The billet machining process stands as a cornerstone of precision manufacturing in today’s engineering landscape. This sophisticated approach to creating metal components offers unparalleled accuracy, material integrity, and design flexibility that many alternative methods simply cannot match. As industries demand increasingly complex and precise parts, understanding the distinct advantages of billet machined components becomes essential for engineers, designers, and procurement specialists seeking optimal manufacturing solutions.

Understanding the Billet Machining Process

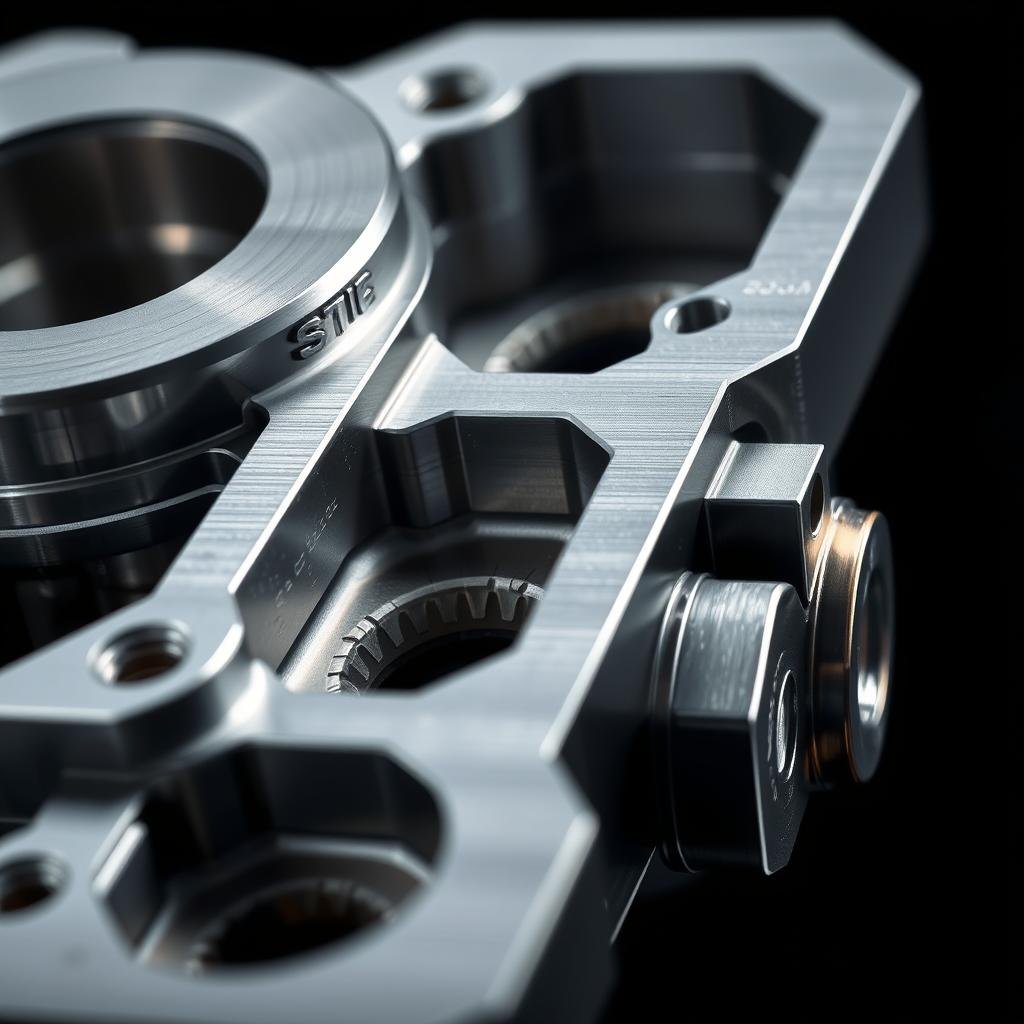

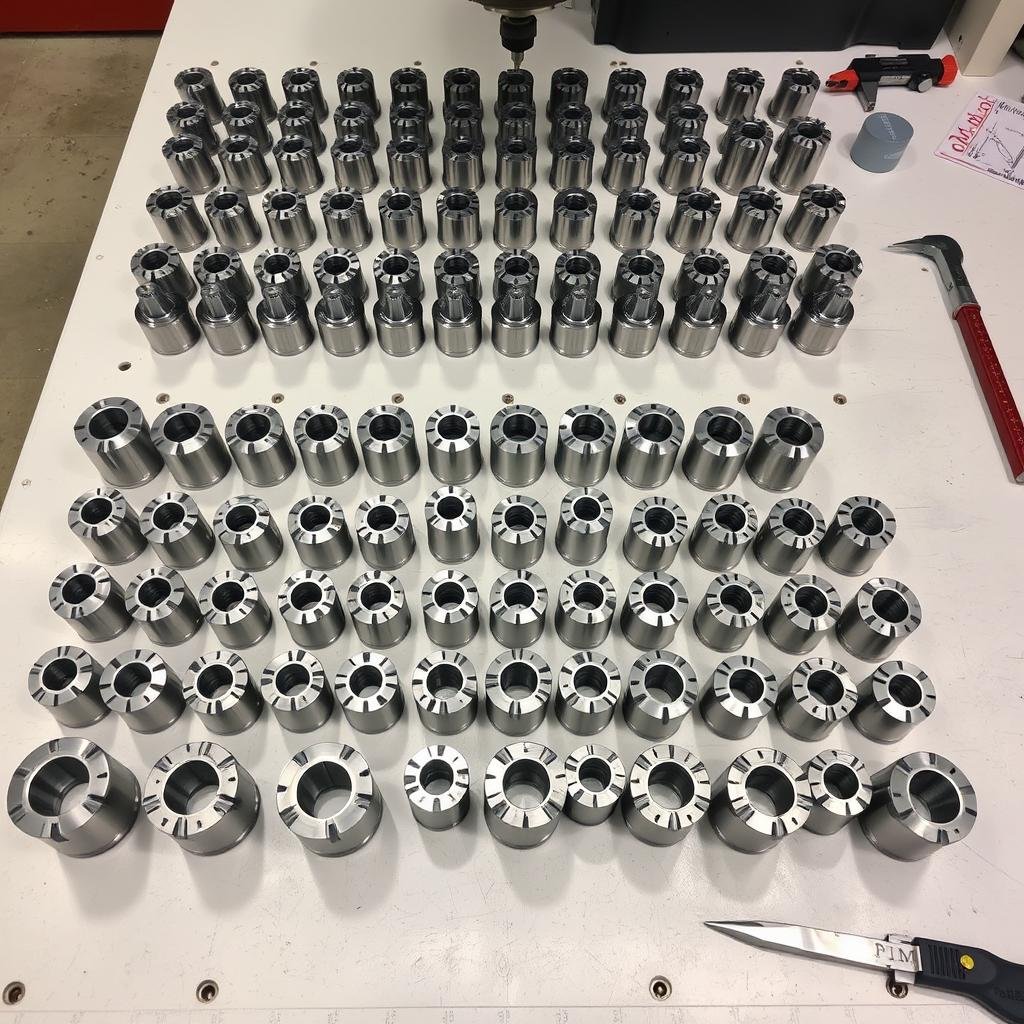

State-of-the-art CNC machine performing precision billet machining at MAIKONG facility

State-of-the-art CNC machine performing precision billet machining at MAIKONG facility

The billet machining process begins with a solid block of metal, known as a billet. This pre-formed metal block, typically created through casting or extrusion, serves as the raw material from which the final component will emerge. Unlike additive manufacturing methods that build parts layer by layer, billet machining is a subtractive process where material is precisely removed until only the desired shape remains.

Key Steps in the Billet Machining Process

- Material Selection – Choosing the appropriate metal alloy based on the component’s requirements for strength, weight, corrosion resistance, and other properties

- CAD/CAM Programming – Creating detailed digital models and toolpaths that guide the CNC machines with extreme precision

- CNC Machining – Using computer-controlled equipment to remove material through milling, turning, drilling, and other operations

- Quality Inspection – Verifying dimensions and tolerances using advanced measurement technologies

- Surface Finishing – Applying treatments like anodizing, powder coating, or polishing as required

At MAIKONG, our advanced billet machining process utilizes 60+ CNC machines with a combined capacity exceeding 100 tons per month. This substantial capability allows us to handle projects of any scale while maintaining the highest standards of precision and quality.

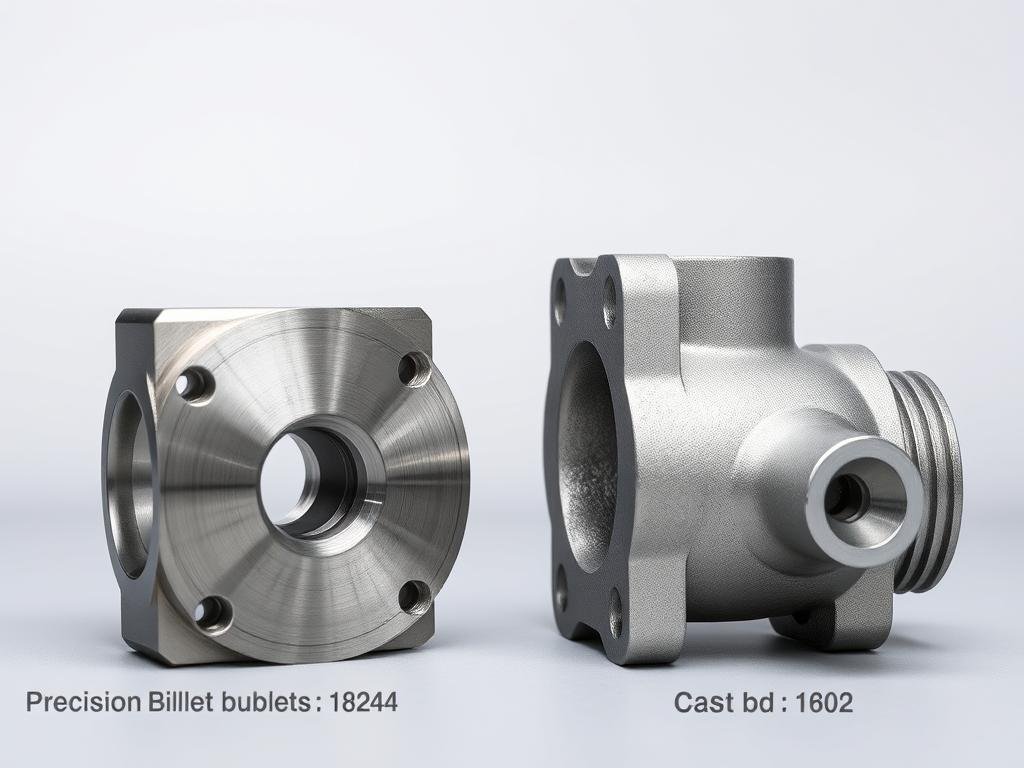

Billet Machining vs. Alternative Manufacturing Methods

To fully appreciate the advantages of the billet machining process, it’s valuable to compare it with other common manufacturing methods. Each approach has its place in modern manufacturing, but billet machining offers distinct benefits for precision applications.

| Manufacturing Aspect |

Billet Machining |

Casting |

Forging |

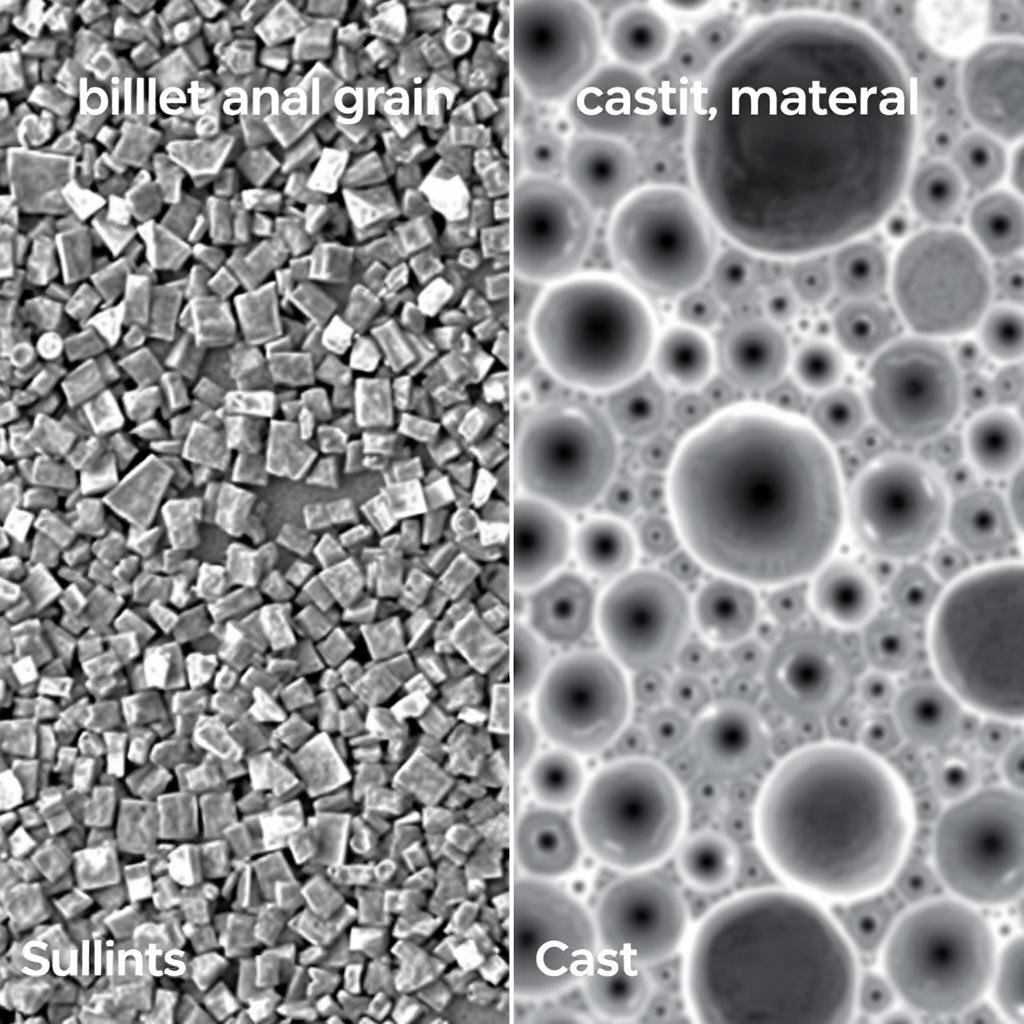

| Material Structure |

Uniform, non-directional grain |

Potential for porosity and inclusions |

Directional grain following part shape |

| Dimensional Accuracy |

Excellent (±0.0005″) |

Good (±0.010″) |

Moderate (±0.015″) |

| Surface Finish |

Superior |

Requires post-processing |

Requires machining |

| Design Complexity |

High with some limitations |

Excellent for complex geometries |

Limited by die design |

| Production Volume |

Ideal for low to medium |

Economical for high volume |

Best for medium to high volume |

| Material Waste |

Higher (recyclable) |

Low |

Low to moderate |

| Tooling Cost |

Low (standard tooling) |

Moderate (molds required) |

High (dies required) |

Need Help Choosing the Right Manufacturing Process?

Our engineering team can analyze your requirements and recommend the optimal approach for your specific application.

Get Expert Advice

Superior Advantages of the Billet Machining Process

The billet machining process offers numerous advantages that make it the preferred choice for applications requiring precision, consistency, and superior mechanical properties. At MAIKONG, we leverage these advantages to deliver exceptional components for our clients.

Unmatched Precision and Accuracy

Modern CNC equipment used in the billet machining process can achieve tolerances as tight as ±0.0005 inches (0.0127mm). This exceptional precision ensures components fit perfectly in complex assemblies and function exactly as designed. For industries like aerospace, medical, and high-performance automotive, this level of accuracy is not just beneficial—it’s essential.

Superior Material Integrity

Unlike casting, which can introduce porosity and inclusions, the billet machining process starts with solid metal stock that already possesses uniform grain structure and consistent mechanical properties. This translates to parts with predictable performance under stress, critical for safety-sensitive applications.

Design Flexibility and Complexity

Modern multi-axis CNC machines can create incredibly complex geometries from a single billet, including undercuts, internal features, and intricate surface patterns that would be challenging or impossible with other manufacturing methods. This flexibility allows engineers to optimize designs for performance rather than manufacturability.

Exceptional Surface Finish

The billet machining process produces components with superior surface quality directly from the machine, often requiring minimal post-processing. This not only improves aesthetics but can be critical for components where surface imperfections could lead to premature failure through stress concentration or corrosion initiation.

Rapid Prototyping and Iteration

With minimal tooling requirements, the billet machining process allows for quick production of prototype parts directly from CAD models. This accelerates development cycles and enables design refinement through physical testing, giving companies a competitive edge in bringing products to market.

Consistency Across Production Runs

Computer-controlled machining ensures that every part produced is virtually identical, regardless of when it was manufactured or by which machine. This consistency is crucial for components that must be interchangeable or that form part of a larger assembly where variations could cause issues.

Experience Precision Manufacturing Excellence

MAIKONG’s advanced CNC machining capabilities deliver exceptional quality and consistency for your most demanding applications.

Request a Quote

Industries Benefiting from Billet Machined Components

The exceptional qualities of billet machined components make them ideal for numerous industries where precision, reliability, and performance are paramount. At MAIKONG, we serve diverse sectors with our advanced billet machining process.

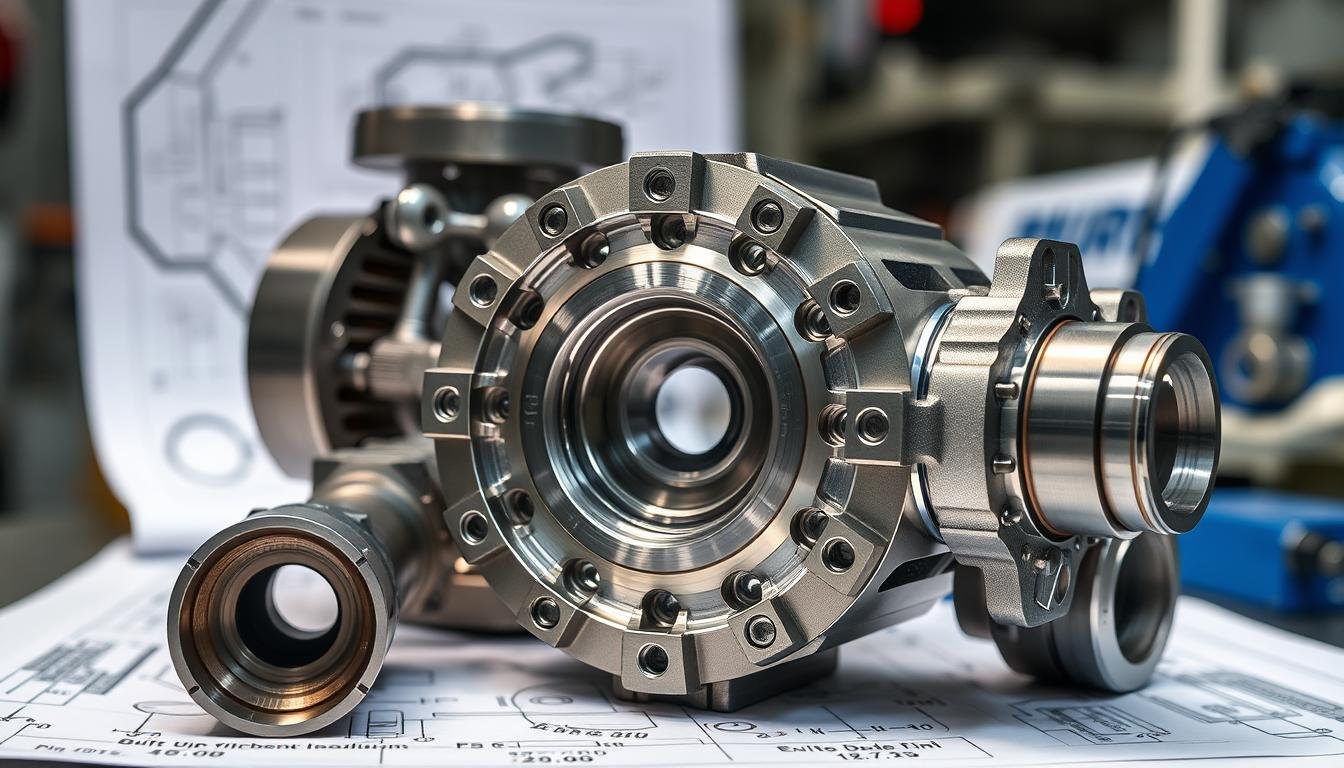

Aerospace

Aerospace applications demand the highest levels of precision and reliability. Billet machined components are used in critical systems including:

- Structural brackets and mounts

- Hydraulic manifolds and valve bodies

- Control system components

- Lightweight structural elements

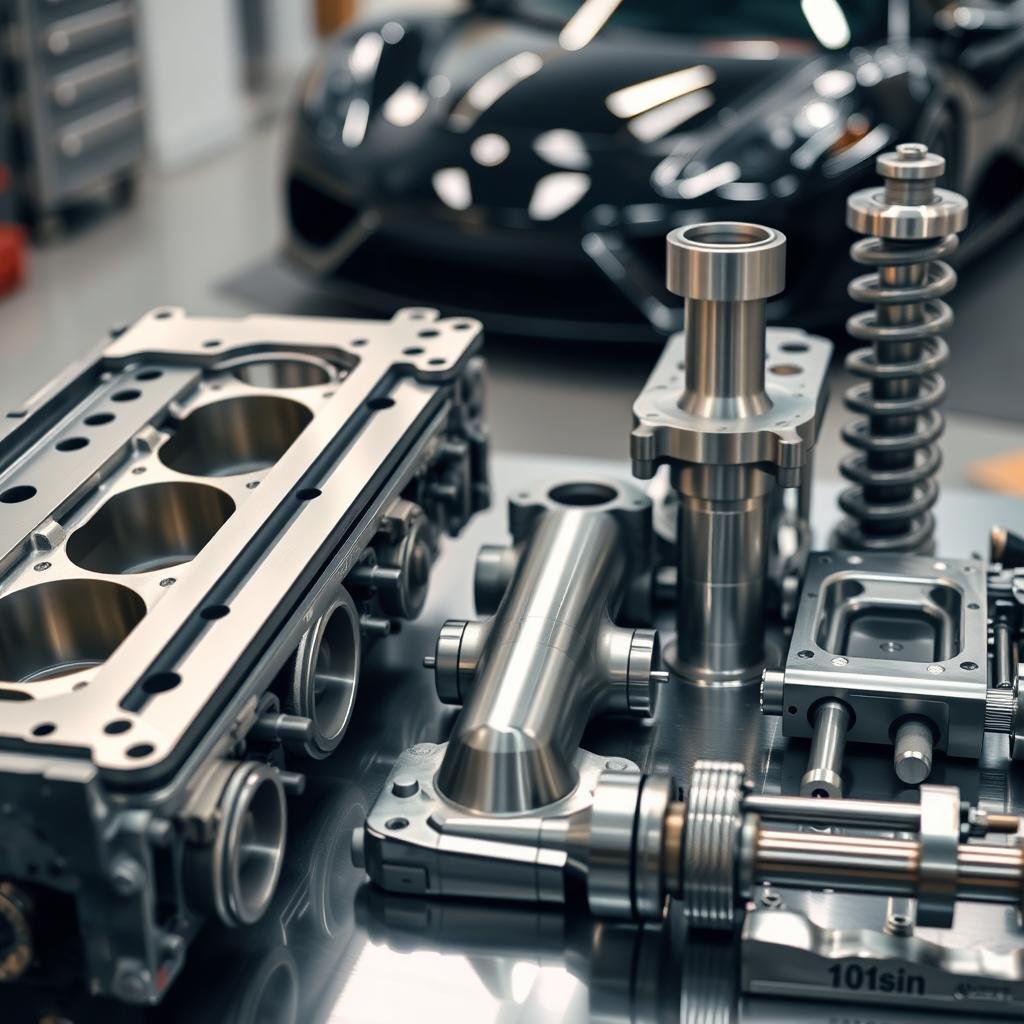

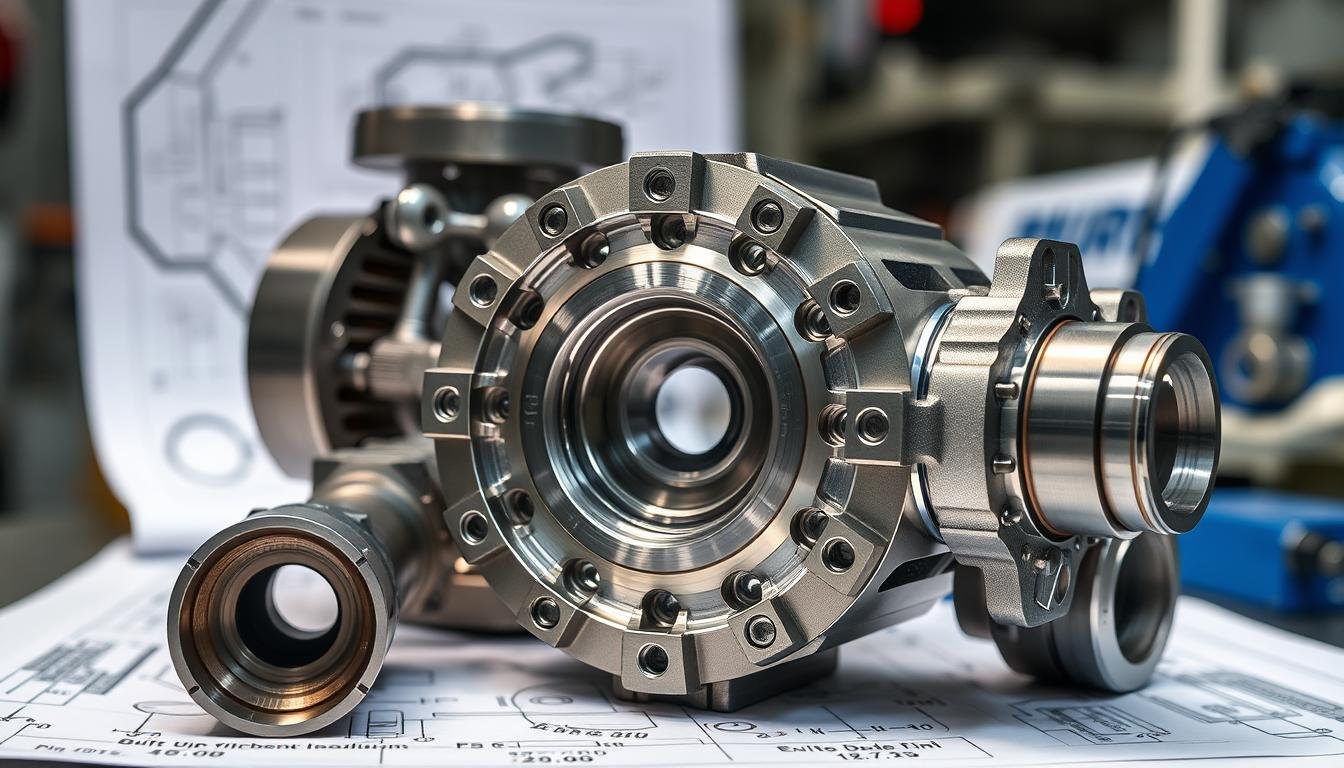

Automotive

Performance automotive manufacturers rely on billet machined parts for their superior strength and precision:

- Engine blocks and cylinder heads

- Transmission components

- Suspension and steering parts

- Brake system components

Medical

Medical applications benefit from the cleanliness and precision of the billet machining process:

- Surgical instruments

- Implant components

- Medical device housings

- Diagnostic equipment parts

Defense

Defense applications require components that perform reliably under extreme conditions:

- Weapon system components

- Communication equipment housings

- Vehicle parts and armor mounts

- Tactical equipment components

Electronics

The electronics industry benefits from the thermal management properties and precision of billet machined components:

- Heat sinks and thermal management

- Precision enclosures and chassis

- Test equipment components

- High-frequency RF housings

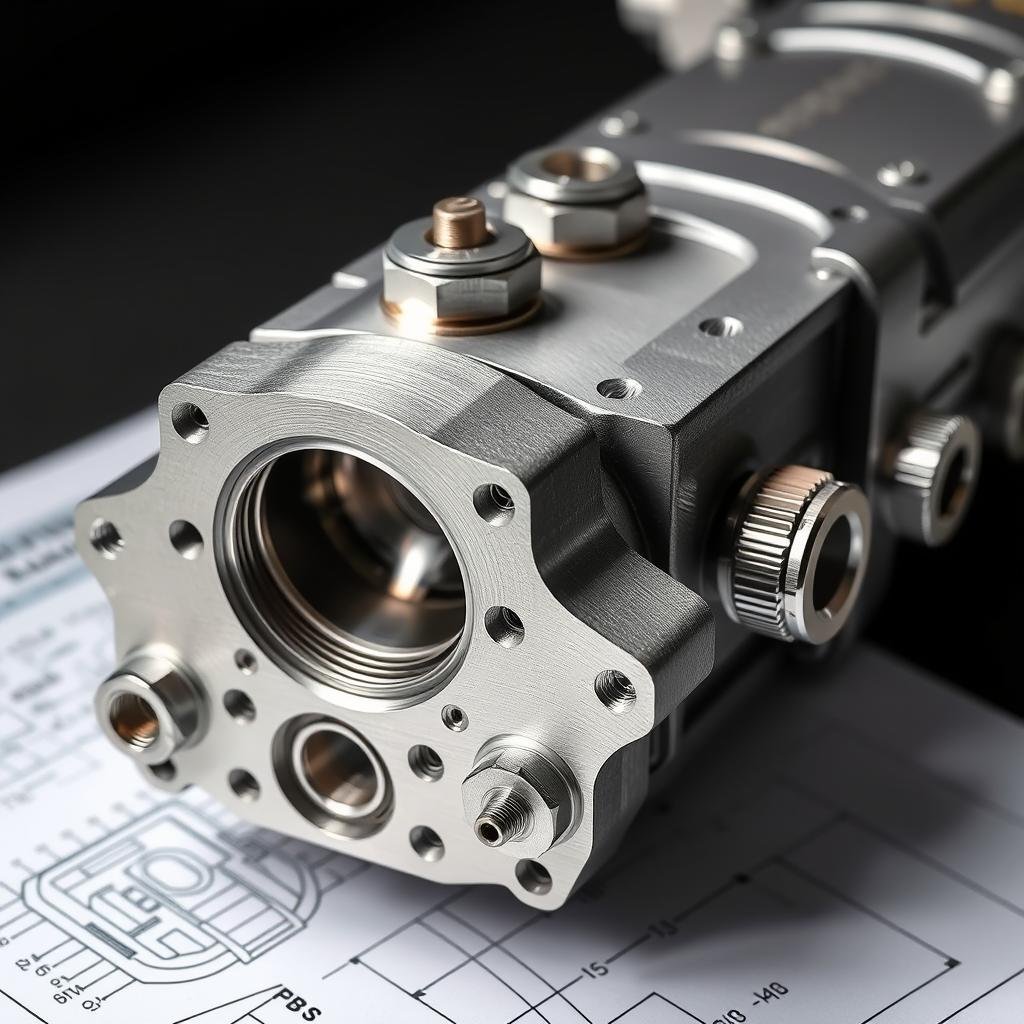

Oil & Gas

The oil and gas sector relies on the durability and precision of billet machined parts:

- Downhole tools and equipment

- Valve bodies and actuators

- Pump components

- High-pressure fittings and connectors

MAIKONG’s Advanced Billet Machining Process Capabilities

At MAIKONG, we’ve invested in cutting-edge technology and skilled personnel to deliver exceptional billet machined components. Our comprehensive capabilities ensure we can handle your most challenging projects with precision and efficiency.

Equipment and Capacity

- 60+ CNC Machines – Including multi-axis machining centers capable of complex geometries

- 100+ Tons Monthly Capacity – Ensuring we can handle projects of any scale

- Advanced CAD/CAM Systems – For precise programming and simulation

- Comprehensive Quality Lab – With CMM and other precision measurement equipment

Comprehensive Services

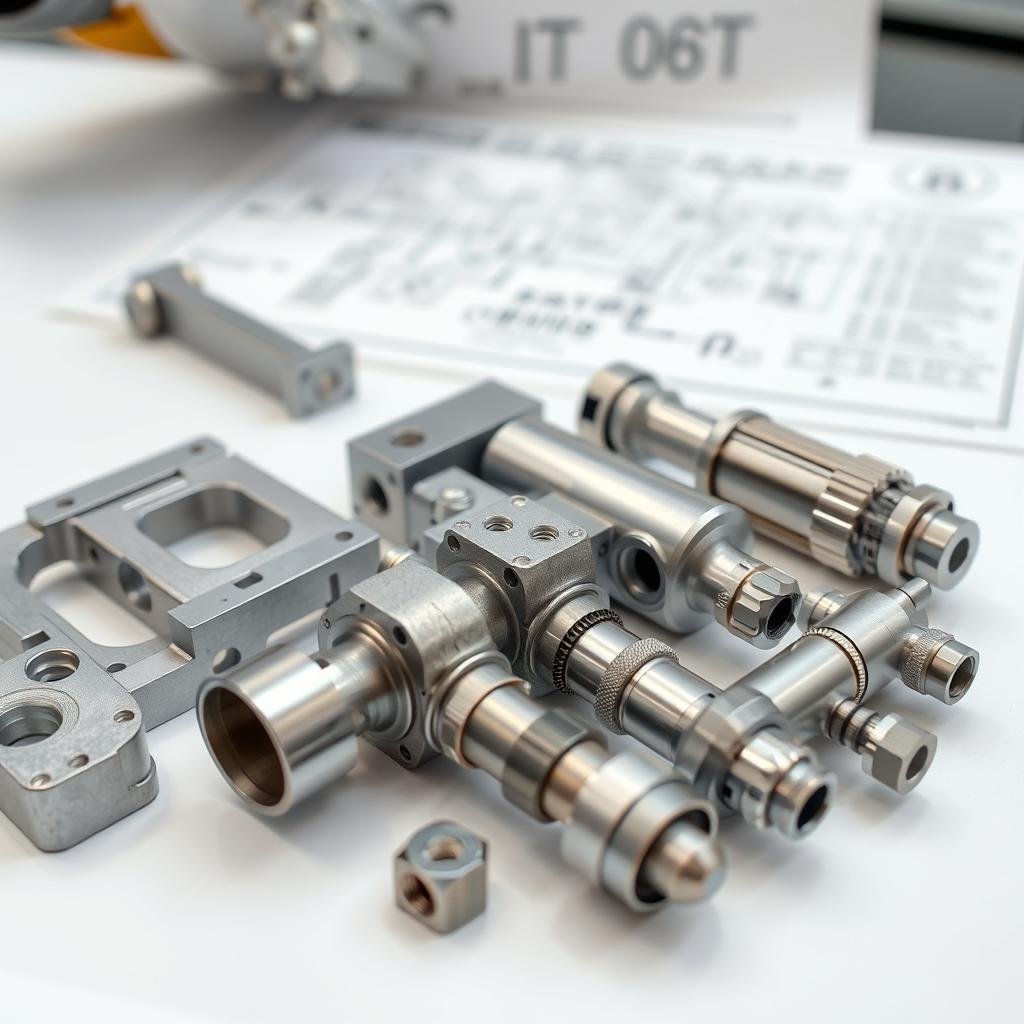

- CNC Turning – Precision manufacturing of cylindrical components with superior surface finishes

- CNC Milling – Complex prismatic shapes and flat surfaces with exceptional accuracy

- Swiss-Type Machining – Specialized precision for small parts and long shaft components

- Multi-Axis Machining – 3-axis, 4-axis, and 5-axis capabilities for complex geometries

- Surface Treatments – Including anodizing, powder coating, and precision finishing

Materials Expertise

Our billet machining process accommodates a wide range of materials to meet diverse application requirements:

Aluminum Alloys

- 6061, 7075, 2024

- Lightweight with excellent strength

- Superior corrosion resistance

- Ideal for aerospace and automotive

Stainless Steel

- 304, 316, 17-4PH

- Exceptional corrosion resistance

- High strength and durability

- Perfect for medical and food processing

Specialty Metals

- Titanium, Brass, Copper

- Unique mechanical properties

- Application-specific advantages

- Custom solutions for specialized needs

Ready to Discuss Your Billet Machining Requirements?

Contact our engineering team to explore how MAIKONG’s advanced capabilities can deliver the precision components your project demands.

Contact via WhatsApp

Email Us

Quality Assurance in the Billet Machining Process

At MAIKONG, quality is integrated throughout our billet machining process, not just inspected at the end. Our comprehensive quality management system ensures consistent excellence in every component we produce.

Certifications and Standards

Our commitment to quality is validated through rigorous certification:

- ISO 9001:2015 Certified – Comprehensive quality management system

- Material Verification – Testing to confirm alloy composition and properties

- Dimensional Inspection – Coordinate measuring machines for precision verification

- Surface Quality Analysis – Advanced equipment to verify finish requirements

Testing and Validation

We employ comprehensive testing to ensure component performance:

- Non-Destructive Testing – Including ultrasonic and dye penetrant inspection

- Hardness Testing – Verification of material properties

- First Article Inspection – Detailed validation of initial production units

- Statistical Process Control – Ongoing monitoring for consistent quality

“Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction and skillful execution. At MAIKONG, we integrate quality into every step of our billet machining process.”

– MAIKONG Quality Management Team

Success Stories: Billet Machining Process in Action

Aerospace Hydraulic Manifold

Challenge: An aerospace client needed a complex hydraulic manifold with intricate internal passages that maintained absolute cleanliness and met stringent weight requirements.

Solution: MAIKONG’s advanced billet machining process created the component from a single aluminum billet, eliminating potential leak paths from assembled parts while maintaining tight tolerances on all critical dimensions.

Result: The finished component passed all pressure and flow tests, weighed 22% less than the previous design, and has performed flawlessly in service.

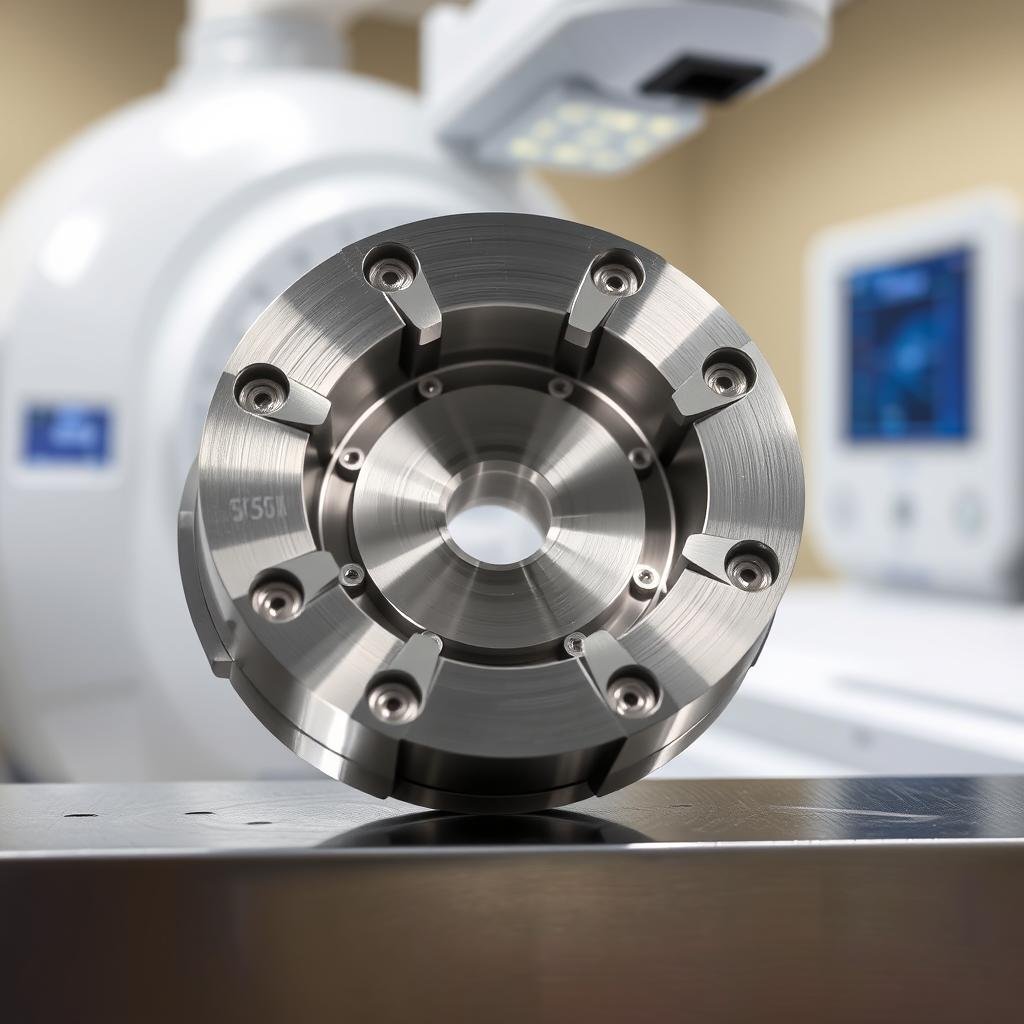

Medical Imaging Equipment Component

Challenge: A medical equipment manufacturer required an ultra-precise positioning component for an advanced imaging system with tolerances of ±0.0005 inches.

Solution: Using our 5-axis CNC capabilities and comprehensive in-process measurement, we machined the component from medical-grade stainless steel with specialized fixturing to maintain positioning throughout the machining process.

Result: The component met all specifications and helped the client’s imaging system achieve a 15% improvement in resolution over previous generations.

Conclusion: The Future of Precision with Billet Machining Process

As engineering demands continue to evolve toward higher precision, greater complexity, and enhanced performance, the billet machining process remains at the forefront of manufacturing technology. Its unmatched ability to create components with exceptional accuracy, material integrity, and design flexibility makes it indispensable for industries where performance and reliability are paramount.

At MAIKONG, we continue to invest in advanced equipment, skilled personnel, and robust quality systems to deliver the highest standard of billet machined components. Whether your application is in aerospace, automotive, medical, or any other precision-critical industry, our team is ready to help you achieve your manufacturing goals with excellence.

Contact us today to discover how our expertise in the billet machining process can elevate your next project to new levels of precision and performance.

State-of-the-art CNC machine performing precision billet machining at MAIKONG facility

State-of-the-art CNC machine performing precision billet machining at MAIKONG facility