Why Choose Billet Machining for Your Next US Manufacturing Project?

»

Billet Machining » Why Choose Billet Machining for Your Next US Manufacturing Project?

When precision, strength, and design flexibility are non-negotiable for your manufacturing needs, the Billet Machining Process stands as a superior choice. At MAIKONG, we’ve perfected this sophisticated manufacturing technique to deliver exceptional custom metal parts that meet the most demanding specifications. Whether you’re in aerospace, automotive, medical, or any industry requiring high-performance components, our advanced Billet Machining Process ensures your parts are manufactured with uncompromising quality and precision.

Understanding the Billet Machining Process

MAIKONG’s advanced CNC equipment performing precision billet machining

MAIKONG’s advanced CNC equipment performing precision billet machining

The Billet Machining Process begins with a solid block of metal—called a billet—which is then precisely shaped through subtractive manufacturing techniques. Unlike casting or forging, where metal is melted or deformed, billet machining removes material from a solid piece to create the final part with exceptional accuracy.

What Makes the Billet Machining Process Unique

Billet machining starts with high-quality metal stock that has a uniform, non-directional grain structure. This consistency provides excellent strength and predictability, especially for parts that require precise tolerances and superior structural integrity. Our CNC machines can achieve tolerances down to thousandths of an inch, creating components that fit perfectly in complex assemblies.

The Billet Material Advantage

Billets are solid lengths of metal with consistent cross-sections, available in virtually any metal or alloy including aluminum, stainless steel, carbon steel, brass, and specialty alloys. This versatility allows us to select the ideal material for your specific application requirements.

The CNC Machining Process

Using state-of-the-art multi-axis CNC machines, we transform these billets into precision components through a series of carefully programmed cutting operations. This process allows for complex geometries, internal features, and precise surface finishes that would be difficult or impossible to achieve with other manufacturing methods.

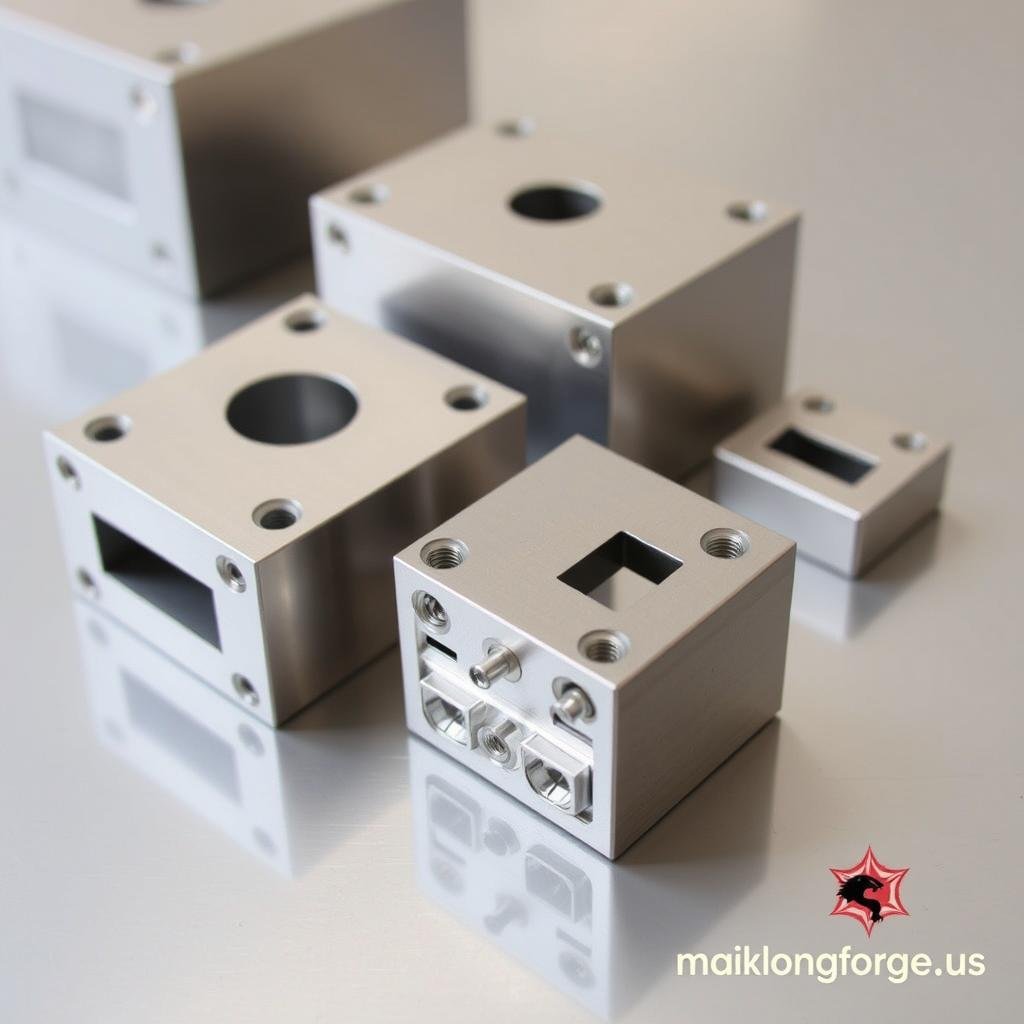

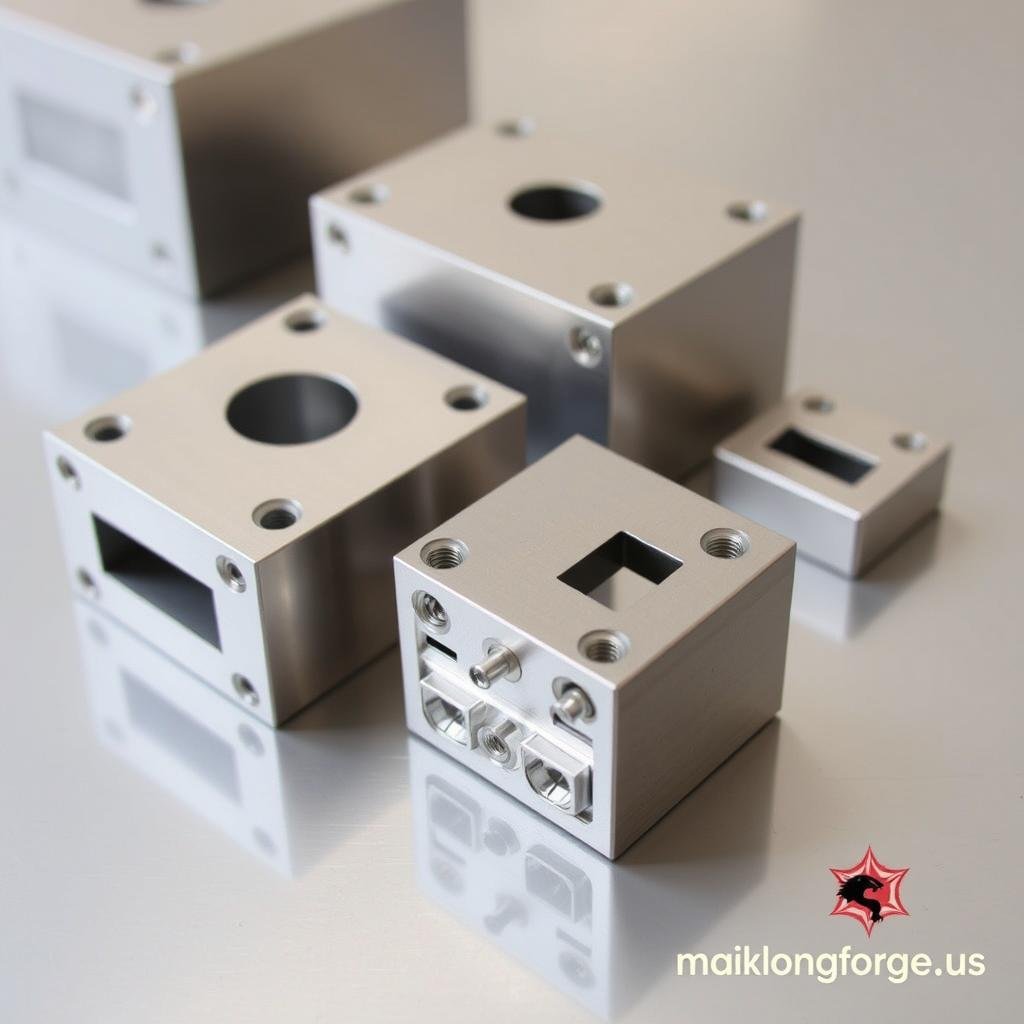

Various metal billets ready for the machining process

Advantages of MAIKONG’s Billet Machining Process

Billet Machining Advantages

- Superior precision with tolerances down to ±0.0005″

- Excellent structural integrity and material consistency

- Flexibility for complex geometries and internal features

- No tooling costs for low-volume production

- Exceptional surface finishes with minimal post-processing

- Ideal for prototyping and design iterations

- Short lead times for urgent projects

Limitations to Consider

- Higher per-unit cost for very high volumes

- Material waste compared to additive methods

- Size limitations based on machine capacity

- Higher energy consumption than some processes

- Not always cost-effective for simple geometries

Billet vs. Other Manufacturing Methods

| Comparison Criteria |

Billet Machining |

Casting |

Forging |

| Precision & Tolerances |

Excellent (±0.0005″) |

Fair (±0.010″) |

Good (±0.005″) |

| Material Strength |

Very Good |

Fair |

Excellent |

| Surface Finish |

Excellent |

Poor to Fair |

Good |

| Design Complexity |

High |

Very High |

Limited |

| Low Volume Cost |

Good |

Fair |

Poor |

| High Volume Cost |

Fair |

Good |

Excellent |

| Lead Time |

Short |

Long |

Medium |

Visual comparison: Billet machined part (left), cast part (center), and forged part (right)

Ready to Experience Superior Precision?

Our billet machining capabilities deliver exceptional quality for your most demanding applications. Let’s discuss your project requirements today.

Get A Quick Quote

Contact via WhatsApp

MAIKONG’s Comprehensive Billet Machining Process Capabilities

MAIKONG’s state-of-the-art manufacturing facility with 60+ CNC machines

At MAIKONG, we’ve invested in advanced equipment and expertise to deliver exceptional billet machining services. Our facility in GD, SZ houses over 60 CNC machines with a monthly metal processing capacity exceeding 100 tons. This robust infrastructure allows us to handle projects of any size with consistent quality and on-time delivery.

CNC Turning

Our precision CNC turning capabilities are ideal for creating cylindrical shapes, deep holes, and machined threads with superior surface finishes. Perfect for shafts, bushings, and rotational components.

CNC Milling

Our multi-axis milling machines create complex prismatic shapes and flat surfaces with exceptional accuracy. Ideal for housings, brackets, and components with intricate geometries.

Swiss-Type Machining

Specialized in precision small parts and long shaft components, our Swiss-type machines feature dual spindles and multi-axis capabilities for one-stop manufacturing solutions.

Our Billet Machining Process Workflow

MAIKONG’s comprehensive billet machining workflow from design to delivery

Design & Engineering

- Advanced CAD/CAM capabilities

- Design for manufacturability analysis

- Material selection consultation

- Tolerance optimization

- 3D modeling and simulation

Production

- Multi-axis CNC machining

- High-precision turning and milling

- Swiss-type machining for small parts

- Surface grinding and finishing

- Heat treatment capabilities

Quality Assurance

- Comprehensive inspection protocols

- Advanced CMM measurement

- Material testing laboratory

- ISO-certified quality systems

- Complete documentation packages

Rigorous quality inspection ensures every billet machined part meets exact specifications

“Our investment in advanced CNC technology and skilled machinists allows us to deliver billet machined parts with exceptional precision and consistency. We’re committed to being your trusted manufacturing partner.”

– MAIKONG Engineering Team

Quality Assurance in Our Billet Machining Process

At MAIKONG, quality isn’t just a department—it’s a core value embedded throughout our Billet Machining Process. Our comprehensive quality management system ensures that every part we produce meets or exceeds your specifications.

Our quality control team uses advanced measurement technology to verify dimensional accuracy

Material Verification

Our in-house material testing laboratory ensures that all raw materials meet exact specifications before entering our production process. We conduct comprehensive material analysis including chemical composition, hardness testing, and microstructure evaluation to guarantee the highest quality billets for your parts.

Precision Measurement

Using advanced coordinate measuring machines (CMM) and precision gauging equipment, we verify that every dimension meets your specified tolerances. Our inspection protocols include first article inspection, in-process checks, and final verification to ensure consistent quality throughout production.

Dimensional Accuracy

4.9/5

Our Quality Certifications

MAIKONG maintains rigorous quality management systems certified to international standards, ensuring consistent quality across all our manufacturing processes. Our commitment to excellence is reflected in our comprehensive quality documentation and traceability systems.

Industries Served by MAIKONG’s Billet Machining Process

Our precision billet machining capabilities serve diverse industries with demanding requirements for quality, performance, and reliability. Here’s how different sectors benefit from our expertise:

Aerospace

Lightweight, high-strength components with exceptional reliability for critical applications.

Automotive

Performance parts with precise tolerances for improved efficiency and durability.

Medical

Surgical-grade components with exceptional surface finish and biocompatibility.

Electronics

Precision housings and heat sinks with excellent thermal properties and EMI shielding.

Defense

Mission-critical parts with certified materials and documented quality assurance.

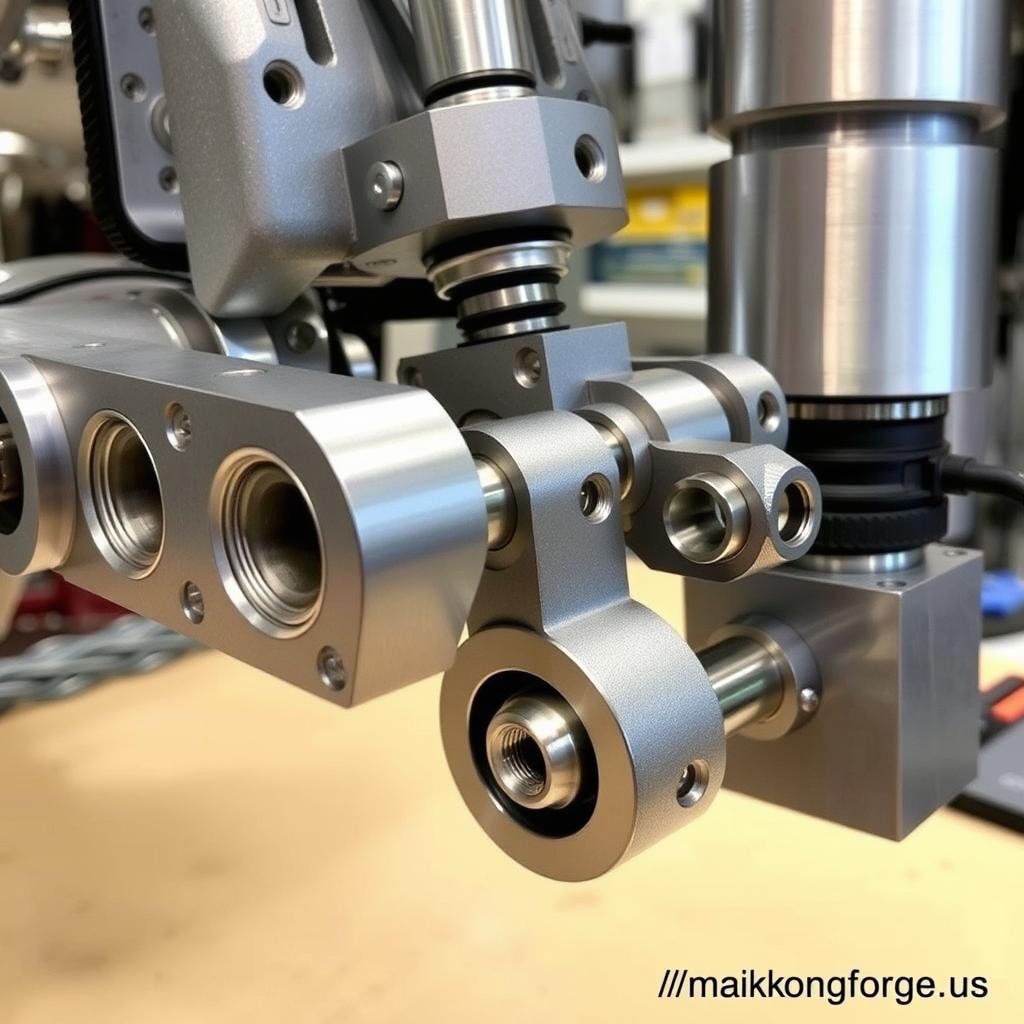

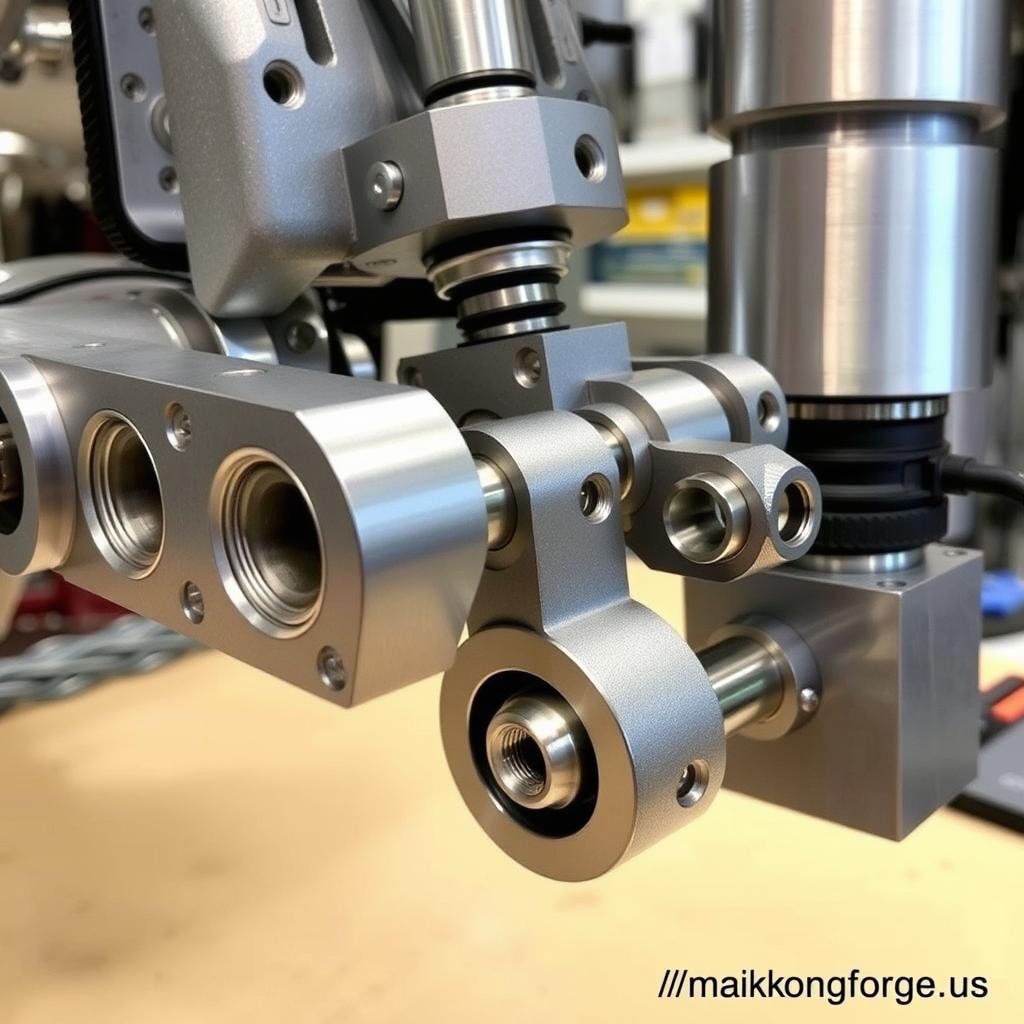

Robotics

Lightweight, high-strength components with precise interfaces for optimal performance.

Need Custom Billet Machined Parts for Your Industry?

Our engineering team has extensive experience across multiple industries. Let us help you optimize your components for performance and cost-effectiveness.

Discuss Your Industry Requirements

Or contact us directly: Lucy@maikongforge.us

Why Partner with MAIKONG for Your US Manufacturing Needs

Our experienced team works closely with clients to deliver optimal manufacturing solutions

What makes MAIKONG different from other manufacturers?

MAIKONG combines advanced manufacturing capabilities with exceptional value. With over 60 CNC machines and 100+ tons of monthly capacity, we deliver both quality and scale. Our comprehensive in-house capabilities—from design assistance to finishing—ensure seamless project execution with fewer vendors and complications.

How does MAIKONG ensure quality for US customers?

We maintain rigorous quality control systems with advanced testing equipment and comprehensive inspection protocols. Our material testing laboratory verifies all raw materials, while our skilled quality team ensures dimensional accuracy and surface finish meet exact specifications. We provide complete documentation and maintain traceability throughout the manufacturing process.

What are the advantages of working with MAIKONG as your manufacturing partner?

Partnering with MAIKONG gives you access to exceptional manufacturing capabilities at competitive prices. Our technical expertise helps optimize your designs for manufacturability, while our efficient processes ensure on-time delivery. We offer transparent communication, responsive service, and the flexibility to accommodate both prototype and production volumes.

Become a US Agent for MAIKONG

We’re actively recruiting representatives across the United States to help bring our exceptional manufacturing capabilities to more American businesses. If you have experience in manufacturing sales and a network of potential clients, we offer competitive commission structures and comprehensive support.

Contact us at Lucy@maikongforge.us to discuss partnership opportunities.

Ready to Experience the MAIKONG Difference?

The Billet Machining Process offers unmatched precision, strength, and design flexibility for your most demanding applications. At MAIKONG, we’ve perfected this process to deliver exceptional quality parts at competitive prices. Our comprehensive capabilities, from design assistance to finishing services, make us your ideal manufacturing partner.

Precision-machined components ready for delivery to our valued customers

MAIKONG’s advanced CNC equipment performing precision billet machining

MAIKONG’s advanced CNC equipment performing precision billet machining