Finding the right Hot Forging Aluminum Supplier can make or break your manufacturing project. With global supply chains becoming increasingly complex, US buyers face critical decisions that impact product quality, delivery timelines, and bottom-line costs. This comprehensive guide will walk you through everything you need to know about selecting a reliable aluminum forging partner that delivers exceptional value without compromising on quality.

Why Aluminum Forging Matters: Strength-to-Weight Excellence

Aluminum forging represents a critical manufacturing process where raw aluminum is shaped under significant pressure to create components with exceptional mechanical properties. The Hot Forging Aluminum Supplier you choose directly influences these properties, as the forging process aligns the grain structure of aluminum to maximize strength, durability, and performance.

The Science Behind Hot Forging

Hot forging aluminum involves heating the metal to temperatures between 700°F and 950°F (370°C-510°C), making it malleable enough to be shaped with precision. This process, when executed by an experienced Hot Forging Aluminum Supplier, creates parts with:

- Superior tensile strength

- Enhanced fatigue resistance

- Improved dimensional stability

- Optimized grain flow

- Reduced internal defects

Ready to Elevate Your Manufacturing Quality?

MAIKONG delivers premium hot forged aluminum components with superior mechanical properties and competitive pricing.

Get A Quick Quote

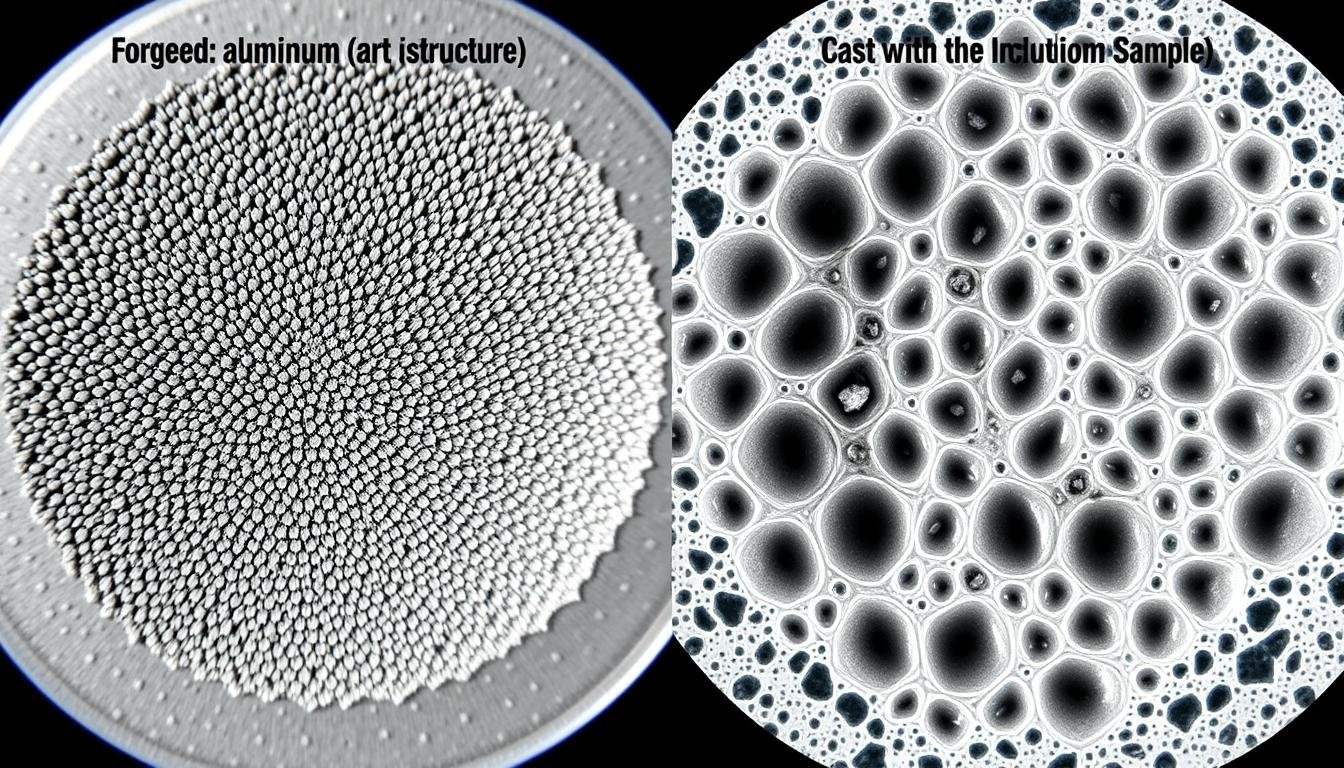

Forging vs. Casting: Why Your Hot Forging Aluminum Supplier Choice Matters

Understanding the fundamental differences between forged and cast aluminum helps clarify why selecting the right Hot Forging Aluminum Supplier is crucial for your manufacturing success.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

Can achieve complex shapes in one session |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Critical Applications |

Ideal for structural members and load-bearing parts |

Limited suitability for critical applications |

As this comparison demonstrates, partnering with a reputable Hot Forging Aluminum Supplier like MAIKONG ensures you receive components with superior mechanical properties essential for demanding applications.

Essential Checklist: Evaluating Your Hot Forging Aluminum Supplier

When selecting a Hot Forging Aluminum Supplier for your US-based manufacturing needs, consider these critical factors to ensure you’re making the right partnership decision:

Technical Capabilities

- Equipment specifications and capacity

- Range of forging processes offered

- Maximum part dimensions

- Ability to handle complex geometries

- In-house secondary processing

Quality Assurance

- ISO certifications

- Material testing capabilities

- Inspection procedures

- Defect rates and quality metrics

- Traceability systems

Business Reliability

- Years in business

- Industry reputation

- Financial stability

- On-time delivery performance

- Communication responsiveness

Need Expert Guidance on Your Aluminum Forging Project?

MAIKONG’s engineering team is ready to help you select the optimal aluminum alloy and forging process for your specific application.

Contact Our Engineers

MAIKONG: Your Premier Hot Forging Aluminum Supplier

At MAIKONG, we’ve established ourselves as a leading Hot Forging Aluminum Supplier by combining advanced manufacturing capabilities with rigorous quality control and exceptional customer service. Our state-of-the-art facility in GD, SZ is equipped with the latest forging technology to deliver superior aluminum components for demanding applications.

Our Comprehensive Aluminum Forging Services

We offer end-to-end solutions from design consultation through final delivery:

- CAD/CAM integration for optimized design

- Material selection expertise across aluminum alloys

- Hot and cold forging capabilities

- Precision CNC machining services

- Heat treatment for enhanced properties

- Surface finishing options

- Comprehensive quality testing

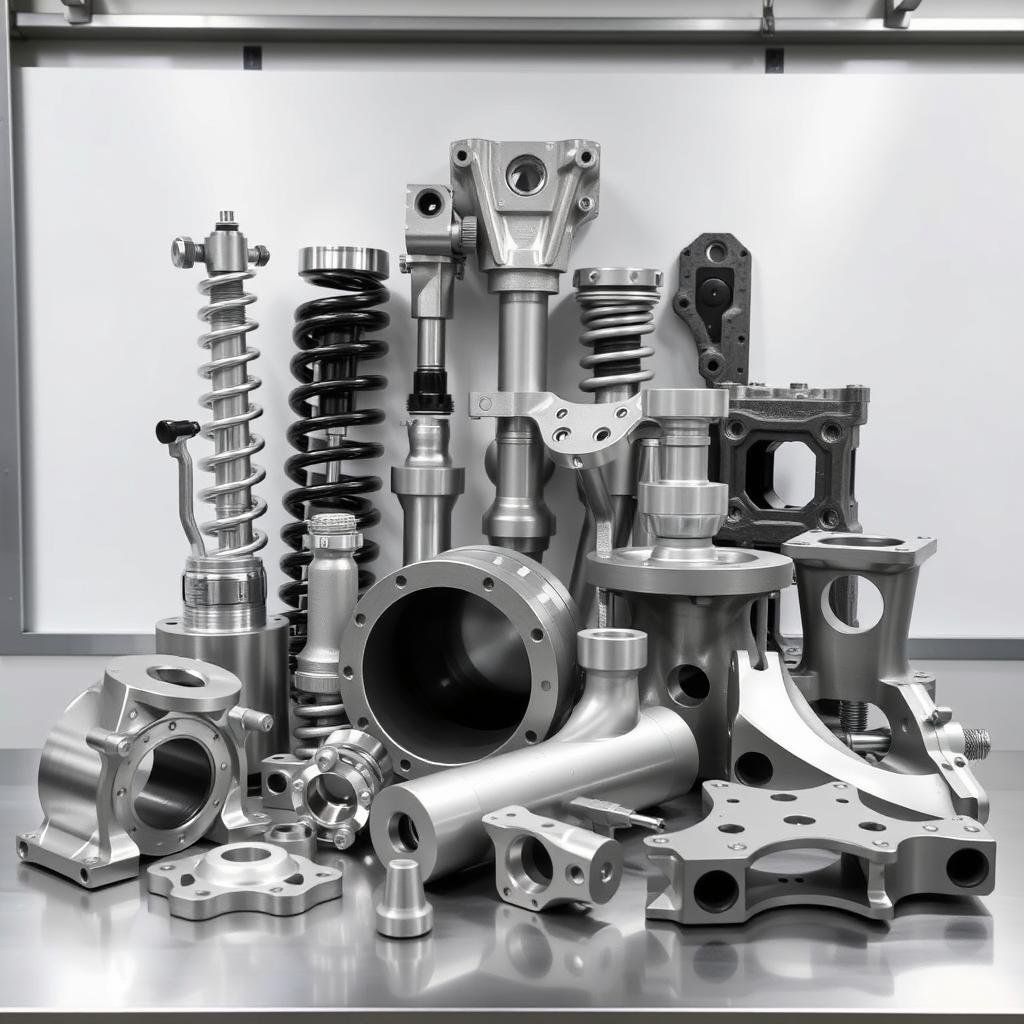

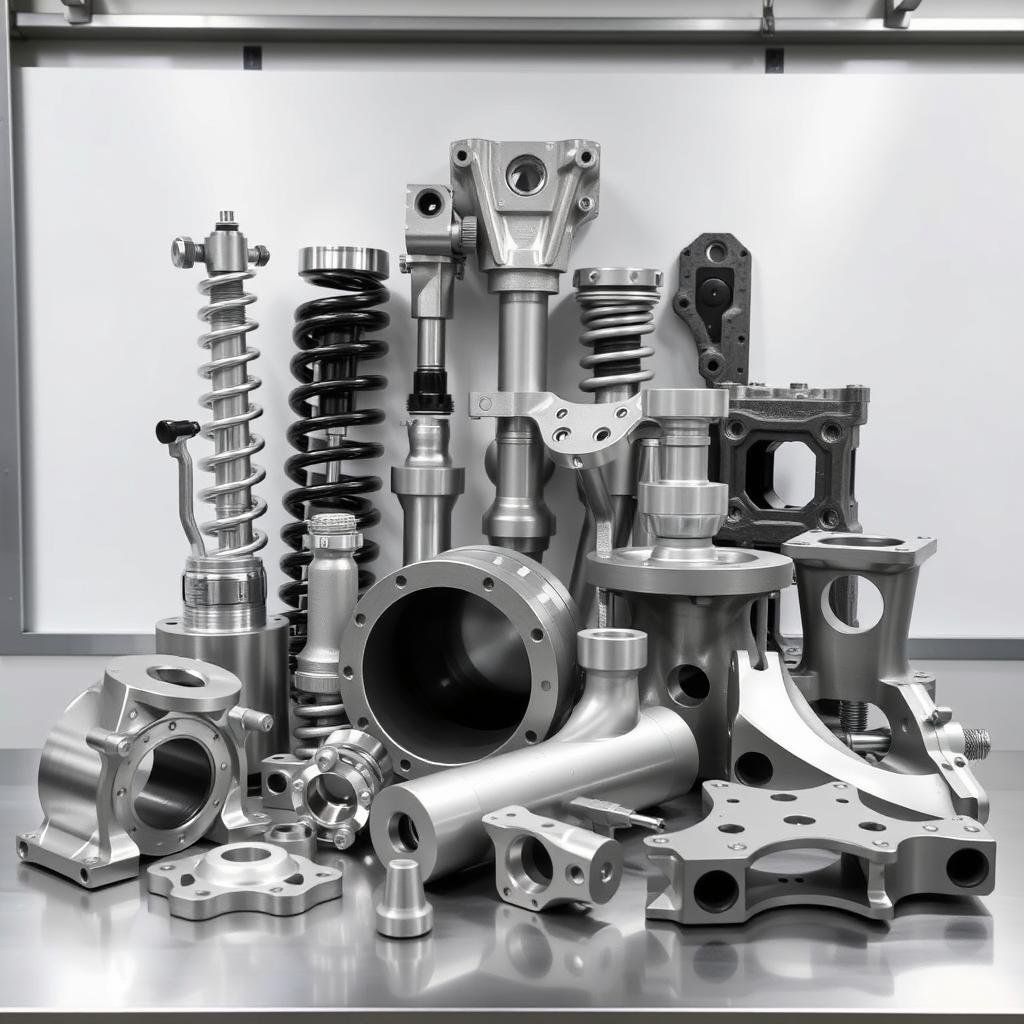

Industries We Serve

Automotive

Automotive

Aerospace

Aerospace

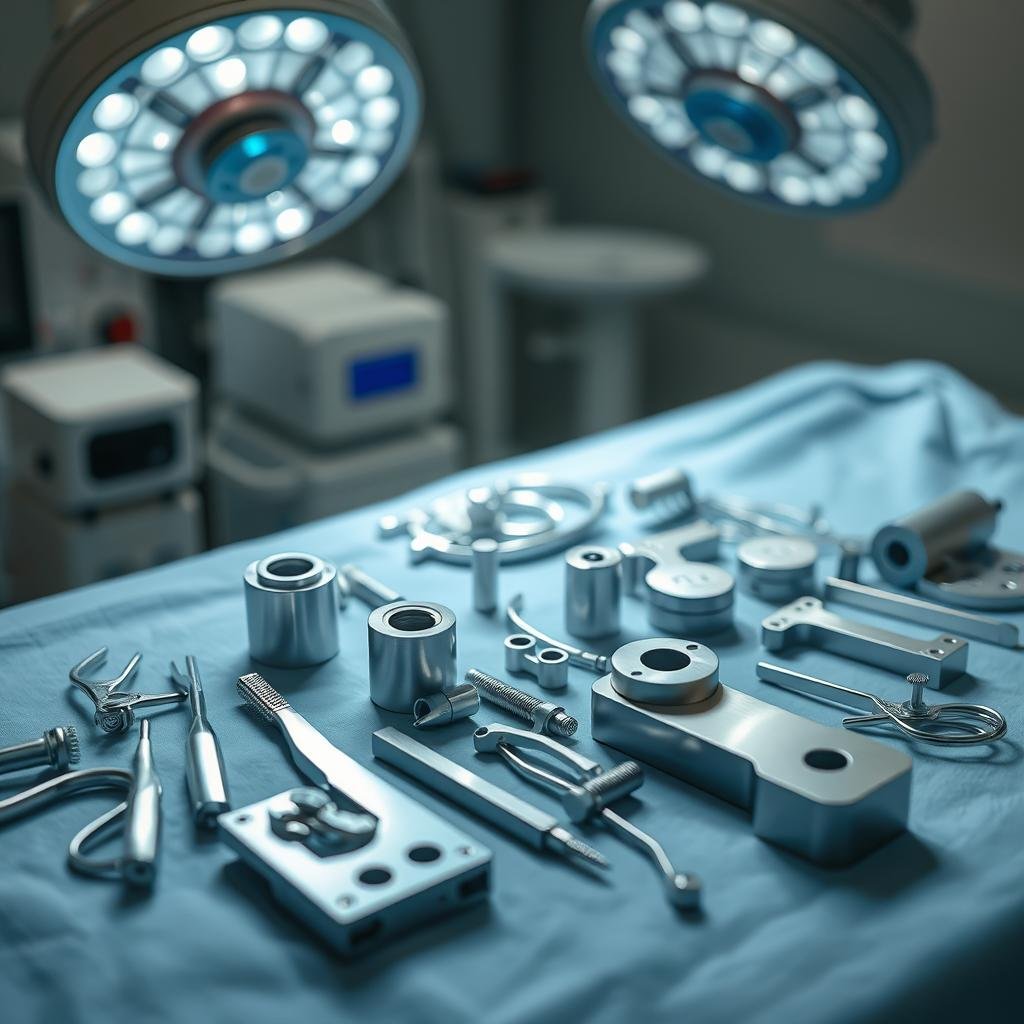

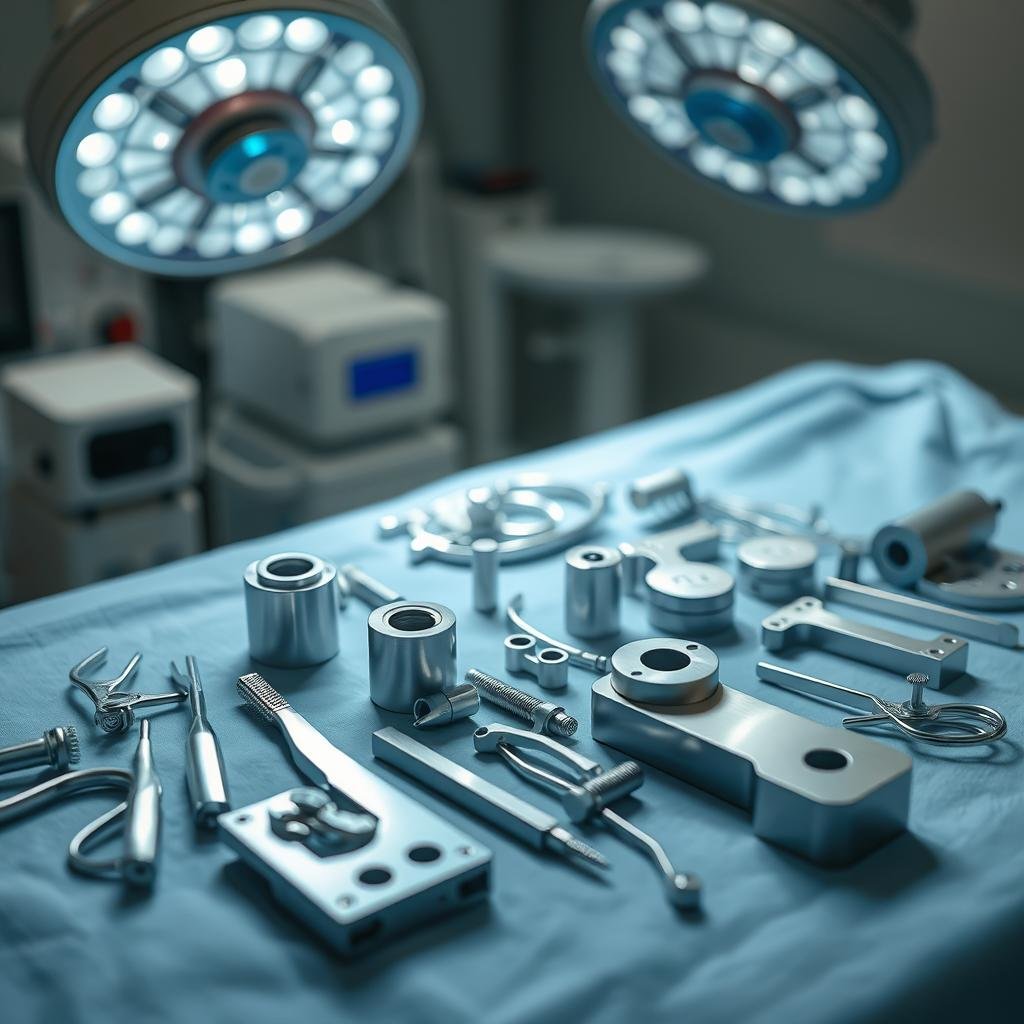

Medical

Medical

Industrial

Industrial

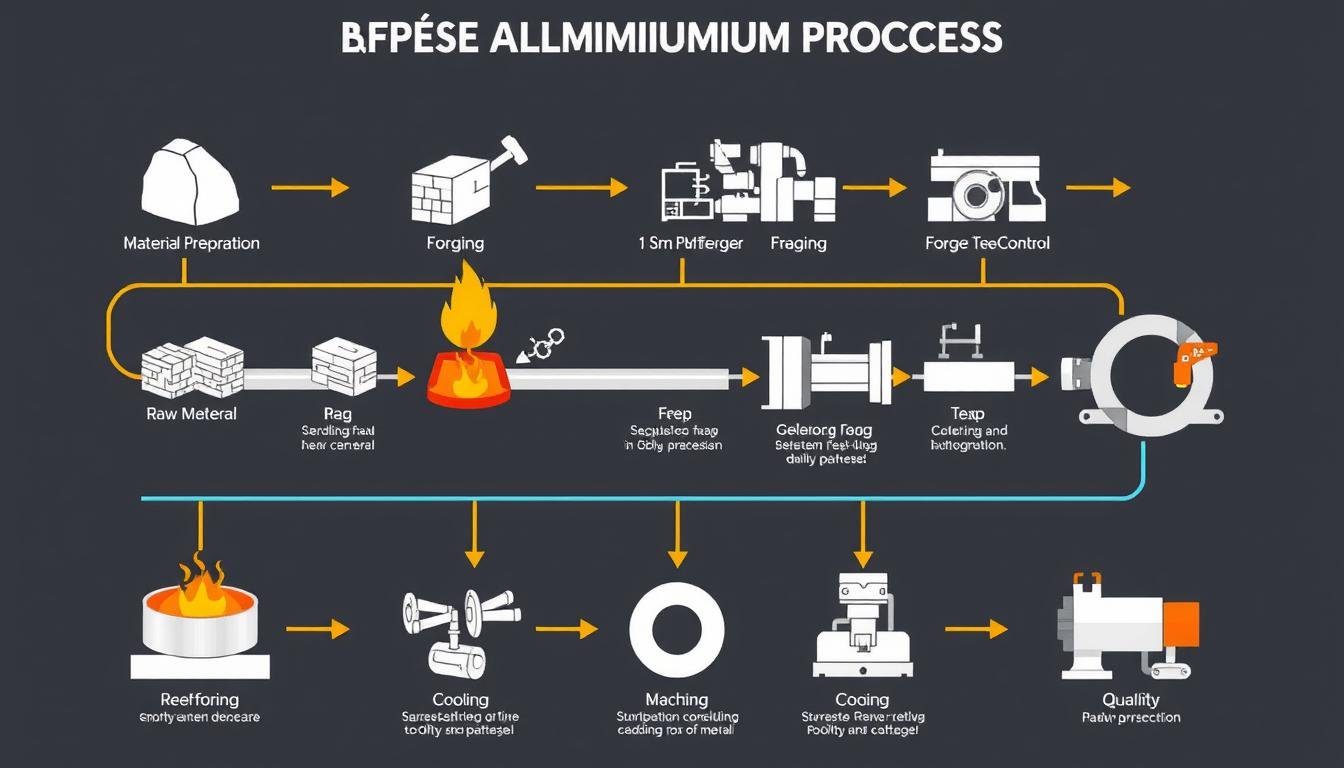

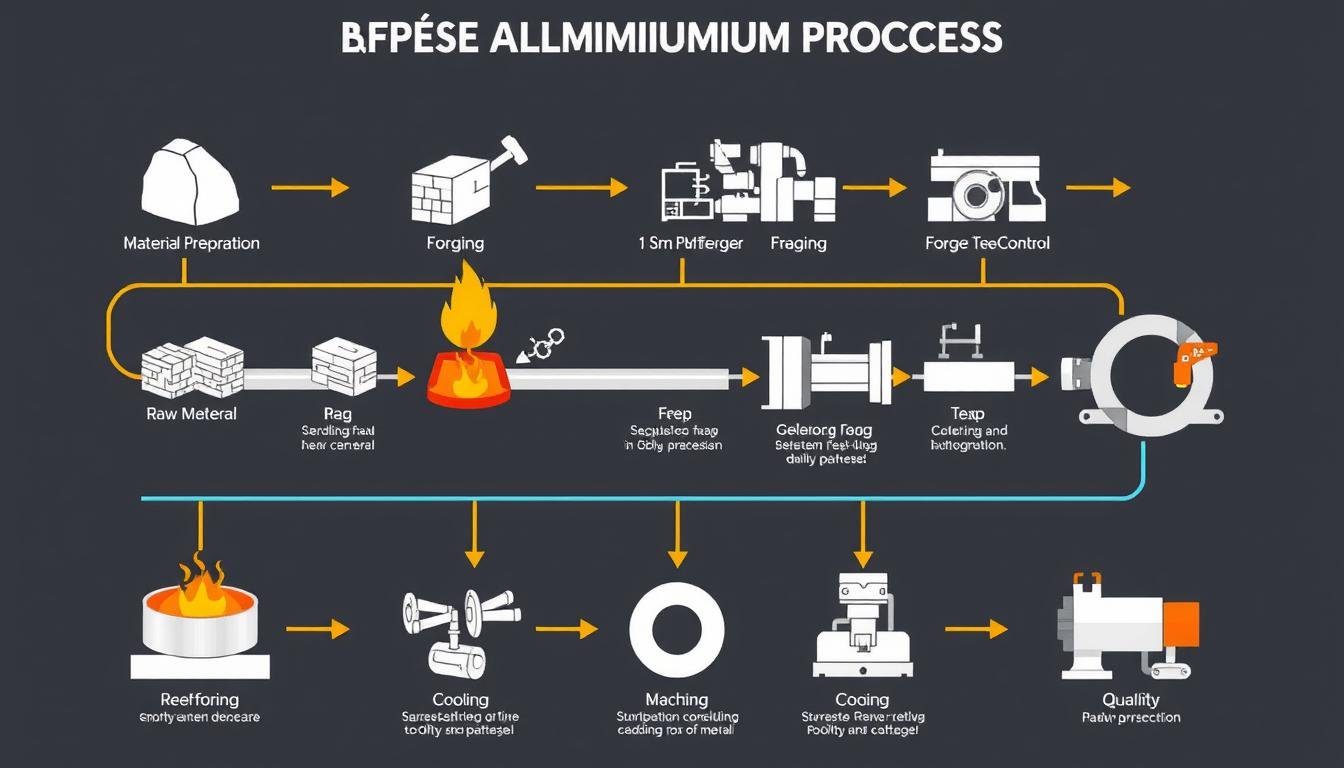

The MAIKONG Aluminum Forging Process

As a leading Hot Forging Aluminum Supplier, MAIKONG has refined our forging process to ensure optimal results for every component we produce. Here’s how we transform raw aluminum into precision-engineered parts:

- Design & EngineeringOur team works with your specifications to optimize designs for the forging process, utilizing advanced CAD/CAM systems to identify potential issues before production.

- Material SelectionWe help select the optimal aluminum alloy based on your application requirements, considering mechanical properties, machinability, heat treatment characteristics, and cost-effectiveness.

- Tooling DesignCustom die designs ensure initial quality while regular maintenance preserves consistency—both critical for producing high-quality forgings.

- Forging OperationOur workshop accommodates diverse aluminum forging specifications, with precise temperature control and pressure application.

- Heat TreatmentIn-house heat treatment with comprehensive statistical analysis and documentation ensures optimal mechanical properties.

- Secondary ProcessingFrom precision CNC machining to surface treatments, we handle all post-forging operations to deliver components ready for your application.

- Quality ControlRigorous inspection at every stage guarantees that your components meet all specifications and quality standards.

Ready to Start Your Aluminum Forging Project?

Contact MAIKONG today to discuss your requirements and receive a competitive quote.

Email Our Team

Aluminum Alloy Expertise: The MAIKONG Advantage

As your trusted Hot Forging Aluminum Supplier, MAIKONG offers extensive expertise across a wide range of aluminum alloys. Our material knowledge ensures you get the perfect balance of properties for your specific application.

6000 Series Alloys

6061-T6: Excellent corrosion resistance and weldability, ideal for structural applications.

6082-T6: High strength and good machinability, widely used in transport and structural applications.

7000 Series Alloys

7075-T6: Superior strength-to-weight ratio, commonly used in aerospace and automotive industries.

7050-T7451: Excellent toughness and corrosion resistance, suitable for aerospace structural parts.

2000 Series Alloys

2024-T3: High fatigue resistance and excellent strength, best for aerospace components.

2014-T6: High strength and good machinability, ideal for aerospace and structural parts.

“The right alloy selection is critical to component performance. At MAIKONG, we don’t just forge aluminum—we engineer solutions that optimize strength, weight, and cost for your specific application.”

— MAIKONG Engineering Team

Quality Assurance: The MAIKONG Commitment

As a premier Hot Forging Aluminum Supplier, MAIKONG implements rigorous quality control procedures throughout our manufacturing process. Our commitment to excellence ensures that every component we deliver meets or exceeds your specifications.

Our Quality Control Process

- Material certification and verification

- In-process inspections at critical stages

- Dimensional verification using precision equipment

- Mechanical property testing

- Surface quality inspection

- Final comprehensive quality check

- Detailed documentation and traceability

4.9

Customer Satisfaction

Conclusion: Making the Right Hot Forging Aluminum Supplier Choice

Selecting the right Hot Forging Aluminum Supplier is a critical decision that impacts your product quality, manufacturing efficiency, and bottom line. By partnering with MAIKONG, you gain access to world-class aluminum forging capabilities, comprehensive machining services, and dedicated customer support—all at competitive prices that help you maintain your competitive edge.

Whether you need complex aerospace components, high-performance automotive parts, or precision industrial elements, our team is ready to deliver solutions that exceed your expectations. Contact MAIKONG today to discuss your aluminum forging requirements and discover why leading US manufacturers trust us as their preferred supplier.

Ready to Elevate Your Manufacturing with Premium Forged Aluminum?

Contact MAIKONG today for expert consultation and competitive pricing on your next project.

Request Your Quote Now

Automotive

Automotive Aerospace

Aerospace Medical

Medical Industrial

Industrial