Why Aluminum Forging Companies Offer Superior Parts for Critical Applications

In industries where performance and safety are non-negotiable, aluminum forging companies play a crucial role in delivering components that meet the most demanding specifications. MAIKONG stands at the forefront of this specialized field, combining advanced manufacturing techniques with metallurgical expertise to produce aluminum forgings that outperform alternative manufacturing methods. When structural integrity, weight optimization, and reliability matter most, our precision-engineered aluminum forgings deliver exceptional value across aerospace, automotive, medical, and industrial applications.

Superior Strength-to-Weight Ratio: The Aluminum Forging Advantage

Need components that combine lightweight properties with exceptional strength? Contact our engineering team today to discuss your specific requirements.

Get A Quick Quote

MAIKONG’s precision forging process aligns aluminum grain structure for optimal strength properties

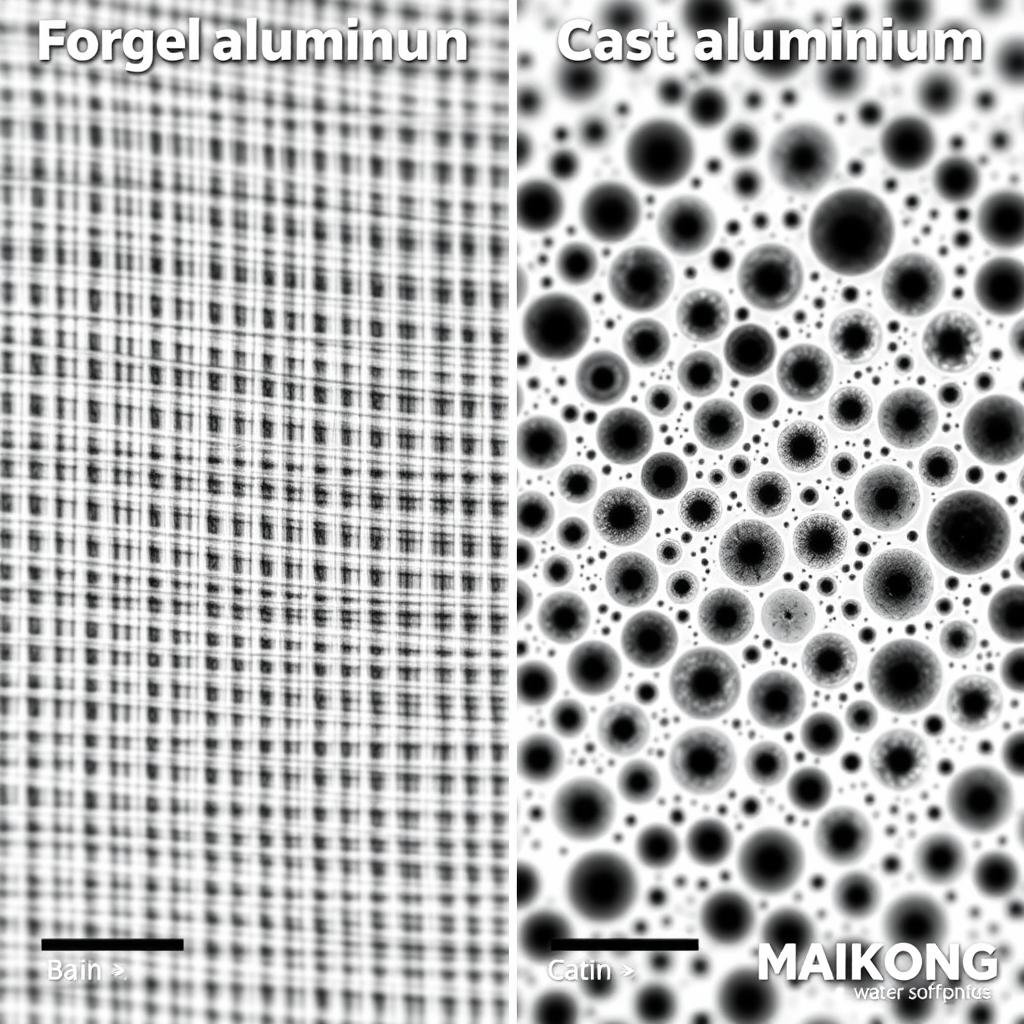

Strength-to-weight ratio represents a fundamental engineering principle that addresses the critical balance between material strength and weight—an essential consideration in industries where performance, efficiency, and safety are paramount. Aluminum, recognized for its lightweight properties and robust mechanical characteristics, undergoes significant enhancement through the forging process.

During forging, the internal grain structure of aluminum is refined and aligned, creating a more resilient and stronger material. This transformation makes aluminum forgings the optimal choice for applications that must withstand both static and dynamic loads while maintaining minimal weight. The resulting components showcase engineering excellence—a sophisticated combination of material science, metallurgy, and precision manufacturing that reshapes possibilities across critical industries.

How Forging Enhances Aluminum’s Properties

The forging process fundamentally transforms aluminum’s microstructure by applying controlled pressure that eliminates voids and aligns the metal’s grain flow with the part’s geometry. This directional grain alignment significantly improves:

- Tensile strength and yield strength

- Fatigue resistance and crack propagation resistance

- Impact toughness and durability

- Dimensional stability under load

- Performance consistency across production runs

Why Aluminum Forging Companies Outperform Casting Methods

When evaluating manufacturing methods for critical aluminum components, understanding the fundamental differences between forging and casting is essential. MAIKONG’s engineering team specializes in leveraging the superior mechanical properties achieved through our advanced forging processes.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Critical Applications |

✅ Structural members and load-bearing capabilities |

Limited suitability for critical applications |

Need High-Performance Aluminum Components?

MAIKONG’s engineering team can help you determine the optimal manufacturing approach for your critical applications.

Contact Our Engineers

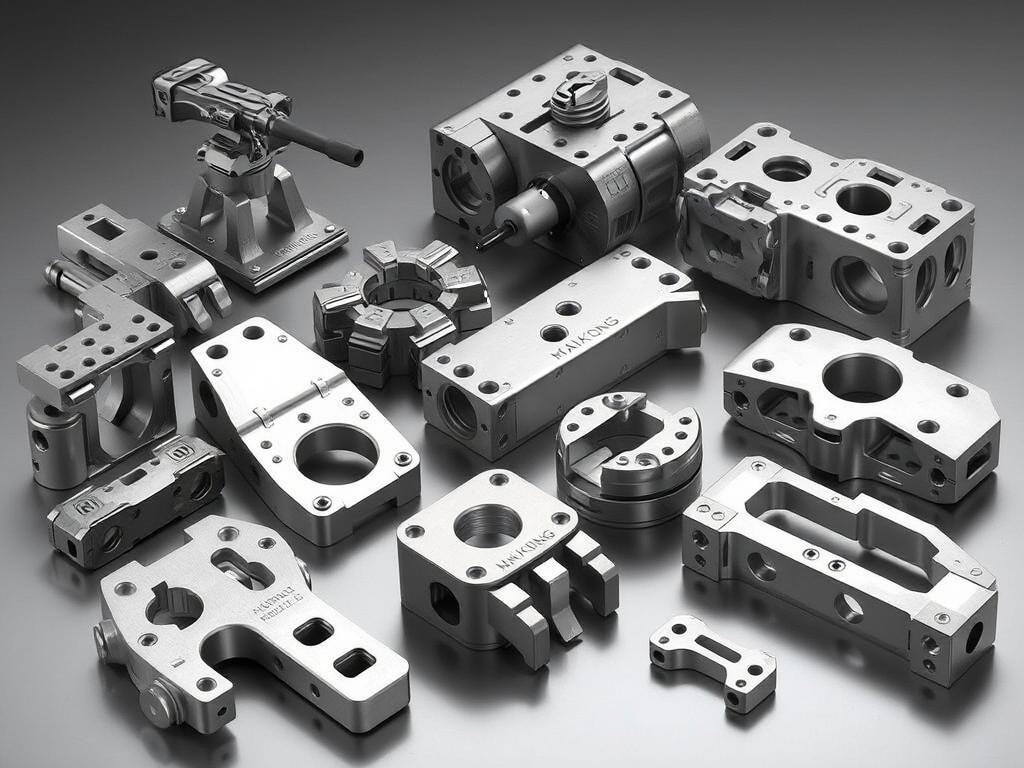

MAIKONG’s Comprehensive Aluminum Forging Capabilities

As a leading provider among aluminum forging companies, MAIKONG delivers end-to-end manufacturing solutions that ensure superior quality and performance. Our integrated approach combines advanced technology with metallurgical expertise to produce components that meet the most demanding specifications.

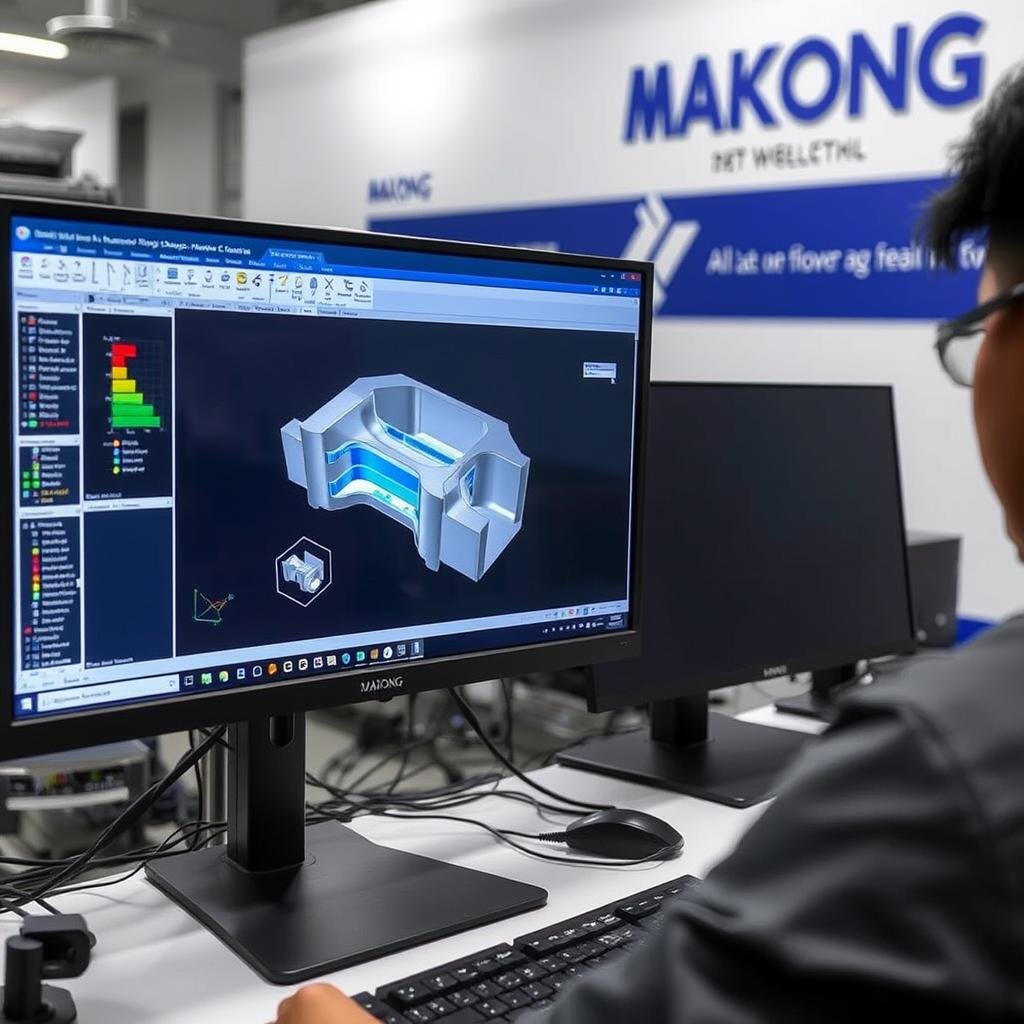

CAD/CAM Design

Our engineering team utilizes advanced analysis software to identify and mitigate potential issues early in the design phase, optimizing both the component design and manufacturing process.

Material Expertise

We thoroughly evaluate mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness of aluminum alloys to select the optimal material for each application.

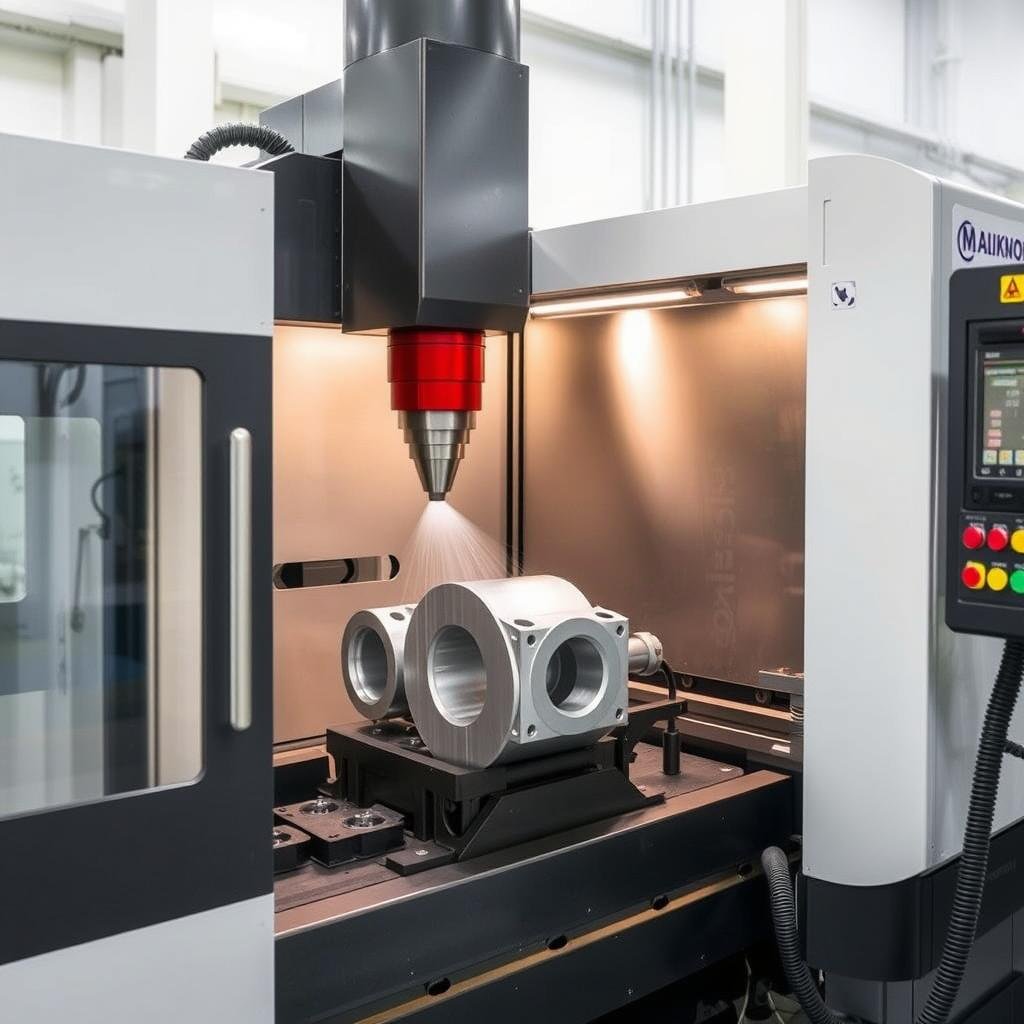

Precision Tooling

Our tooling design ensures initial quality, while regular maintenance preserves consistency—both critical factors in producing high-quality aluminum forgings that meet precise specifications.

Forging Excellence

Our forging workshop is equipped with state-of-the-art hydraulic presses and specialized equipment to accommodate diverse aluminum forging specifications and volumes.

Heat Treatment

We conduct comprehensive statistical analysis and documentation for our in-house heat treatment processes, ensuring optimal mechanical properties and dimensional stability.

Precision Machining

Our machining workshop features advanced CNC machines capable of executing precise and intricate operations on forged components to achieve tight tolerances and superior surface finishes.

Experience MAIKONG’s End-to-End Manufacturing Excellence

From initial design to final inspection, our integrated approach ensures superior quality and performance for your critical aluminum components.

Request Manufacturing Consultation

Quality Assurance: The MAIKONG Difference

Our comprehensive quality control procedures ensure every component meets stringent standards

At MAIKONG, quality isn’t just a department—it’s a core philosophy that permeates every aspect of our operation. As one of the leading aluminum forging companies, we implement rigorous quality control procedures throughout our manufacturing process to ensure that every forged component meets or exceeds industry standards and customer specifications.

Our Quality Control Process

- Material verification and certification before production

- In-process inspections during forging operations

- Heat treatment verification and documentation

- Dimensional inspection using precision measuring equipment

- Non-destructive testing for internal integrity

- Surface finish evaluation and documentation

- Final inspection and comprehensive reporting

Our commitment to quality isn’t just about meeting specifications—it’s about delivering components that perform reliably in the most demanding applications. Every aluminum forging that leaves our facility represents our dedication to excellence and precision.

— MAIKONG Quality Assurance Team

Industry Applications: Where MAIKONG Aluminum Forgings Excel

The superior properties of forged aluminum make it the material of choice for critical applications across multiple industries. MAIKONG’s expertise as one of the premier aluminum forging companies enables us to deliver specialized solutions tailored to each sector’s unique requirements.

Aerospace

Our aerospace-grade aluminum forgings deliver the exceptional strength-to-weight ratio and reliability required for critical aircraft components, including structural members, landing gear components, and engine mounts.

Automotive

From suspension components to engine parts, our automotive aluminum forgings provide the perfect balance of strength, weight reduction, and durability required in modern vehicle design.

Medical

The biocompatibility and precision of our aluminum forgings make them ideal for medical device components, surgical instruments, and diagnostic equipment where reliability is paramount.

Industrial Equipment

Our industrial aluminum forgings provide exceptional performance in demanding environments, offering superior strength, corrosion resistance, and reliability for critical machinery components.

Defense & Military

The exceptional reliability and performance of our aluminum forgings make them ideal for defense applications where failure is not an option, from vehicle components to tactical equipment.

Energy

From oil and gas to renewable energy, our aluminum forgings deliver the durability and performance required in challenging environments where reliability and safety are critical.

The MAIKONG Manufacturing Process

Our state-of-the-art manufacturing facility ensures precision and quality at every step

At MAIKONG, we’ve refined our aluminum forging process to deliver consistent quality and exceptional performance. Our comprehensive approach integrates advanced technology with metallurgical expertise to produce superior components for the most demanding applications.

1. Design & Engineering

Our process begins with collaborative engineering, where our technical team works closely with clients to optimize component design for both performance and manufacturability. Using advanced CAD/CAM tools and simulation software, we identify potential issues before production begins, ensuring a smooth manufacturing process and superior end product.

2. Material Selection

We carefully select the optimal aluminum alloy based on application requirements, considering factors such as strength, corrosion resistance, machinability, and heat treatment response. All materials are verified for composition and quality before entering our production process.

3. Forging Operation

Our forging operations utilize precision-controlled hydraulic presses that apply optimal pressure to shape the aluminum while enhancing its mechanical properties. The forging process aligns the metal’s grain structure with the part geometry, significantly improving strength and durability.

4. Heat Treatment

Our in-house heat treatment facilities allow precise control over the thermal processing of aluminum forgings, optimizing mechanical properties such as hardness, strength, and ductility. Each batch undergoes rigorous monitoring and documentation to ensure consistent results.

5. Precision Machining

Our advanced CNC machining centers bring forged components to their final dimensions with exceptional precision. Our machining capabilities include multi-axis operations that can achieve complex geometries and tight tolerances required for critical applications.

6. Quality Assurance

Every component undergoes comprehensive inspection using advanced measuring equipment, non-destructive testing, and visual examination. Our quality documentation provides complete traceability and verification that all specifications have been met or exceeded.

Experience Manufacturing Excellence with MAIKONG

Our integrated manufacturing approach ensures superior quality and performance for your most critical aluminum components.

Contact Our Manufacturing Team