In the world of metal manufacturing, the choice between forged aluminum and cast aluminum can significantly impact the performance, durability, and reliability of your components. When applications demand superior mechanical properties and structural integrity, understanding these differences becomes crucial for making informed decisions. This comprehensive guide explores the distinct advantages that set forged aluminum apart from its cast counterparts, helping you determine the optimal manufacturing approach for your critical applications.

Understanding Forged Aluminum: The Foundation of Superior Performance

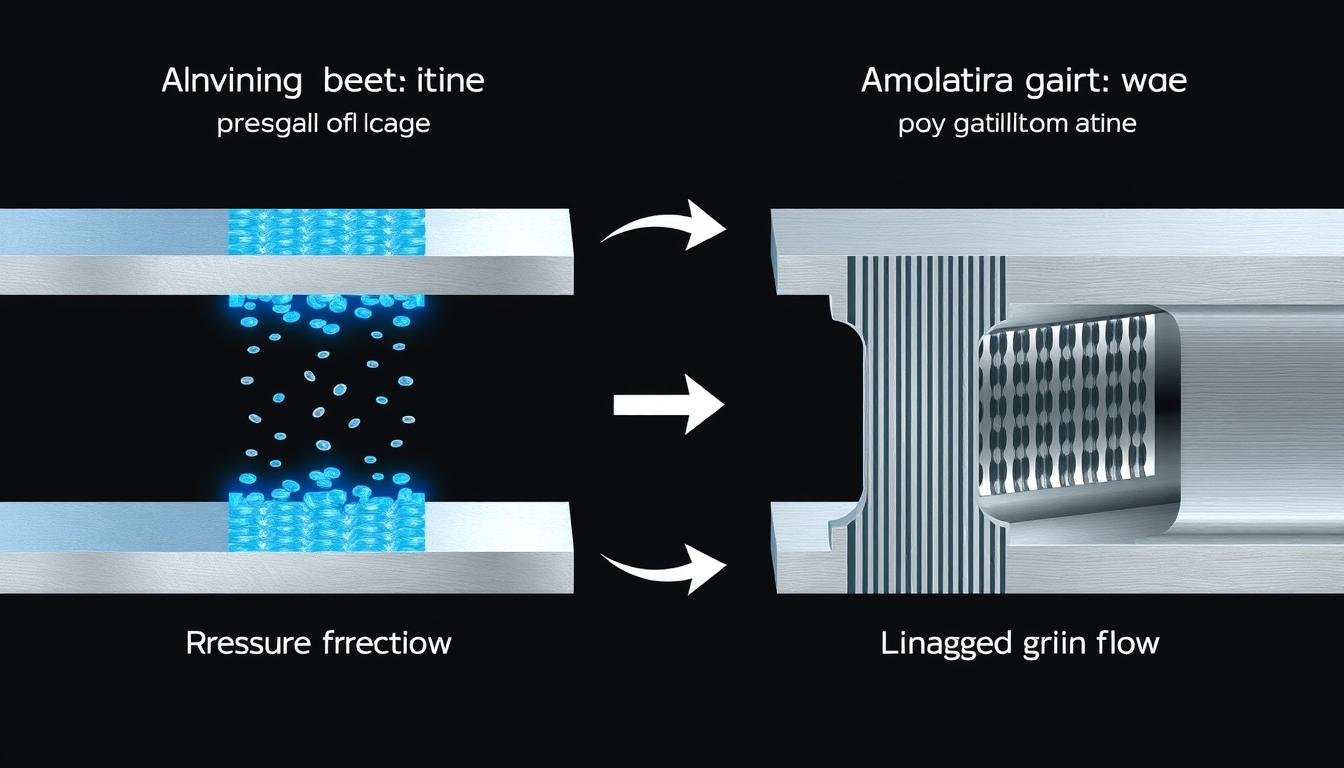

The forged aluminum process creates superior internal grain structure through controlled pressure application

The forged aluminum process creates superior internal grain structure through controlled pressure application

Forged aluminum refers to aluminum that has been shaped using compression force under high pressure. During the forging process, manufacturers heat solid aluminum pieces and then hammer, press, or roll them into the desired shape. Unlike casting, which involves pouring molten metal into molds, forging fundamentally alters the metal’s internal structure, creating a denser, stronger material with enhanced mechanical properties.

The forging process deliberately rearranges the metal’s grain structure, aligning it along the lines of force application. This strategic realignment significantly improves the material’s strength, toughness, and overall performance characteristics. The result is a refined grain structure with superior mechanical properties that make forged aluminum the preferred choice for applications where performance and safety are paramount.

Mechanical Advantages of Forged Aluminum vs. Cast Aluminum

When comparing forged aluminum to cast aluminum, several key mechanical advantages become apparent. These differences stem directly from the manufacturing processes and significantly impact the performance capabilities of the final components.

Superior Strength and Structural Integrity

The most significant advantage of forged aluminum is its enhanced strength. The forging process compresses the metal, eliminating internal voids and creating a more uniform, dense structure. This compression results in tensile strength values typically ranging from 45,000 to over 50,000 psi, significantly higher than cast aluminum’s 23,000 to 34,500 psi range.

This strength difference becomes critical in applications subjected to high stress, impact, or fatigue conditions. Forged aluminum components can withstand greater loads without deformation or failure, making them ideal for safety-critical applications in aerospace, automotive, and industrial equipment.

Enhanced Fatigue Resistance

Forged aluminum exhibits superior fatigue resistance compared to cast alternatives. The aligned grain structure created during forging allows the material to better withstand repeated stress cycles without developing cracks or failing. This enhanced fatigue life is particularly valuable in components subject to cyclic loading, vibration, or fluctuating stresses.

For applications like aircraft components, automotive suspension parts, or industrial machinery, this improved fatigue resistance translates to longer service life, reduced maintenance requirements, and enhanced safety margins.

Improved Impact Resistance

The dense, uniform structure of forged aluminum provides exceptional impact resistance. When subjected to sudden shocks or impacts, forged components absorb and distribute energy more effectively than their cast counterparts. This characteristic makes forged aluminum particularly valuable in applications where impact protection is critical.

The superior toughness of forged components helps prevent catastrophic failures in demanding environments, providing an additional safety margin for critical applications.

Comprehensive Comparison: Forged Aluminum vs. Cast Aluminum

| Comparison Categories |

Forged Aluminum |

Cast Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength (45,000-50,000+ psi) |

Lower tensile strength (23,000-34,500 psi) |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Grain Structure |

✅ Directional grain flow for improved properties |

No directional grain structure |

| Weight-to-Strength Ratio |

✅ High strength-to-weight ratio |

Bulkier parts may be needed for equivalent strength |

Need High-Performance Aluminum Components?

Discover how MAIKONG’s precision forged aluminum services can enhance your product performance and reliability.

Get a Custom Quote

The Science Behind Forged Aluminum‘s Superior Performance

Grain Structure Alignment Through the Forging Process

The exceptional performance of forged aluminum stems directly from its unique grain structure. During the forging process, the application of pressure causes the metal’s grains to deform and align along the direction of material flow. This alignment creates a fibrous structure that significantly enhances the material’s mechanical properties.

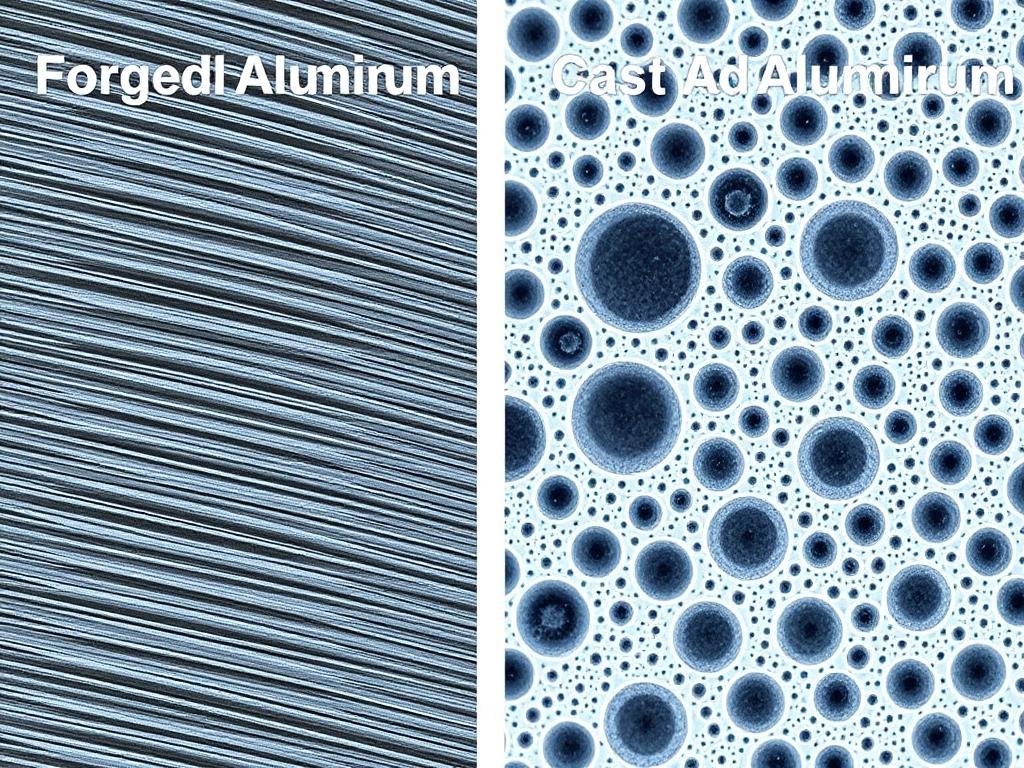

In contrast, cast aluminum forms with a random grain structure as the molten metal cools in a mold. This random orientation creates inherent weaknesses and potential failure points, particularly at grain boundaries. The controlled deformation during forging eliminates these weaknesses by creating a more cohesive, aligned internal structure.

Elimination of Internal Defects

Another critical advantage of the forging process is the elimination of internal defects commonly found in cast aluminum. Casting can introduce porosity, shrinkage cavities, and inclusions as the molten metal cools and solidifies. These defects act as stress concentrators and potential failure points under load.

The high pressure applied during forging effectively closes these voids and consolidates the material, resulting in a denser, more homogeneous structure. This defect elimination significantly contributes to the superior mechanical properties and reliability of forged aluminum components.

Optimizing the Strength-to-Weight Ratio with Forged Aluminum

The strength-to-weight ratio represents a fundamental engineering principle that balances material strength against weight—a critical consideration in industries prioritizing performance, efficiency, and safety. Aluminum’s naturally lightweight properties combined with the enhanced mechanical characteristics achieved through forging create an optimal balance that few other materials can match.

Through the forging process, aluminum’s internal grain structure is refined to deliver enhanced resilience and strength without adding weight. This makes forged aluminum components the optimal choice for applications that must withstand significant static and dynamic loads while maintaining minimal weight.

This optimized strength-to-weight ratio showcases true engineering excellence—a sophisticated combination of material science, metallurgy, and precision manufacturing. It embodies efficiency and performance, reshaping possibilities across industries from aerospace to automotive and beyond.

Weight Reduction Benefits

- Improved fuel efficiency in transportation applications

- Reduced energy consumption in moving components

- Easier handling and installation

- Lower shipping and logistics costs

- Reduced overall system weight

Strength Enhancement Benefits

- Higher load-bearing capacity

- Improved resistance to deformation

- Enhanced safety margins in critical applications

- Extended component lifespan

- Reduced maintenance requirements

Industry Applications of Forged Aluminum

The superior mechanical properties of forged aluminum make it the material of choice across numerous industries where performance, reliability, and safety are paramount. Let’s explore some key applications where forged aluminum demonstrates its exceptional value.

Aerospace

In aerospace applications, forged aluminum components provide the critical combination of lightweight construction and exceptional strength required for aircraft structural elements, landing gear components, and engine parts. The superior fatigue resistance and reliability of forged parts are essential in this safety-critical industry.

Automotive

The automotive industry relies on forged aluminum for components that require high strength and durability, such as suspension parts, connecting rods, crankshafts, and wheel hubs. These components benefit from the material’s excellent strength-to-weight ratio, contributing to improved vehicle performance and fuel efficiency.

Industrial Machinery

Industrial equipment benefits from forged aluminum‘s durability and reliability in high-stress applications. Components such as hydraulic cylinders, valves, and structural elements leverage the material’s superior mechanical properties to withstand demanding operating conditions and extend service life.

Medical Equipment

The medical industry utilizes forged aluminum for equipment components that require precision, reliability, and corrosion resistance. Surgical instruments, imaging equipment frames, and patient handling devices benefit from the material’s strength and lightweight properties.

Defense

Military and defense applications leverage forged aluminum for components that must perform reliably under extreme conditions. Weapon systems, vehicle components, and portable equipment benefit from the material’s durability, impact resistance, and weight advantages.

Sports Equipment

High-performance sports equipment, including bicycle components, golf club heads, and tennis racket frames, utilizes forged aluminum to achieve the optimal balance of strength, weight, and performance characteristics required by competitive athletes.

MAIKONG: Your Expert Partner for Forged Aluminum Solutions

At MAIKONG, we specialize in delivering premium forged aluminum components that meet the most demanding performance requirements across industries. Our comprehensive capabilities encompass the entire production process, from initial design consultation through final inspection and delivery.

Comprehensive Forged Aluminum Services

- Design Optimization: Our engineering team collaborates with clients to optimize component designs for the forging process, ensuring maximum performance and cost-effectiveness.

- Material Selection: We help identify the ideal aluminum alloy for your specific application requirements, balancing mechanical properties, machinability, and cost considerations.

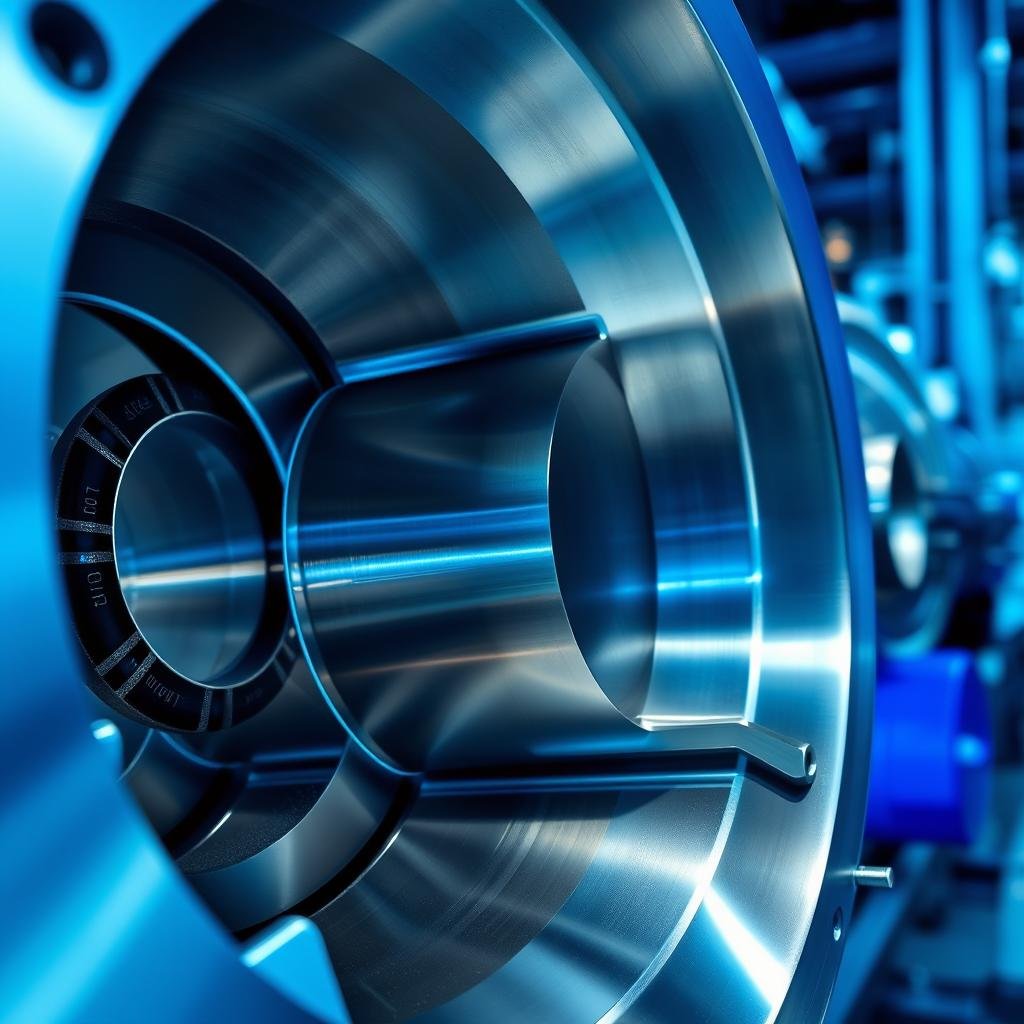

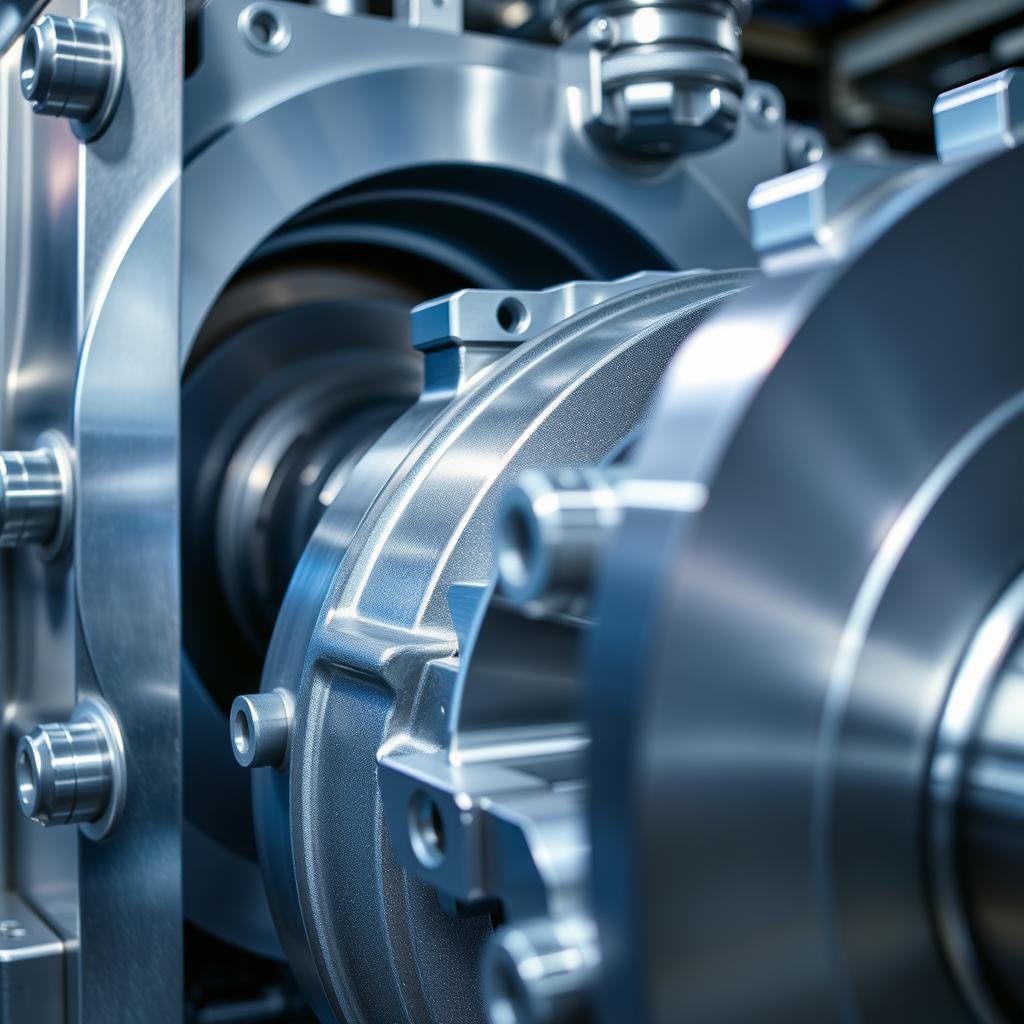

- Precision Forging: Our state-of-the-art forging equipment produces components with exceptional dimensional accuracy and superior internal grain structure.

- Heat Treatment: In-house heat treatment capabilities allow us to precisely control material properties, enhancing strength, hardness, and other critical characteristics.

- CNC Machining: Advanced CNC machining centers provide precise secondary operations to achieve final dimensions and features with tight tolerances.

- Surface Treatments: We offer comprehensive surface finishing options, including anodizing, painting, and other treatments to enhance appearance and performance.

- Quality Assurance: Rigorous inspection protocols and advanced testing capabilities ensure every component meets or exceeds specified requirements.

- Full-Service Support: From prototype development through high-volume production, MAIKONG provides complete support throughout your project lifecycle.

Ready to Enhance Your Components with Forged Aluminum?

Contact MAIKONG today to discuss your specific requirements and discover how our forging expertise can benefit your applications.

Request a Consultation

Quality Assurance in Forged Aluminum Production

At MAIKONG, we understand that the performance and reliability of forged aluminum components depend on rigorous quality control throughout the manufacturing process. Our comprehensive quality assurance program ensures that every component meets the highest standards of excellence.

Our Quality Control Process

Material Verification

We begin with thorough verification of all incoming aluminum alloys, conducting chemical composition analysis and mechanical property testing to ensure material compliance with specifications before entering the production process.

In-Process Inspection

Throughout the forging process, our technicians perform regular inspections and measurements to verify dimensional accuracy, surface quality, and other critical parameters, allowing for immediate adjustments if needed.

Comprehensive Testing

Finished components undergo extensive testing, including dimensional verification, mechanical property testing, and non-destructive examination techniques to ensure they meet all specified requirements.

Certifications and Standards

MAIKONG maintains rigorous quality management systems certified to international standards, ensuring consistent quality and reliability in all our forged aluminum products. Our commitment to quality is reflected in our comprehensive documentation and traceability systems, providing customers with complete confidence in our components.

Why Choose MAIKONG for Your Forged Aluminum Needs

The MAIKONG Advantage

- Over two decades of specialized experience in aluminum forging

- Comprehensive in-house capabilities from design through finishing

- Advanced equipment and technologies for superior quality

- Competitive pricing with excellent value proposition

- Flexible production capabilities for both prototype and high-volume requirements

- Dedicated engineering support throughout your project

- Rigorous quality control and material traceability

- Global shipping and logistics expertise

When you partner with MAIKONG for your forged aluminum components, you gain access to our comprehensive expertise, advanced manufacturing capabilities, and unwavering commitment to quality. Our team works closely with you to understand your specific requirements and deliver solutions that enhance your product performance and competitive advantage.

We pride ourselves on building long-term relationships with our customers, serving as a trusted partner in their success. From initial concept through ongoing production, MAIKONG provides the support, expertise, and quality you need to excel in your market.

Conclusion: The Clear Advantages of Forged Aluminum

The mechanical advantages of forged aluminum over cast alternatives are clear and significant. Through the specialized forging process, aluminum components achieve superior strength, enhanced fatigue resistance, improved impact tolerance, and optimal strength-to-weight ratios that simply cannot be matched by casting methods.

For applications where performance, reliability, and safety are critical, forged aluminum represents the superior choice. The controlled grain structure alignment and elimination of internal defects create components that can withstand the most demanding operating conditions while maintaining their integrity over extended service lives.

At MAIKONG, we leverage these inherent advantages of forged aluminum while adding our own expertise in design optimization, precision manufacturing, and comprehensive quality control. The result is components that not only meet but exceed your performance expectations, helping your products stand out in competitive markets.

Contact MAIKONG today to discuss your specific forged aluminum requirements and discover how our comprehensive capabilities can benefit your applications.

The forged aluminum process creates superior internal grain structure through controlled pressure application

The forged aluminum process creates superior internal grain structure through controlled pressure application