The aluminum forging process transforms raw aluminum into high-strength, precision-engineered components through controlled deformation under pressure. This manufacturing method creates parts with superior mechanical properties compared to casting or machining alone. At MAIKONG, we’ve mastered this sophisticated process to deliver exceptional aluminum forged components that meet the most demanding specifications across industries. This comprehensive guide explores every aspect of aluminum forging, from material selection to finishing operations.

The Critical Importance of the Aluminum Forging Process

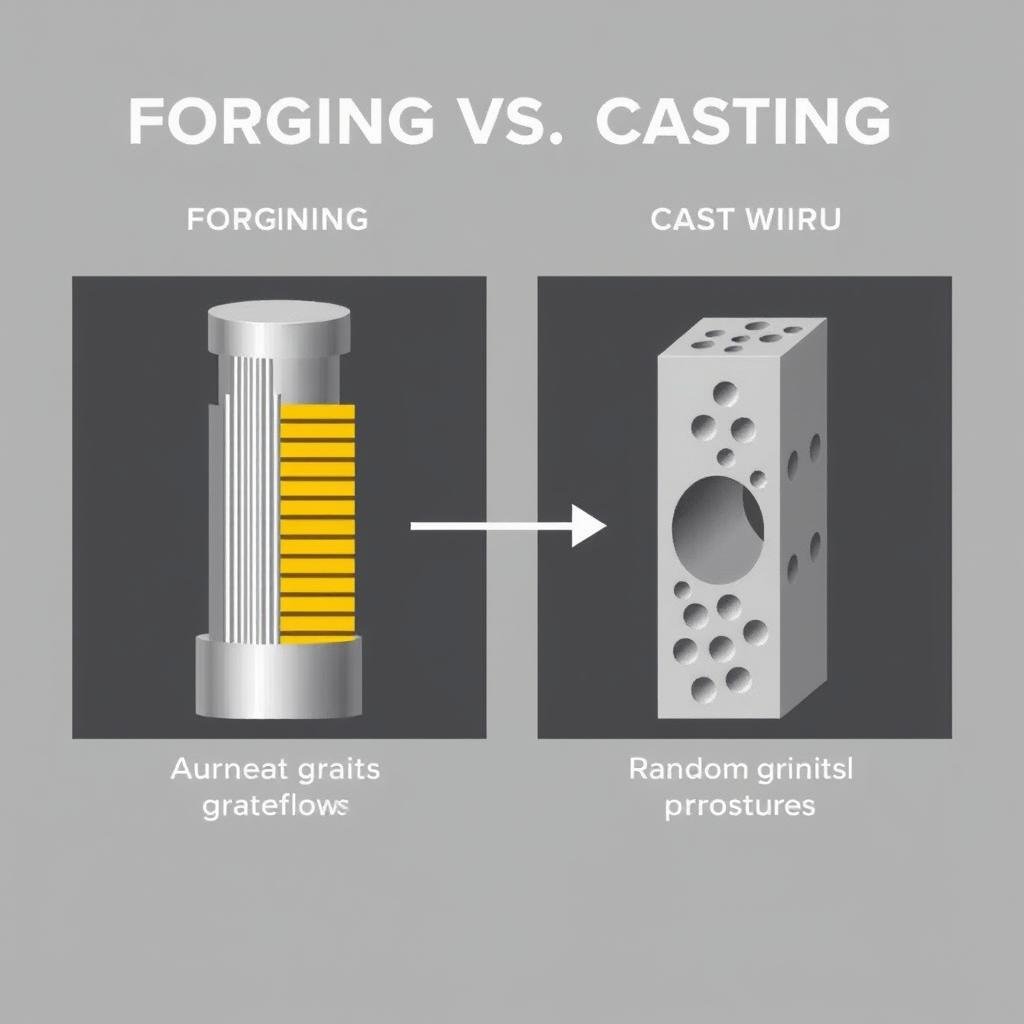

Aluminum forging stands apart from other metalworking methods by creating components with exceptional strength-to-weight ratios and superior grain structures. Unlike casting, where molten metal solidifies in a mold, forging physically reshapes solid metal, aligning its grain structure to follow the part’s contours. This alignment dramatically enhances mechanical properties, including fatigue resistance, impact strength, and overall durability.

Industries ranging from aerospace and automotive to defense and medical rely on forged aluminum components where failure is not an option. The aluminum forging process delivers parts with consistent internal integrity, minimal porosity, and excellent mechanical properties that simply cannot be achieved through other manufacturing methods.

Key Advantages of Forged Aluminum

- Superior strength-to-weight ratio

- Enhanced directional strength

- Excellent fatigue resistance

- Improved impact toughness

- Consistent mechanical properties

- Minimal internal defects

Need High-Performance Aluminum Components?

MAIKONG specializes in precision aluminum forging with superior mechanical properties and competitive pricing. Our engineering team can help optimize your design for the forging process.

Get Expert Consultation

Step-by-Step Guide to the Aluminum Forging Process

The aluminum forging process requires precision at every stage to ensure optimal results. At MAIKONG, we’ve refined each step to deliver consistently exceptional components. Here’s a detailed breakdown of our comprehensive approach:

1. Material Selection and Preparation

The foundation of successful aluminum forging begins with selecting the appropriate alloy. Different alloys offer varying combinations of strength, corrosion resistance, and machinability. Common forging alloys include 6061, 7075, and 2024, each with specific applications based on their unique properties.

At MAIKONG, we maintain strict quality control for all incoming materials, verifying chemical composition and mechanical properties before processing. The aluminum billet—the raw material for forging—must be properly sized and prepared, with surfaces cleaned of contaminants that could compromise the final product.

Our material laboratory conducts comprehensive testing to ensure every billet meets exact specifications, establishing the foundation for high-quality forged components.

| Aluminum Alloy |

Typical Applications |

Key Properties |

| 6061 |

Structural components, frames |

Good corrosion resistance, excellent formability |

| 7075 |

Aerospace, high-stress parts |

High strength, good fatigue resistance |

| 2024 |

Aircraft structures |

High strength-to-weight ratio, good machinability |

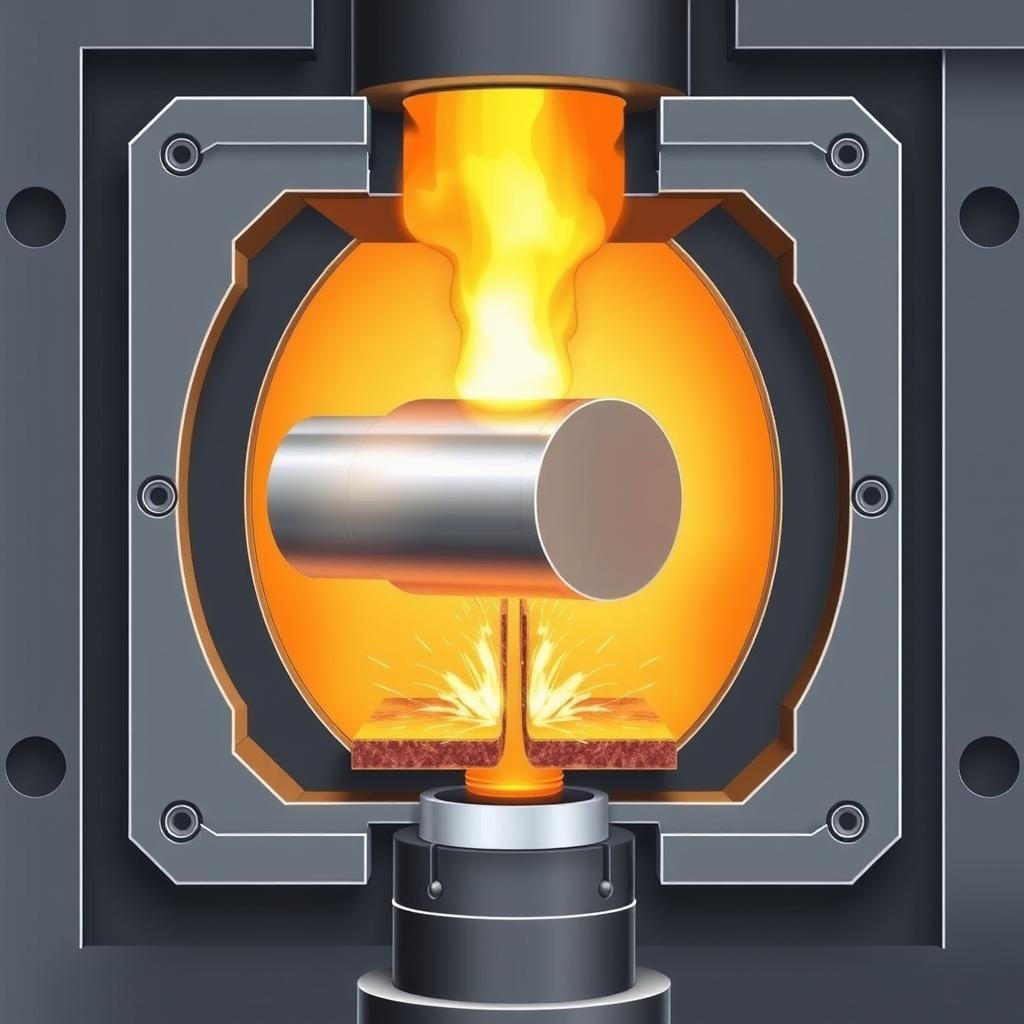

2. Heating Process

Temperature control is critical in the aluminum forging process. Unlike steel, which glows red when properly heated, aluminum requires precise temperature monitoring equipment as it shows no visible color change. Most aluminum alloys are forged between 700°F and 950°F (370°C to 510°C), with the exact temperature depending on the specific alloy.

At MAIKONG, our temperature-controlled furnaces maintain precise heating conditions, with continuous monitoring to prevent overheating that could compromise the material’s properties. Uniform heating is essential to ensure consistent material flow during forging and prevent defects in the finished component.

Technical Note: Overheating aluminum can lead to incipient melting at grain boundaries, severely compromising structural integrity. Our precision temperature control systems maintain optimal forging temperatures within ±5°F to prevent this issue.

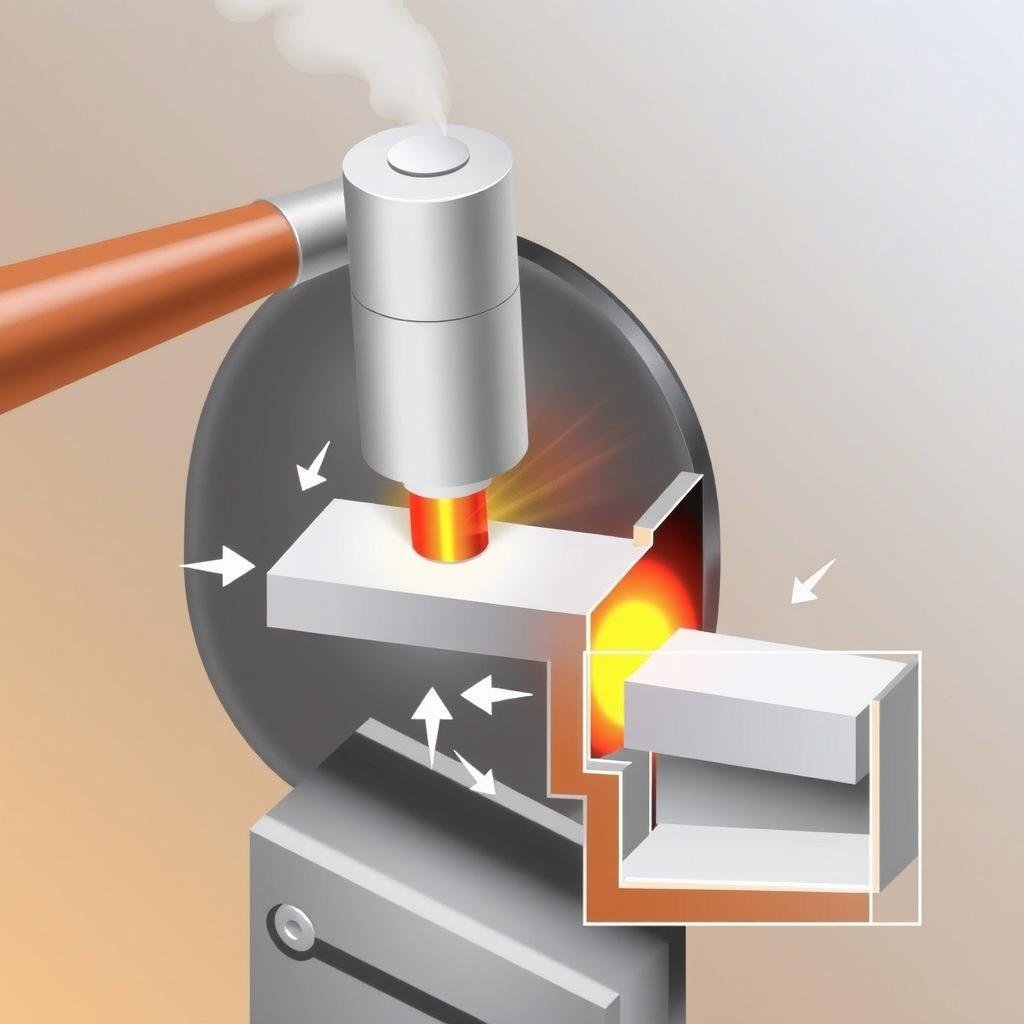

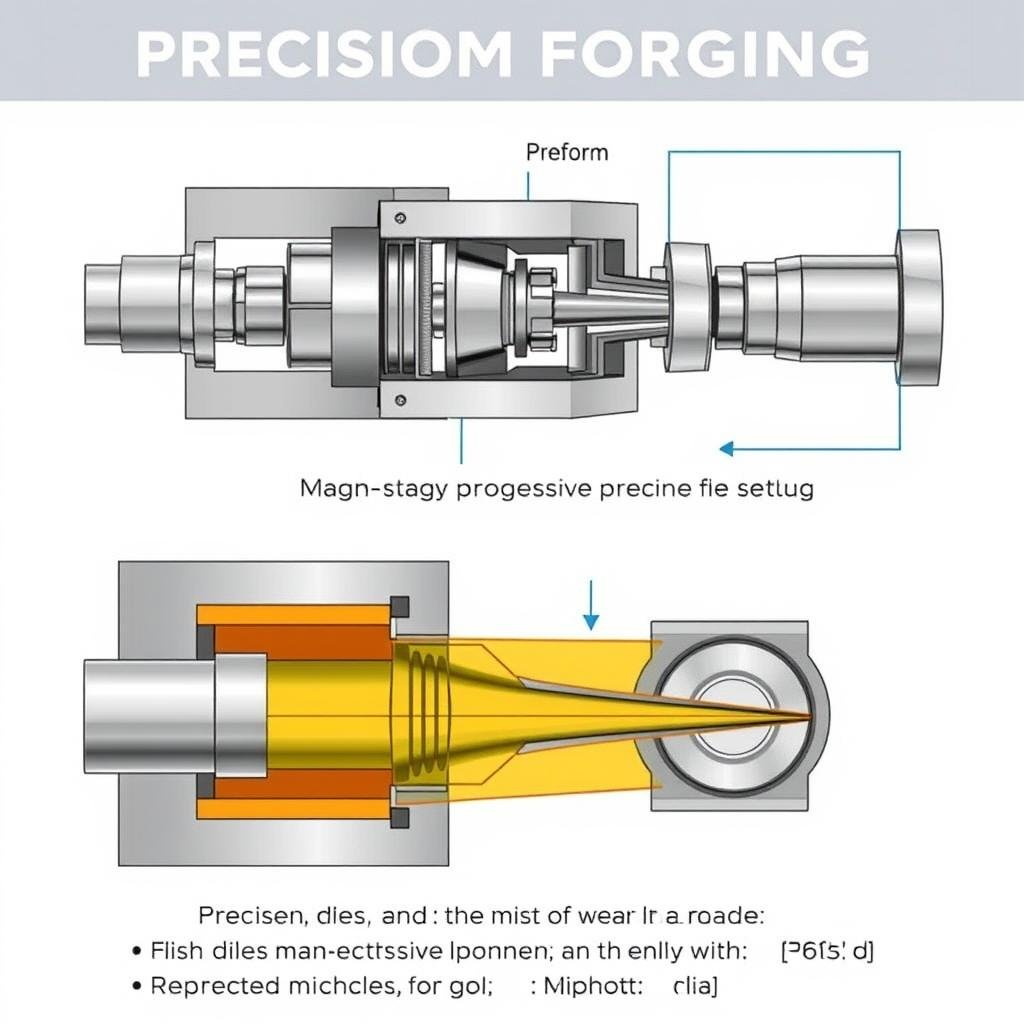

3. Forging Operations

Once properly heated, the aluminum billet undergoes one or more forging operations to achieve the desired shape. The specific forging method depends on part complexity, production volume, and required tolerances.

Open Die Forging

Simple dies shape the material through repeated hammer or press strokes. Ideal for larger parts or low-volume production.

Closed Die Forging

Material is shaped within a die cavity, creating complex geometries with tighter tolerances. Most common for precision components.

Precision Forging

Advanced process creating near-net shape parts with minimal machining requirements and exceptional dimensional accuracy.

The forging operation applies controlled pressure to reshape the heated aluminum, typically using hydraulic presses ranging from 800 to 8,000 tons of force. This pressure causes the aluminum to flow within the die cavity, filling all details while maintaining a continuous grain structure throughout the part.

4. Trimming and Initial Inspection

After forging, excess material (flash) is removed through trimming operations. This process creates clean part edges and prepares the component for heat treatment. Initial inspection identifies any visible defects or dimensional issues before proceeding to subsequent operations.

5. Heat Treatment

Heat treatment is essential to achieve the desired mechanical properties in forged aluminum components. The process typically involves:

- Solution Heat Treatment: Heating to a specific temperature to dissolve alloying elements into solid solution

- Quenching: Rapid cooling to lock the alloying elements in place

- Aging: Controlled precipitation of alloying elements to achieve optimal strength and hardness

MAIKONG’s in-house heat treatment facilities ensure precise control over these critical processes, with comprehensive documentation and statistical analysis to verify consistent results.

6. Finishing Operations

The final stages of the aluminum forging process involve various finishing operations to achieve the required dimensions, surface finish, and appearance:

- CNC Machining: Precision machining to achieve final dimensions and features

- Surface Treatment: Anodizing, painting, or other treatments for appearance and corrosion protection

- Final Inspection: Comprehensive quality verification including dimensional, visual, and mechanical testing

Ready to Optimize Your Component Design?

Our engineering team can help you design parts that maximize the benefits of the aluminum forging process while minimizing costs.

Request Design Consultation

Aluminum Forging vs. Casting: Making the Right Choice

When designing aluminum components, engineers must choose between forging and casting based on performance requirements, production volume, and cost considerations. Understanding these differences is crucial for making informed manufacturing decisions.

| Comparison Factor |

Aluminum Forging |

Aluminum Casting |

| Mechanical Strength |

Superior strength due to aligned grain structure |

Lower strength with potential porosity issues |

| Fatigue Resistance |

Excellent resistance to cyclic loading |

Reduced fatigue performance |

| Design Complexity |

Limited to moderately complex geometries |

Capable of highly complex shapes |

| Internal Integrity |

Minimal to no porosity or inclusions |

Potential for internal voids and inclusions |

| Production Volume |

Economical for medium to high volumes |

Suitable for low to high volumes |

| Dimensional Accuracy |

High precision with proper tooling |

Variable depending on casting method |

| Ideal Applications |

Safety-critical, high-stress components |

Complex geometries with moderate stress |

While casting offers advantages for complex geometries and certain production scenarios, forging remains the superior choice for components where mechanical performance is critical. The aluminum forging process creates parts with significantly higher strength, improved fatigue resistance, and better overall reliability—essential factors in safety-critical applications.

MAIKONG’s Comprehensive Aluminum Forging Capabilities

At MAIKONG, we’ve developed extensive capabilities to handle every aspect of the aluminum forging process in-house. Our integrated approach ensures consistent quality, optimized lead times, and competitive pricing for our customers.

Design & Engineering

- Advanced CAD/CAM systems

- Forging simulation software

- Design for manufacturability

- Material optimization

Forging Equipment

- Hydraulic presses up to 5,000 tons

- Precision die systems

- Automated handling equipment

- Temperature-controlled environment

Secondary Processing

- 60+ CNC machines

- Heat treatment facilities

- Surface finishing capabilities

- Assembly services

Our state-of-the-art facility in GD, SZ is equipped to handle 100+ tons of metal processing monthly, with specialized capabilities for aluminum forging and precision machining. By controlling the entire production process, we ensure consistent quality while optimizing costs and lead times.

Quality Assurance in the Aluminum Forging Process

Quality control is integrated throughout our aluminum forging operations, with comprehensive inspection protocols at each production stage. Our ISO 9001:2015 certified quality management system ensures consistent adherence to the highest standards.

Our Quality Control Measures Include:

- Material Verification: Chemical composition and mechanical property testing

- In-Process Inspection: Dimensional and visual checks during production

- Non-Destructive Testing: Ultrasonic, magnetic particle, and dye penetrant inspection

- Mechanical Testing: Tensile, hardness, and impact testing

- Final Dimensional Inspection: CMM verification of critical dimensions

- Documentation: Comprehensive production and testing records

Our dedicated quality engineering team monitors every aspect of the production process, ensuring that each component meets or exceeds customer specifications. This commitment to quality has established MAIKONG as a trusted supplier for industries where component reliability is critical.

Partnership Opportunities with MAIKONG

MAIKONG is actively seeking US distributors and agents to represent our aluminum forging and precision machining capabilities. We offer competitive advantages that make us an ideal manufacturing partner:

Why Partner with MAIKONG

- Comprehensive Capabilities: One-stop solution from design to finished components

- Competitive Pricing: Excellent value without compromising quality

- Technical Expertise: Engineering support for design optimization

- Quality Assurance: ISO 9001:2015 certified processes

- Production Capacity: 100+ tons monthly capacity with 60+ CNC machines

- Responsive Communication: Dedicated account management

Experience the MAIKONG Difference in Aluminum Forging

The aluminum forging process creates components with exceptional mechanical properties that cannot be achieved through other manufacturing methods. At MAIKONG, we’ve perfected this process through years of experience, continuous investment in technology, and a relentless commitment to quality.

From aerospace and automotive to medical and defense applications, our aluminum forging capabilities deliver the performance, consistency, and value that demanding industries require. Contact us today to discover how MAIKONG can support your manufacturing needs with our comprehensive aluminum forging and precision machining services.

Ready to Get Started?

Contact our team today for a consultation on your aluminum forging requirements.

Get A Quick Quote