In today’s demanding manufacturing landscape, forged aluminum stands as a cornerstone material for industries requiring exceptional strength-to-weight ratios and superior mechanical properties. The transformation from raw aluminum ingot to precision-engineered component represents a fascinating journey of metallurgical science and manufacturing expertise. This comprehensive guide explores how forged aluminum is created, its remarkable advantages over alternatives, and why leading manufacturers choose this material for their most critical applications.

Understanding Forged Aluminum: Definition and Fundamentals

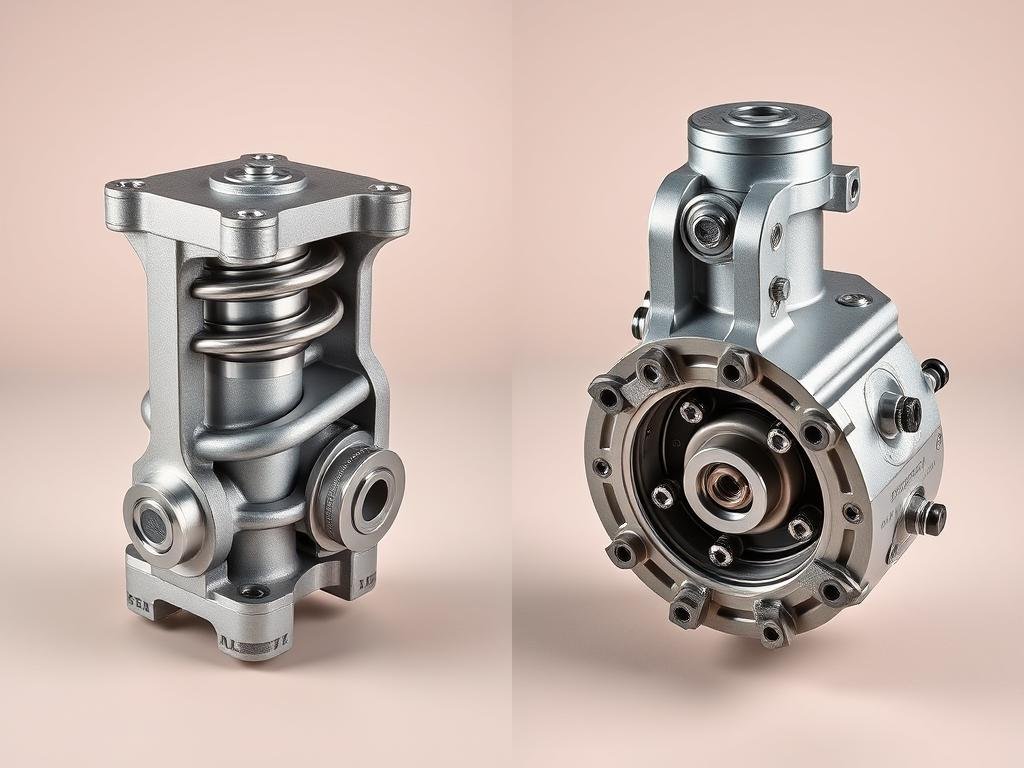

Various forged aluminum components showing distinctive grain structure and finished parts

Various forged aluminum components showing distinctive grain structure and finished parts

Forged aluminum refers to aluminum that has undergone a forging process, where solid aluminum is heated to a plastic state and then shaped through compression force under high pressure. Unlike casting, which involves pouring molten metal into molds, forging rearranges the metal’s internal grain structure, creating a denser, stronger material with enhanced mechanical properties.

The process begins with aluminum alloy billets or ingots that are carefully selected based on the intended application. These raw materials are then subjected to controlled heating and precise deformation, resulting in components that exhibit superior strength, toughness, and fatigue resistance compared to their cast counterparts.

The Science Behind Forged Aluminum’s Superior Properties

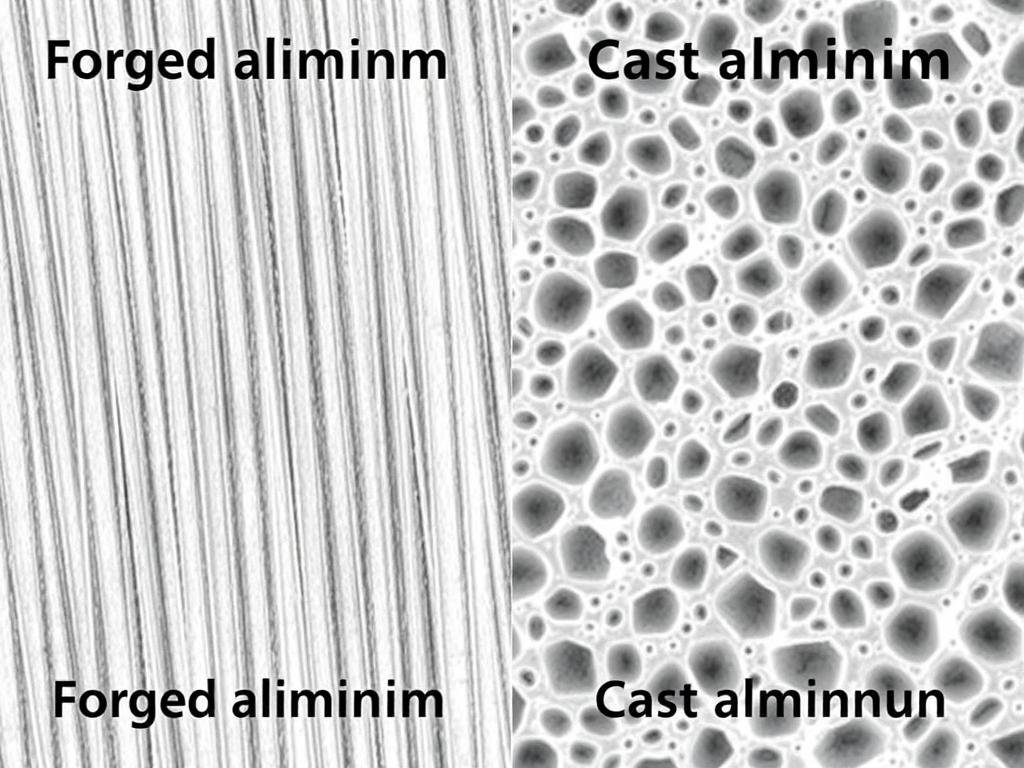

What makes forged aluminum truly exceptional is the fundamental changes that occur at the microstructural level during the forging process. The applied pressure eliminates internal voids and porosity while aligning the metal’s grain structure along the directional lines of force. This grain alignment is key to the material’s enhanced mechanical properties, as it creates a more uniform and predictable stress distribution throughout the component.

The Forged Aluminum Manufacturing Process: Step by Step

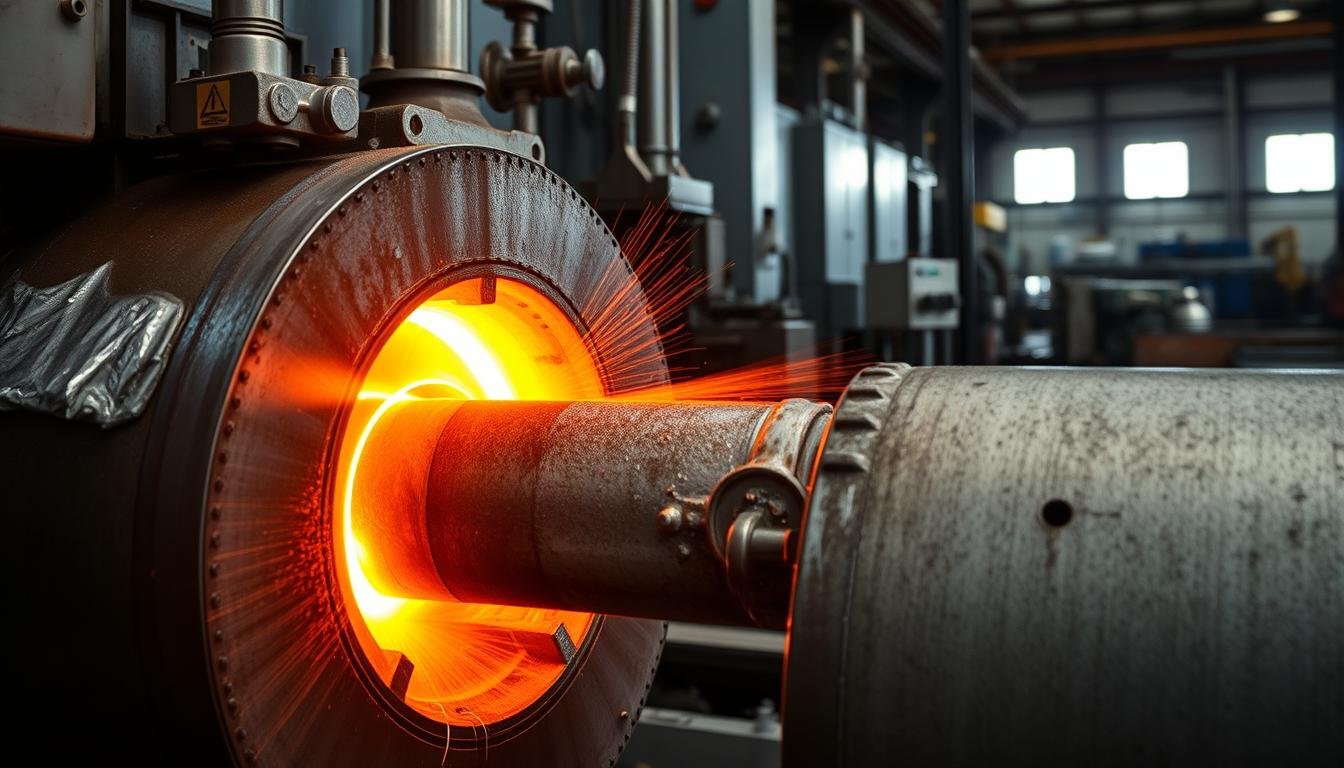

The transformation process of raw aluminum into forged components

The journey from raw aluminum to finished forged aluminum component involves several critical stages, each contributing to the final product’s exceptional quality and performance characteristics.

1. Material Selection and Preparation

The process begins with selecting the appropriate aluminum alloy based on the intended application’s specific requirements. At MAIKONG, we carefully analyze mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness to determine the optimal aluminum alloy for each project. The selected material is then cut into billets of appropriate size for the forging process.

2. Heating to Achieve Optimal Plasticity

The aluminum billets are heated to a specific temperature range (typically between 750°F and 950°F) where the metal becomes malleable without melting. This temperature is critical – too low and the metal won’t deform properly; too high and it could develop unwanted microstructural changes or even melt.

3. Forging: Applying Controlled Pressure

The heated billet is placed between dies in a forging press, where tremendous pressure (often several thousand tons) is applied to shape the metal. MAIKONG utilizes various forging techniques depending on the component requirements:

- Open-die forging for larger, simpler shapes

- Closed-die forging for more complex geometries

- Precision forging for components requiring minimal finishing

4. Controlled Cooling

After forging, the component undergoes controlled cooling to maintain its newly formed structure without introducing unwanted stresses. This step is crucial for preserving the mechanical properties achieved during forging.

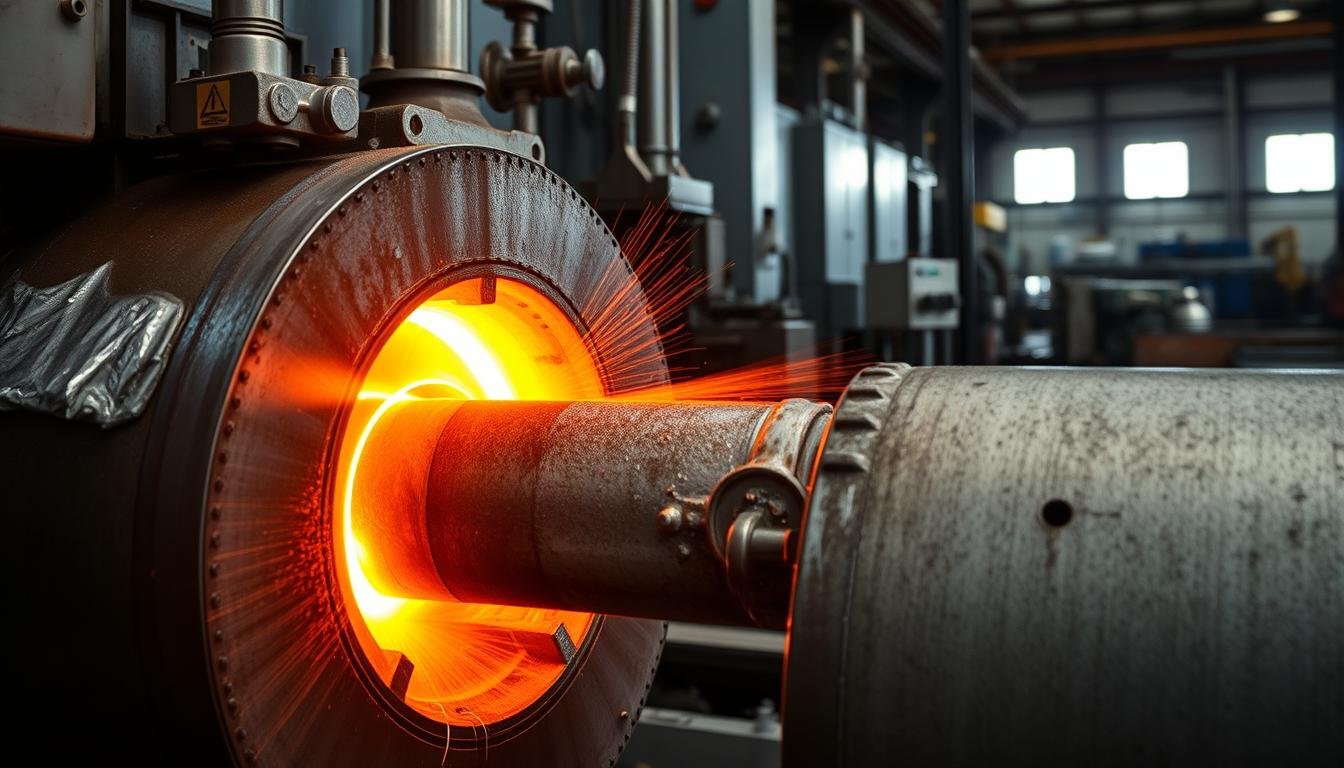

5. Heat Treatment

Many forged aluminum components undergo heat treatment to further enhance specific properties. This might include solution heat treatment, quenching, and aging processes to optimize strength, hardness, and other characteristics for the intended application.

Heat treatment process for optimizing forged aluminum properties

6. Finishing Operations

The final stages involve various finishing operations to achieve the required dimensions, tolerances, and surface characteristics:

- CNC machining for precise dimensions and features

- Surface grinding to remove parting lines

- Surface treatments like anodizing or painting for enhanced appearance and corrosion resistance

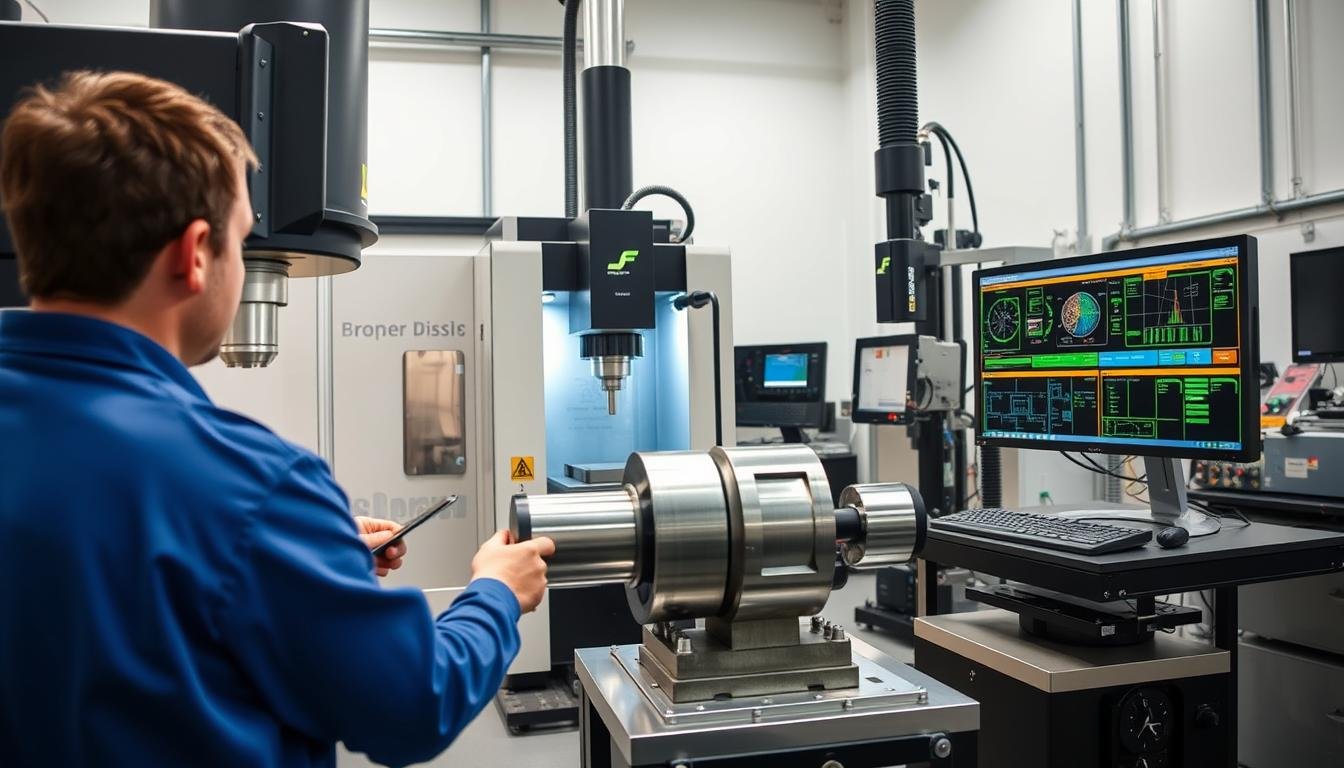

7. Quality Control and Testing

Throughout the entire process, rigorous quality control measures ensure that each component meets or exceeds the required specifications. This includes dimensional inspection, material testing, and performance validation.

Why Forged Aluminum Outperforms Cast Aluminum

When comparing manufacturing methods for aluminum components, the differences between forging and casting are significant and directly impact the performance of the final product. Understanding these differences is crucial for making informed decisions about which process best suits your specific application requirements.

| Comparison Categories |

Forged Aluminum |

Cast Aluminum |

| Strength and Durability |

✅ Superior due to dense, uniform grain structure |

Lower due to air pockets and inclusions |

| Tensile Properties |

✅ Excellent tensile strength (30,000-50,000+ psi) |

Moderate tensile strength (23,000-34,500 psi) |

| Fatigue Resistance |

✅ Exceptional resistance to repeated stress cycles |

Potentially lower fatigue resistance |

| Complex Geometries |

Requires multiple steps for complex shapes |

✅ Can achieve complex shapes in one operation |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies due to shrinkage |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Often requires more machining due to porosity |

| Weight-to-Strength Ratio |

✅ Exceptional strength-to-weight ratio |

Requires bulkier parts for equivalent strength |

| Ideal Applications |

Critical components in aerospace, automotive, high-stress applications |

Consumer goods, decorative items, non-critical components |

Key Benefits of Forged Aluminum

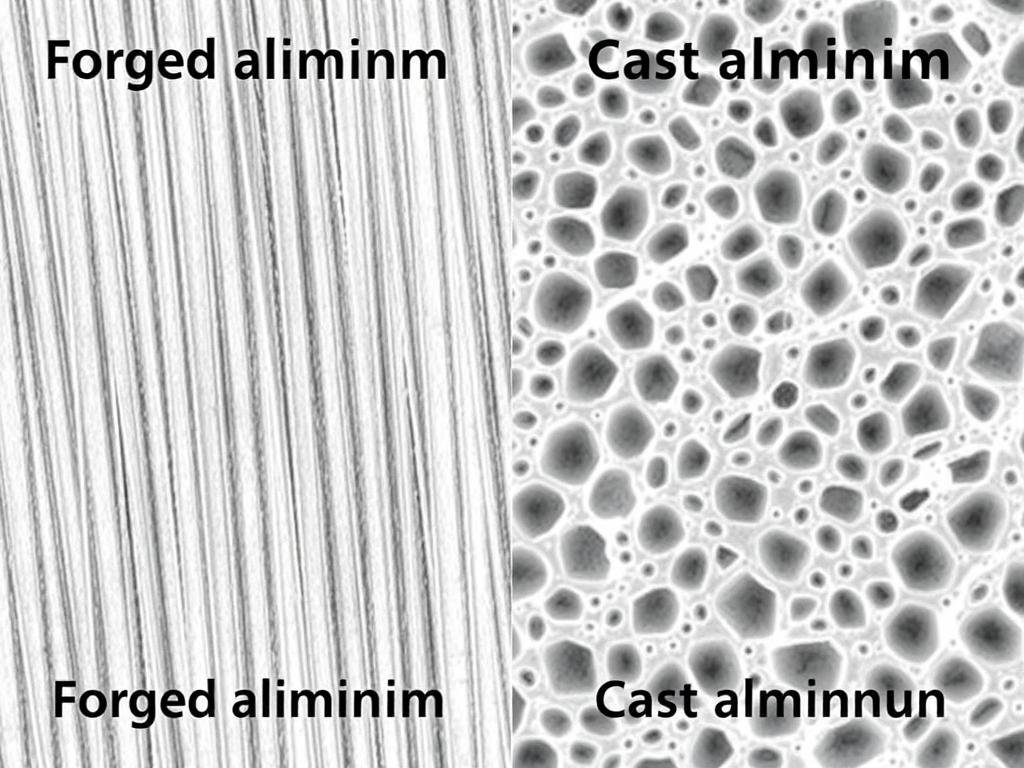

Microscopic comparison showing the superior grain structure of forged aluminum (left) vs. cast aluminum (right)

Superior Strength and Durability

The forging process creates a refined grain structure that significantly enhances the material’s strength. Forged aluminum components can withstand higher loads and stresses without failure, making them ideal for safety-critical applications.

Enhanced Fatigue Resistance

Components made from forged aluminum demonstrate superior resistance to fatigue failure, even after thousands of stress cycles. This makes them particularly valuable in applications subject to repeated loading and unloading, such as aircraft components and automotive suspension parts.

Improved Impact Resistance

The aligned grain structure of forged aluminum provides exceptional toughness and impact resistance. This translates to components that can better absorb sudden shocks without catastrophic failure.

Optimal Strength-to-Weight Ratio

Perhaps the most compelling advantage of forged aluminum is its remarkable strength-to-weight ratio. This property allows engineers to design lighter components without compromising structural integrity – a critical consideration in aerospace, automotive, and other weight-sensitive applications.

MAIKONG: Your Expert Partner for Forged Aluminum Components

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

At MAIKONG, we combine decades of manufacturing expertise with cutting-edge technology to deliver superior forged aluminum components that meet the most demanding specifications. Our comprehensive capabilities span the entire production process, from initial design consultation to final quality verification.

Our Comprehensive Forged Aluminum Services

CNC Machining Services

With over 60 advanced CNC machines and 100+ tons of monthly metal processing capacity, MAIKONG offers precision fabrication for both prototype and production volumes. Our capabilities include:

- CNC Turning

- CNC Milling

- Swiss-Type Machining

- Multi-Axis Machining

Metal Forging Expertise

Our specialized forging workshop is equipped to handle diverse aluminum specifications with precision and consistency. We offer:

- Aluminum Forging Services

- Steel Forging

- Brass Forging

- Custom Metal Parts

Comprehensive Processing

Beyond forging and machining, we provide complete secondary operations to deliver finished components:

- Heat Treatment

- Surface Finishing

- Quality Testing

- Custom Metal Fabrication

The MAIKONG Advantage

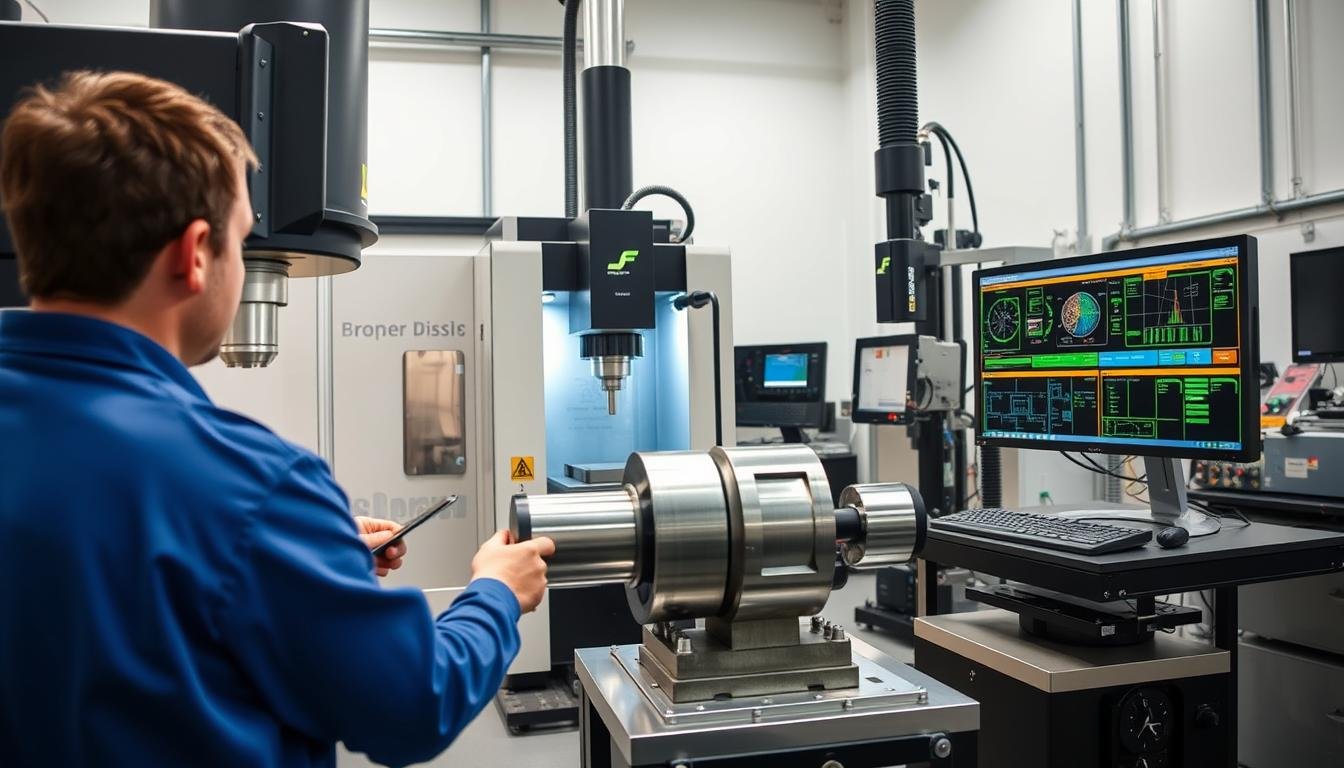

Rigorous quality control ensures every forged aluminum component meets exact specifications

Material Expertise

Our dedicated material laboratory enables us to achieve precise results by thoroughly understanding aluminum alloys, their properties, and interactions. This expertise ensures optimal material selection for each application.

Comprehensive Quality Control

Quality is embedded throughout our production process. From raw material verification to final inspection, we employ rigorous testing protocols to ensure every component meets or exceeds specifications.

Cost-Effective Solutions

By managing the entire production process in-house – from forging through machining to surface treatment – we eliminate intermediaries and optimize efficiency, resulting in competitive pricing without compromising quality.

Global Partnership Approach

As both a producer and consumer of our customers’ products, we understand the critical importance of consistency, strength, and weight in each forged aluminum part. We’re actively seeking US distributors to expand our global reach.

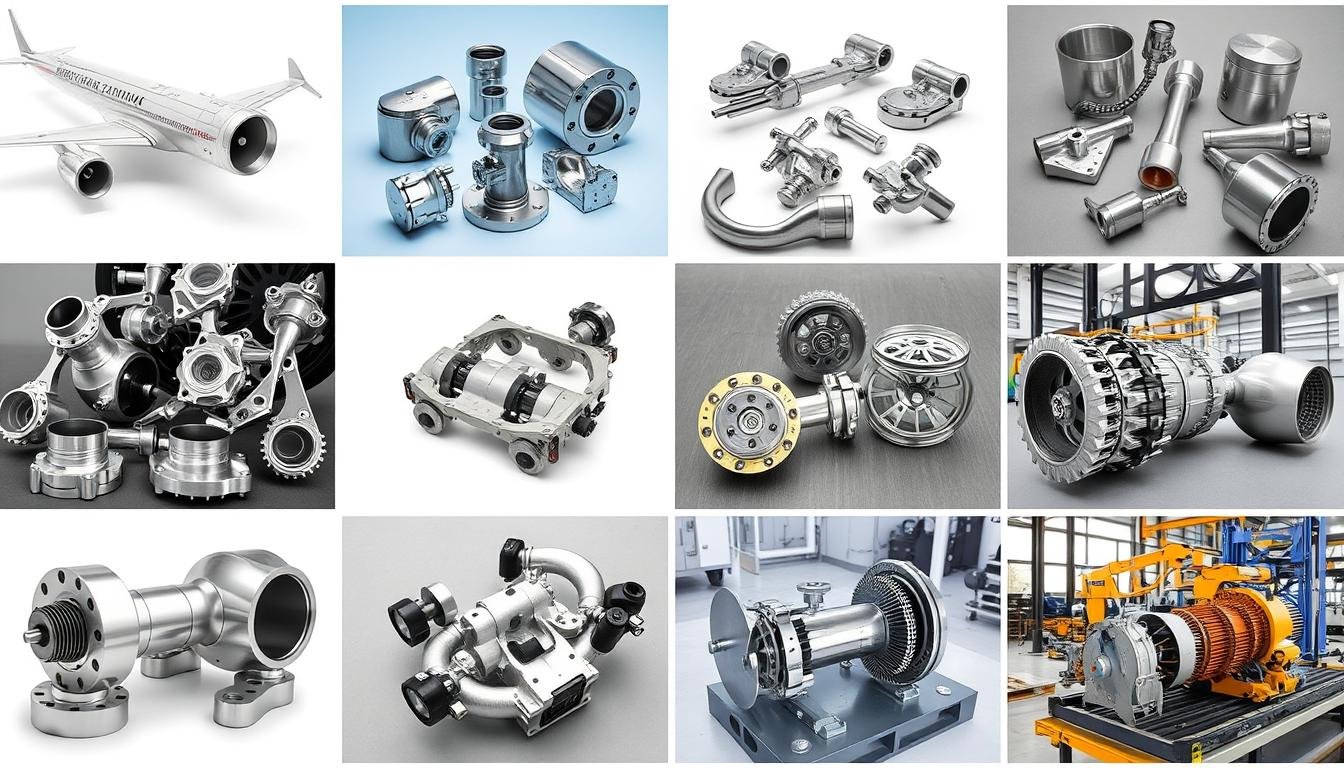

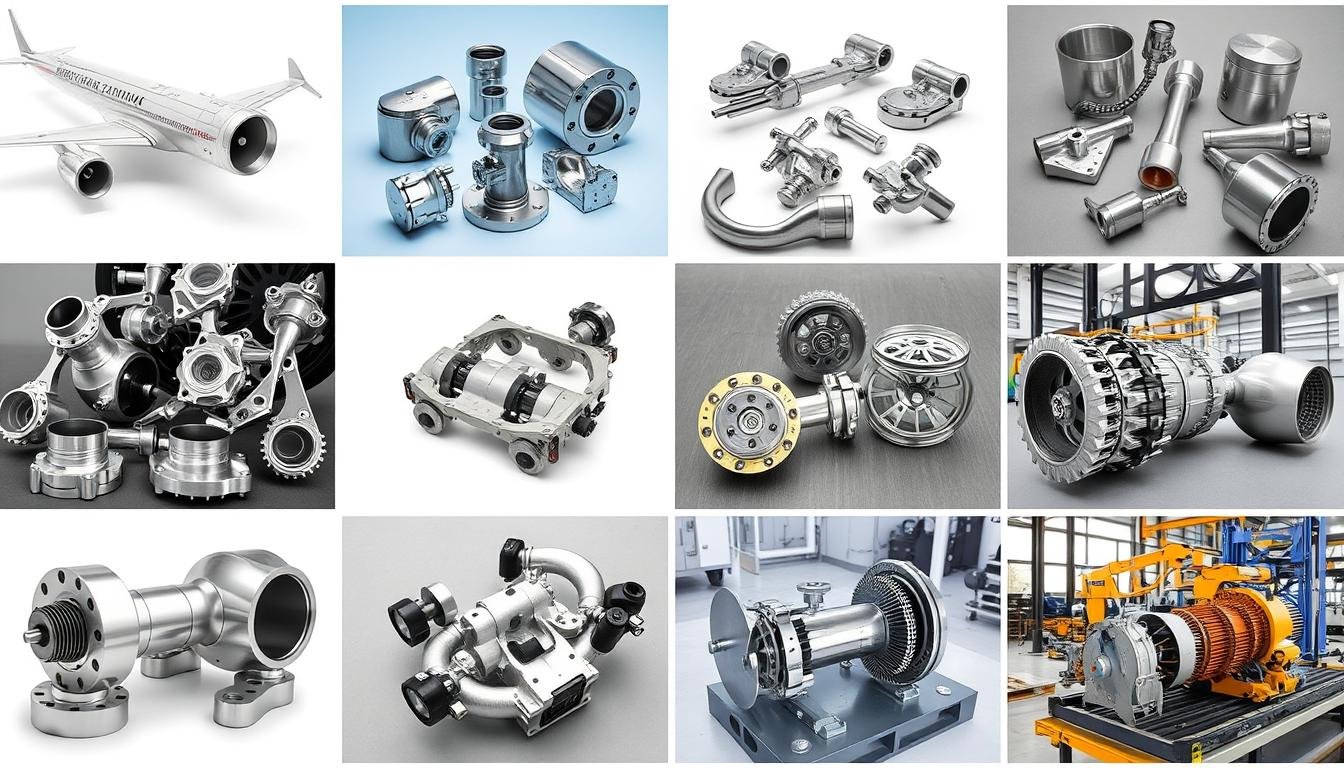

Industry Applications for Forged Aluminum Components

The exceptional properties of forged aluminum make it the material of choice across numerous industries where performance, reliability, and weight considerations are paramount.

Forged aluminum components serve critical functions across diverse industries

Aerospace

Forged aluminum is essential in aerospace applications where the combination of light weight and high strength is critical:

- Aircraft structural components

- Landing gear components

- Engine mounts and brackets

- Wing structures

Automotive

The automotive industry relies on forged aluminum for components that require exceptional strength and fatigue resistance:

- Suspension components

- Wheel hubs and rims

- Connecting rods

- Drivetrain components

Industrial & Specialized

Beyond transportation, forged aluminum serves critical functions in various specialized applications:

- Medical device components

- High-performance sporting equipment

- Military and defense applications

- Precision machinery components

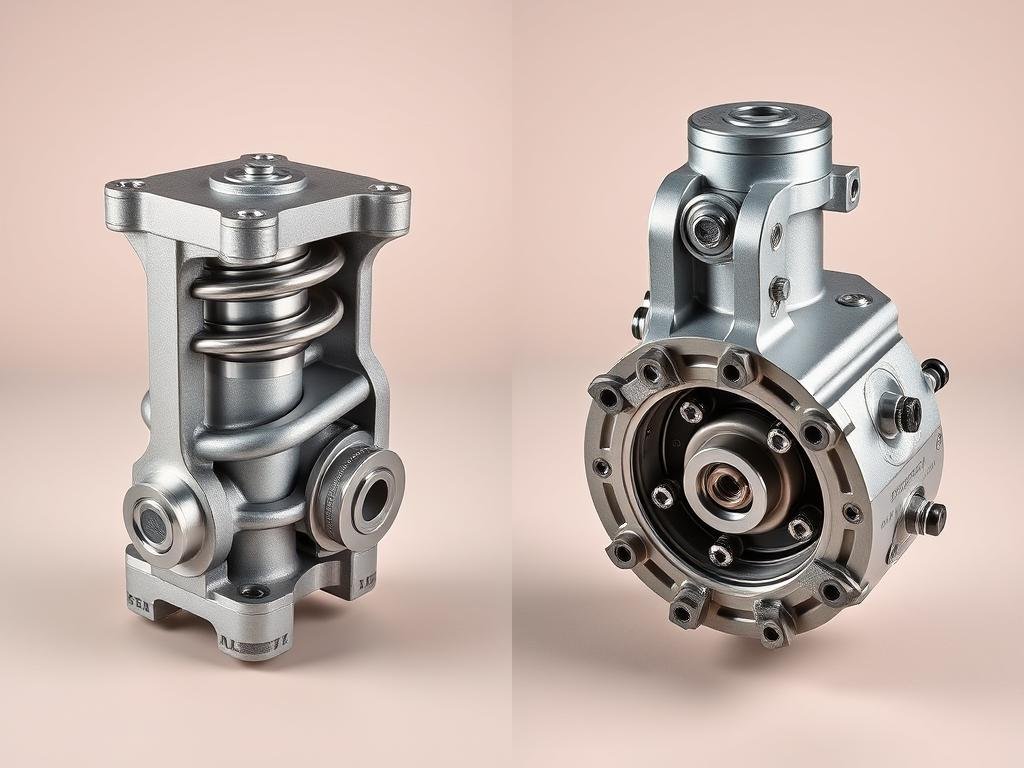

Case Study: Forged Aluminum in Action

Transformation from raw forging to precision-machined component for automotive application

A leading automotive manufacturer approached MAIKONG seeking to reduce weight in their vehicle suspension system without compromising safety or performance. Our engineering team developed a forged aluminum solution that:

- Reduced component weight by 35% compared to the previous steel design

- Maintained equivalent strength and durability metrics

- Improved fatigue resistance by 28%

- Resulted in 3% better fuel efficiency for the vehicle

This case exemplifies how forged aluminum, when properly engineered and manufactured, can deliver transformative benefits across multiple performance parameters.

Quality Assurance in Forged Aluminum Manufacturing

Advanced testing ensures every forged aluminum component meets rigorous quality standards

At MAIKONG, quality isn’t just a department – it’s a philosophy embedded throughout our entire operation. Our comprehensive quality management system ensures that every forged aluminum component we produce meets or exceeds the most demanding specifications.

Our Quality Control Process

Material Verification

Before production begins, we verify the chemical composition and mechanical properties of all incoming aluminum alloys to ensure they meet the required specifications.

In-Process Inspection

Throughout the forging and machining processes, our technicians perform regular inspections to catch any potential issues before they affect the final product.

Comprehensive Testing

Finished components undergo rigorous testing, including dimensional inspection, hardness testing, and when required, non-destructive testing methods like ultrasonic or penetrant inspection.

Documentation and Traceability

We maintain comprehensive documentation for all production processes, ensuring complete traceability from raw material to finished component.

Since 2015, MAIKONG has maintained ISO 9001:2015 certification, demonstrating our commitment to consistent quality management practices. Our quality engineering staff continuously monitors production processes to ensure the consistency and performance of every component we produce.

Partner with MAIKONG for Superior Forged Aluminum Solutions

Our expert team works closely with clients to develop optimal forged aluminum solutions

Whether you’re seeking a manufacturing partner for prototype development or high-volume production, MAIKONG offers the expertise, capabilities, and commitment to quality that ensure successful outcomes. We’re actively seeking US distributors to expand our global reach and bring our cost-effective, high-quality forged aluminum solutions to new markets.

Ready to Elevate Your Components with Forged Aluminum?

Contact MAIKONG today to discuss your specific requirements and discover how our comprehensive forging and machining capabilities can deliver superior components at competitive prices.

Get A Quick Quote

Visit Us Online

Website: https://maikongforge.us

Discover our full range of capabilities and see how MAIKONG can transform your manufacturing challenges into competitive advantages.

Conclusion: The Future of Forged Aluminum Manufacturing

As industries continue to demand lighter, stronger, and more durable components, forged aluminum remains at the forefront of materials technology. The unique combination of light weight, exceptional strength, and superior fatigue resistance makes it irreplaceable in applications where performance cannot be compromised.

At MAIKONG, we’re committed to advancing forged aluminum manufacturing through continuous innovation, process optimization, and quality enhancement. By partnering with us, you gain access not only to superior components but also to a team of experts dedicated to your success.

Contact MAIKONG today to explore how our comprehensive forged aluminum capabilities can help you achieve your manufacturing goals with confidence.

Various forged aluminum components showing distinctive grain structure and finished parts

Various forged aluminum components showing distinctive grain structure and finished parts