Forge Tooling: The Definitive Guide for US Metal Forging Manufacturers & Engineers

In the competitive world of metal manufacturing, quality forge tooling makes all the difference between mediocre results and exceptional performance. At MAIKONG, we’ve dedicated ourselves to mastering the art and science of forge tooling design and production, helping US manufacturers achieve superior results through precision-engineered tooling solutions. This comprehensive guide will walk you through everything you need to know about modern forge tooling technology, applications, and how to select the right tooling partner for your specific manufacturing needs.

Ready to Enhance Your Forging Operations?

Get a personalized quote for your specific forge tooling requirements today.

Get A Quick Quote

MAIKONG’s Manufacturing Capabilities

With over 60 CNC machines and a monthly metal processing capacity exceeding 100 tons, MAIKONG stands as a leading provider of comprehensive forge tooling solutions. Our state-of-the-art facilities in GD, SZ combine traditional forging expertise with cutting-edge technology to deliver tooling that exceeds industry standards.

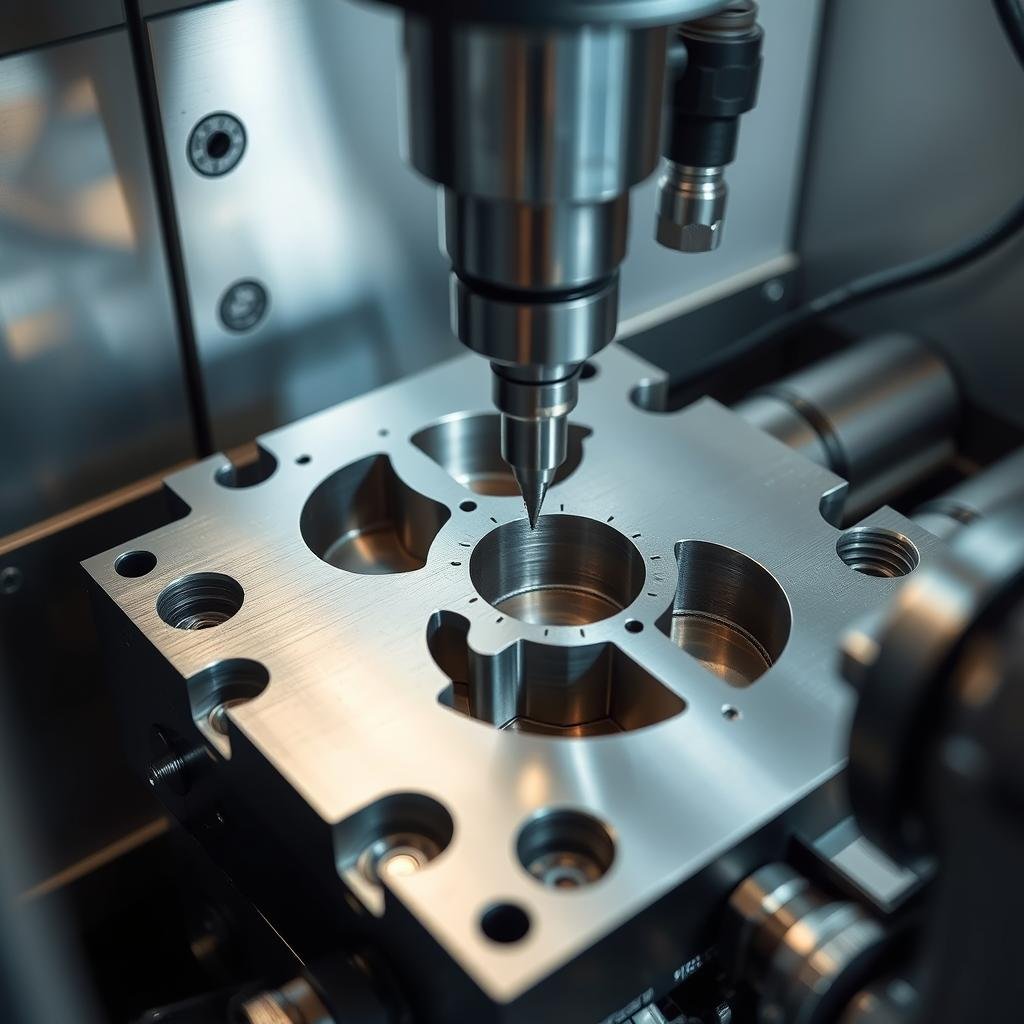

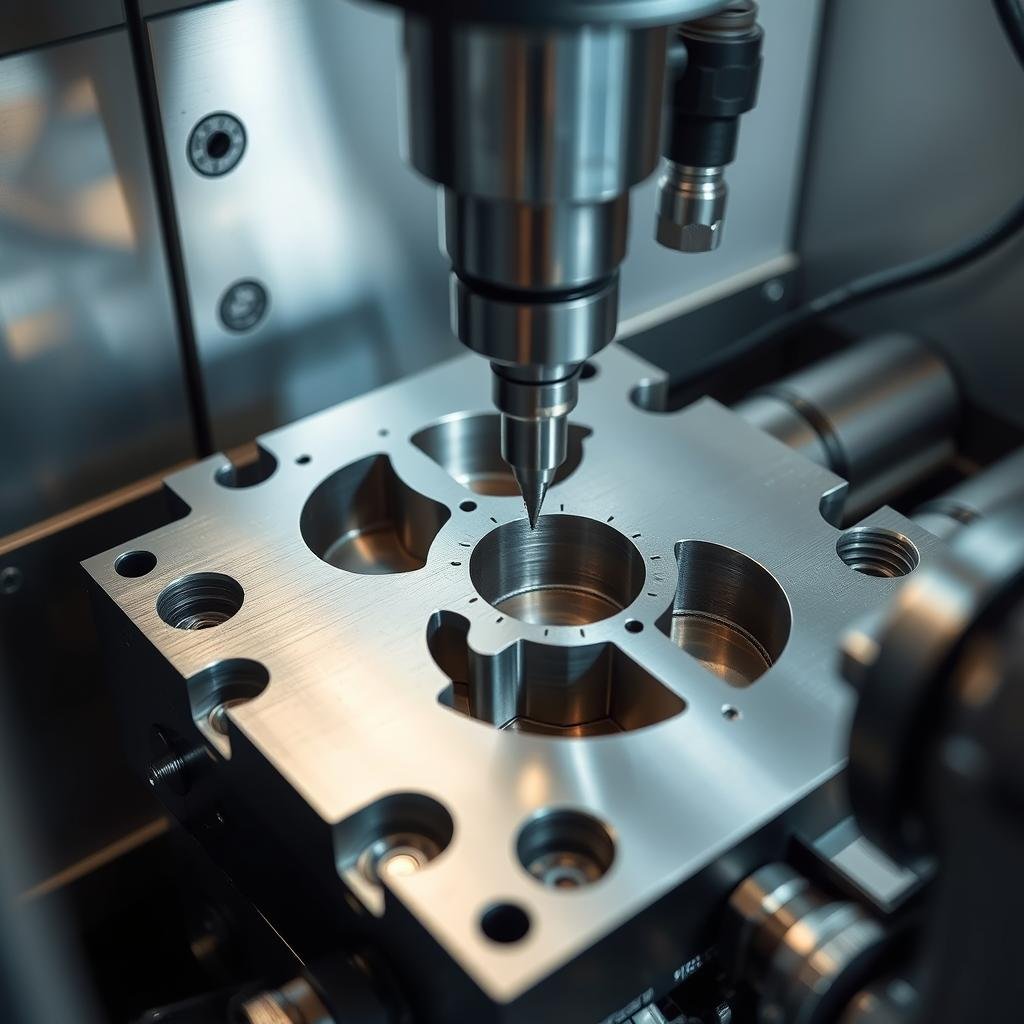

Precision CNC Machining

Our advanced CNC machining centers ensure dimensional accuracy within ±0.005mm, critical for creating forge tooling that delivers consistent results throughout its lifecycle.

Material Testing Laboratory

Our in-house testing facility verifies all raw materials and finished products, ensuring your tooling meets exact specifications for hardness, durability, and performance.

Heat Treatment Facilities

Specialized heat treatment processes optimize the mechanical properties of our forge tooling, extending die life by 2-3 times compared to standard industry offerings.

MAIKONG’s state-of-the-art CNC machining facility https://maikongforge.us

Experience Our Manufacturing Excellence

Contact us to discuss your specific forge tooling requirements or schedule a virtual facility tour.

Contact via WhatsApp

Email Us

Comprehensive CNC Services for Forge Tooling

Our specialized CNC services are tailored to meet the unique demands of forge tooling production, ensuring precision, durability, and performance across all components.

CNC turning operation for forge tooling components https://maikongforge.us

CNC Turning Services

Our CNC turning capabilities excel at creating cylindrical forge tooling components with superior surface finishes. This process is ideal for producing deep holes, machined threads, and precision cylindrical shapes essential for high-performance forge tooling systems.

Multi-axis CNC milling for complex die geometries https://maikongforge.us

CNC Milling Services

For complex prismatic shapes and flat surfaces required in forge dies and bolsters, our multi-axis CNC milling services deliver exceptional accuracy without fixed tooling constraints. This flexibility allows us to create custom forge tooling solutions for unique applications.

Swiss-type machining for precision small components https://maikongforge.us

Swiss-Type Machining

For small, intricate forge tooling components and long shaft parts, our Swiss-type CNC machining delivers unmatched precision. With dual spindles and multi-axis capabilities, we create complex small parts in a single setup, ensuring consistency and accuracy.

Need Custom CNC Services for Your Forge Tooling?

Our engineering team can develop tailored solutions for your specific requirements.

Get A Quick Quote

Full-Service Aluminum Forging Center

Advanced aluminum forging process at MAIKONG’s facility https://maikongforge.us

Beyond forge tooling, MAIKONG offers comprehensive aluminum forging services that leverage our tooling expertise to deliver exceptional forged components. Our integrated approach ensures optimal grain flow and material homogeneity, maximizing impact toughness, fracture resistance, and fatigue strength in every aluminum forging we produce.

The MAIKONG Advantage in Aluminum Forging

Superior Strength-to-Weight Ratio

Our aluminum forgings deliver an optimal balance of strength and weight—critical for aerospace, automotive, and other performance-driven applications where every gram matters while structural integrity cannot be compromised.

Comprehensive In-House Processing

From initial CAD/CAM design to final surface treatments, we handle every aspect of aluminum forging production in-house, ensuring quality control at each stage and eliminating the variables introduced by multiple vendors.

Forged aluminum’s superior grain structure vs. cast aluminum https://maikongforge.us

Forge Tooling Applications: Forging vs. Casting

Understanding the advantages of forging over casting helps illustrate why quality forge tooling is so critical to manufacturing success. Our tooling is designed specifically to maximize these inherent advantages.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Lower due to potential air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Critical Applications |

Ideal for structural members and load-bearing components |

Limited suitability for critical applications |

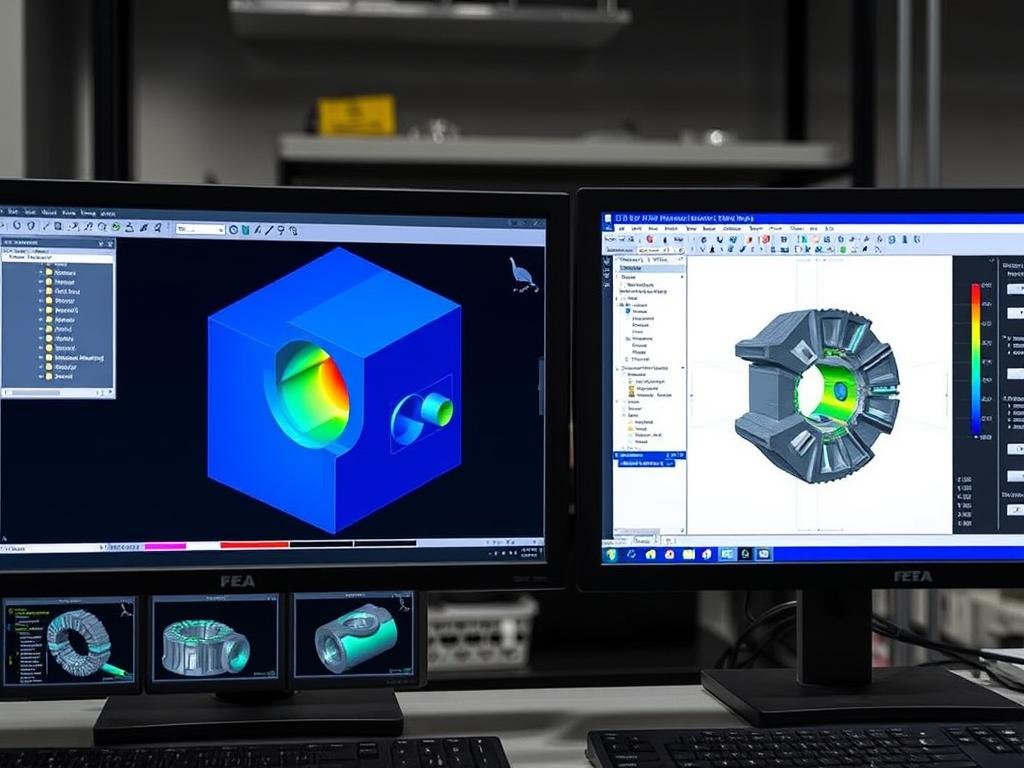

MAIKONG engineers optimizing forge tooling designs for specific applications https://maikongforge.us

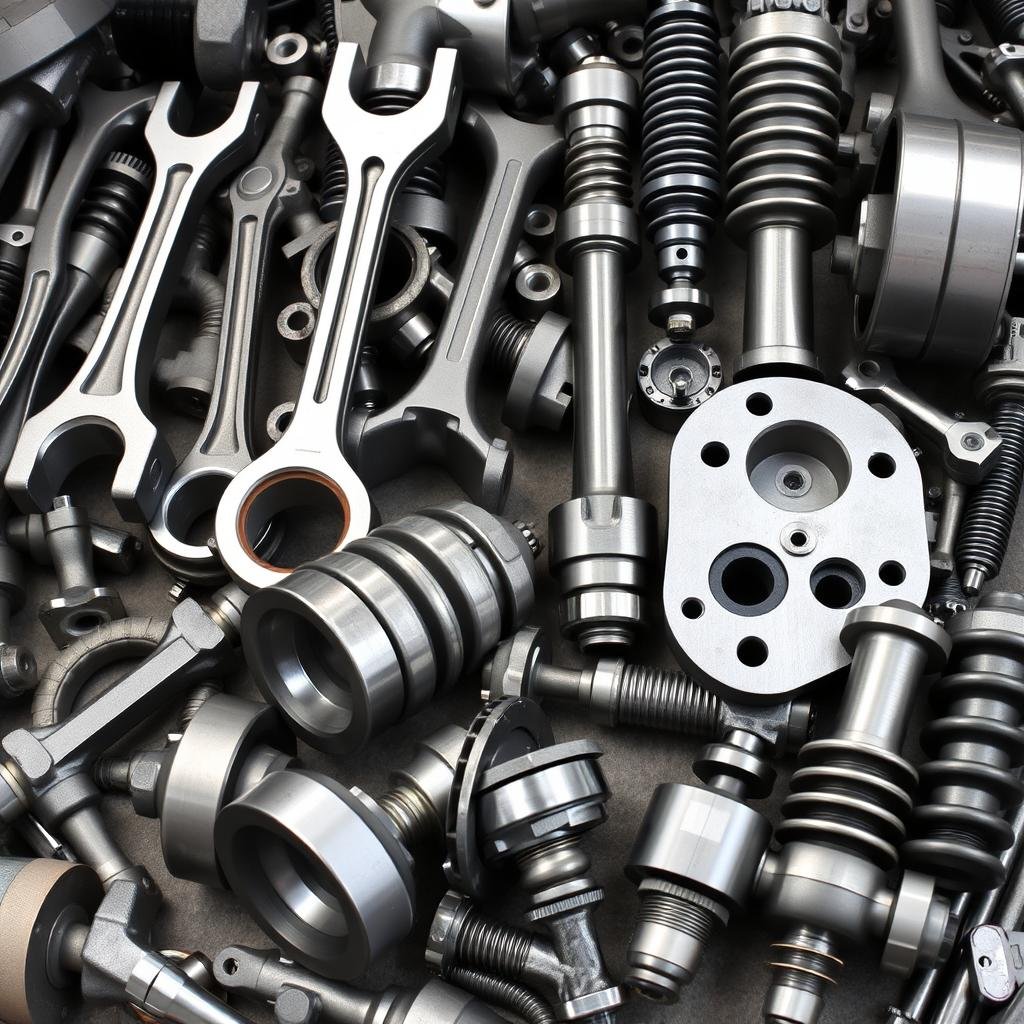

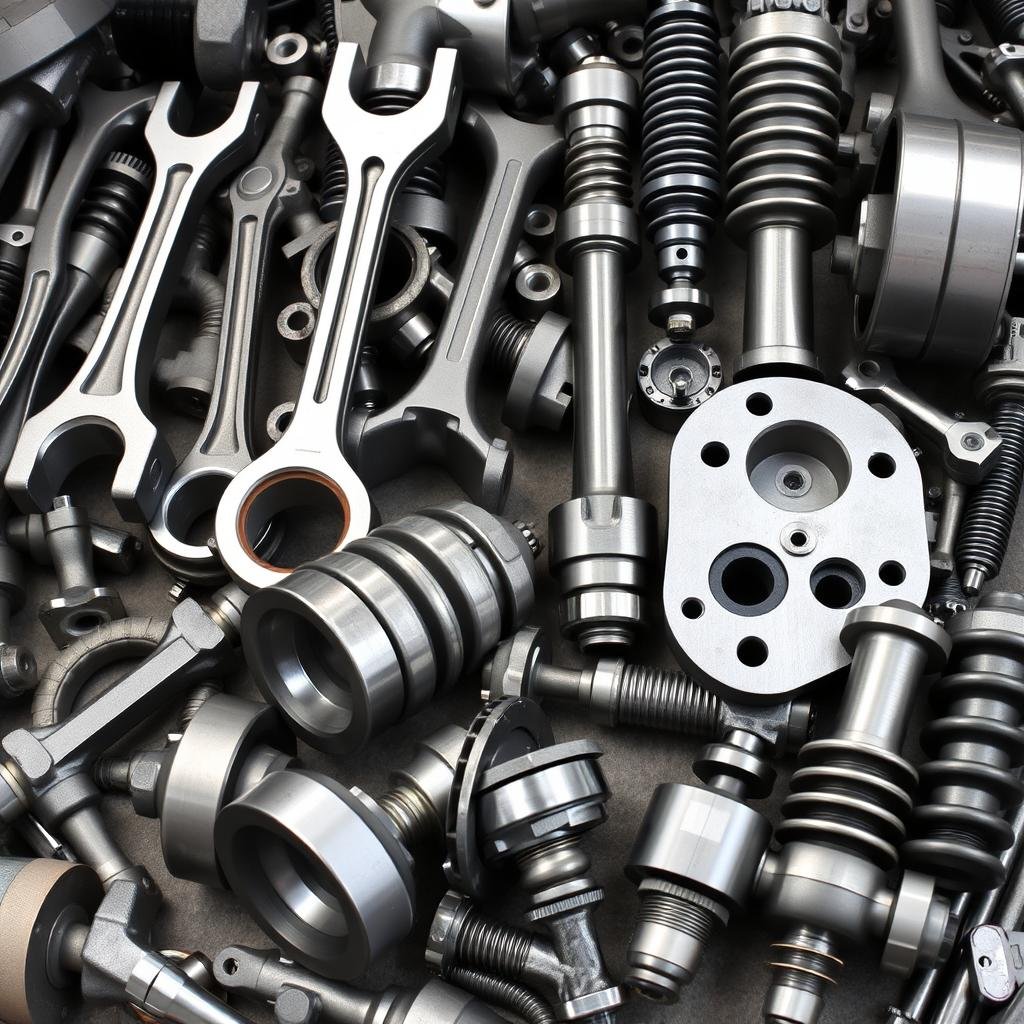

Forge Tooling Applications Across Industries

Our forge tooling solutions serve diverse industries with specialized requirements. Each application demands specific tooling characteristics to ensure optimal performance and product quality.

Aerospace components requiring precision forge tooling https://maikongforge.us

Aerospace

Our aerospace forge tooling creates components with exceptional strength-to-weight ratios and strict dimensional tolerances. These parts must withstand extreme conditions while maintaining structural integrity for safety-critical applications.

Automotive components requiring durable forge tooling https://maikongforge.us

Automotive

Automotive applications require forge tooling that can produce high-volume components with consistent quality. Our tooling creates parts with superior fatigue resistance and durability for critical vehicle systems.

Heavy machinery components requiring robust forge tooling https://maikongforge.us

Heavy Machinery

For construction and mining equipment, our forge tooling creates components that withstand extreme loads and harsh operating conditions. These large-scale parts require tooling with exceptional durability and precision.

MAIKONG’s forge tooling solutions serve diverse industry applications https://maikongforge.us

Quality Assurance in Forge Tooling Production

Quality control is integral to every aspect of our forge tooling production. As an ISO 9001:2015 certified manufacturer, we implement rigorous testing and inspection protocols throughout the manufacturing process.

Our Quality Control Process

- Material verification through chemical analysis and hardness testing

- Dimensional inspection using precision CMM equipment

- Surface finish evaluation to ensure optimal performance

- Heat treatment verification through metallurgical testing

- Functional testing under simulated operating conditions

- Comprehensive documentation and traceability

Precision quality control inspection of forge tooling components https://maikongforge.us

“Quality in forge tooling isn’t just about meeting specifications—it’s about creating tools that consistently deliver exceptional performance throughout their entire lifecycle. At MAIKONG, quality is built into every step of our process.”

– MAIKONG Quality Assurance Team

Partner with MAIKONG for Superior Forge Tooling Solutions

Our engineering team collaborates closely with clients to develop optimal solutions https://maikongforge.us

With over 30 years of industry experience, MAIKONG has established itself as a trusted partner for forge tooling solutions across the United States. Our commitment to quality, innovation, and customer satisfaction has made us the preferred choice for manufacturers seeking reliable, high-performance tooling at competitive prices.

US Distributor and Agent Opportunities

We’re actively expanding our presence in the US market and seeking qualified distributors and agents to represent our forge tooling products and services. Join our team and offer your customers access to premium forge tooling solutions with exceptional value.

Become a MAIKONG Partner

Interested in representing our forge tooling products in the US market? Contact us today to discuss distributor and agent opportunities.

Email for Partnership Details

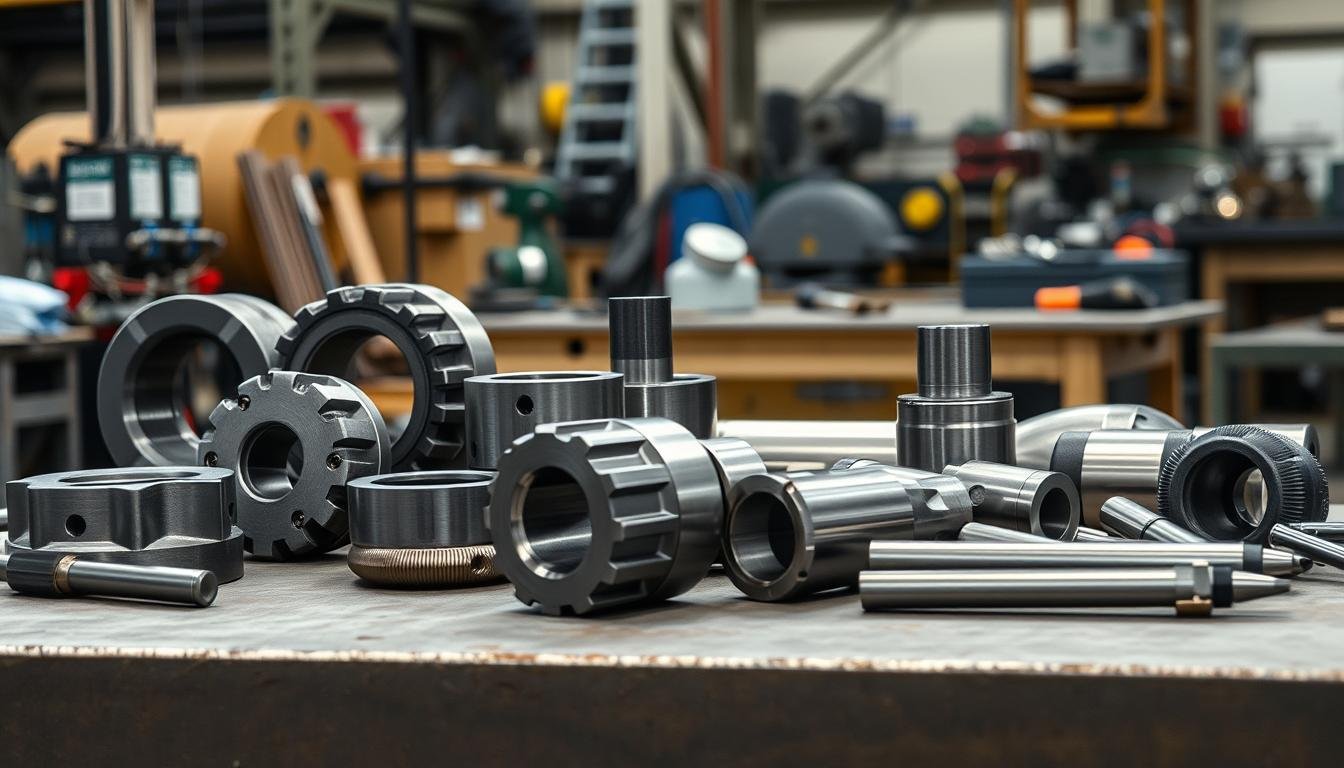

Precision-engineered forge tooling components from MAIKONG https://maikongforge.us

Precision-engineered forge tooling components from MAIKONG https://maikongforge.us