MAIKONG stands as a premier Hot Forging Aluminum Supplier dedicated to delivering precision-engineered components that drive American innovation. With state-of-the-art facilities in GD, SZ, we combine advanced technology with decades of expertise to provide superior aluminum forging solutions at competitive prices. Our commitment to quality, reliability, and customer satisfaction makes us the ideal partner for businesses seeking high-performance custom metal parts.

Comprehensive Capabilities from Your Hot Forging Aluminum Supplier

MAIKONG’s state-of-the-art hot forging facility in GD, SZ

MAIKONG’s state-of-the-art hot forging facility in GD, SZ

As a leading Hot Forging Aluminum Supplier, MAIKONG offers end-to-end manufacturing solutions that encompass every stage of the production process. Our 60+ CNC machines provide over 100 tons of monthly metal processing capacity, ensuring we can meet your most demanding requirements with precision and efficiency.

Hot Forging Excellence

Our specialized aluminum forging processes create components with superior strength-to-weight ratios and optimized grain flow for enhanced mechanical properties.

Precision CNC Machining

Advanced multi-axis CNC capabilities deliver tight tolerances and exceptional surface finishes for complex geometries and critical applications.

Comprehensive Testing

Our in-house material laboratory ensures all raw materials and finished components meet exact specifications and quality standards.

Ready to Elevate Your Manufacturing?

Discover how MAIKONG’s aluminum forging expertise can enhance your products’ performance and reduce costs.

Get A Quick Quote

Premium Metal Manufacturing Services

MAIKONG delivers a comprehensive suite of metal manufacturing services designed to meet the diverse needs of American businesses. Our integrated approach ensures seamless production from concept to completion.

CNC Machining Services

- CNC Turning Services for cylindrical components with superior surface finishes

- CNC Milling Services for complex prismatic shapes and flat surfaces

- Swiss-Type Machining for precision small parts and long shaft components

- Multi-axis machining for intricate geometries

- Surface grinding for exceptional finishes

- Laser engraving for permanent marking

Metal Forging Expertise

- Hot forging aluminum for optimal strength-to-weight ratio

- Steel forging for high-strength applications

- Brass forging for electrical and decorative components

- Closed-die forging for near-net shapes

- Open-die forging for larger components

- Custom metal parts with complex geometries

The MAIKONG Advantage: Why Choose Our Hot Forging Aluminum

As your dedicated Hot Forging Aluminum Supplier, MAIKONG leverages the inherent benefits of the forging process to deliver components with exceptional performance characteristics. Understanding these advantages helps you make informed decisions for your critical applications.

Aluminum Forging and its Optimal Strength-to-Weight Ratio

Strength-to-weight ratio is a fundamental engineering principle that addresses the balance between material strength and weight—an essential consideration in industries prioritizing performance, efficiency, and safety. Aluminum, recognized for its lightweight properties and robust mechanical characteristics, is enhanced through forging, refining its internal grain structure for enhanced resilience and strength.

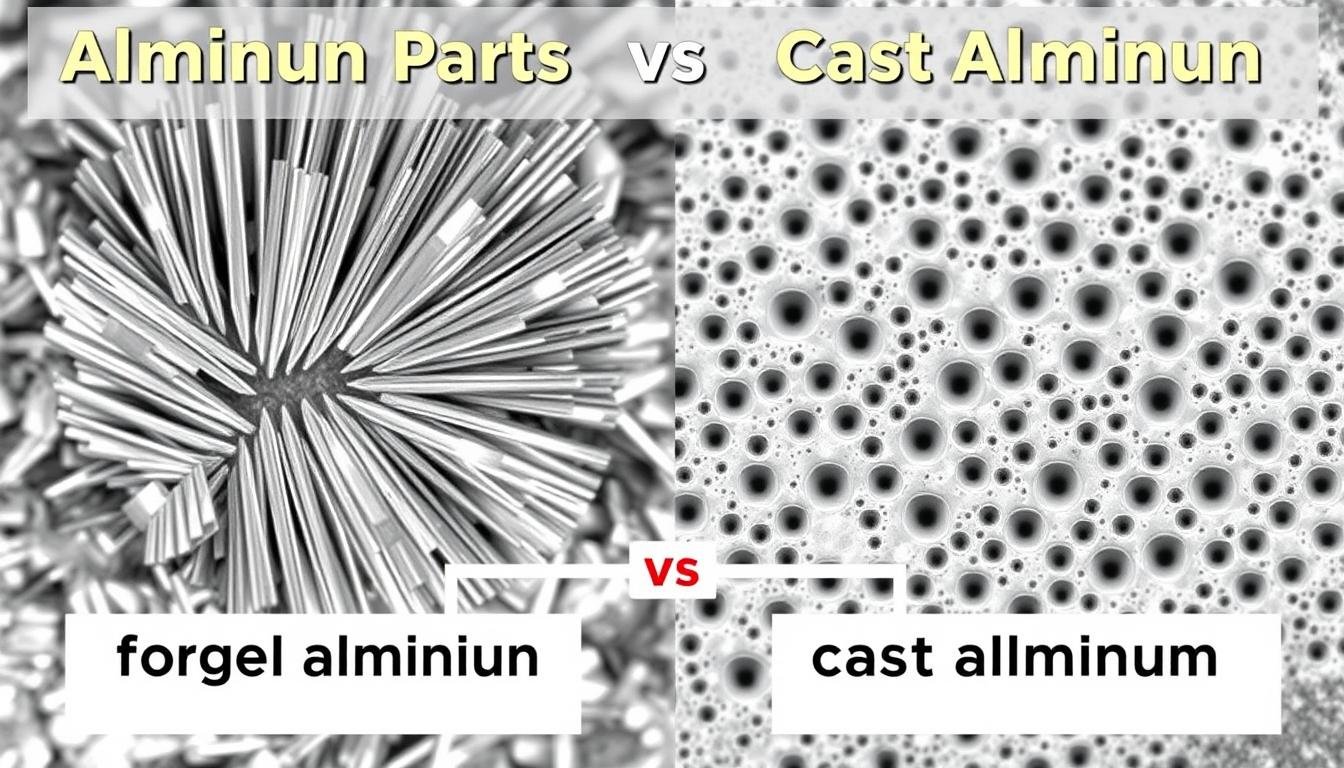

The Advantage of Aluminum Forging over Casting Aluminum

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Weight-to-Strength Ratio |

✅ High strength-to-weight ratio |

Bulkier parts may be needed |

| Ideal Applications |

Aerospace, automotive, medical devices |

Consumer goods, simple parts, non-critical sectors |

Experience Superior Forged Aluminum Components

Let MAIKONG’s expertise elevate your product performance with precision-engineered forged aluminum parts.

Get A Quick Quote

Our Comprehensive Manufacturing Process

At MAIKONG, we’ve developed a comprehensive end-to-end manufacturing process that ensures exceptional quality and consistency for every component we produce. Our integrated approach allows us to maintain strict quality control throughout the entire production cycle.

Design & Engineering

Our engineering team utilizes advanced CAD/CAM software to optimize designs for manufacturability and performance. Early-stage analysis identifies potential issues before production begins.

Material Selection

We carefully select aluminum alloys based on mechanical properties, machinability, heat treatment characteristics, and cost-effectiveness for your specific application.

Tooling & Die Design

Precision tooling ensures initial quality, while our regular maintenance program preserves consistency throughout production runs.

Forging Operations

Our forging workshop accommodates diverse aluminum forging specifications with precision control of temperature, pressure, and timing.

Heat Treatment

In-house heat treatment facilities with comprehensive statistical analysis and documentation ensure optimal mechanical properties.

Precision Machining

State-of-the-art CNC machines perform precise and intricate operations to achieve final dimensions and surface finishes.

Surface Treatment

Advanced surface treatments enhance appearance, performance, and corrosion resistance for competitive advantage in demanding applications.

Quality Assurance

Rigorous inspection protocols and advanced testing equipment verify that every component meets stringent quality standards.

Packaging & Logistics

Secure packaging and efficient logistics ensure your components arrive safely and on schedule, anywhere in the United States.

Partner with MAIKONG for Manufacturing Excellence

Experience our comprehensive manufacturing capabilities and attention to detail.

Email: Lucy@maikongforge.us

Industry Solutions from Your Trusted Hot Forging Aluminum Supplier

MAIKONG delivers specialized aluminum forging solutions tailored to the unique requirements of diverse industries. Our expertise in creating high-performance components makes us the preferred Hot Forging Aluminum Supplier for businesses across multiple sectors.

Aerospace

High-performance components for aircraft structures, rocket adapters, space frames, satellite panels, and aerospace-grade fasteners that meet rigorous industry standards.

Automotive

Precision-engineered forged wheels, suspension arms, transmission components, and structural elements that combine lightweight properties with exceptional strength.

Defense

Mission-critical components for missile casings, armored vehicle frames, launch tubes, and tactical weapon systems designed to perform under extreme conditions.

Medical

Precision components for orthopedic devices, surgical instruments, and medical equipment that meet strict regulatory requirements for safety and reliability.

Industrial

Robust structural connectors, load-bearing joints, brackets, and pressure equipment components engineered for durability in demanding industrial environments.

Sports & Recreation

High-performance components for bicycles, archery equipment, marine applications, and recreational vehicles that combine lightweight design with exceptional durability.

Find Industry-Specific Solutions

Discover how MAIKONG can address your unique industry challenges with custom forged aluminum components.

Get A Quick Quote

Quality Assurance: The MAIKONG Commitment

Quality is the cornerstone of everything we do at MAIKONG. Our comprehensive quality management system ensures that every component we produce meets or exceeds the most stringent industry standards and customer specifications.

Quality Management System

- ISO 9001:2015 certified quality management system

- Comprehensive statistical process control

- Advanced inspection technologies and methodologies

- 100% traceability from raw material to finished product

- Continuous improvement through PDCA and lean principles

Testing Capabilities

- Material composition analysis

- Mechanical property testing

- Dimensional inspection with advanced CMM technology

- Non-destructive testing methods

- Surface finish and coating thickness measurement

“At MAIKONG, we recognize the crucial importance of consistency, strength, and weight in each forged part for the final product. Our dedicated focus on crafting superior forged components ensures we meet your exact requirements for heat treating, machining, and testing.”

– MAIKONG Quality Assurance Team

Partner with MAIKONG: Your Reliable Hot Forging Aluminum Supplier

MAIKONG is actively seeking distribution partners across the United States to bring our high-quality, cost-effective aluminum forging solutions to more American businesses. As your trusted Hot Forging Aluminum Supplier, we offer competitive advantages that help you and your customers succeed.

Cost-Effective Solutions

Our efficient manufacturing processes and strategic location in GD, SZ allow us to offer exceptional quality at competitive prices, helping you maximize value.

Comprehensive Capabilities

From design assistance to finished components, our end-to-end services simplify your supply chain and reduce management complexity.

Reliable Communication

Our dedicated team ensures clear, timely communication throughout every project, overcoming traditional challenges of international sourcing.

Become a US Distributor

Join MAIKONG’s network of successful distribution partners and bring premium aluminum forging solutions to your customers.

Contact Us Today

Why Choose MAIKONG as Your Hot Forging Aluminum Supplier

MAIKONG stands as your premier partner for high-quality aluminum forging solutions that drive American innovation. Our commitment to excellence, comprehensive capabilities, and customer-focused approach make us the ideal Hot Forging Aluminum Supplier for businesses seeking reliable, cost-effective manufacturing solutions.

Quality Assurance

ISO 9001:2015 certified processes and rigorous testing ensure consistent, high-quality components that meet your exact specifications.

Competitive Pricing

Our efficient operations and strategic location allow us to offer premium quality at competitive prices, maximizing your value.

Technical Expertise

Our experienced engineering team provides valuable insights and solutions to optimize your designs for manufacturability and performance.

Start Your Journey with MAIKONG Today

Experience the difference of working with a dedicated aluminum forging partner committed to your success.

Get A Quick Quote

MAIKONG’s state-of-the-art hot forging facility in GD, SZ

MAIKONG’s state-of-the-art hot forging facility in GD, SZ