The Aluminum Forging Process represents one of the most effective manufacturing methods for creating high-strength, lightweight components essential across numerous industries. At MAIKONG, we’ve perfected this sophisticated metalworking technique through decades of experience, cutting-edge equipment, and rigorous quality control. This comprehensive guide explores how our state-of-the-art facility in GD, SZ transforms raw aluminum into precision-engineered components that meet the most demanding specifications.

Need high-quality aluminum forged parts with competitive pricing? MAIKONG is currently recruiting agents across the United States.

Get A Quick Quote

Understanding the Aluminum Forging Process

MAIKONG’s precision temperature-controlled forge for aluminum processing

Aluminum forging involves reshaping metal through compressive forces, creating components with superior mechanical properties compared to casting or machining alone. This transformative process aligns the metal’s grain structure, significantly enhancing strength, durability, and fatigue resistance while maintaining aluminum’s inherent lightweight characteristics.

At MAIKONG, our Aluminum Forging Process combines traditional metalworking principles with advanced technology to deliver exceptional results. Our comprehensive approach encompasses every stage from initial design to final inspection, ensuring each component meets precise specifications.

Key Benefits of Forged Aluminum Components

Superior Strength

Forged aluminum exhibits exceptional tensile strength and structural integrity, making it ideal for critical applications where failure is not an option.

Lightweight Construction

Aluminum’s natural lightweight properties combined with forging’s strength enhancement create an optimal strength-to-weight ratio for efficiency-focused designs.

Enhanced Durability

The aligned grain structure achieved through forging significantly improves fatigue resistance and overall component lifespan.

Precision Engineering

Our advanced forging techniques allow for tight tolerances and complex geometries that maintain consistency across production runs.

Cost Efficiency

Reduced material waste and minimal secondary machining requirements make forging economically advantageous for many applications.

Corrosion Resistance

Forged aluminum naturally forms a protective oxide layer, providing excellent resistance to environmental degradation.

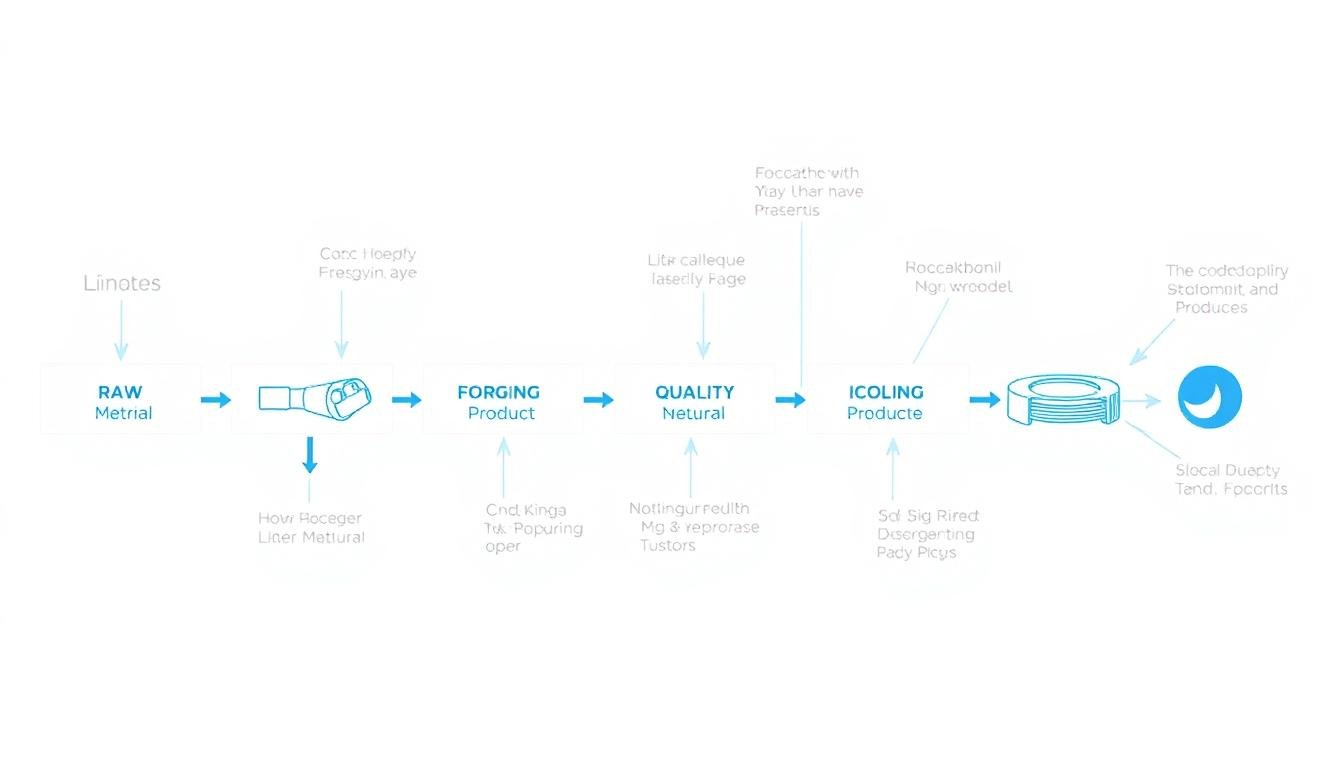

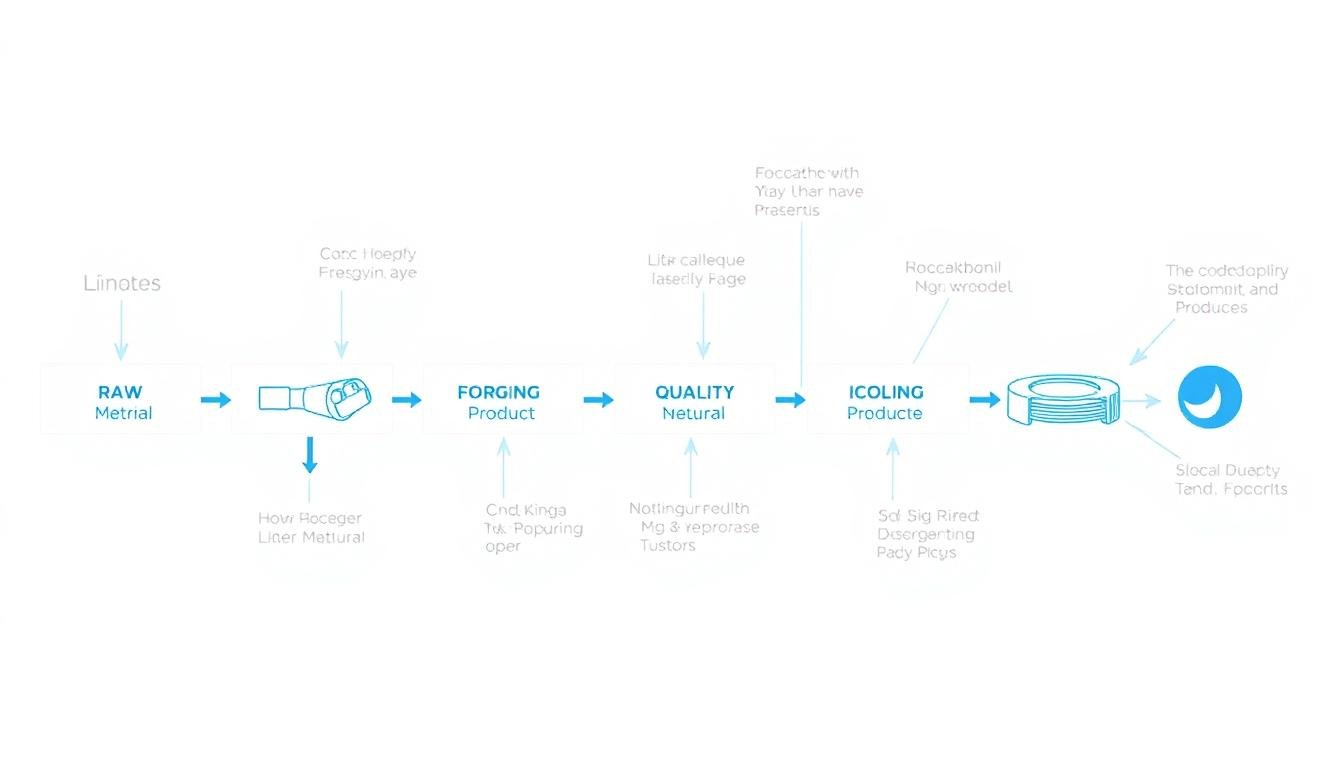

Step-by-Step Aluminum Forging Process

At MAIKONG, we’ve refined each stage of the aluminum forging process to ensure optimal results. Our comprehensive approach combines traditional craftsmanship with modern technology to deliver superior components.

-

Material Selection and Preparation

We begin by selecting the optimal aluminum alloy for your specific application. Common forging alloys include 6061, 7075, and 2024, each offering distinct mechanical properties. The raw material is cut to precise dimensions, creating billets that serve as the foundation for the forging process.

-

Heating to Forging Temperature

The aluminum billet is heated to a specific temperature range (typically 700°F to 950°F) in our precision-controlled furnaces. This critical step requires expert monitoring, as aluminum must reach the ideal temperature for malleability without approaching its melting point.

-

Forging Operations

Once properly heated, the aluminum undergoes one or more forging operations depending on the complexity of the final component. At MAIKONG, we employ various forging techniques:

- Open Die Forging: Ideal for larger, simpler shapes with excellent mechanical properties

- Closed Die Forging: Creates complex geometries with tight tolerances and minimal material waste

- Ring Rolling: Specialized technique for producing seamless rings with consistent properties

- Precision Forging: Achieves near-net shapes that require minimal secondary machining

-

Controlled Cooling

After forging, components undergo controlled cooling to prevent thermal shock and maintain dimensional stability. This process is carefully monitored to ensure optimal microstructure development.

-

Heat Treatment

Many aluminum forgings require heat treatment to enhance specific mechanical properties. Our in-house heat treatment facilities provide solution treatment, quenching, and aging processes tailored to each alloy’s requirements.

-

Secondary Operations

Depending on design specifications, forgings may undergo secondary operations such as CNC machining, grinding, or surface treatments to achieve final dimensions and finishes.

-

Quality Inspection

Every component undergoes rigorous inspection using advanced measurement equipment and non-destructive testing methods to verify dimensional accuracy and structural integrity.

Need Precision Aluminum Forgings?

MAIKONG delivers high-quality forged components with competitive pricing and comprehensive capabilities.

Contact Us on WhatsApp

Aluminum Forging vs. Casting: A Comprehensive Comparison

Understanding the differences between forging and casting is crucial when selecting the optimal manufacturing process for your aluminum components. While both methods create metal parts, they differ significantly in process, properties, and applications.

Microscopic comparison: Forged aluminum (left) shows aligned grain structure while cast aluminum (right) exhibits random grain orientation

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Typically lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Requires multiple steps to achieve complex shapes |

Can achieve complex shapes in one session |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Weight-to-Strength Ratio |

High strength-to-weight ratio |

Bulkier parts may be needed for equivalent strength |

| Ideal Applications |

Aerospace, automotive, structural components |

Consumer goods, decorative items, complex housings |

For applications requiring maximum mechanical performance, structural integrity, and reliability, the Aluminum Forging Process provides clear advantages. At MAIKONG, we specialize in delivering these superior forged components while maintaining competitive pricing.

Explore Our Aluminum Forging Capabilities

Contact our engineering team to discuss your specific requirements and discover how our forging expertise can benefit your projects.

Email Our Engineering Team

Advanced Technologies in Our Aluminum Forging Process

At MAIKONG, we continuously invest in cutting-edge technologies to enhance our aluminum forging capabilities. Our modern facility in GD, SZ integrates advanced systems throughout the production process, ensuring exceptional quality and efficiency.

CAD/CAM Integration

Our engineering team utilizes sophisticated Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems to optimize every aspect of the forging process. This integrated approach allows us to:

- Simulate material flow during forging to predict and prevent potential defects

- Optimize die designs for maximum efficiency and minimal material waste

- Create precise tooling paths for secondary CNC operations

- Analyze structural performance under various loading conditions

- Streamline production workflows for improved efficiency

Precision CNC Machining Integration

Our facility houses over 60 advanced CNC machines with a monthly processing capacity exceeding 100 tons. This extensive capability allows us to perform precision secondary operations on forged components, including:

CNC Turning

Ideal for creating precise cylindrical features, deep holes, and machined threads with superior surface finishes on forged aluminum components.

CNC Milling

Creates complex prismatic shapes and flat surfaces with exceptional accuracy, enhancing the dimensional precision of forged parts.

Swiss-Type Machining

Specializes in precision small parts and long shaft components, utilizing multi-axis capabilities for complete one-stop solutions.

Discover Our Complete Manufacturing Capabilities

From aluminum forging to precision CNC machining, MAIKONG offers comprehensive manufacturing solutions.

Explore Our Services

Quality Assurance in the Aluminum Forging Process

At MAIKONG, quality isn’t just a department—it’s a fundamental aspect of our entire operation. Our comprehensive quality management system ensures that every forged aluminum component meets or exceeds the most stringent industry standards.

Our quality control laboratory features advanced measurement and testing equipment

Comprehensive Quality Control Measures

Material Verification

Our in-house material laboratory conducts thorough testing of all incoming aluminum alloys to verify chemical composition and mechanical properties before processing begins.

Process Monitoring

Advanced sensors and monitoring systems track critical parameters throughout the forging process, ensuring consistent temperature, pressure, and timing for optimal results.

Dimensional Inspection

Precision coordinate measuring machines (CMMs) verify that all components meet exact dimensional specifications with tolerances as tight as ±0.005mm where required.

Non-Destructive Testing

Ultrasonic, magnetic particle, and dye penetrant testing methods identify any internal or surface defects that might compromise component integrity.

Mechanical Testing

Tensile, hardness, and impact testing verify that forged components meet specified mechanical property requirements for their intended applications.

Documentation & Traceability

Comprehensive documentation maintains complete traceability from raw material to finished component, supporting quality certification and regulatory compliance.

Certifications and Standards

MAIKONG maintains ISO 9001:2015 certification, demonstrating our commitment to consistent quality management practices. Our aluminum forging processes adhere to international standards including:

- ASTM B247 – Standard Specification for Aluminum and Aluminum-Alloy Die Forgings, Hand Forgings, and Rolled Ring Forgings

- AMS-QQ-A-367 – Aerospace Material Specification for Aluminum Alloy Forgings

- EN 586 – European Standard for Aluminum and Aluminum Alloys – Forgings

Industry Applications for Aluminum Forged Components

The exceptional properties of forged aluminum make it the material of choice across numerous industries where performance, reliability, and weight considerations are critical. At MAIKONG, we serve diverse sectors with our advanced Aluminum Forging Process.

Aerospace

Forged aluminum components provide the ideal combination of lightweight construction and high strength for aircraft structural members, landing gear components, and engine parts where reliability is paramount.

Automotive

Vehicle manufacturers rely on forged aluminum for suspension components, engine parts, and structural elements to reduce weight, improve fuel efficiency, and enhance performance while maintaining safety standards.

Industrial Equipment

Heavy machinery benefits from forged aluminum components in applications requiring high strength-to-weight ratios, excellent wear resistance, and the ability to withstand demanding operating conditions.

Electronics

Precision forged aluminum housings and heat sinks provide excellent thermal management, electromagnetic shielding, and structural integrity for sensitive electronic components.

Medical Devices

The biocompatibility, strength, and precision of forged aluminum make it suitable for various medical device components where reliability and performance are critical.

Sports Equipment

From bicycle components to golf clubs, forged aluminum delivers the performance advantages athletes demand, combining lightweight construction with exceptional durability.

Custom Aluminum Forging for Your Industry

Whatever your application, MAIKONG can deliver forged aluminum components that meet your exact specifications.

Request Industry-Specific Solutions

MAIKONG Aluminum Forging Gallery

Explore examples of our precision aluminum forged components across various industries and applications. Each project demonstrates our commitment to quality, precision, and technical excellence.

See How MAIKONG Can Serve Your Specific Needs

Contact our engineering team to discuss your custom aluminum forging requirements.

Or email us at:

Lucy@maikongforge.us

Why Choose MAIKONG for Your Aluminum Forging Needs

With decades of experience, state-of-the-art facilities, and a commitment to excellence, MAIKONG stands as your ideal partner for precision aluminum forging and machining services. Our comprehensive capabilities ensure that we can meet your most demanding requirements with quality, efficiency, and competitive pricing.

The MAIKONG Advantage

- Comprehensive in-house capabilities from forging to finishing

- Advanced CAD/CAM integration for optimized production

- ISO 9001:2015 certified quality management system

- 60+ CNC machines with 100+ tons monthly capacity

- Competitive pricing with exceptional quality

- Experienced engineering team for technical support

- Flexible production volumes from prototypes to high-volume runs

Experience the difference that MAIKONG’s expertise in the Aluminum Forging Process can make for your projects. Contact us today to discuss your specific requirements and discover how our capabilities can support your manufacturing needs.

Ready to Get Started?

Contact MAIKONG today to discuss your aluminum forging requirements.

Get A Quick Quote Now