In today’s competitive manufacturing landscape, finding the right partner for your aluminum forging process needs can significantly impact your product quality, timeline, and bottom line. Working directly with a specialized aluminum forging factory like MAIKONG offers numerous advantages that can transform your production capabilities. This comprehensive guide explores how partnering with an experienced forging manufacturer can streamline your supply chain, enhance product quality, and provide cost-effective solutions for your custom metal components.

Understanding the Aluminum Forging Process: A Technical Overview

The aluminum forging process involves shaping aluminum alloys using localized compressive forces. This sophisticated manufacturing technique creates components with superior strength, durability, and lightweight properties that are essential across numerous industries.

The

aluminum forging process at MAIKONG’s state-of-the-art facility in GD, SZ

Key Stages in the Aluminum Forging Process

- Material Selection: Choosing the appropriate aluminum alloy based on application requirements

- Heating: Warming the aluminum billet to optimal forging temperature (typically 750°F to 900°F)

- Deformation: Applying controlled pressure to shape the heated aluminum

- Cooling: Carefully managing the cooling process to achieve desired properties

- Heat Treatment: Enhancing mechanical properties through specialized heating processes

- Finishing: Precision machining and surface treatments to complete the component

At MAIKONG, we’ve refined each stage of this process to deliver exceptional quality forged components with consistent mechanical properties and precise dimensional accuracy.

Why Choose Forged Aluminum Components?

Understanding the distinct advantages of aluminum forgings helps explain why this manufacturing process is preferred for critical applications where performance cannot be compromised.

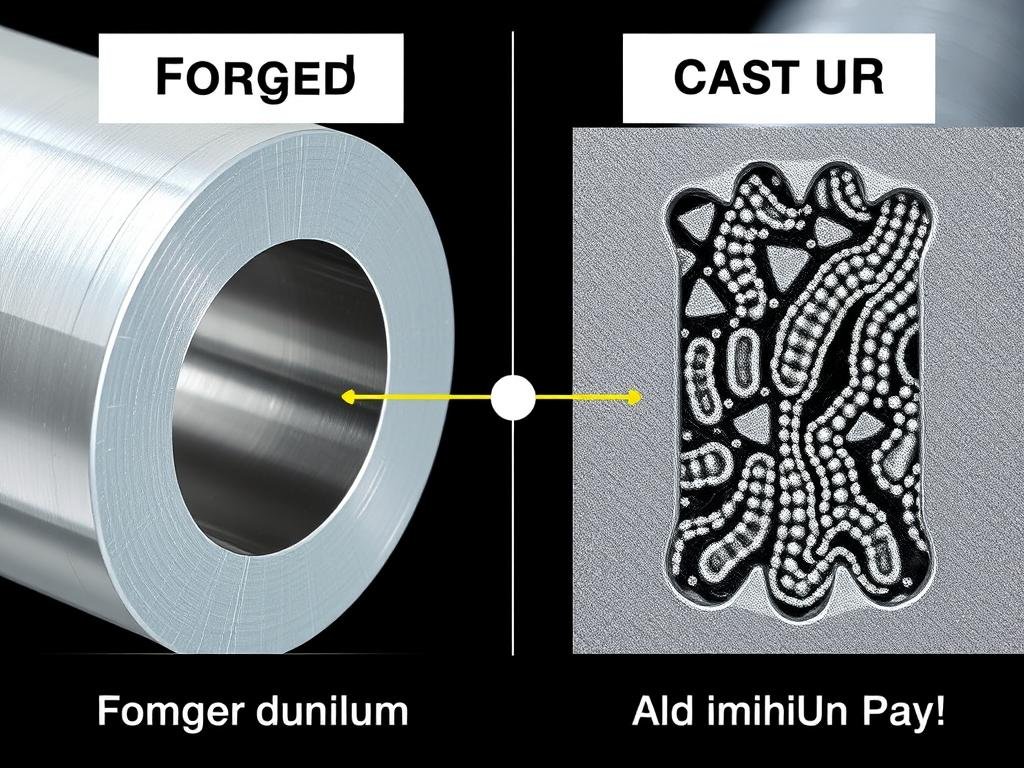

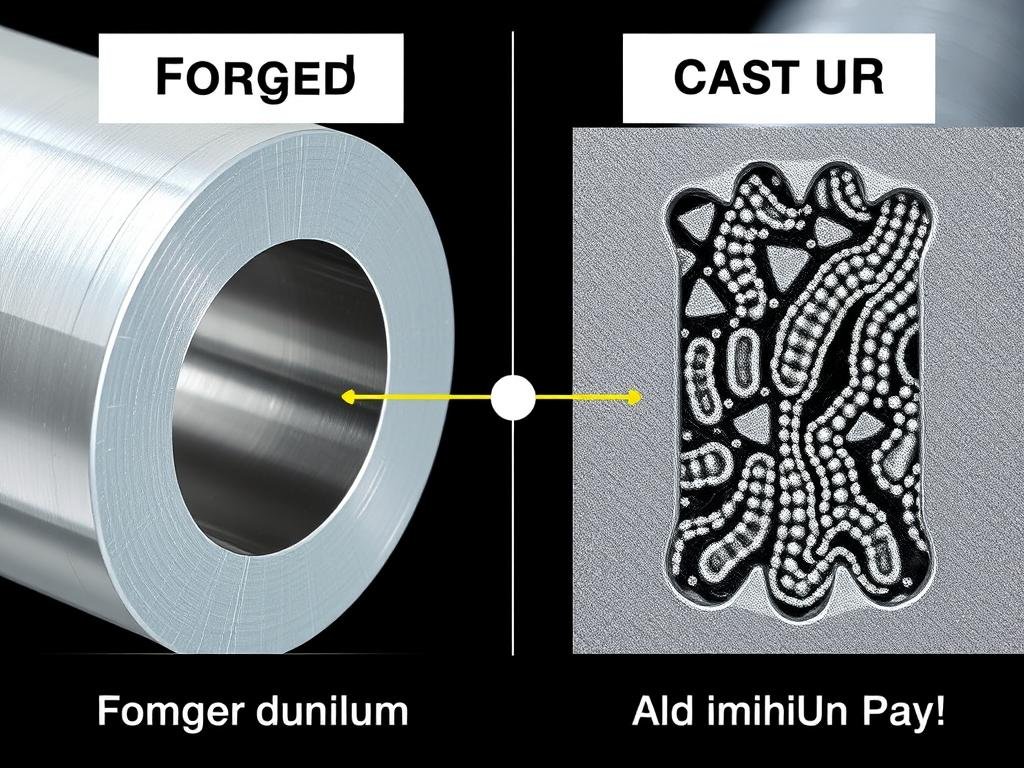

Forged aluminum’s aligned grain structure provides superior strength compared to cast alternatives

Forging Process Aligns the Grain Structure of Aluminum

One of the most significant benefits of the aluminum forging process is how it aligns the metal’s grain structure. Unlike casting, which creates a random grain pattern, forging produces a directional grain flow that follows the component’s shape, dramatically enhancing strength and fatigue resistance.

Optimal Strength-to-Weight Ratio

Forged aluminum components offer an exceptional balance between mechanical strength and weight reduction—a critical factor in aerospace, automotive, and other weight-sensitive applications. This optimal ratio enables engineers to design lighter yet stronger components that improve overall system performance.

Aluminum Forging vs. Casting: A Comprehensive Comparison

When deciding between manufacturing processes, understanding the key differences between forging and casting is essential for making informed decisions.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps of effort to achieve complex shape |

✅Can achieve complex shape in one session |

| Dimensional Accuracy |

✅Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅Smoother surfaces, reduced post-processing |

Might require more machining due to air pocket |

| Weight-to-Strength Ratio |

✅High strength-to-weight ratio |

Bulkier parts may be needed |

| Critical Applications |

✅Structural Members and load-bearing capabilities |

Limited suitability for critical applications |

Need Expert Guidance on Your Aluminum Component Design?

Our engineering team can help determine whether forging is the optimal process for your specific application.

Get Expert Consultation

MAIKONG’s Comprehensive Aluminum Forging Capabilities

As a leading aluminum forging factory, MAIKONG offers end-to-end manufacturing solutions from initial design to finished components. Our integrated approach ensures quality control at every stage of production.

MAIKONG’s advanced CNC machining center for post-forging precision operations

Full-Service Aluminum Forging Solutions

Design & Engineering

Our engineering team utilizes advanced CAD/CAM software to optimize component design for the aluminum forging process. This early-stage analysis identifies potential issues before production begins, saving time and resources.

Material Selection

We work with a wide range of aluminum alloys including 1100, 2014, 2024, 2219, 2618, 3003, 4032, 5052, 5083, 5086, 5383, 5456, 6061, 7039, 7050, 7075, 7079, and 7175. Each alloy is carefully selected based on your application’s specific requirements.

Tooling Design & Maintenance

Precision tooling is critical for quality forgings. Our in-house tooling department designs and maintains dies to ensure consistent quality throughout production runs of any size.

Forging Workshop

Our forging facility in GD, SZ is equipped with state-of-the-art hydraulic presses capable of handling diverse aluminum forging specifications with precision and efficiency.

Post-Forging Processing Capabilities

Heat Treatment

Our in-house heat treatment facilities allow precise control over the mechanical properties of forged components. We conduct comprehensive statistical analysis and documentation to ensure consistent results.

Precision Grinding

Automated grinding with specialized robotics removes parting lines and achieves precise dimensional tolerances that meet the most demanding specifications.

CNC Machining

With over 60 CNC machines providing 100+ tons of monthly processing capacity, our machining workshop handles precision turning, milling, swiss machining, and multi-axis operations.

Surface Treatment

We offer comprehensive surface finishing options including anodizing, painting, laser engraving, and sand blasting to enhance both appearance and performance of forged components.

Rigorous quality control inspection ensures every component meets exact specifications

Our integrated approach to the aluminum forging process enables us to maintain strict quality control standards while offering competitive pricing and reliable delivery schedules.

Ready to Discuss Your Aluminum Forging Project?

Contact our technical team today to explore how MAIKONG can meet your specific manufacturing requirements.

Contact via WhatsApp

Industries Benefiting from Precision Aluminum Forgings

The exceptional properties of forged aluminum components make them ideal for applications across numerous industries where performance, reliability, and weight considerations are critical.

MAIKONG produces custom aluminum forgings for diverse industry applications

Aerospace

The aerospace industry relies on forged aluminum for critical components like landing gears, structural frames, and engine parts due to its exceptional strength-to-weight ratio and reliability under extreme conditions.

Automotive

In automotive applications, aluminum forgings are used for suspension components, engine parts, and structural elements where weight reduction improves fuel efficiency without compromising safety.

Industrial Equipment

Heavy machinery and industrial equipment benefit from aluminum forgings’ durability, corrosion resistance, and ability to withstand high mechanical stress in demanding environments.

Defense

Military and defense applications utilize aluminum forgings for their reliability, precision, and performance in critical situations where component failure is not an option.

Marine

The marine industry values aluminum forgings for their excellent corrosion resistance in saltwater environments, combined with high strength and reduced weight.

Semiconductor

Semiconductor manufacturing equipment requires the precision, thermal conductivity, and dimensional stability that only properly forged aluminum components can provide.

MAIKONG’s expertise in the aluminum forging process enables us to serve these diverse industries with components that meet their specific performance requirements and quality standards.

Quality Assurance in the Aluminum Forging Process

At MAIKONG, quality is built into every stage of our manufacturing process, from material selection to final inspection. Our comprehensive quality management system ensures consistent excellence in all our forged components.

Our material testing laboratory ensures every component meets exact specifications

Comprehensive Quality Control Procedures

- Material Verification: Testing of incoming aluminum alloys to confirm chemical composition and mechanical properties

- Process Monitoring: Continuous oversight of forging parameters including temperature, pressure, and timing

- Dimensional Inspection: Precision measurement to verify components meet exact specifications

- Non-Destructive Testing: Ultrasonic, magnetic particle, and dye penetrant testing to detect internal and surface defects

- Mechanical Testing: Verification of tensile strength, yield strength, elongation, and hardness

- Final Inspection: Comprehensive review of all components before shipment

Certifications and Standards

MAIKONG maintains ISO 9001:2015 certification, demonstrating our commitment to quality management systems that ensure consistent product excellence. Our manufacturing processes adhere to international standards including ASTM, SAE, and industry-specific requirements.

When you partner with MAIKONG for your aluminum forging needs, you benefit from our rigorous quality assurance processes that minimize risk and maximize component reliability.

The Strategic Advantages of Direct Partnership with MAIKONG

Working directly with MAIKONG as your aluminum forging manufacturer offers significant benefits that can enhance your supply chain efficiency and product quality.

Our engineering team works closely with clients to optimize designs for manufacturability

Cost-Effectiveness Without Compromising Quality

By eliminating intermediaries, MAIKONG offers competitive pricing while maintaining exceptional quality standards. Our efficient manufacturing processes and strategic location in GD, SZ provide cost advantages that we pass directly to our customers.

Technical Expertise and Collaborative Development

Our engineering team brings decades of experience in the aluminum forging process to every project. We collaborate closely with your design team to optimize components for manufacturability, performance, and cost-efficiency.

Supply Chain Simplification

MAIKONG’s comprehensive capabilities—from forging to machining to surface treatment—simplify your supply chain by reducing the number of vendors needed to complete your components. This integrated approach improves quality control while reducing logistics complexity.

Flexible Production Capacity

Whether you need prototype quantities or high-volume production runs, our manufacturing facility can scale to meet your requirements with consistent quality and reliable delivery schedules.

Become a MAIKONG Distribution Partner in the US

We’re actively seeking US distributors for our high-quality aluminum forged components. Join our network and offer your customers exceptional value.

Discuss Partnership Opportunities

Conclusion: Elevate Your Manufacturing with Expert Aluminum Forging

The aluminum forging process represents one of the most effective manufacturing methods for creating high-strength, lightweight components for critical applications. By partnering directly with MAIKONG, you gain access to comprehensive technical expertise, cost-effective production capabilities, and quality assurance that can transform your supply chain.

Whether you’re designing components for aerospace, automotive, industrial, or other demanding applications, our team is ready to support your manufacturing needs with precision aluminum forgings that meet the highest performance standards. Contact MAIKONG today to discover how our aluminum forging solutions can benefit your next project.

The aluminum forging process at MAIKONG’s state-of-the-art facility in GD, SZ

The aluminum forging process at MAIKONG’s state-of-the-art facility in GD, SZ