In today’s demanding manufacturing landscape, material selection can make or break product performance. Benefits of forged aluminum extend far beyond basic structural applications, offering superior strength-to-weight ratios and enhanced durability that outperform cast alternatives. At MAIKONG, we’ve perfected aluminum forging processes that deliver exceptional performance for critical components across industries. Discover how our precision forging solutions can transform your manufacturing capabilities and product quality.

What is Forged Aluminum and Its Fundamental Benefits?

Forged aluminum refers to aluminum alloy materials processed through forging techniques. During this process, aluminum undergoes plastic deformation under carefully controlled pressure to achieve precise shapes and sizes. This transformative process creates a denser, more refined grain structure that significantly enhances the material’s mechanical properties.

Refined grain structure in forged aluminum components provides superior strength

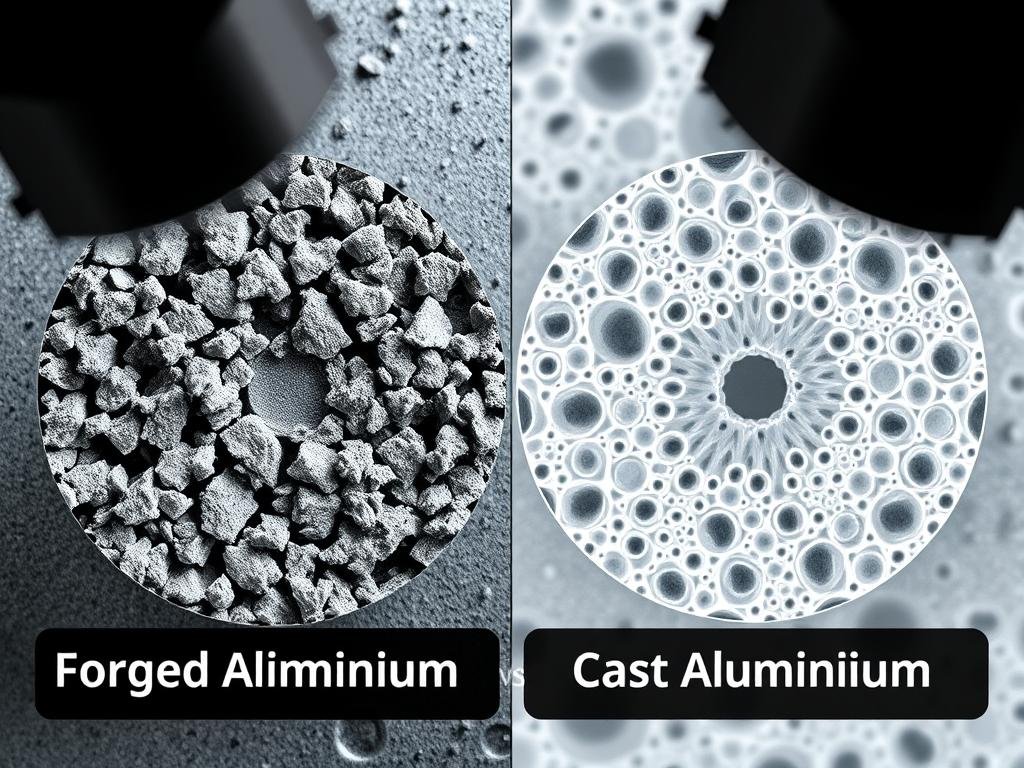

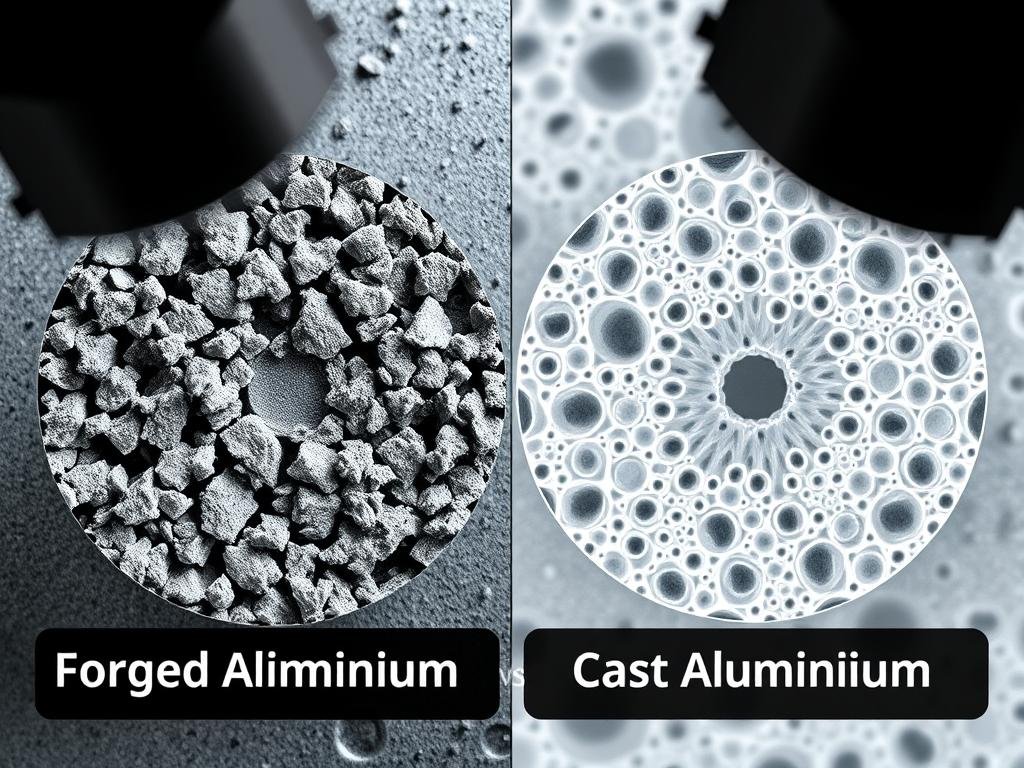

Unlike casting, which involves pouring molten aluminum into molds, forging manipulates solid metal through compressive force. This fundamental difference in processing creates distinct material characteristics that deliver significant performance advantages in demanding applications.

The Science Behind Forged Aluminum’s Superior Properties

The forging process realigns the internal grain structure of aluminum along the contours of the part. This directional grain flow creates a continuous fiber structure that significantly enhances mechanical properties. The result is a material with:

- Enhanced tensile and yield strength

- Improved ductility and malleability

- Superior fatigue resistance under cyclic loading

- Exceptional impact resistance and toughness

- Reduced internal porosity and defects

- Greater structural integrity under stress

These enhanced properties make forged aluminum the preferred choice for critical components in aerospace, automotive, and other high-performance applications where failure is not an option.

Forged vs. Cast Aluminum: Understanding the Critical Differences

When selecting aluminum for manufacturing applications, understanding the fundamental differences between forging and casting processes is essential for making informed decisions. Each method creates distinct material properties that directly impact performance in real-world applications.

Microstructure comparison: Forged aluminum (left) vs. Cast aluminum (right)

| Comparison Categories |

Forged Aluminum |

Cast Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

Can achieve complex shapes in one session |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Weight-to-Strength Ratio |

High strength-to-weight ratio |

Bulkier parts may be needed for equivalent strength |

| Critical Applications |

Ideal for structural members and load-bearing components |

Limited suitability for critical applications |

The superior mechanical properties of forged aluminum make it the optimal choice for applications where performance and safety are paramount. While cast aluminum offers advantages in producing complex shapes at lower initial costs, the benefits of forged aluminum become evident in demanding environments where component failure could have serious consequences.

Need Help Choosing Between Forged and Cast Aluminum?

Our engineering team can analyze your application requirements and recommend the optimal material solution.

Get Expert Material Consultation

Key Benefits of Forged Aluminum in Modern Manufacturing

Forged aluminum delivers exceptional performance characteristics that make it indispensable in high-demand manufacturing applications. Understanding these benefits helps engineers and procurement specialists make informed material selections for critical components.

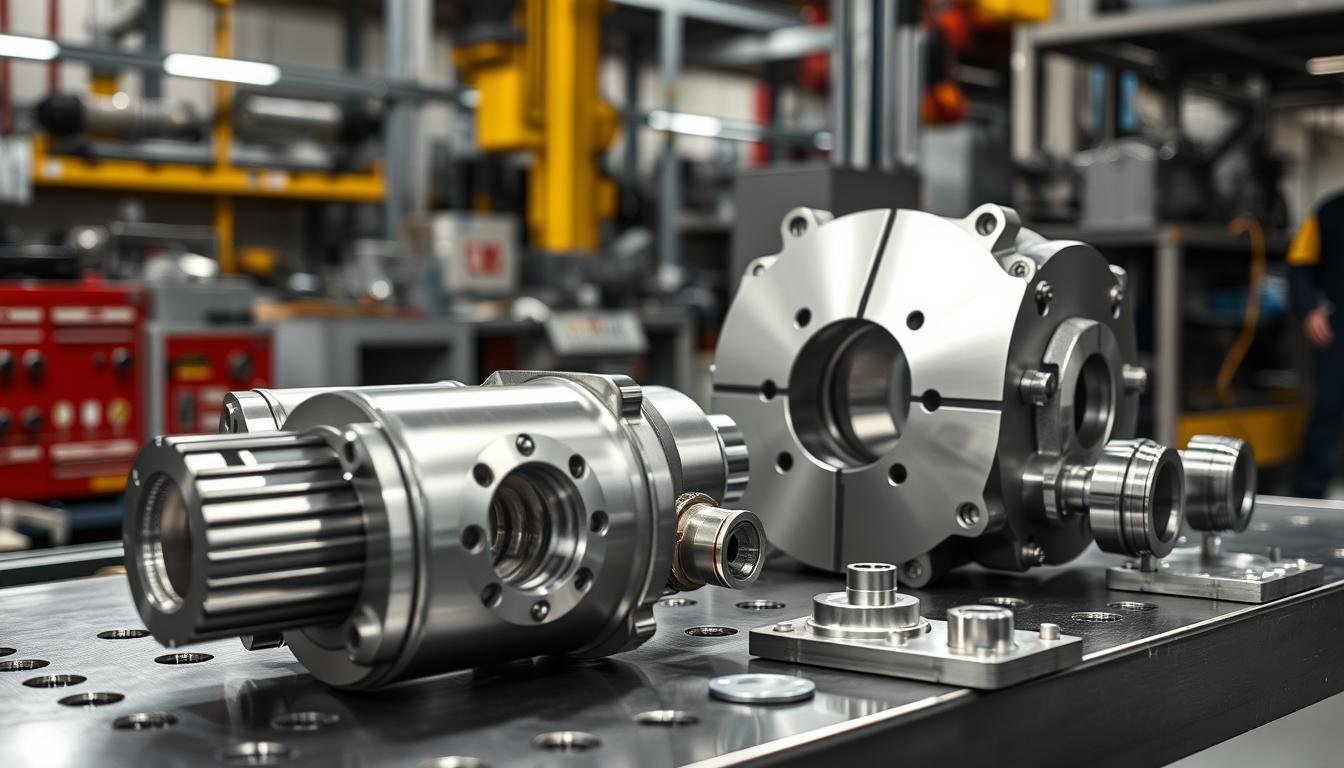

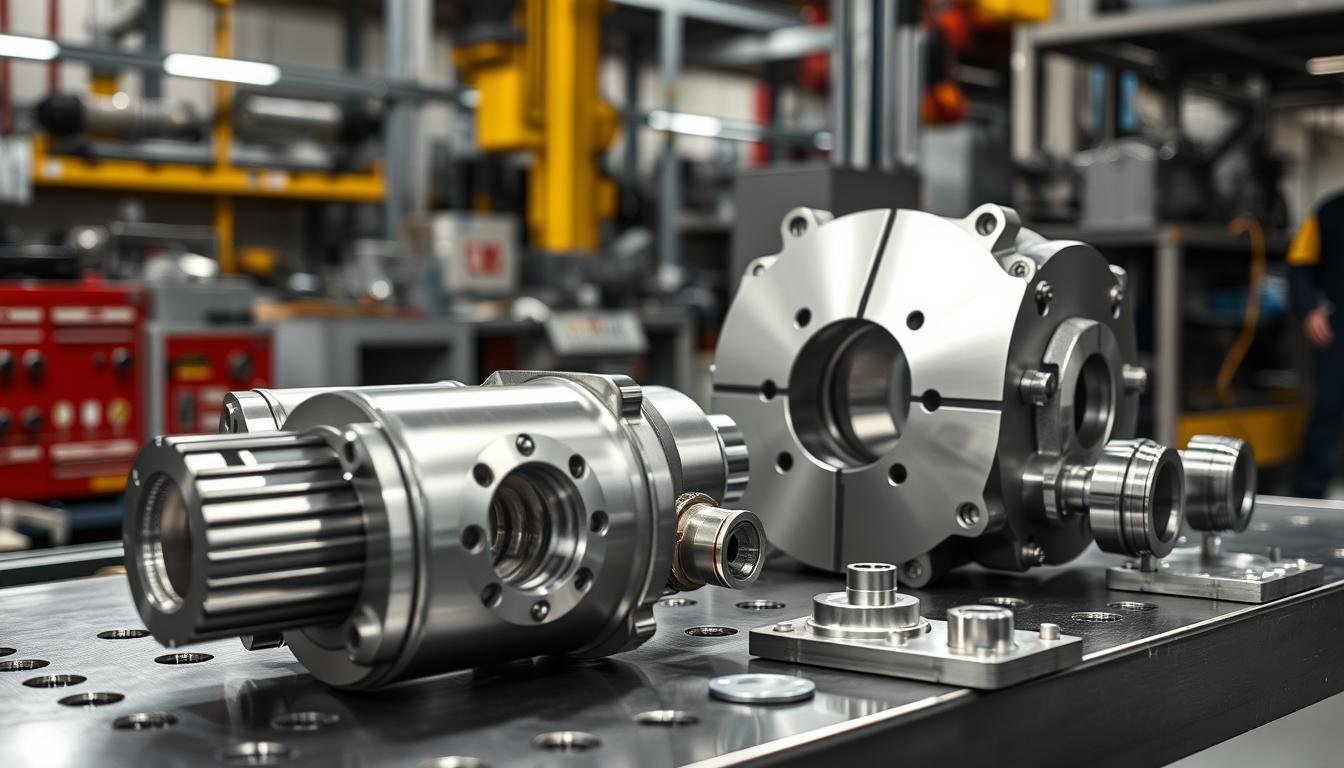

Precision-machined forged aluminum components for aerospace applications

Superior Strength-to-Weight Ratio

One of the most significant benefits of forged aluminum is its exceptional strength-to-weight ratio. This fundamental engineering principle addresses the critical balance between material strength and weight—essential in industries prioritizing performance, efficiency, and safety.

Forged aluminum components can withstand substantial loads while maintaining a lightweight profile, making them ideal for:

- Aerospace structural components requiring high strength with minimal weight

- Automotive suspension and drivetrain parts that reduce vehicle mass

- Industrial equipment components that enhance efficiency through weight reduction

- Medical devices requiring both strength and lightweight properties

Enhanced Mechanical Properties

The forging process fundamentally transforms aluminum’s mechanical properties, creating components with:

Improved Tensile Strength

Forged aluminum exhibits significantly higher tensile strength compared to cast alternatives, allowing components to withstand greater pulling forces without deformation or failure.

Superior Fatigue Resistance

Components subjected to cyclic loading benefit from forged aluminum’s exceptional fatigue resistance, extending service life in dynamic applications.

Enhanced Impact Resistance

The refined grain structure of forged aluminum provides superior impact resistance, making components more resilient against sudden loads and impacts.

Greater Ductility

Forged aluminum maintains excellent ductility, allowing components to deform under stress rather than experiencing catastrophic failure.

Laboratory testing demonstrates superior mechanical properties of forged aluminum

Reduced Internal Defects

The forging process significantly reduces internal defects commonly found in cast aluminum:

- Minimized porosity for enhanced structural integrity

- Reduced inclusions that can act as stress concentration points

- Elimination of shrinkage cavities that compromise strength

- Consistent internal structure throughout the component

These improvements translate to more reliable components with predictable performance characteristics, essential for critical applications where component failure is not an option.

Industry Applications Leveraging the Benefits of Forged Aluminum

The exceptional properties of forged aluminum make it the material of choice across diverse industries where performance, reliability, and efficiency are paramount. MAIKONG’s precision forging capabilities serve these demanding sectors with components that meet the highest standards.

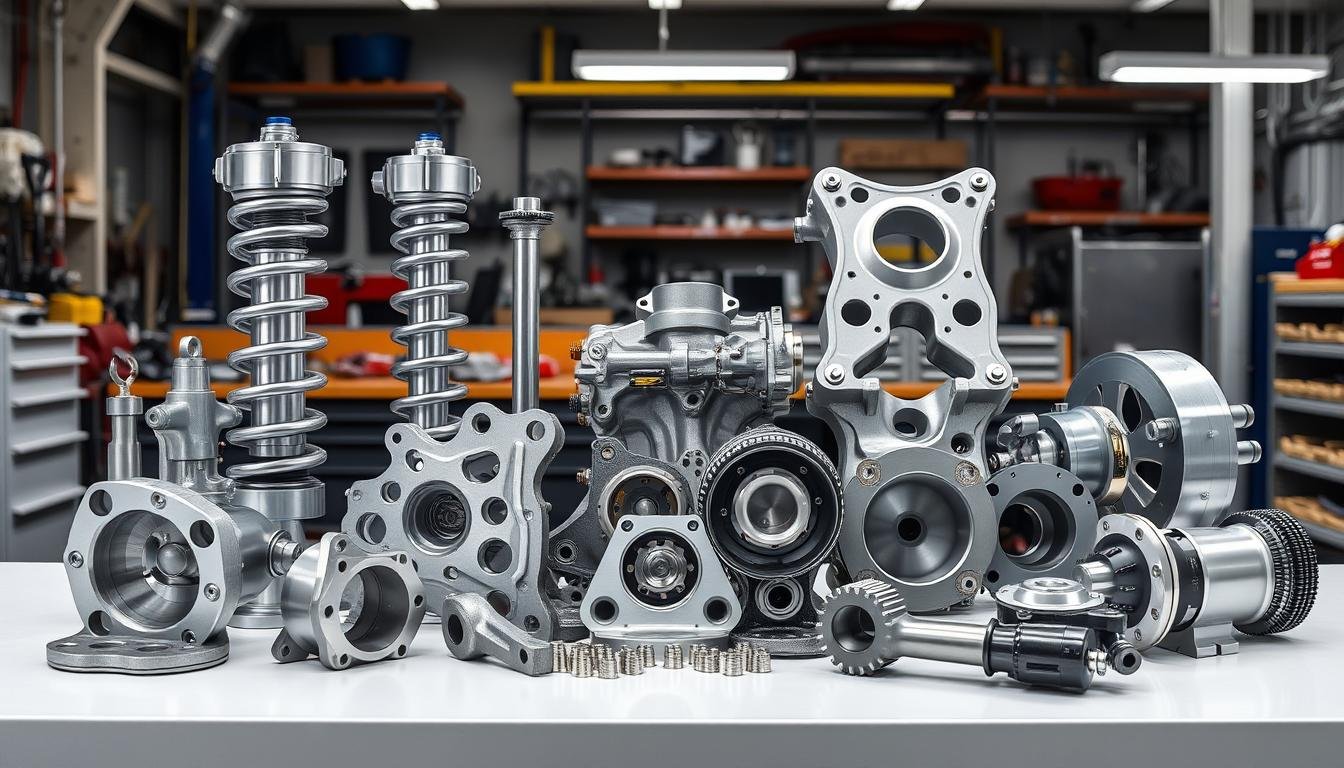

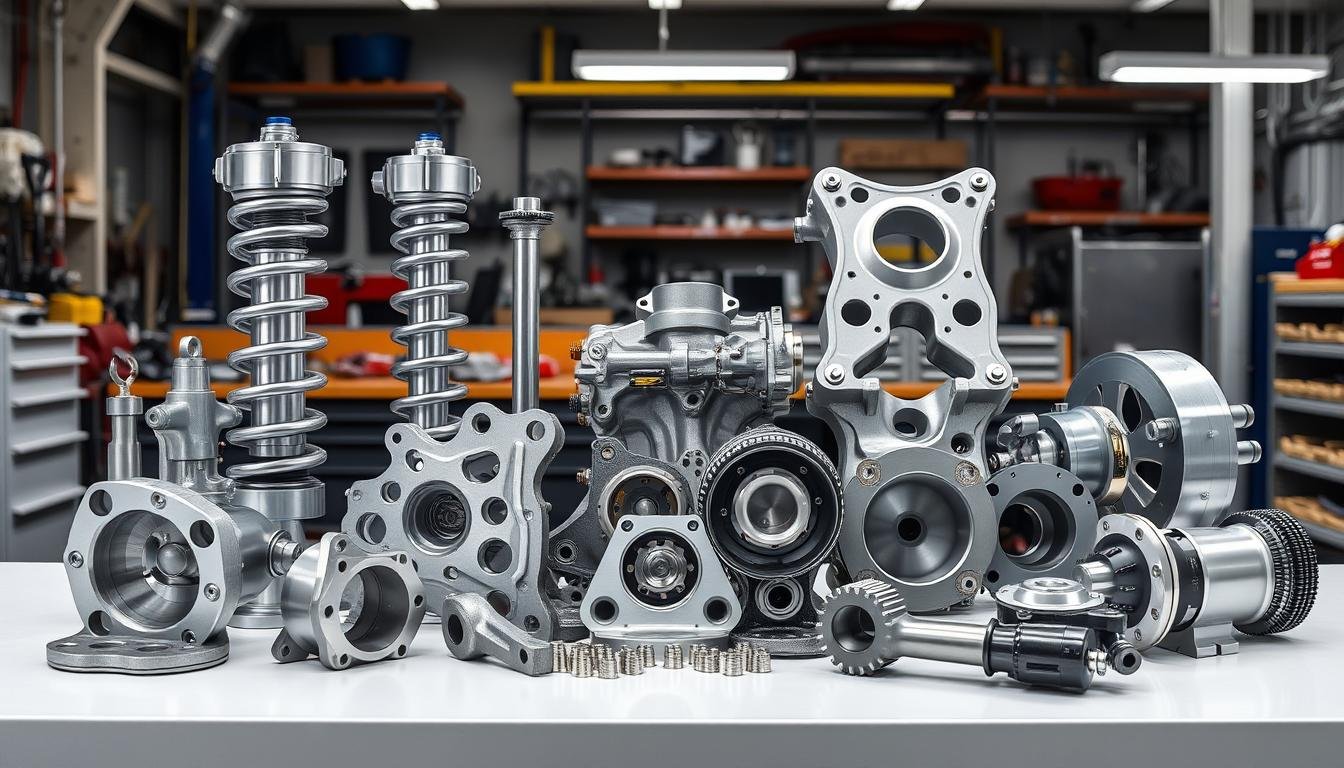

Forged aluminum automotive components including suspension parts and drivetrain elements

Aerospace

Forged aluminum components are critical in aerospace applications where weight reduction directly impacts fuel efficiency and performance. Key applications include:

- Structural airframe components

- Landing gear components

- Engine mounting brackets

- Control system housings

Automotive

The automotive industry relies on forged aluminum to enhance vehicle performance while reducing weight for improved fuel economy. Applications include:

- Suspension components

- Wheel hubs and knuckles

- Connecting rods and pistons

- Drivetrain components

Industrial Equipment

Heavy machinery and industrial equipment benefit from forged aluminum’s durability and strength in demanding environments:

- Hydraulic system components

- High-pressure valve bodies

- Structural support brackets

- Precision mechanical linkages

Precision medical equipment leveraging forged aluminum components

Medical Equipment

The medical sector utilizes forged aluminum for equipment requiring precision, reliability, and sterilization compatibility:

- Surgical instrument frames

- Imaging equipment components

- Patient positioning systems

- Medical device housings

Sports Equipment

Performance sports equipment benefits from forged aluminum’s strength-to-weight advantages:

- Bicycle components

- Golf club heads

- High-performance wheel systems

- Climbing equipment

Defense Applications

Military and defense applications rely on forged aluminum’s durability and performance in critical situations:

- Tactical equipment components

- Weapons system parts

- Vehicle armor support structures

- Communication equipment housings

Explore Custom Forged Aluminum Solutions for Your Industry

MAIKONG specializes in precision forged aluminum components tailored to your specific industry requirements.

Request Industry-Specific Solutions

MAIKONG’s Advanced Manufacturing Process

At MAIKONG, we’ve developed a comprehensive manufacturing process that maximizes the benefits of forged aluminum through precision engineering and quality control. Our integrated approach ensures consistent, high-performance components that meet the most demanding specifications.

MAIKONG’s state-of-the-art forging facility in GD, SZ

Our Comprehensive Manufacturing Workflow

Our end-to-end manufacturing process integrates advanced technologies with expert craftsmanship to deliver superior forged aluminum components:

1. Design & Engineering

Our engineering team utilizes advanced CAD/CAM systems to optimize component design for the forging process, identifying potential issues before production begins. This proactive approach ensures manufacturability while maintaining critical performance characteristics.

2. Material Selection

We carefully select premium aluminum alloys based on your application requirements, considering mechanical properties, machinability, heat treatment response, and cost-effectiveness to ensure optimal performance.

3. Tooling Design

Precision tooling is critical for high-quality forgings. Our tooling experts design and maintain dies that ensure initial quality and consistent results throughout production runs.

4. Forging Process

Our forging workshop accommodates diverse aluminum forging specifications, utilizing controlled heating and precision hydraulic presses to achieve optimal grain structure and mechanical properties.

5. Heat Treatment

In-house heat treatment facilities allow precise control over material properties, with comprehensive statistical analysis and documentation ensuring consistent results.

6. Precision Machining

Our machining workshop features 60+ state-of-the-art CNC machines capable of precise and intricate operations, transforming forgings into finished components with tight tolerances.

7. Surface Treatment

We offer comprehensive surface treatment options including anodizing, painting, laser engraving, and sand blasting to enhance appearance, performance, and corrosion resistance.

8. Quality Assurance

Rigorous quality control procedures ensure that every component meets stringent standards, with advanced testing equipment verifying dimensional accuracy and material properties.

Precision quality control inspection ensures component excellence

Our integrated manufacturing capabilities allow us to maintain complete control over the production process, ensuring consistent quality and performance in every forged aluminum component we deliver.

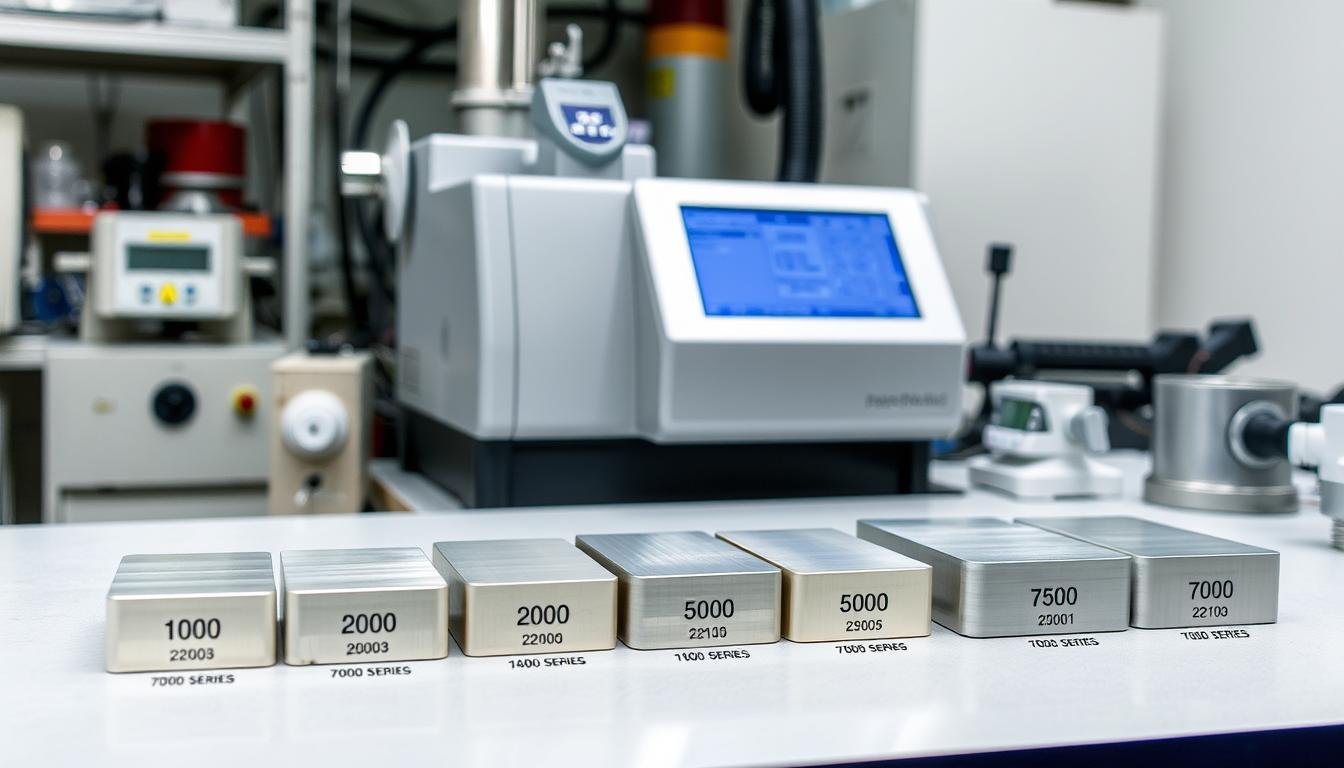

Optimizing Performance Through Alloy Selection

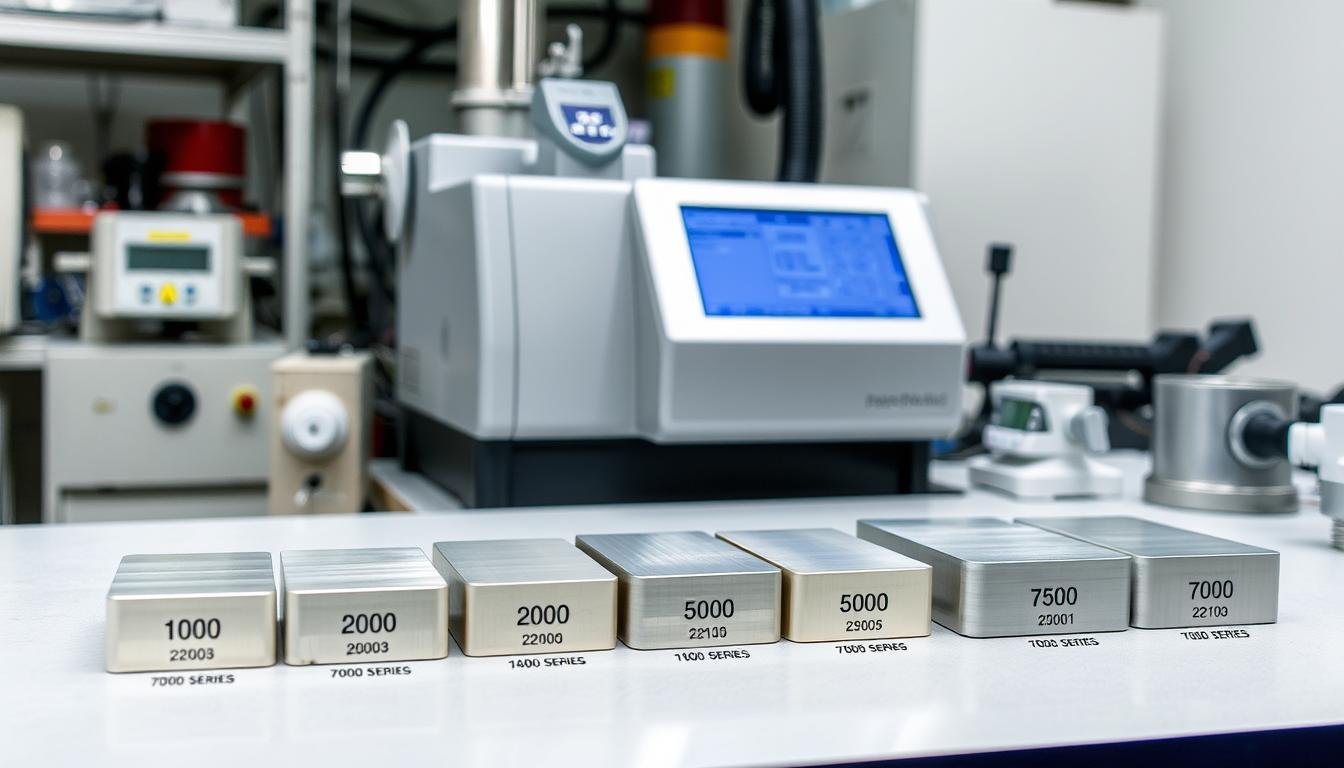

The specific benefits of forged aluminum can be further enhanced through careful alloy selection. Different aluminum alloys offer distinct performance characteristics that can be matched to your application requirements.

Various aluminum alloy series offer distinct performance characteristics

| Alloy Series |

Composition |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Key Applications |

| 1000 Series |

99.00% to 99.99% aluminum |

82 – 166 |

28 – 152 |

Electrical components, decorative items |

| 2000 Series |

2.2% to 6.8% copper |

186 – 467 |

76 – 345 |

Aerospace structures, high-strength components |

| 5000 Series |

0.5% to 5.5% Magnesium |

124 – 352 |

41 – 345 |

Marine components, pressure vessels |

| 6000 Series |

0.2% to 1.8% silicon, 0.35% to 1.5% magnesium |

124 – 310 |

55 – 276 |

Automotive, structural components |

| 7000 Series |

0.8% to 8.2% zinc, 0.1% to 3.4% magnesium |

228 – 572 |

103 – 503 |

Aerospace, high-stress applications |

MAIKONG’s material experts can help you select the optimal aluminum alloy for your specific application, ensuring the perfect balance of performance characteristics and cost-effectiveness.

Need Help Selecting the Right Aluminum Alloy?

Our materials engineering team can recommend the optimal alloy for your specific application requirements.

Contact Our Materials Experts

Case Studies: The Benefits of Forged Aluminum in Action

See how MAIKONG’s forged aluminum solutions have delivered exceptional results across diverse applications. These real-world examples demonstrate the tangible benefits our precision components provide.

Automotive suspension component weight reduction

Automotive Weight Reduction

A leading automotive manufacturer needed to reduce vehicle weight while maintaining safety and performance standards. MAIKONG developed forged aluminum suspension components that:

- Reduced component weight by 32% compared to steel alternatives

- Maintained equivalent strength and durability metrics

- Improved vehicle fuel efficiency by 3.8%

- Passed all safety and durability testing requirements

The forged aluminum components are now standard across the manufacturer’s premium vehicle line, contributing to improved performance and efficiency.

Aerospace component fatigue testing

Aerospace Fatigue Resistance

An aerospace supplier faced challenges with premature fatigue failure in critical structural components. MAIKONG’s forged aluminum solution delivered:

- 5.3x improvement in fatigue life under cyclic loading

- Enhanced crack resistance in high-stress areas

- 15% weight reduction while improving performance

- Simplified inspection requirements due to improved reliability

The improved components have operated without failure for over 5 years, significantly reducing maintenance costs and improving safety margins.

Discover How MAIKONG Can Improve Your Components

Our engineering team can analyze your current components and identify opportunities for performance enhancement through forged aluminum solutions.

Request Component Analysis

Why Choose MAIKONG for Your Forged Aluminum Needs

MAIKONG stands as a premier provider of precision forged aluminum components, offering comprehensive manufacturing capabilities and exceptional service. Our commitment to quality and performance makes us the ideal partner for your critical component needs.

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

Comprehensive Capabilities

- 60+ CNC machines with 100+ tons monthly capacity

- Complete in-house production from raw material to finished product

- Advanced forging, machining, and surface treatment facilities

- ISO 9001:2015 certified quality management system

Technical Expertise

- Experienced engineering team with deep metallurgical knowledge

- Advanced CAD/CAM capabilities for optimized component design

- Material selection expertise across aluminum alloy families

- Process optimization for enhanced component performance

Customer-Focused Service

- Dedicated project management for seamless communication

- Flexible production capabilities for both prototype and high-volume needs

- Competitive pricing with exceptional value

- Reliable delivery schedules you can count on

Unlock the Full Benefits of Forged Aluminum with MAIKONG

The exceptional properties of forged aluminum make it the material of choice for demanding applications where performance, reliability, and efficiency are non-negotiable. MAIKONG’s expertise in aluminum forging and precision machining enables us to deliver components that maximize these benefits for your specific requirements.

From material selection through design, forging, machining, and surface treatment, our comprehensive capabilities ensure consistent quality and performance in every component we produce. Our commitment to excellence has made us a trusted partner for manufacturers across industries who demand the very best.

Ready to Experience the MAIKONG Difference?

Contact us today to discuss your forged aluminum component needs and discover how our precision manufacturing solutions can enhance your products.

Email: Lucy@maikongforge.us | Website: https://maikongforge.us