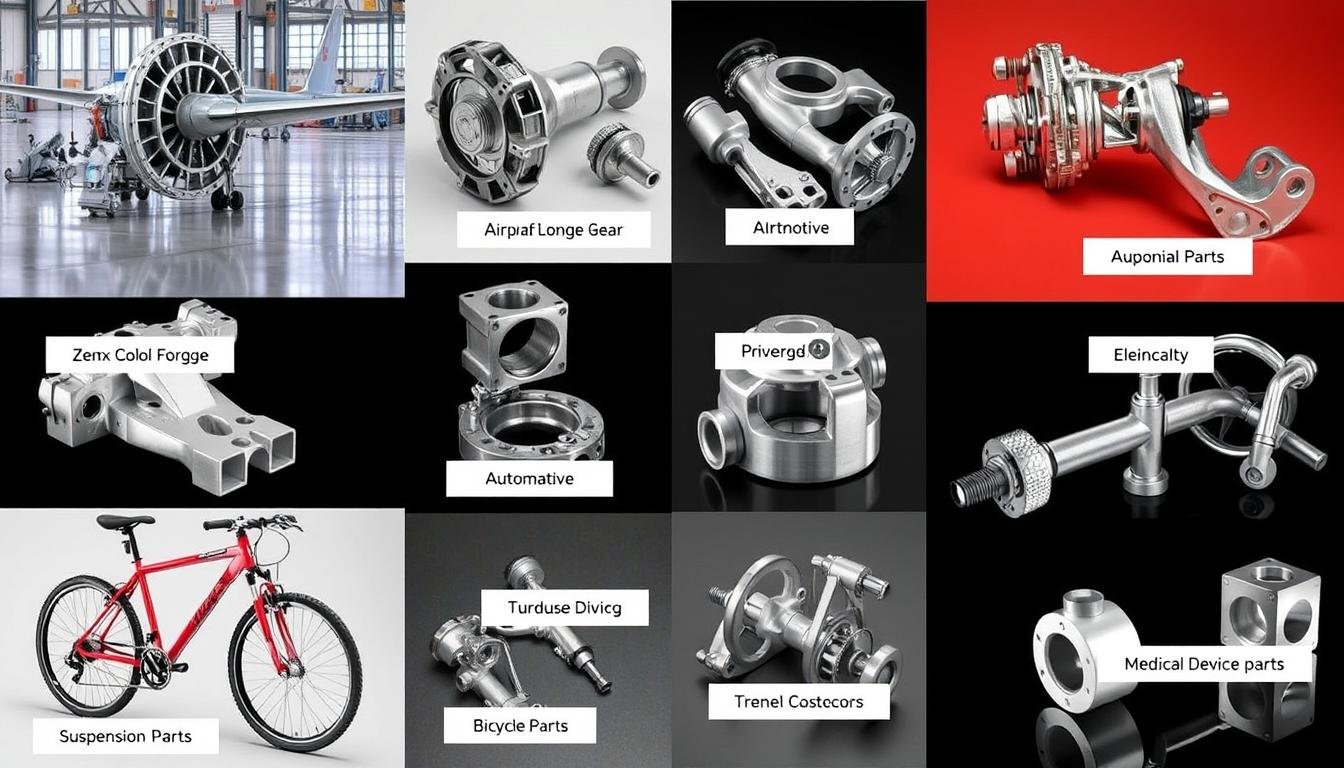

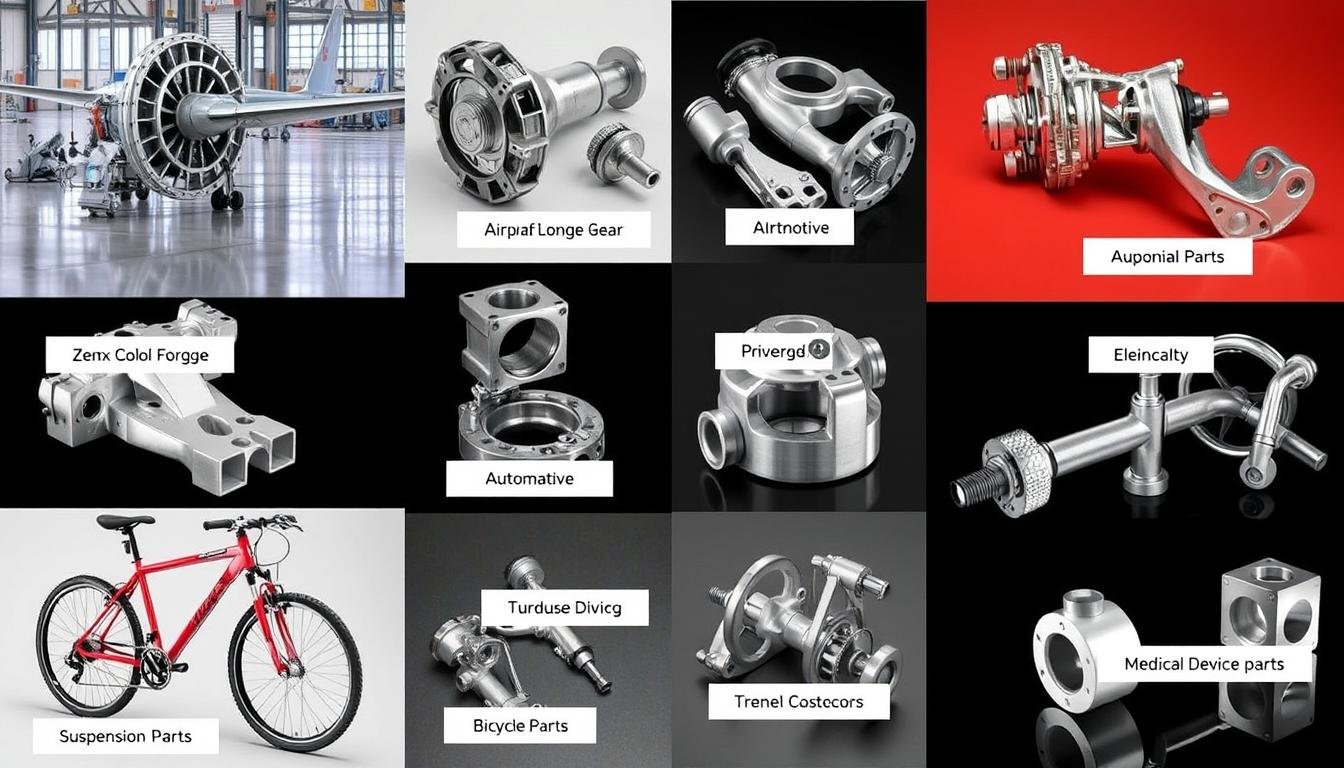

Industry Applications and Case Studies

Diverse applications of aluminum forged components across industries

The History of Aluminum Forging has seen the technology applied across an increasingly diverse range of industries. Today, aluminum forged components are critical in applications where performance, reliability, and weight are paramount concerns.

Key Industries Served by MAIKONG

Aerospace

Aluminum forgings are essential in aircraft structural components, landing gear, and engine parts where high strength-to-weight ratio and reliability are critical safety factors.

Automotive

From suspension components to engine parts, aluminum forgings help reduce vehicle weight, improve fuel efficiency, and enhance performance in modern automobiles.

Medical Devices

Precision aluminum forgings provide the strength, biocompatibility, and reliability needed for surgical instruments and medical equipment.

Sporting Equipment

Bicycle components, golf clubs, and other sporting goods benefit from the lightweight strength and durability of forged aluminum parts.

Electronics

Heat sinks, chassis components, and structural elements for electronic devices leverage aluminum’s thermal conductivity and strength.

Construction

Structural components, fasteners, and decorative elements utilize aluminum forgings for their corrosion resistance and durability.

MAIKONG’s precision aluminum forged components for aerospace applications

At MAIKONG, we’ve successfully delivered aluminum forging solutions across these industries and more. Our expertise in material selection, process optimization, and quality control ensures that each component meets the specific requirements of its intended application.

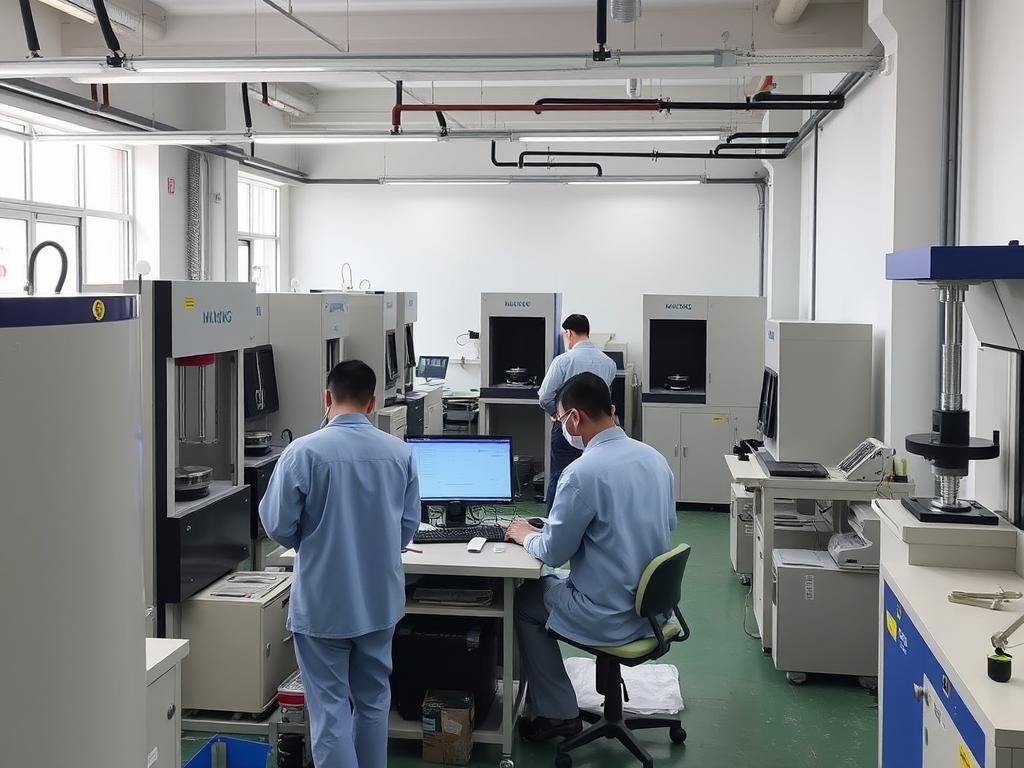

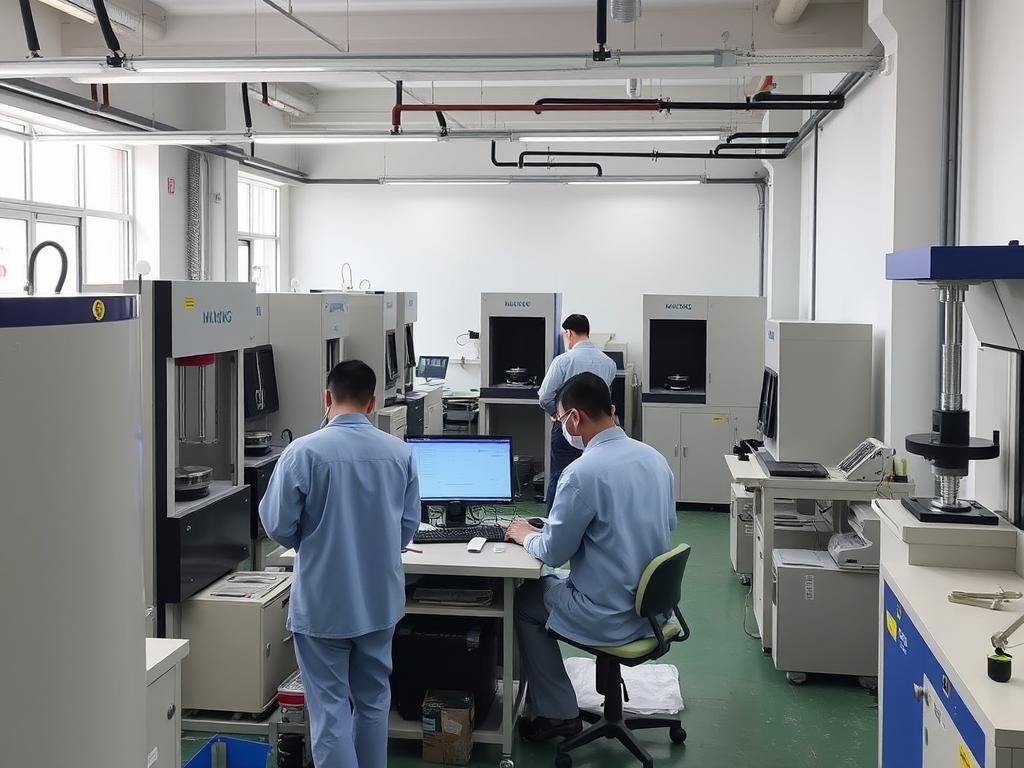

MAIKONG’s Quality Assurance and Manufacturing Capabilities

MAIKONG’s comprehensive quality testing laboratory

Quality has been a driving force throughout the History of Aluminum Forging, and at MAIKONG, we maintain this tradition with rigorous quality assurance processes and state-of-the-art manufacturing capabilities.

Our Quality Management System

MAIKONG’s quality management system encompasses every aspect of our operation, from material sourcing to final inspection. We employ advanced testing methods including:

- Non-destructive testing (NDT) for internal integrity verification

- Dimensional inspection using coordinate measuring machines (CMMs)

- Material composition analysis via spectrometry

- Mechanical property testing including tensile, hardness, and impact tests

- Metallurgical analysis to verify grain structure and flow

- Surface finish measurement and visual inspection

- Heat treatment verification through hardness testing

- Statistical process control (SPC) for continuous improvement

Manufacturing Facilities

Our manufacturing facility in GD, SZ houses a comprehensive range of equipment for aluminum forging and related processes:

- Hydraulic forging presses ranging from 500 to 3,000 tons

- Uniform heat treatment furnaces with precise temperature control

- Over 60 CNC machines with multi-axis capabilities

- Automated surface finishing equipment

- Advanced die design and manufacturing capabilities

- Specialized material handling equipment

- Comprehensive inspection and testing facilities

- Environmentally controlled production areas

This extensive infrastructure allows us to maintain control over every aspect of the production process, ensuring consistent quality and timely delivery for our customers worldwide.

Future Trends in Aluminum Forging Technology

Next-generation aluminum forging technology with advanced automation and AI integration

As we look to the future, the History of Aluminum Forging continues to evolve with exciting new developments on the horizon. At MAIKONG, we stay at the forefront of these innovations to deliver cutting-edge solutions to our customers.

Emerging Technologies and Approaches

Advanced Simulation and Modeling

Computational modeling and simulation tools are revolutionizing forging design, allowing for virtual optimization of processes before physical production begins. These technologies reduce development time and improve first-time quality.

Artificial Intelligence and Machine Learning

AI and machine learning applications are increasingly being integrated into forging operations, optimizing process parameters in real-time and predicting potential issues before they occur.

New Aluminum Alloys

Ongoing research into advanced aluminum alloys promises materials with even better combinations of strength, weight, and formability specifically designed for forging applications.

Sustainable Manufacturing

Energy-efficient forging processes and increased use of recycled aluminum are reducing the environmental impact of aluminum forging while maintaining or improving performance characteristics.

At MAIKONG, we’re actively investing in these technologies to enhance our capabilities and provide even greater value to our customers. Our commitment to innovation ensures that we’ll continue to be a leader in aluminum forging for decades to come.

Partner with MAIKONG for Your Aluminum Forging Needs

MAIKONG’s team of aluminum forging experts

The History of Aluminum Forging has transformed from precious metal to industrial workhorse, enabling countless innovations across industries. At MAIKONG, we’re proud to continue this legacy by combining traditional expertise with modern technology to deliver exceptional aluminum forging solutions.

With our comprehensive capabilities in aluminum forging, CNC machining, and related services, we offer a one-stop solution for your most demanding applications. Our commitment to quality, innovation, and customer satisfaction makes us the ideal partner for your manufacturing needs.

Contact MAIKONG Today

Ready to discuss your aluminum forging requirements? Our team of experts is standing by to help you find the perfect solution for your application.

Become a MAIKONG Agent in the USA

We’re recruiting agents across the United States to represent our high-quality, cost-effective aluminum forging and machining services. Join our team and grow your business with MAIKONG’s comprehensive manufacturing capabilities.

Apply to Become an Agent

Early aluminum extraction using the Hall-Héroult process, circa 1886

Early aluminum extraction using the Hall-Héroult process, circa 1886