In today’s competitive manufacturing landscape, the choice between forged and cast aluminum can significantly impact product performance, durability, and customer satisfaction. Forged aluminum alloys outperform their cast counterparts in critical applications where strength, reliability, and fatigue resistance are non-negotiable. As a wholesaler, understanding these differences is essential for providing your customers with components that truly deliver on their performance requirements.At MAIKONG, we’ve spent years perfecting our aluminum forging processes to deliver components that consistently exceed expectations. This comprehensive guide explores the technical advantages of forged aluminum alloys and why they represent the superior choice for demanding applications across industries.

Understanding How Forged Aluminum Alloys Outperform Through Superior Processing

MAIKONG’s advanced forging process aligns aluminum grain structure for superior strength

MAIKONG’s advanced forging process aligns aluminum grain structure for superior strength

The fundamental difference between forged and cast aluminum lies in how the metal’s internal structure is formed. Forging is a thermo-mechanical process that shapes solid aluminum through controlled pressure and deformation, while casting involves pouring molten aluminum into a mold where it solidifies.

This difference in processing creates dramatic variations in the material’s microstructure. When aluminum is forged, its grain structure becomes refined and aligned along the direction of metal flow. This alignment significantly enhances the material’s mechanical properties, particularly its strength, toughness, and fatigue resistance.

The Science Behind Why Forged Aluminum Alloys Outperform

During the forging process, aluminum undergoes plastic deformation under carefully controlled conditions. This deformation:

- Eliminates internal voids and porosity that commonly occur in cast aluminum

- Creates a more uniform, dense material structure

- Aligns the grain flow to follow the contours of the part

- Refines the grain size, enhancing overall mechanical properties

- Distributes alloying elements more evenly throughout the material

The result is a component with superior structural integrity that can withstand higher loads, resist fatigue failure, and maintain dimensional stability under stress – all critical factors in high-performance applications.

Measurable Ways Forged Aluminum Alloys Outperform Cast Alternatives

Microscopic comparison: Forged aluminum (left) shows aligned grain structure; cast aluminum (right) shows porosity and random grain orientation

| Performance Metric |

Forged Aluminum |

Cast Aluminum |

Advantage |

| Tensile Strength |

Up to 26% higher |

Lower |

Forged |

| Yield Strength |

Superior (typically 20-30% higher) |

Lower |

Forged |

| Fatigue Resistance |

Up to 37% higher |

Lower, more variable |

Forged |

| Impact Toughness |

Significantly higher |

Lower, more brittle |

Forged |

| Structural Integrity |

Consistent, minimal defects |

Variable, potential porosity |

Forged |

| Dimensional Accuracy |

High precision possible |

Variable, affected by shrinkage |

Forged |

| Complex Geometries |

Limited by tooling |

Excellent capability |

Cast |

Strength-to-Weight Ratio: Where Forged Aluminum Truly Shines

One of the most compelling advantages of forged aluminum is its exceptional strength-to-weight ratio. This metric is particularly crucial in industries where weight reduction directly impacts performance, efficiency, and operating costs.

Forged aluminum components can achieve the same or greater strength as their cast counterparts while using less material. This translates to lighter components that maintain or exceed performance requirements – a significant advantage in aerospace, automotive, and other weight-sensitive applications.

MAIKONG’s precision-forged aluminum components for aerospace applications

Industries Where Forged Aluminum Alloys Outperform Expectations

Aerospace

In aerospace applications, the superior fatigue resistance and consistent quality of forged aluminum are critical for safety and reliability. MAIKONG provides forged components for:

- Structural airframe components

- Landing gear components

- Engine mounts and brackets

- Control system components

Automotive

Automotive manufacturers rely on forged aluminum to reduce weight while maintaining strength and safety. Our components include:

- Suspension components

- Steering knuckles

- Connecting rods

- Wheel hubs and wheels

- Drivetrain components

Medical

Medical devices demand the highest levels of reliability and precision. Forged aluminum delivers:

- Surgical instrument components

- Diagnostic equipment frames

- Prosthetic device components

- Medical imaging equipment parts

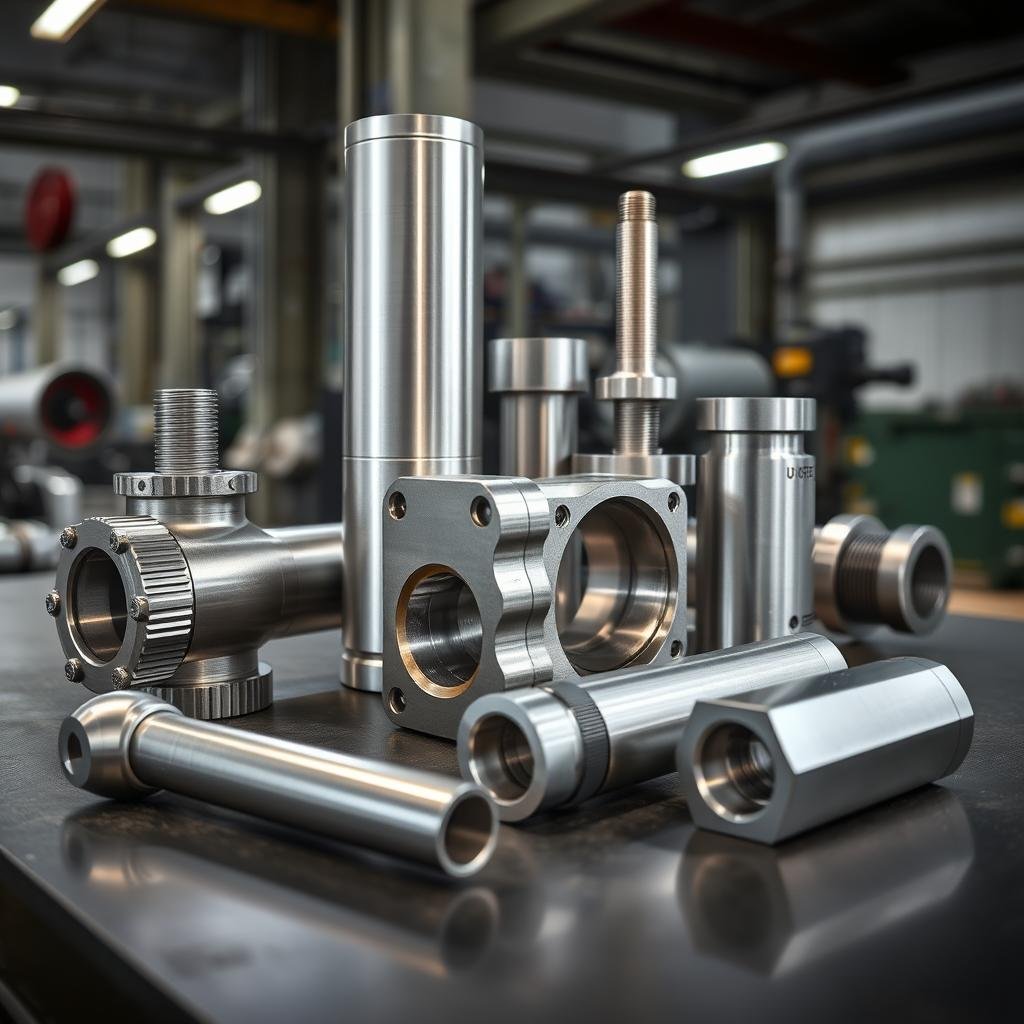

Industrial Equipment

Industrial applications benefit from the durability and reliability of forged aluminum in:

- Hydraulic system components

- High-pressure fittings

- Pump and valve components

- Structural load-bearing elements

Sports Equipment

The strength-to-weight advantages of forged aluminum make it ideal for:

- Bicycle components

- Golf club heads

- Tennis racket frames

- Climbing equipment

Defense & Military

Military applications demand the highest performance standards, which forged aluminum delivers in:

- Weapons systems components

- Vehicle armor supports

- Communication equipment housings

- Tactical equipment components

Find the Perfect Forged Aluminum Solution for Your Industry

Our engineering team specializes in developing custom forged aluminum solutions for specific industry applications. Contact us to discuss your unique requirements.

Get Industry-Specific Solutions

MAIKONG’s Comprehensive Process Ensures Forged Aluminum Alloys Outperform

MAIKONG’s state-of-the-art forging facility in GD, SZ

At MAIKONG, we’ve developed a comprehensive end-to-end manufacturing process that ensures our forged aluminum components consistently deliver superior performance. Our integrated approach includes:

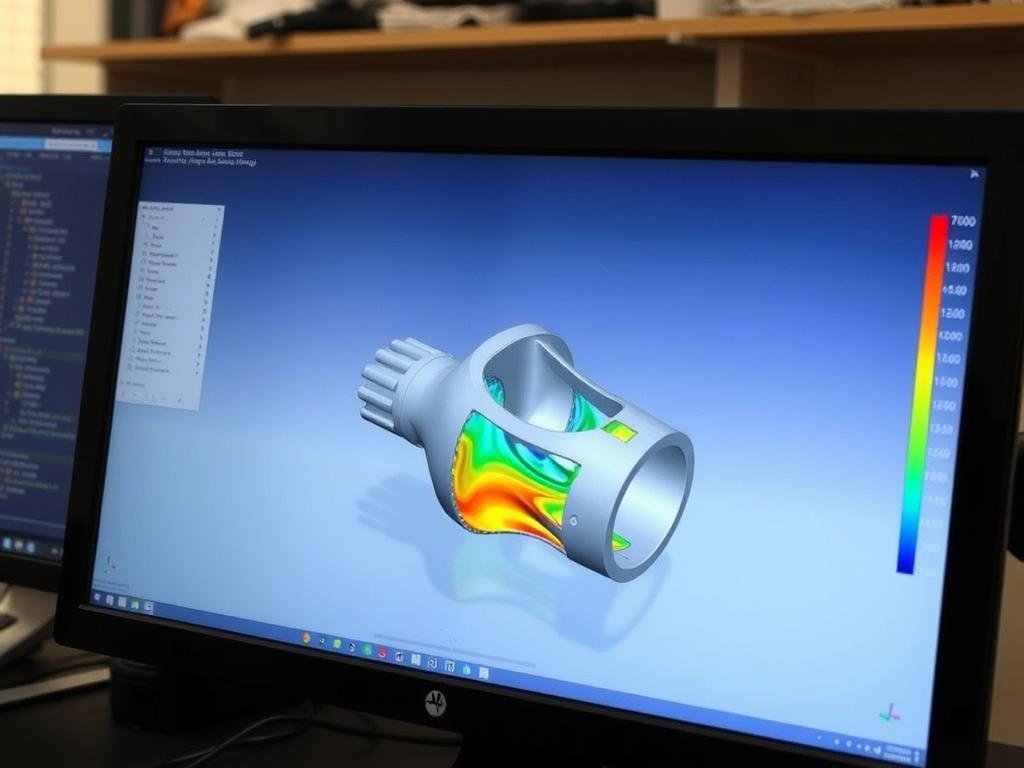

1. Advanced CAD/CAM Design

Our engineering team utilizes sophisticated CAD/CAM software to design optimal forging processes. This technology allows us to:

- Identify potential issues early in the design phase

- Optimize material flow during forging

- Simulate performance under various conditions

- Refine designs before production begins

2. Material Selection & Testing

The foundation of superior forged components begins with material selection. Our material laboratory ensures:

- Precise alloy composition for specific applications

- Comprehensive testing of mechanical properties

- Verification of material integrity before processing

- Documentation of material certifications

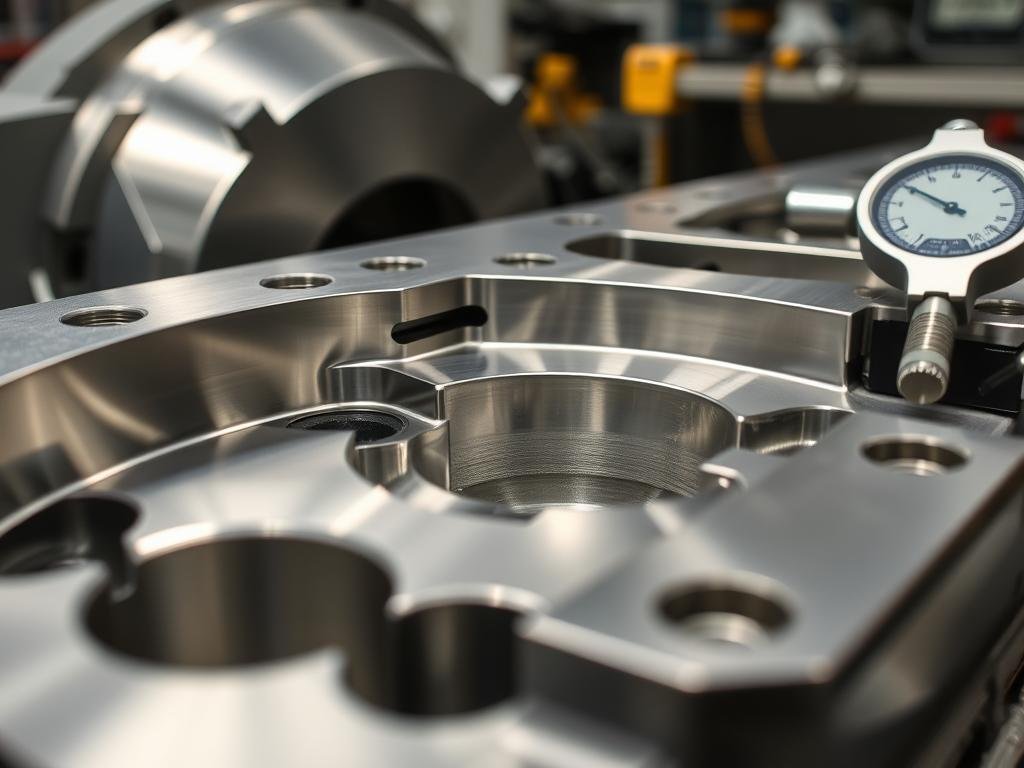

3. Precision Tooling Design

Our tooling experts design and maintain precision dies that ensure consistent quality:

- Custom die designs for specific component requirements

- Regular maintenance to preserve dimensional accuracy

- Multi-stage die sequences for complex geometries

- Advanced surface treatments for extended die life

4. Controlled Forging Process

Our forging workshop utilizes advanced equipment and processes:

- Precise temperature control during heating

- Optimized press force and speed parameters

- Multi-stage forging for complex components

- Controlled cooling to preserve material properties

5. Heat Treatment Expertise

Our in-house heat treatment capabilities enhance material properties:

- Solution treatment to optimize alloy structure

- Aging processes to achieve specific strength requirements

- Stress relief treatments for dimensional stability

- Comprehensive documentation of heat treatment parameters

6. Precision CNC Machining

Our advanced CNC machining capabilities ensure dimensional accuracy:

- 5-axis machining for complex geometries

- High-precision turning and milling

- Swiss-type machining for small, precise components

- Automated quality verification during machining

Experience Our End-to-End Manufacturing Excellence

From design to delivery, MAIKONG’s comprehensive manufacturing process ensures superior forged aluminum components that meet your exact specifications.

Request Manufacturing Consultation

Quality Assurance That Guarantees Forged Aluminum Alloys Outperform

MAIKONG’s comprehensive quality testing ensures every component meets rigorous standards

At MAIKONG, quality isn’t just a department – it’s a core value embedded throughout our organization. Our ISO 9001:2015 certified quality management system ensures that every forged aluminum component we produce meets or exceeds the most demanding specifications.

Our Multi-Stage Quality Assurance Process

| Quality Stage |

Testing Methods |

Verification Standards |

| Material Verification |

Spectrographic analysis, Hardness testing |

ASTM, ISO material standards |

| Pre-Forging Inspection |

Visual inspection, Dimensional verification |

Internal quality protocols |

| In-Process Monitoring |

Temperature monitoring, Press force verification |

Process parameter specifications |

| Post-Forging Inspection |

Visual inspection, Dimensional verification |

Customer specifications |

| Heat Treatment Verification |

Hardness testing, Microstructure analysis |

ASTM, AMS heat treatment standards |

| Non-Destructive Testing |

Ultrasonic testing, Magnetic particle inspection |

ASTM E1444, ASTM E2375 |

| Final Dimensional Inspection |

CMM measurement, Gauge verification |

Customer drawings, GD&T standards |

| Performance Testing |

Tensile testing, Fatigue testing |

ASTM E8, ASTM E466 |

4.9

Customer Satisfaction

Experience the MAIKONG Quality Difference

Our rigorous quality assurance processes ensure that every forged aluminum component we deliver meets the highest standards of performance and reliability.

Request Quality Documentation

Cost-Effective Solutions: When Forged Aluminum Alloys Outperform Economically

MAIKONG helps customers analyze total lifecycle costs to make informed decisions

While forged aluminum components may have a higher initial cost compared to cast alternatives, a comprehensive cost analysis often reveals that forged components offer superior economic value over their entire lifecycle. At MAIKONG, we help our customers understand the total cost of ownership:

Lifecycle Cost Advantages of Forged Aluminum

- Extended service life reduces replacement frequency

- Higher reliability minimizes costly failures and downtime

- Lighter weight can reduce operational costs (fuel, energy)

- Consistent quality reduces inspection and rework costs

- Better performance can enhance end-product value

- Reduced warranty claims and service interventions

Initial Cost Considerations

- Higher tooling costs for low-volume production

- More complex manufacturing process

- Additional machining may be required for complex geometries

- Higher energy consumption during manufacturing

- Longer lead times for specialized components

Volume-Based Cost Analysis

The economic advantage of forged aluminum becomes increasingly apparent as production volumes increase. Our competitive pricing structure is designed to provide maximum value at various production scales:

| Production Volume |

Forged Aluminum Cost Efficiency |

Recommended Approach |

| Prototype (1-10 units) |

Higher initial cost due to tooling |

CNC machining from solid stock |

| Low Volume (10-100 units) |

Moderate – tooling costs amortized |

Open-die forging + machining |

| Medium Volume (100-1,000 units) |

Good – economies of scale begin |

Closed-die forging + finishing |

| High Volume (1,000+ units) |

Excellent – fully amortized tooling |

Precision forging + minimal machining |

Get a Customized Cost Analysis for Your Project

Our team can help you evaluate the total lifecycle cost benefits of forged aluminum for your specific application.

Request Cost Analysis

Conclusion: The Clear Advantages of Forged Aluminum Alloys Outperform

The superior performance of forged aluminum alloys is not just a marketing claim – it’s a metallurgical reality backed by science and proven in demanding applications across industries. From aerospace to automotive, medical to military, forged aluminum components consistently deliver higher strength, better fatigue resistance, and superior reliability compared to cast alternatives.

At MAIKONG, we’ve built our reputation on delivering these performance advantages to our customers through our comprehensive forging, machining, and finishing capabilities. Our commitment to quality, technical expertise, and customer satisfaction makes us the ideal partner for your forged aluminum component needs.

Contact MAIKONG today to discover how our forged aluminum solutions can enhance the performance, reliability, and value of your products.

Ready to Experience the MAIKONG Difference?

Contact us today to discuss your forged aluminum component requirements.

Get Started Now

MAIKONG’s advanced forging process aligns aluminum grain structure for superior strength

MAIKONG’s advanced forging process aligns aluminum grain structure for superior strength