In the demanding world of metal manufacturing, the difference between standard components and exceptional ones often lies in the meticulous attention given to each forging procedure step. At MAIKONG, we understand that precision throughout the forging process directly impacts structural integrity, performance, and longevity of the final product. This comprehensive guide explores why exactness in every phase of metal forging is essential for meeting and exceeding rigorous US quality standards, and how our expertise ensures superior results for critical applications across industries.

Understanding the Metal Forging Procedure Steps

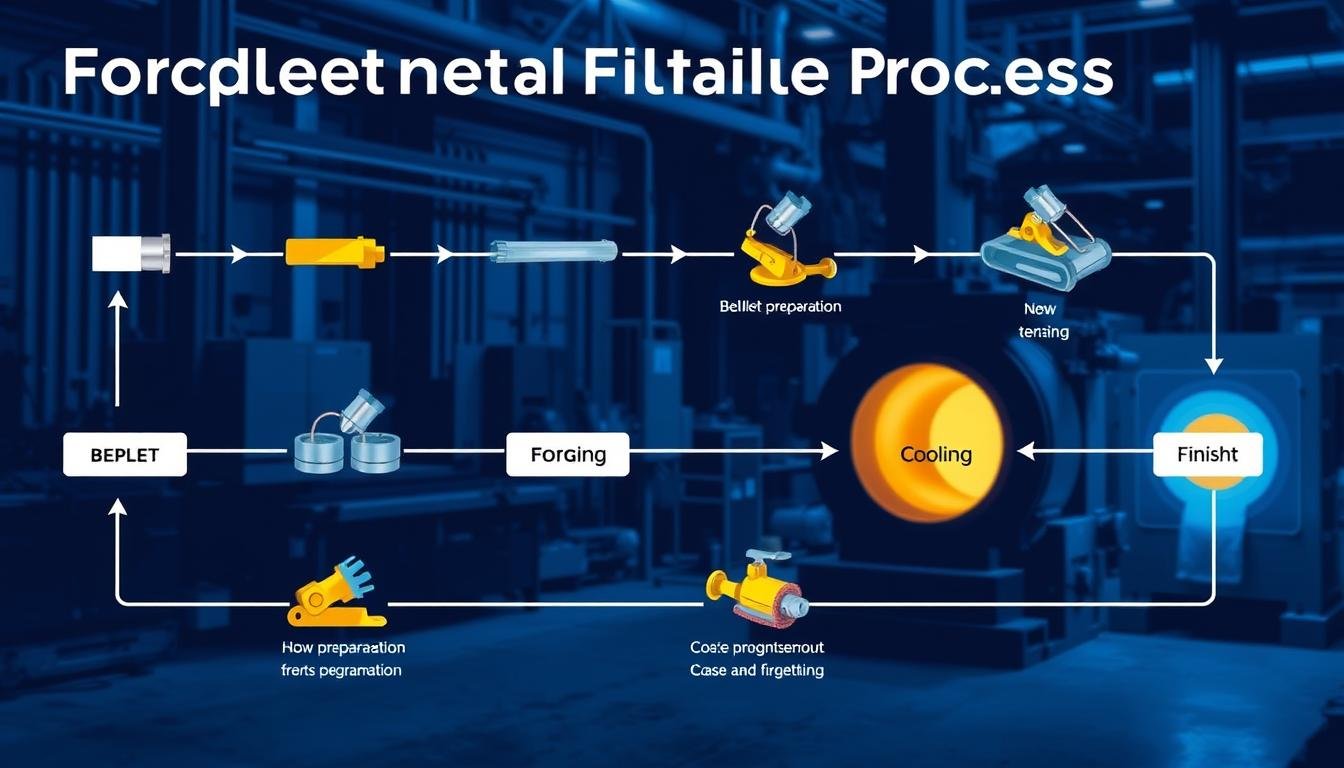

Forging is an ancient metalworking process that has evolved into a sophisticated manufacturing technique. By applying heat and pressure, metals are shaped into components with exceptional strength and durability. Each forging procedure step must be executed with precision to achieve optimal results.

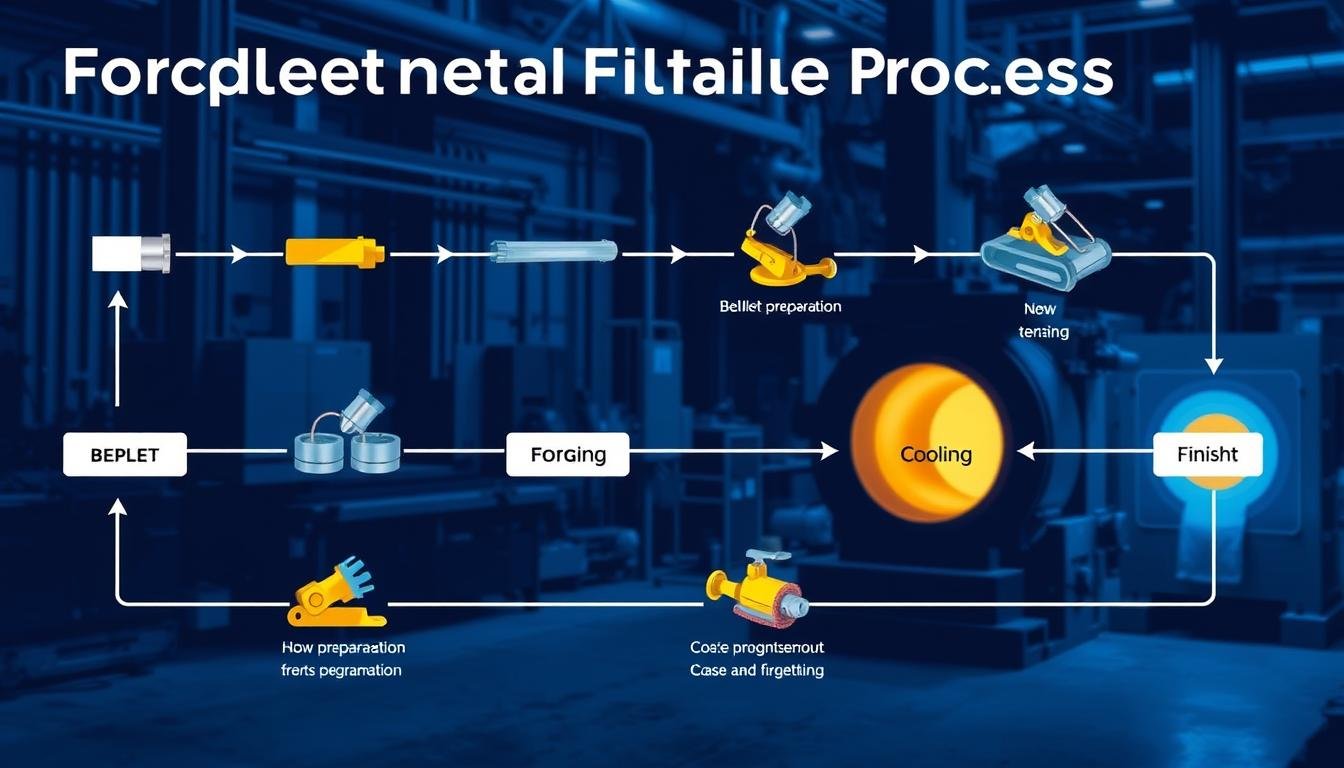

Complete forging process flow showing critical procedure steps

The Critical Sequence of Forging Procedure Steps

- Die Design and Manufacturing – The foundation of precision forging begins with expertly designed dies that determine the final shape and dimensional accuracy.

- Billet/Ingot Preparation – Raw materials are carefully selected and cut to appropriate dimensions based on the final product specifications.

- Heating – Materials are heated to specific temperatures (850-1150°C for steel, up to 500°C for aluminum) to achieve optimal malleability.

- Forging Operation – The heated metal is shaped through compression using various techniques depending on the complexity and requirements.

- Heat Treatment – Post-forging heat treatments enhance mechanical properties like strength, hardness, and toughness.

- Cooling – Controlled cooling influences grain structure and mechanical properties of the forged component.

- Finishing – Final operations including machining, trimming, and surface treatments complete the manufacturing process.

At MAIKONG, we maintain strict control over each of these forging procedure steps, ensuring that every component meets the exacting standards required by US industries. Our commitment to precision begins with the initial design phase and continues through final inspection.

Classification of Forging Processes

Understanding the different types of forging processes is essential for selecting the appropriate method for specific applications. Each process offers unique advantages and is suited to particular materials and component requirements.

Classification by Temperature

Visual comparison of hot, warm, and cold forging temperature ranges

Hot Forging

Performed at temperatures exceeding the metal’s recrystallization point (typically 0.3-0.4 times the melting point for pure metals). This traditional method allows for easier deformation but offers lower precision and rougher surface finish.

Warm Forging

Conducted at temperatures above room temperature but below recrystallization. This intermediate approach balances workability with precision, requiring greater compressive forces than hot forging but yielding better surface quality.

Cold Forging

Performed at room temperature, this method delivers superior surface finish, high dimensional accuracy, and parts ready for immediate use. While requiring significant compressive forces, cold forging is excellent for automated production.

Classification by Tooling and Equipment

The tooling and equipment used in forging significantly impact the quality, precision, and efficiency of the process. Modern forging operations utilize sophisticated machinery to achieve consistent results.

Need Precision Forged Components?

MAIKONG offers comprehensive forging services with 60+ CNC machines and 100+ tons monthly capacity. Our expertise ensures your components meet exact specifications.

Get A Quote

Types of Forging Methods

Various forging methods have been developed to address specific manufacturing requirements. Each technique offers distinct advantages for particular applications and materials.

Modern forging methods in action at MAIKONG’s manufacturing facility

Drop Forging

Drop forging uses a hammer released from a specific height onto metal positioned on a stationary anvil. The process can be categorized into:

- Open-die forging – The hammer makes direct contact with the workpiece surface

- Closed-die forging – The workpiece is encapsulated within dies that impart the desired shape

Press Forging

Unlike drop forging’s impact approach, press forging applies continuous pressure for a longer duration. This controlled squeezing results in plastic deformation throughout the entire volume of the part, not just the surface layer.

Upset Forging

Also known as heading, this process uses a series of dies to deform one end of a workpiece. It’s commonly used for creating fasteners like bolts, screws, and nails by increasing the cross-section at one end.

Roll Forging

This specialized process produces parts with unique cross-sections at scale. Long bars pass through opposing rolls that compress the material, reducing thickness while increasing length. The result is excellent grain structure throughout the workpiece.

Advanced Forging Techniques

Precision Forging

Conducted at lower temperatures than hot forging (750-950°C for steel), precision forging enhances accuracy and is often used as a finishing process. Cold precision forging at near-ambient temperatures yields highly accurate dimensions.

Isothermal Forging

Performed at a fixed temperature throughout the process, with both the blank and die maintained at uniform temperature. This approach maximizes metal plasticity and is particularly effective for aluminum forging.

Rolled Ring Forging

Creates seamless metal rings by piercing a cylindrical stock and manipulating it with rollers. The result is a ring-shaped component with excellent grain structure, ideal for critical applications like gears and bearings.

At MAIKONG, we employ these various forging methods based on your specific requirements, ensuring optimal results for each component. Our expertise across multiple forging techniques allows us to recommend the most appropriate process for your application.

Why Precision Matters in Each Forging Procedure Step

The quality of forged components is directly tied to the precision maintained throughout each forging procedure step. Even minor deviations can significantly impact the final product’s performance and reliability.

Quality control inspection ensuring precision in every forged component

Impact of Precision on Material Properties

Grain Structure Optimization

Precise control of temperature, pressure, and deformation rates during forging aligns the metal’s grain structure, significantly enhancing mechanical properties. This directional grain flow increases strength along primary stress axes.

Elimination of Defects

Meticulous attention to each forging procedure step prevents common defects like porosity, cracks, and blowholes that can compromise structural integrity and lead to premature failure.

Enhanced Mechanical Properties

Precision forging optimizes fatigue resistance, tensile strength, and impact toughness—critical properties for components used in demanding applications like aerospace, automotive, and heavy machinery.

Consistent Performance

Maintaining exact specifications throughout the forging process ensures consistent performance across production batches, essential for safety-critical components where reliability is paramount.

| Forging Procedure Step |

Impact of Precision |

Potential Issues from Imprecision |

| Die Design |

Determines final shape accuracy and material flow |

Dimensional inaccuracy, incomplete die filling |

| Material Selection |

Ensures appropriate mechanical properties |

Inconsistent performance, premature failure |

| Heating |

Optimizes material plasticity |

Uneven deformation, cracking, poor grain structure |

| Forging Operation |

Controls material flow and grain structure |

Laps, folds, incomplete filling |

| Heat Treatment |

Develops specific mechanical properties |

Inconsistent hardness, brittleness, softness |

| Cooling |

Stabilizes microstructure |

Residual stresses, distortion, cracking |

| Finishing |

Achieves final dimensions and surface quality |

Poor fit, surface defects, dimensional variation |

Partner with Precision Forging Experts

MAIKONG delivers superior forged components through meticulous attention to every procedure step. Contact us to discuss your specific requirements.

Contact via WhatsApp

Advantages of Forging Over Casting

When selecting a manufacturing process, understanding the comparative advantages of forging versus casting is crucial for making informed decisions that impact product performance and reliability.

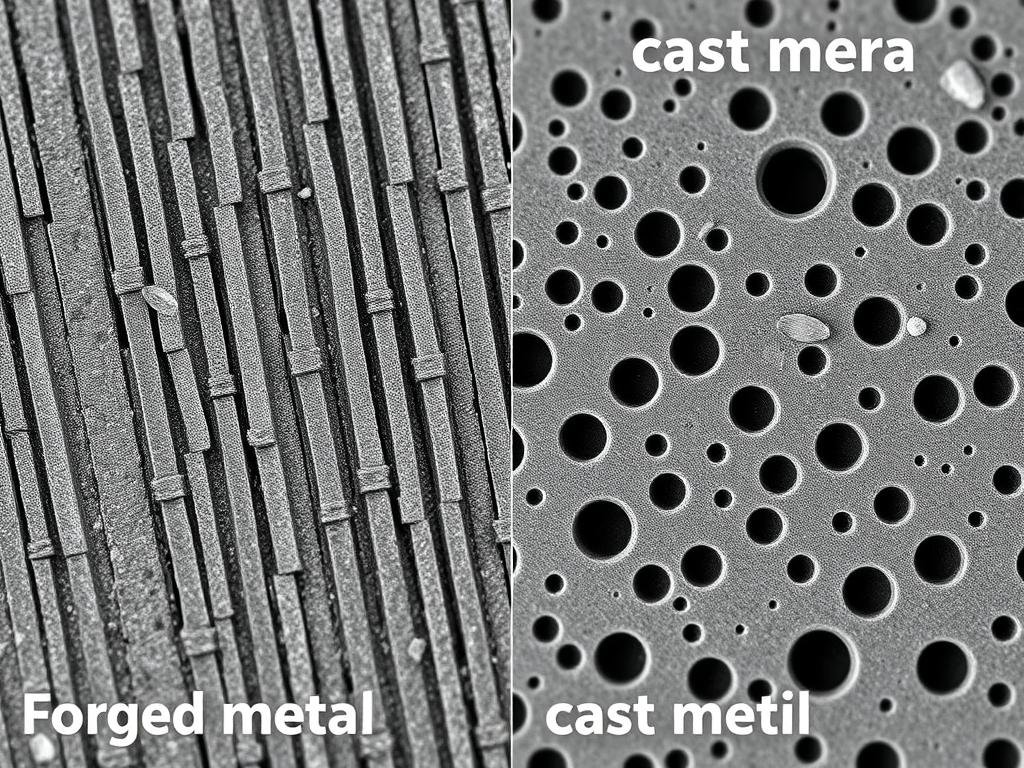

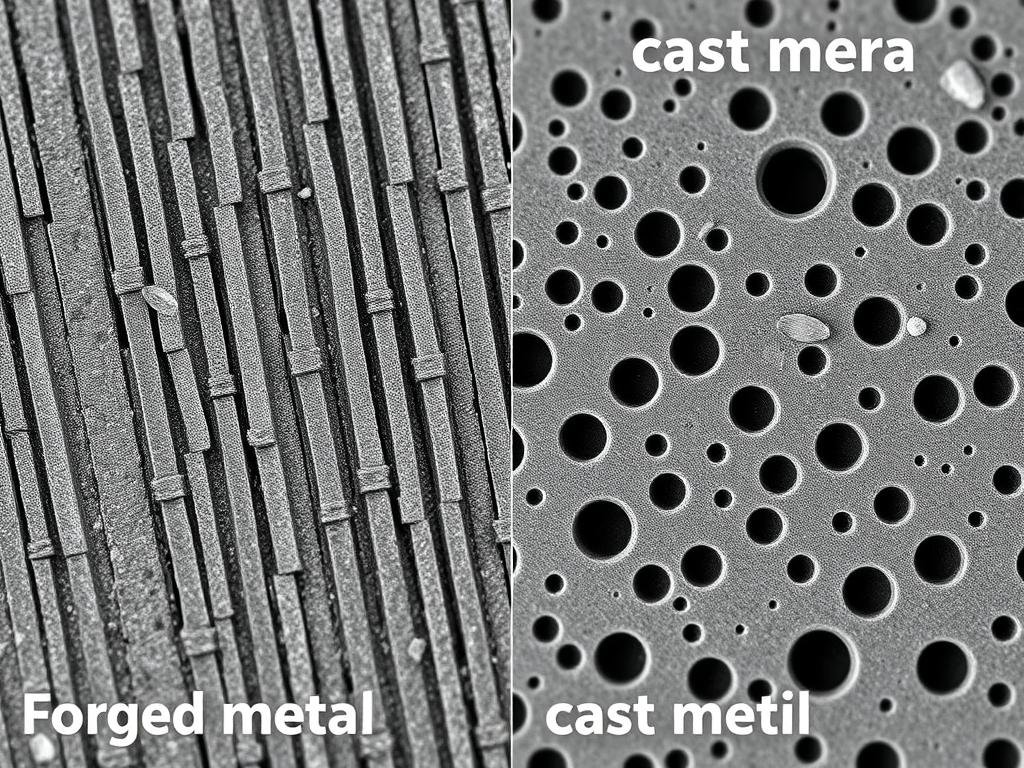

Microscopic comparison of grain structure: forged (left) vs. cast (right) metal

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Heat Treatment Response |

✅ Responsive for controlled material properties |

Less predictable response |

| Critical Applications |

✅ Ideal for structural members and load-bearing components |

Limited suitability for critical applications |

For applications where strength, reliability, and performance are critical, forging offers significant advantages over casting. The superior mechanical properties achieved through precise control of each forging procedure step make forged components the preferred choice for demanding industries.

MAIKONG’s Comprehensive Forging and Machining Services

At MAIKONG, we provide end-to-end manufacturing solutions with a focus on precision and quality. Our extensive capabilities encompass the complete production process from design to delivery.

MAIKONG’s advanced manufacturing facility with 60+ CNC machines

Our CNC Machining Capabilities

MAIKONG operates 60+ CNC machines with a monthly metal processing capacity exceeding 100 tons. Our comprehensive machining services include:

CNC Turning Services

Ideal for producing deep holes, machined threads, and cylindrical shapes with superior surface finishes. Our precision turning capabilities ensure fast turnaround and exact specifications.

CNC Milling Services

Our multi-axis metal CNC machines create complex prismatic shapes and flat surfaces with high flexibility and extreme accuracy, requiring no fixed tooling.

CNC SWISS Type Machining

Specializing in precision small parts and long shaft components, our equipment features dual spindles and multi-axis capabilities for one-stop manufacturing solutions.

Full-Service Aluminum Forging Center

MAIKONG’s comprehensive aluminum forging process from raw material to finished product

Our one-stop forging process considers how to best support the end application at each step. We’ve established a comprehensive service center for aluminum forgings, providing complete technical support and solutions:

- CAD/CAM Integration – Advanced analysis software facilitates early-stage issue identification and mitigation

- Material Selection – Thorough consideration of mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness

- Tooling Design – Expert die design ensures initial quality, while regular maintenance preserves consistency

- Forging Operations – Our workshop accommodates diverse aluminum forging specifications with precision

- Heat Treatment – Comprehensive statistical analysis and documentation for our in-house heat treatment processes

- Surface Treatment – Enhancing appearance, performance, and competitiveness through specialized finishing

- Quality Control – Rigorous procedures ensure forged components meet stringent US standards

Ready to Experience Superior Forging Quality?

MAIKONG delivers precision-forged components with competitive pricing and exceptional quality. Contact us today to discuss your project requirements.

Get A Quick Quote

Applications of Precision Forging Across Industries

The exceptional mechanical properties of forged components make them ideal for various sectors where performance, reliability, and safety are paramount.

Precision-forged components for aerospace, automotive, and industrial applications

Aerospace

The aerospace sector demands superior-quality components that withstand harsh conditions, high temperatures, stress, and fatigue. Precision forging is essential for jet engine components like turbine discs, blades, and rotors, as well as landing gear components designed to support aircraft weight and absorb landing impact.

Automotive

As one of the primary users of forged components, the automotive industry relies on forging for high-strength, durable parts. Engine components (crankshafts, connecting rods, pistons), suspension components (control arms, steering knuckles), and transmission parts (gears, shafts) all benefit from the superior properties achieved through precise forging.

Oil and Gas

Operating under severe conditions that demand equipment capable of withstanding high temperatures, pressures, and corrosive environments, the oil and gas industry depends on forged components for drill bits, mud motors, drilling tools, downhole tools, pipeline segments, and valves.

At MAIKONG, we specialize in creating precision-forged components for these demanding industries and more. Our meticulous attention to each forging procedure step ensures that our products meet the highest performance standards required by US manufacturers.

MAIKONG’s Commitment to Quality

Quality is at the core of everything we do at MAIKONG. Our comprehensive quality assurance processes ensure that every component we produce meets or exceeds the most stringent US standards.

MAIKONG’s quality control laboratory ensuring precision in every component

Our Quality Assurance Process

- Material Verification – Our material laboratory plays a vital role in ensuring that raw materials meet exact specifications before entering production

- Process Monitoring – Continuous monitoring of each forging procedure step maintains consistency and precision throughout manufacturing

- Dimensional Inspection – Advanced measurement tools verify that components meet exact dimensional requirements

- Mechanical Testing – Rigorous testing confirms that forged parts achieve required strength, hardness, and fatigue resistance

- Surface Quality Inspection – Detailed examination ensures components are free from defects that could compromise performance

- Documentation and Traceability – Comprehensive records maintain complete traceability throughout the production process

Our ISO 9001:2015 certification demonstrates our commitment to maintaining the highest quality standards. The advantages of our in-house production—from raw material to forging, heat treatment, CNC milling, and surface treatment—allow our quality engineering staff to monitor production and quality at all times, ensuring consistency in every component.

“At MAIKONG, we recognize the crucial importance of consistency, strength, and weight in each forged part for the final product. Our dedicated focus on crafting superior forged parts enables us to fulfill your requirements for heat treating, machining, and testing.”

Become a US Distributor for MAIKONG

We’re seeking US distributors for our high-quality, cost-effective forged components. Partner with us to bring precision-engineered parts to the American market.

Contact for Distribution Opportunities

Why Choose MAIKONG for Your Forging Needs

MAIKONG combines traditional forging expertise with advanced manufacturing technology to deliver superior components that meet the most demanding requirements. Our commitment to precision in every forging procedure step ensures exceptional quality, performance, and reliability.

MAIKONG’s team of forging experts committed to quality and precision

Why Partner With MAIKONG

- 60+ CNC machines with 100+ tons monthly capacity

- Comprehensive in-house production capabilities

- ISO 9001:2015 certified quality management system

- Expertise across multiple forging methods

- Competitive pricing with superior quality

- Complete traceability and documentation

- Extensive experience serving US markets

Whether you need aluminum forgings, steel components, brass parts, or precision CNC machining, MAIKONG delivers excellence at every step. Our cost-effective manufacturing solutions maintain the highest quality standards while offering competitive pricing for US markets.

Contact MAIKONG Today

Ready to experience the difference that precision in every forging procedure step makes? Contact us to discuss your requirements or request a quote.

Complete forging process flow showing critical procedure steps

Complete forging process flow showing critical procedure steps