How an Aluminum Forging Factory Ensures Superior Strength and Durability

The Aluminum Forging Process stands as the cornerstone of modern manufacturing for industries demanding high-performance metal components. At MAIKONG, we’ve perfected this transformative technique that reshapes aluminum into precision-engineered parts with exceptional strength-to-weight ratios. Whether you’re in aerospace, automotive, or industrial equipment manufacturing, understanding how our forging processes create superior components can give your products the competitive edge they deserve.

Understanding the Aluminum Forging Process: The Foundation of Quality

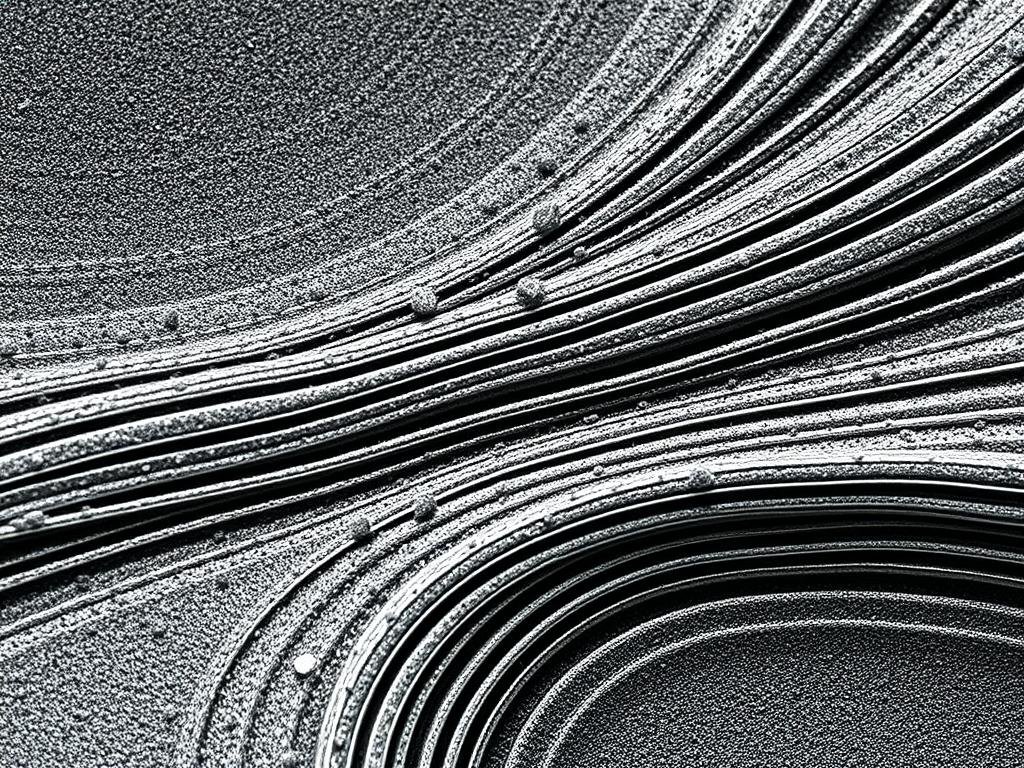

Aluminum forging is a sophisticated metalworking technique that shapes aluminum through controlled pressure application. Unlike casting methods, forging aligns the metal’s grain structure, dramatically enhancing mechanical properties while maintaining aluminum’s inherent lightweight advantages.

The Science Behind Aluminum’s Strength

When aluminum undergoes our precision forging processes, its internal grain structure realigns to follow the contours of the part. This directional grain flow creates components with superior tensile strength, fatigue resistance, and impact toughness compared to cast or machined alternatives.

At MAIKONG, we’ve optimized our Aluminum Forging Process to maximize these mechanical advantages while maintaining tight dimensional tolerances and exceptional surface finishes.

Discover MAIKONG’s Aluminum Forging Expertise

Our engineers can help you determine the optimal forging approach for your specific application requirements.

Explore Our Capabilities

Aluminum Forging vs. Casting: A Comprehensive Comparison

Understanding the differences between forging and casting is crucial when selecting the right manufacturing process for your aluminum components. While both methods have their place in manufacturing, forged aluminum offers distinct advantages for applications where strength and reliability are paramount.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Ideal Applications |

Aerospace, automotive, high-stress components |

Consumer goods, decorative items, complex shapes |

MAIKONG specializes in aluminum forging for applications where mechanical performance cannot be compromised. Our forged components deliver the superior strength, durability, and reliability that critical applications demand.

The MAIKONG Aluminum Forging Process: Step-by-Step Excellence

Our comprehensive aluminum forging workflow combines traditional craftsmanship with cutting-edge technology. Each step is carefully controlled to ensure consistent quality and exceptional performance in the final product.

1. Design & Material Selection

Our process begins with collaborative design using advanced CAD/CAM systems. We select the optimal aluminum alloy based on your application requirements, considering factors like strength, weight, corrosion resistance, and heat treatment response.

2. Tooling Development

We design and manufacture custom forging dies that ensure dimensional accuracy and optimal grain flow. Our tooling experts use simulation software to validate die designs before production, eliminating potential issues.

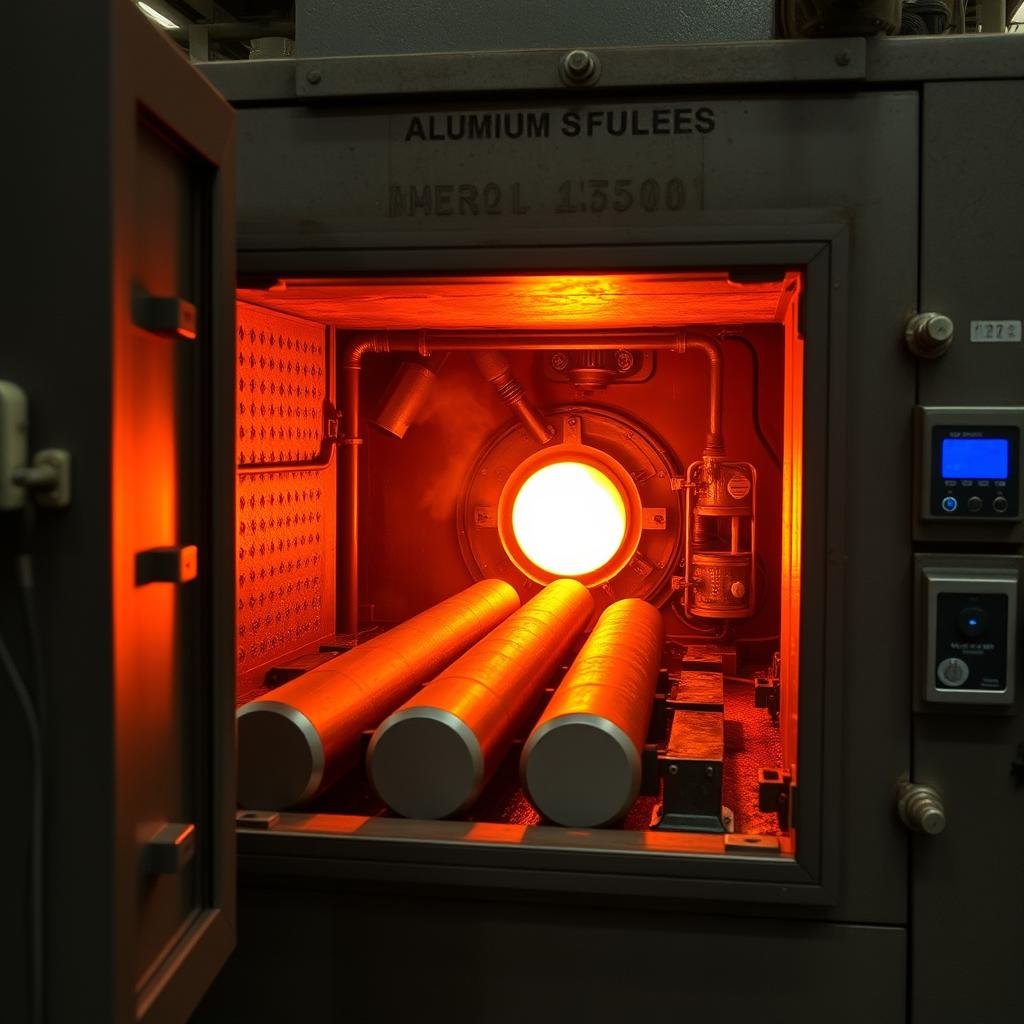

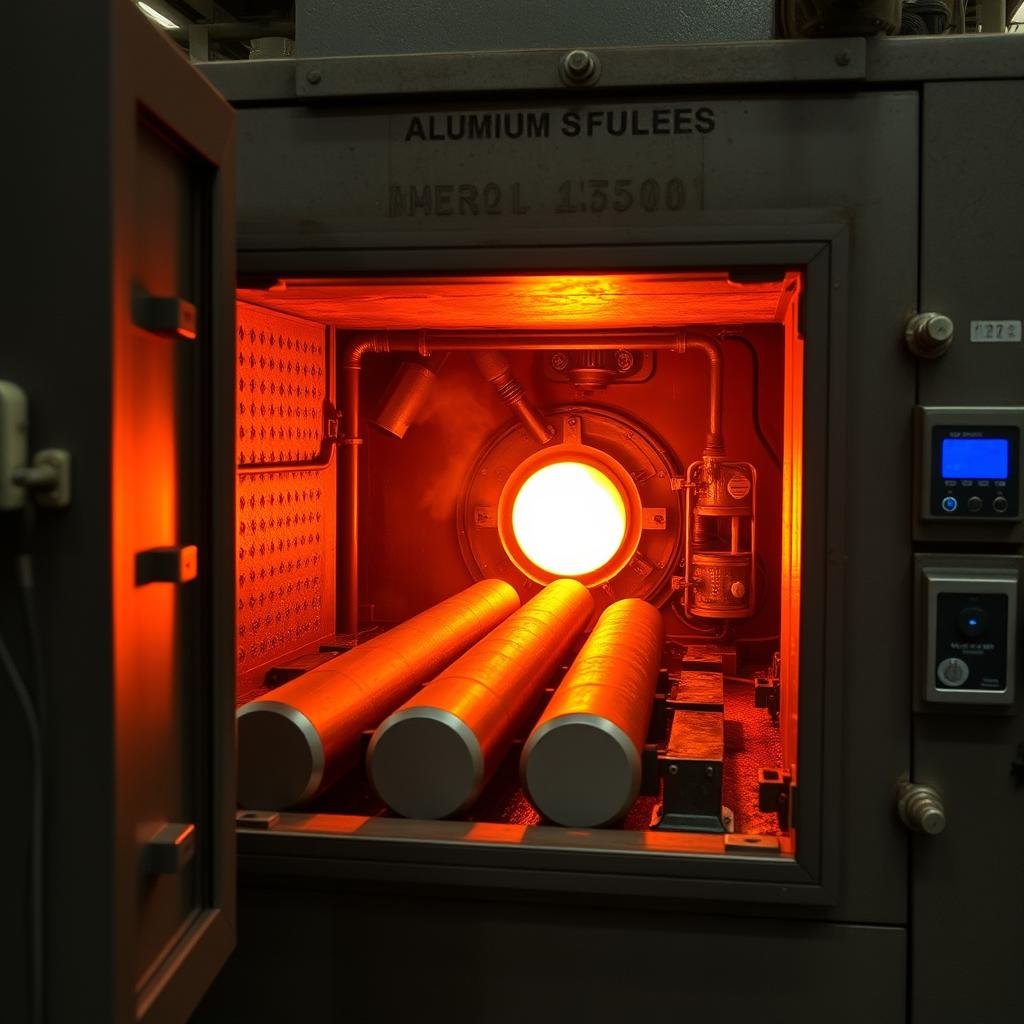

3. Heating Process

Aluminum billets are precisely heated to temperatures between 700°F and 950°F, depending on the specific alloy. Our computer-controlled furnaces ensure uniform heating throughout the material for optimal forgeability.

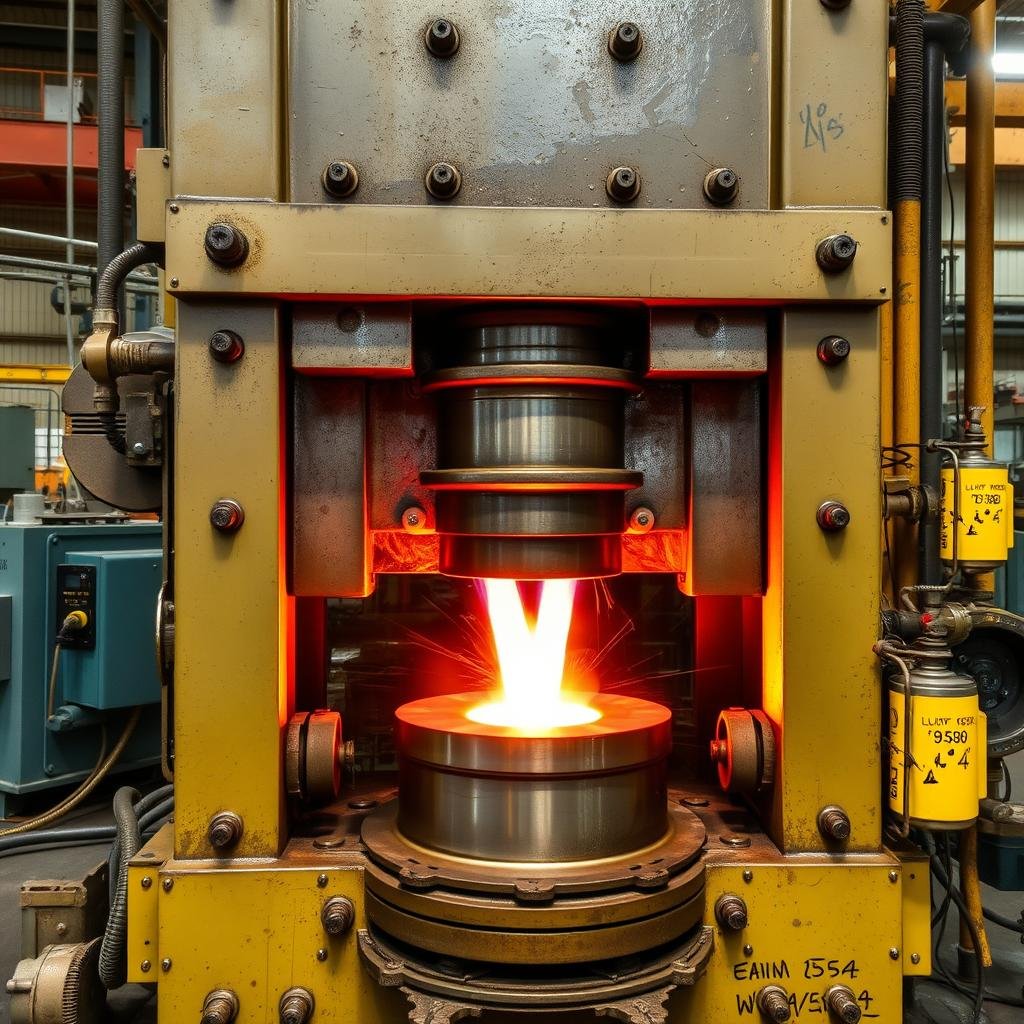

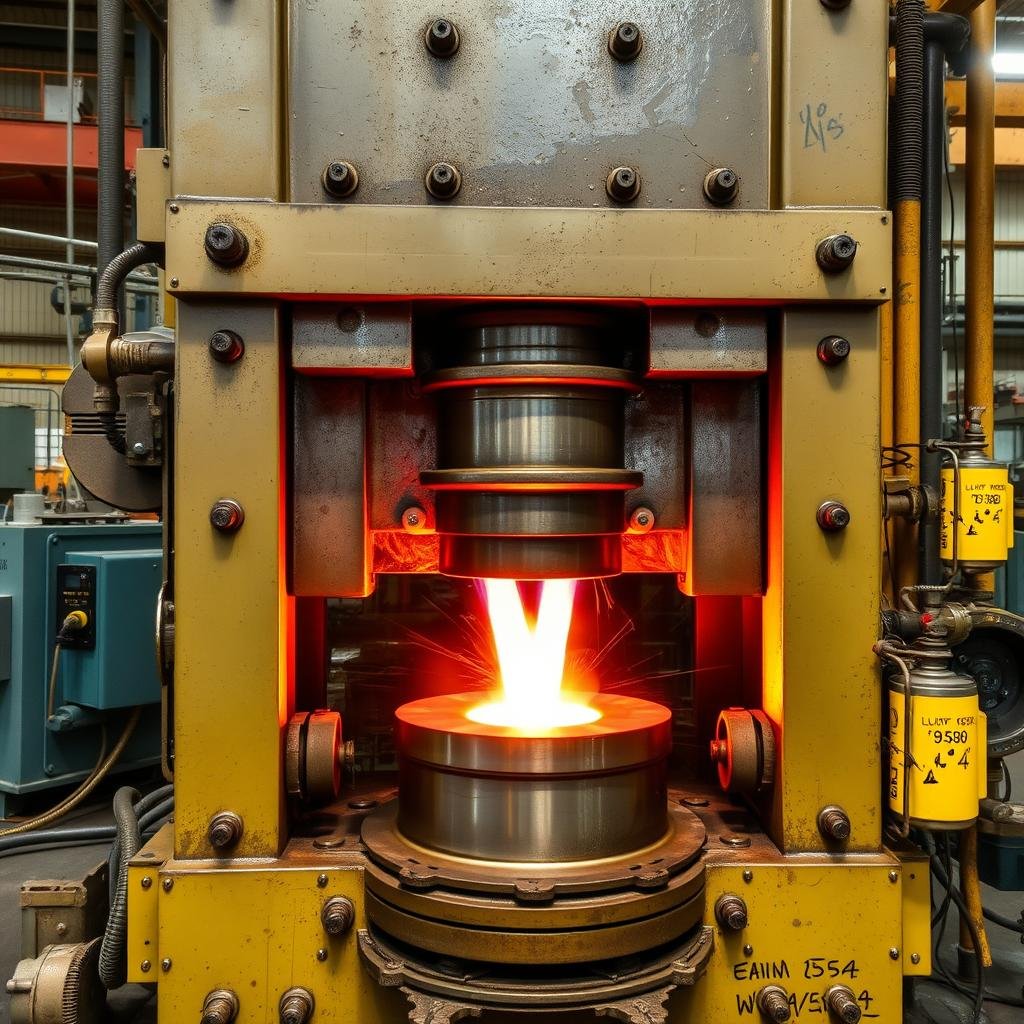

4. Forging Operation

Using hydraulic presses ranging from 800 to 3,000 tons, we apply precisely controlled pressure to shape the heated aluminum. This critical step aligns the metal’s grain structure, dramatically enhancing strength and durability.

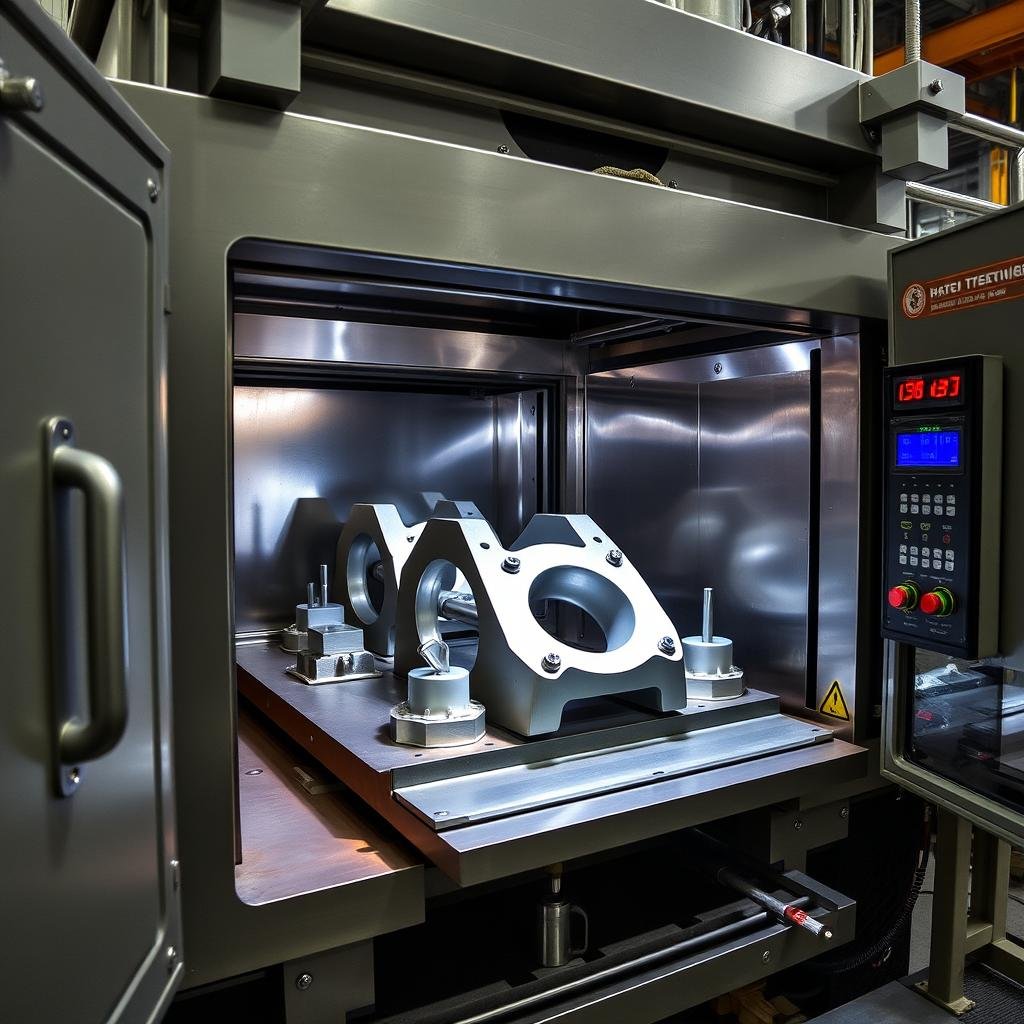

5. Heat Treatment

After forging, components undergo precise heat treatment cycles to achieve the desired mechanical properties. Our in-house heat treatment facilities ensure complete control over this critical process.

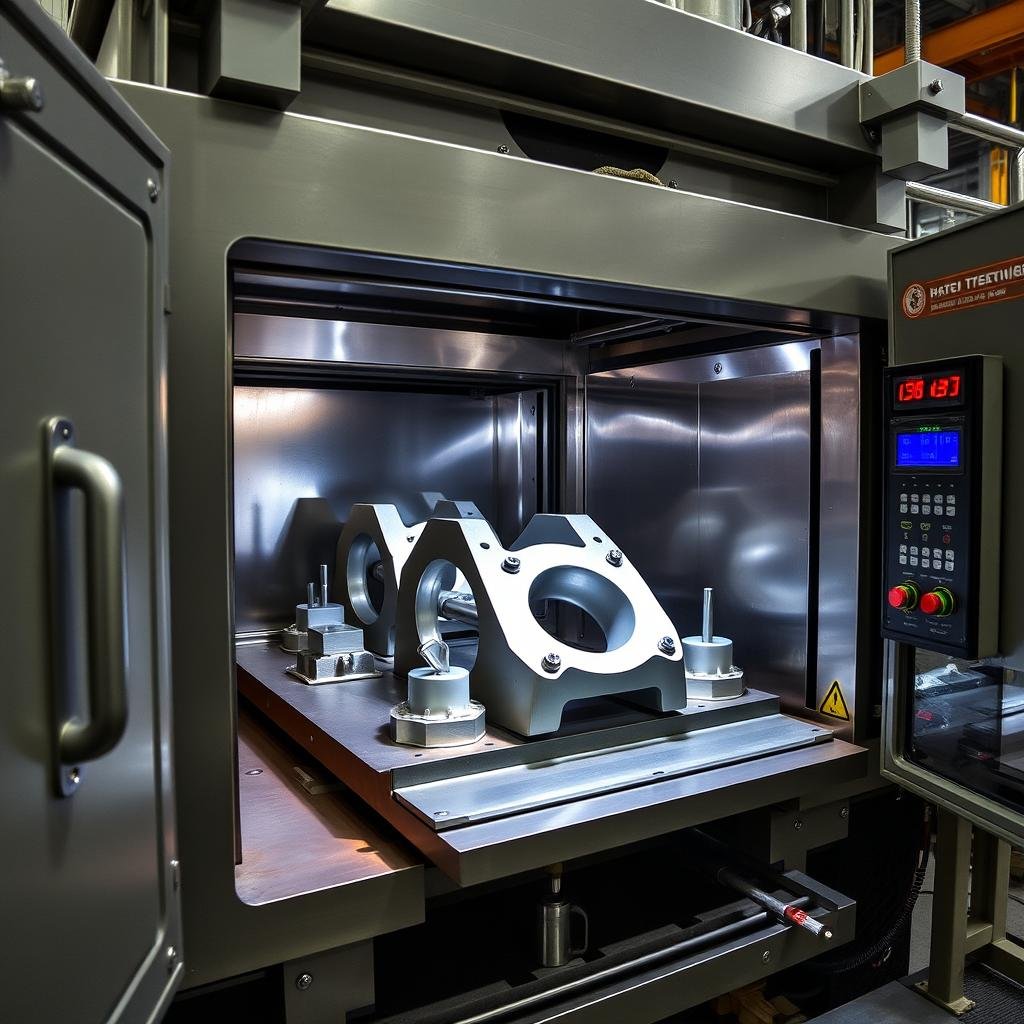

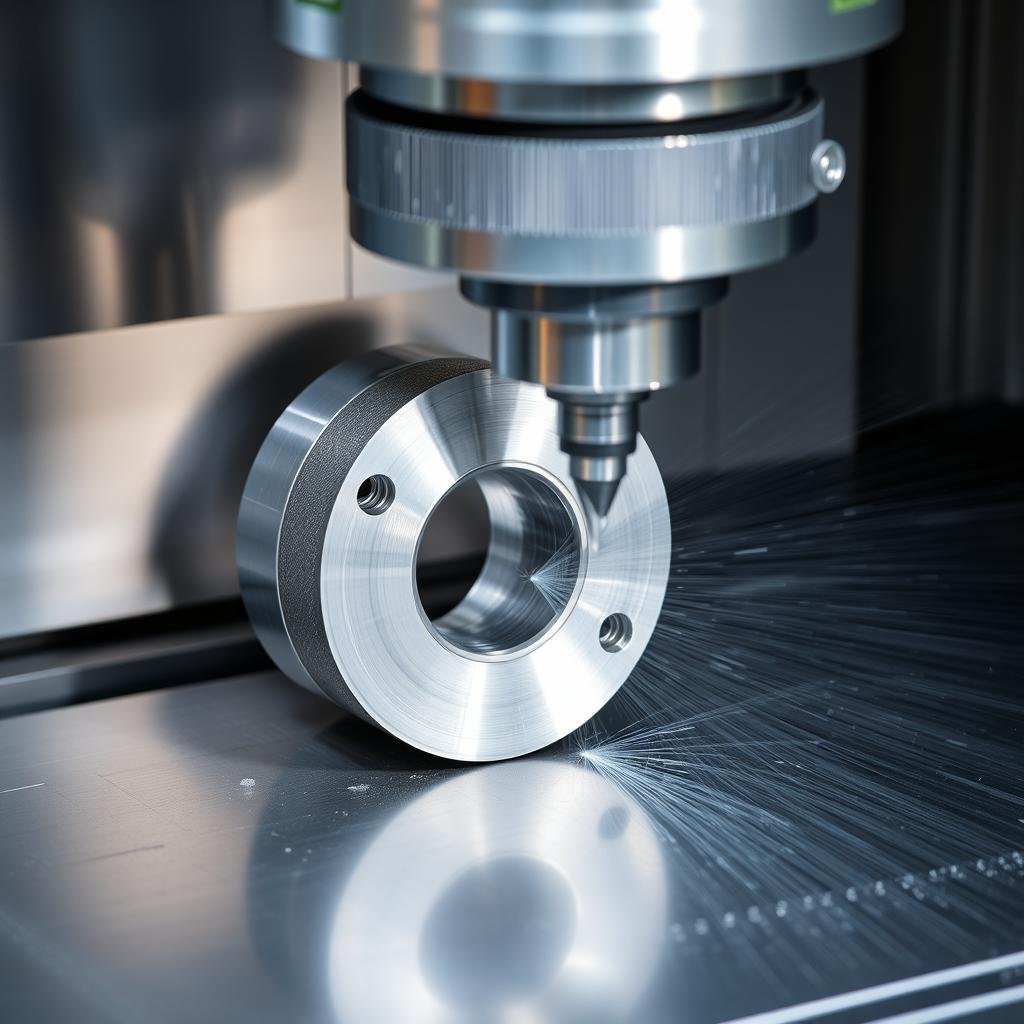

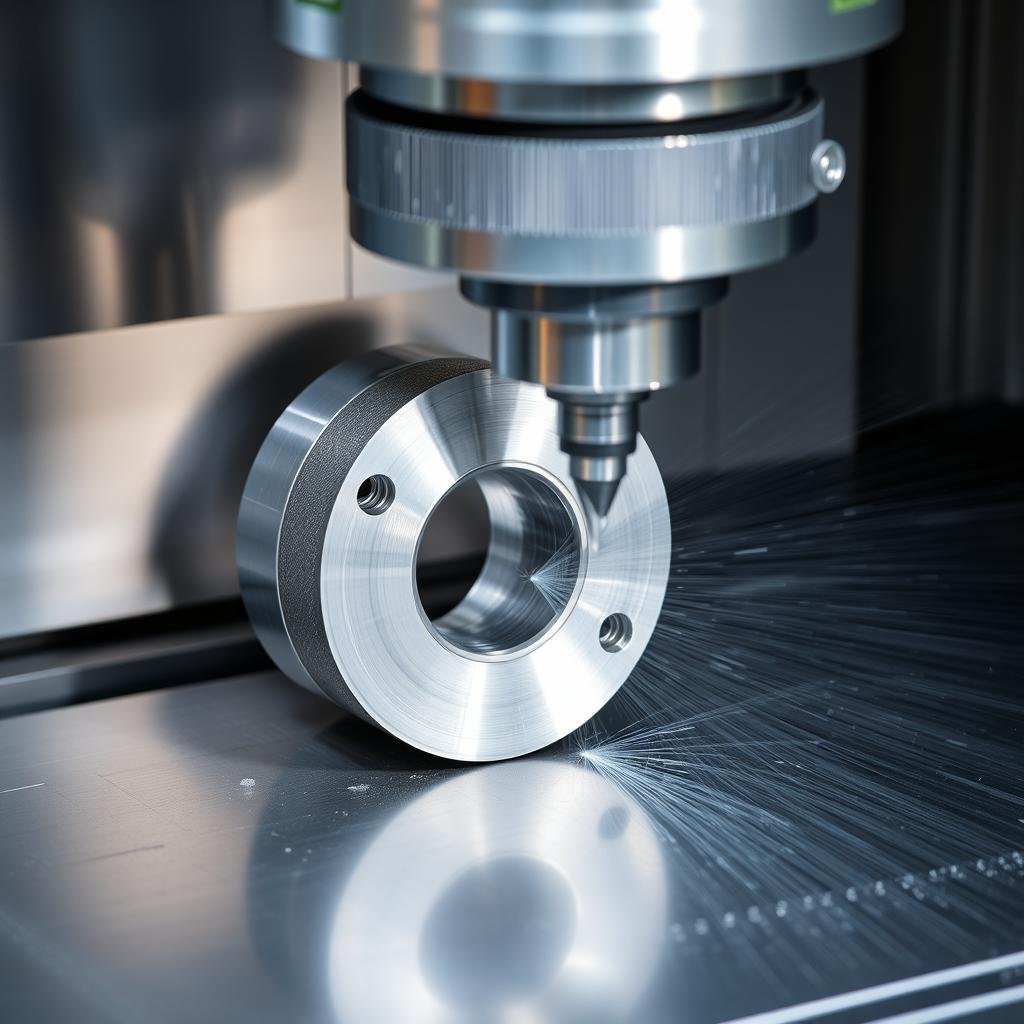

6. Precision Machining

Using our advanced CNC machining centers, we perform precision secondary operations to achieve final dimensions and features. This combination of forging and machining delivers the perfect balance of strength and precision.

Need Custom Aluminum Forged Parts?

Contact our engineering team to discuss your specific requirements and discover how our aluminum forging expertise can benefit your project.

Get a Custom Quote

Quality Assurance in the Aluminum Forging Process

At MAIKONG, quality isn’t just inspected—it’s built into every step of our manufacturing process. Our comprehensive quality management system ensures consistent excellence in every forged component we produce.

Our Quality Control Protocols

- Material certification and verification before processing

- In-process dimensional inspection during forging

- Non-destructive testing including ultrasonic and penetrant inspection

- Mechanical property testing (tensile, hardness, impact)

- Metallurgical analysis of grain structure and flow

- Final dimensional verification using CMM technology

- Surface finish inspection and verification

- Full documentation and traceability

Our ISO 9001:2015 certification demonstrates our commitment to maintaining the highest quality standards throughout our operations.

“Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction and skillful execution.”

MAIKONG Quality Philosophy

Industries Benefiting from MAIKONG’s Aluminum Forging Expertise

Our precision aluminum forged components serve critical applications across multiple industries where performance, reliability, and weight optimization are essential.

Aerospace

Structural components, landing gear parts, and engine mounts where weight reduction and absolute reliability are critical.

Automotive

Suspension components, connecting rods, and drivetrain parts that require exceptional strength-to-weight ratios.

Industrial Equipment

Structural components, hydraulic fittings, and high-stress mechanical parts for demanding industrial applications.

Medical Devices

Surgical instruments, equipment frames, and diagnostic device components requiring precision and reliability.

Custom Solutions for Every Industry

MAIKONG specializes in developing custom aluminum forged solutions tailored to your specific industry requirements. Our engineering team works closely with you to optimize designs for manufacturability, performance, and cost-effectiveness.

MAIKONG’s Comprehensive Manufacturing Capabilities

As a full-service aluminum forging manufacturer, MAIKONG offers end-to-end solutions from concept to finished component. Our integrated capabilities ensure quality control at every stage while streamlining your supply chain.

Forging Capabilities

- Open die forging for larger components

- Closed die forging for precision parts

- Hydraulic presses from 800 to 3,000 tons

- Parts ranging from 0.1 kg to 50 kg

- Wide range of aluminum alloys processed

- Complex geometries and near-net shapes

CNC Machining Services

- 60+ CNC machines with 100+ tons monthly capacity

- CNC turning for cylindrical components

- CNC milling for complex prismatic shapes

- Swiss-type machining for precision small parts

- Multi-axis machining capabilities

- Surface grinding and laser engraving

Additional Services

- In-house heat treatment

- Surface treatments including anodizing

- Material testing and certification

- Prototype development

- Design assistance and optimization

- Full quality documentation

Partner with MAIKONG for Your Aluminum Forging Needs

Experience the MAIKONG difference with our comprehensive manufacturing capabilities and commitment to quality.

Contact Our Engineering Team

Frequently Asked Questions About Aluminum Forging

What makes the Aluminum Forging Process superior to casting?

Aluminum forging creates parts with superior grain structure alignment, resulting in higher strength, better fatigue resistance, and improved durability compared to casting. The forging process eliminates porosity issues common in castings, making forged components ideal for critical applications where reliability is essential.

Which aluminum alloys are best suited for forging?

The most commonly forged aluminum alloys include 6061, 7075, and 2024. Each offers different advantages: 6061 provides excellent corrosion resistance and good mechanical properties; 7075 delivers exceptional strength for aerospace applications; and 2024 offers superior fatigue resistance. At MAIKONG, we can work with a wide range of aluminum alloys based on your specific requirements.

What are the typical lead times for custom aluminum forged parts?

Lead times vary based on part complexity, quantity, and current production schedule. Typical lead times range from 4-8 weeks for new designs requiring tooling development, and 2-4 weeks for repeat orders. MAIKONG offers expedited services for time-critical projects when possible. Contact our team for a specific timeline based on your project requirements.

How does MAIKONG ensure quality in forged aluminum parts?

MAIKONG implements a comprehensive quality management system certified to ISO 9001:2015 standards. Our quality assurance process includes material certification, in-process inspections, non-destructive testing, mechanical property verification, and final dimensional inspection. Every component is fully traceable, with documentation provided to validate compliance with specifications.