In today’s competitive manufacturing landscape, understanding billet machining is essential for industrial buyers seeking precision components. This advanced manufacturing process transforms solid metal blocks into intricate parts with exceptional accuracy and structural integrity. Whether you’re comparing manufacturing methods or looking for a reliable partner, this guide will help you make informed decisions about billet machining for your industrial applications.

Understanding Billet Machining: The Fundamentals

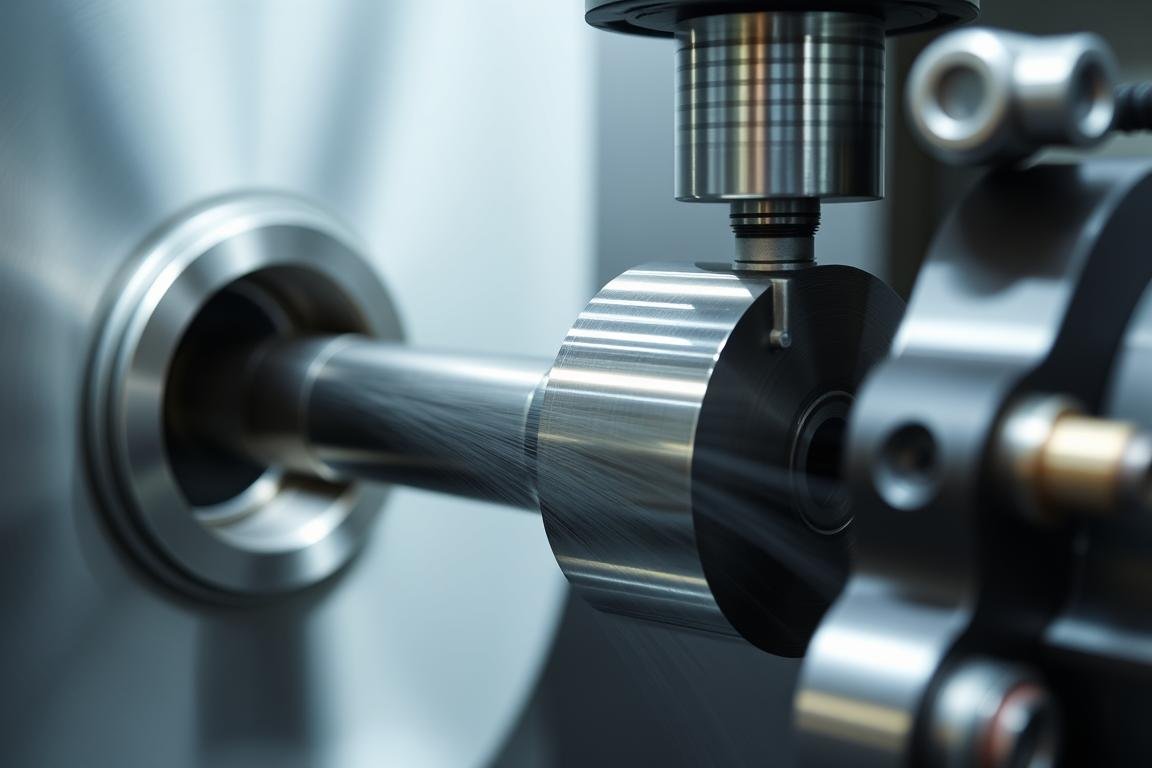

Modern CNC machine performing precision billet machining

Modern CNC machine performing precision billet machining

Billet machining refers to the process of creating parts by removing material from a solid block of metal, known as a billet. Unlike casting or forging, which form metal by pouring or pressing, billet machining is a subtractive process that precisely cuts away excess material to reveal the final component.

The term “billet” refers to the starting form of metal—typically a solid length with square or circular cross-sections. These billets can be made from virtually any metal or alloy, including aluminum, steel, stainless steel, brass, and specialty alloys, making this method incredibly versatile for various industrial applications.

The Billet Machining Process Explained

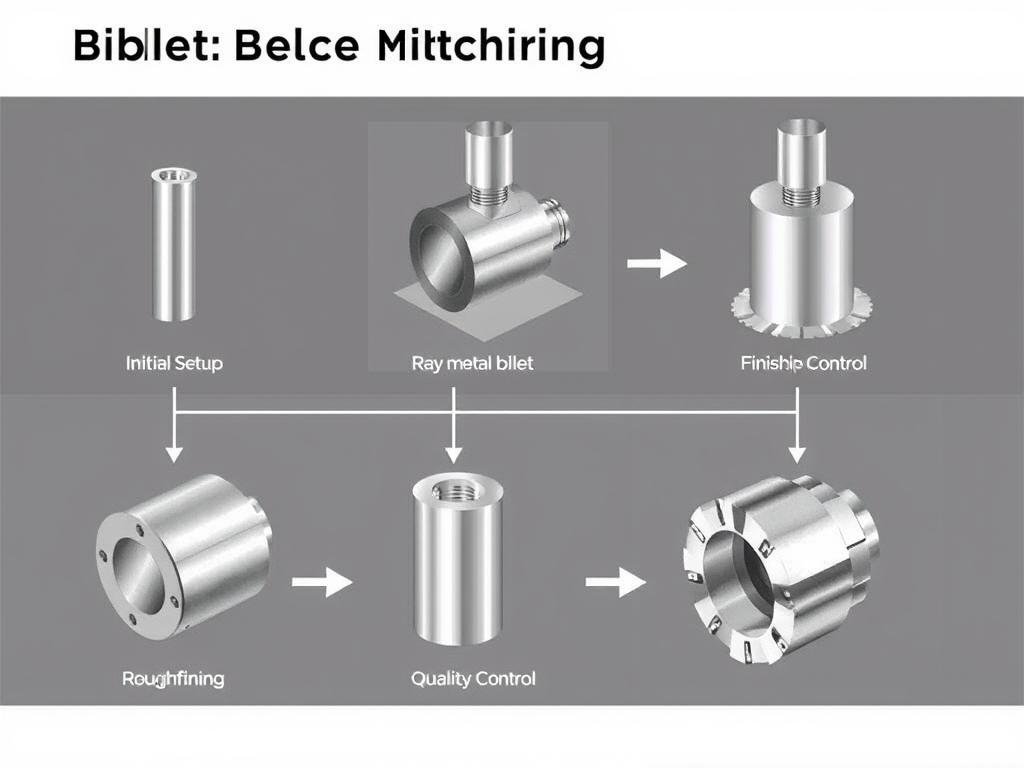

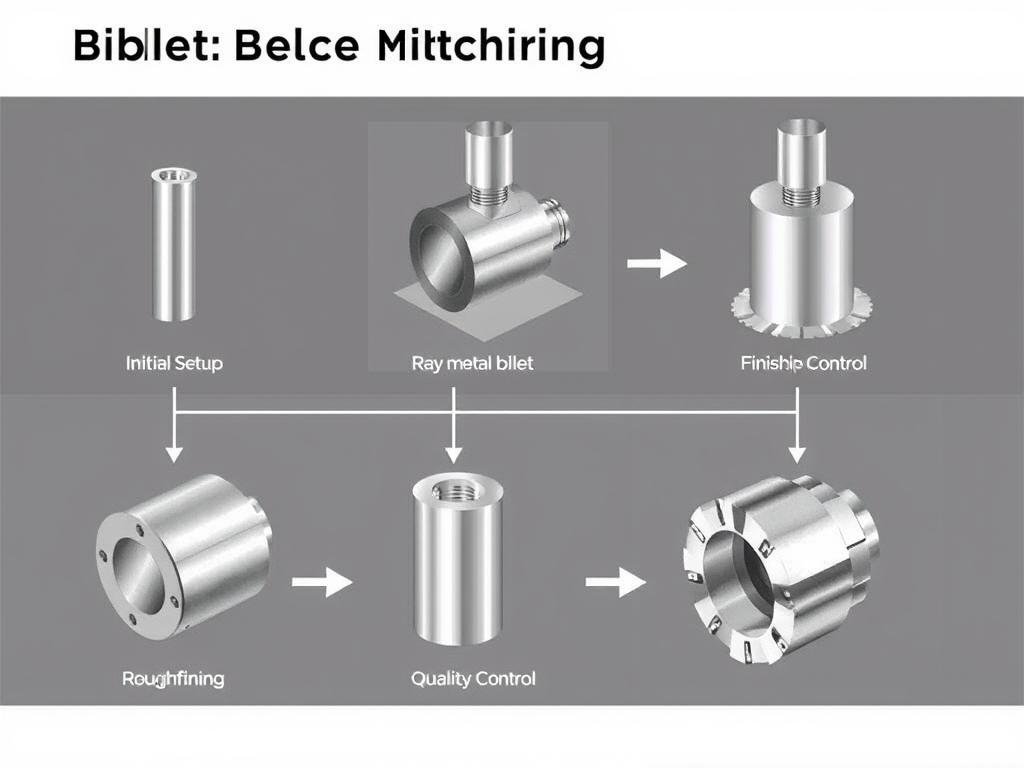

Step-by-step billet machining process

The billet machining process typically follows these key steps:

- Material Selection: Choosing the appropriate metal billet based on the part’s requirements for strength, weight, corrosion resistance, and other properties.

- Design & Programming: Creating detailed CAD designs and converting them into CNC programming instructions.

- Machine Setup: Securing the billet in the CNC machine and setting up the appropriate cutting tools.

- Roughing: Initial removal of excess material to create the general shape.

- Finishing: Precise cutting to achieve final dimensions and surface finish.

- Quality Control: Inspecting the part for dimensional accuracy and surface quality.

At MAIKONG, our advanced CNC equipment enables us to perform these steps with exceptional precision, creating parts that meet the most demanding specifications.

Key Advantages of Billet Machining for Industrial Applications

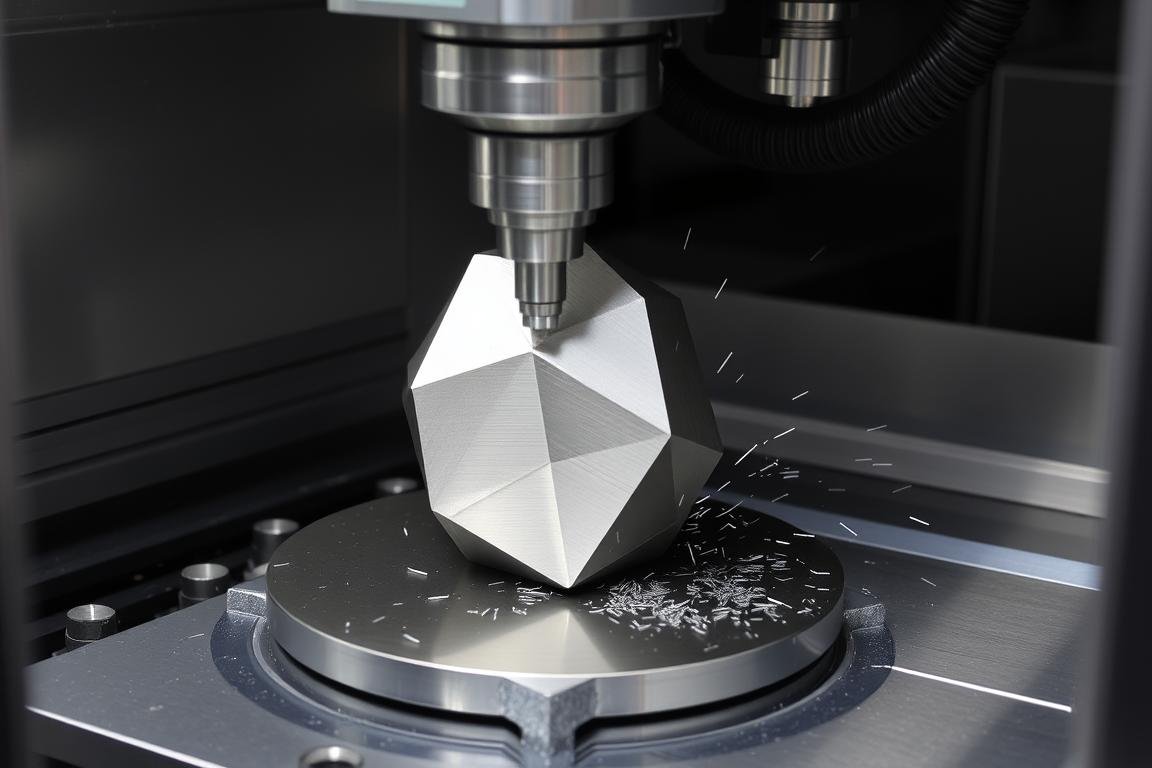

High-precision components produced through billet machining

Advantages of Billet Machining

- Exceptional precision and dimensional accuracy

- Superior structural integrity and material consistency

- Excellent surface finish with minimal post-processing

- Flexibility to create complex geometries

- Cost-effective for low to medium production volumes

- Rapid prototyping capabilities with quick turnaround

- No tooling costs for small production runs

- Ability to work with virtually any metal or alloy

Limitations to Consider

- Higher material waste compared to additive methods

- Can be more costly for very high-volume production

- Heavier than cast parts (30-60% weight difference)

- Higher per-unit labor time for complex parts

- Limited internal features compared to casting

Understanding these advantages helps industrial buyers determine when billet machining is the optimal manufacturing method for their specific requirements.

Need Expert Guidance on Manufacturing Methods?

Our engineering team can help you determine whether billet machining is right for your project. Contact us for a free consultation.

Get Expert Advice

WhatsApp Consultation

Billet Machining vs. Other Manufacturing Methods

Visual comparison of major manufacturing methods

To make informed decisions, industrial buyers should understand how billet machining compares to other common manufacturing methods like casting and forging.

Billet vs. Cast Manufacturing

Cast manufacturing involves heating metal to a molten state, pouring it into a mold, and allowing it to cool and harden. While casting can create complex shapes in a single process, billet-machined parts typically offer superior strength and precision.

| Feature |

Billet Machining |

Cast Manufacturing |

| Material Structure |

Uniform, non-directional grain structure |

Potential for porosity and inclusions |

| Strength |

Higher strength and durability |

Lower tensile strength |

| Precision |

Extremely high dimensional accuracy |

Moderate accuracy, may require machining |

| Complex Geometries |

Limited by machine access |

Excellent for complex internal features |

| Production Volume |

Ideal for low to medium volumes |

Cost-effective for high volumes |

| Material Waste |

Higher (subtractive process) |

Lower (near-net-shape) |

Billet vs. Forged Manufacturing

Forging shapes metal through compressive force, often using heat to make the material more malleable. This process creates parts with excellent directional strength but may require additional machining for precision features.

| Feature |

Billet Machining |

Forged Manufacturing |

| Grain Structure |

Non-directional (uniform) |

Directional (follows part shape) |

| Fatigue Resistance |

Good |

Excellent, especially under load |

| Impact Resistance |

Moderate |

Superior |

| Precision |

Excellent without additional processing |

Requires secondary machining for precision |

| Design Flexibility |

Highly flexible, easy to modify |

Limited by die design, difficult to modify |

| Tooling Investment |

Low (no dies required) |

High (requires custom dies) |

The ideal manufacturing method depends on your specific requirements for strength, precision, volume, and budget. MAIKONG offers both billet machining and forging services, allowing us to recommend the optimal approach for your project.

Common Applications for Billet Machined Parts

Diverse applications of billet machined components across industries

Billet machining excels in applications requiring precision, strength, and customization. Here are some common industries and applications where billet-machined parts are preferred:

Aerospace

- Structural components

- Engine parts

- Landing gear components

- Control system parts

Automotive

- Engine components

- Transmission parts

- Performance upgrades

- Custom brackets

Medical

- Surgical instruments

- Implant components

- Medical device housings

- Laboratory equipment

Defense

- Weapon components

- Communication equipment

- Vehicle parts

- Specialized hardware

Industrial

- Hydraulic components

- Pump parts

- Custom machinery

- Precision tooling

Electronics

- Heat sinks

- Enclosures

- Mounting brackets

- Connector housings

These applications benefit from the precision, strength, and material properties that billet machining provides. At MAIKONG, we specialize in creating custom billet-machined components for all these industries and more.

MAIKONG’s Billet Machining Capabilities

MAIKONG’s state-of-the-art CNC machining facility in GD, SZ

At MAIKONG, we offer comprehensive billet machining services with over 60 advanced CNC machines providing 100+ tons of metal processing capacity monthly. Our expertise spans various machining techniques and materials to meet your exact specifications.

Our CNC Machining Services

CNC Turning Services

Our CNC turning capabilities create precise cylindrical shapes, deep holes, and machined threads with superior surface finishes. Ideal for shafts, bushings, and cylindrical components requiring tight tolerances.

CNC Milling Services

Our multi-axis CNC milling creates complex prismatic shapes and flat surfaces with exceptional accuracy. Perfect for brackets, housings, and components with intricate geometries and tight tolerances.

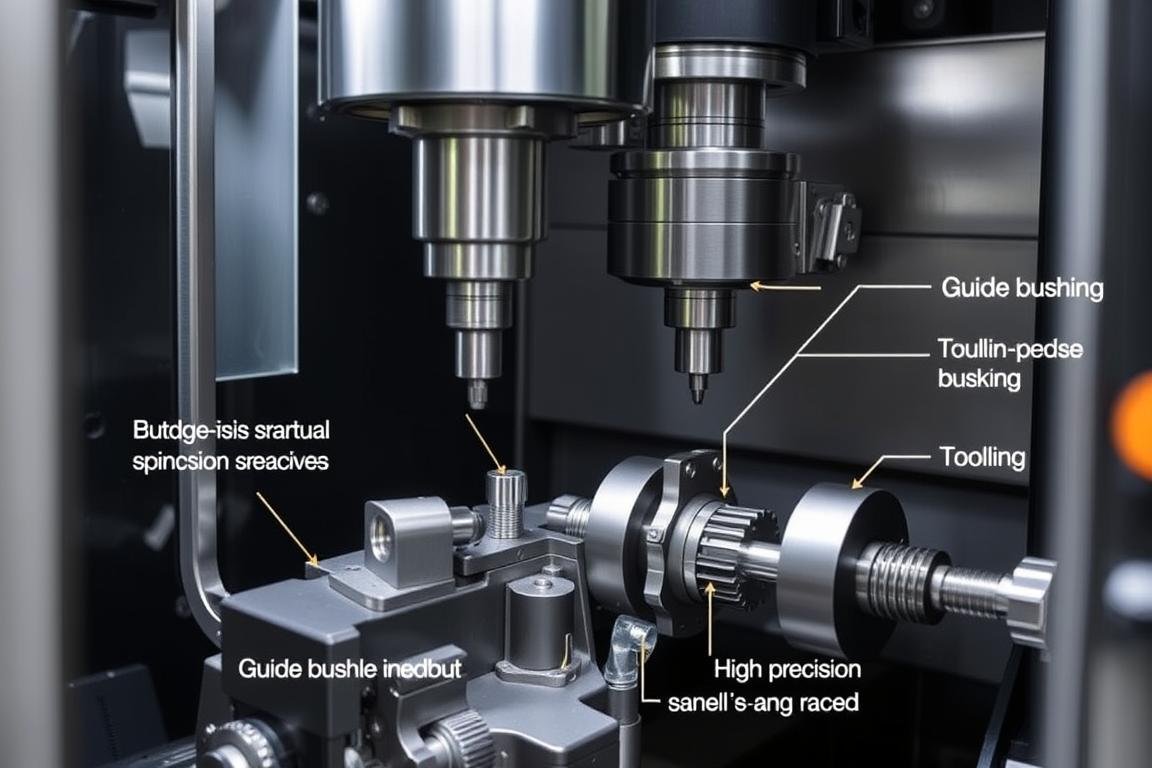

Swiss-Type Machining

Our Swiss-type machining specializes in small precision parts and long shaft components. With dual spindles and multi-axis capabilities, we provide one-stop solutions for the most demanding applications.

Materials We Work With

Metals

- Aluminum alloys (6061, 7075, etc.)

- Steel (carbon, alloy, tool steel)

- Stainless steel (303, 304, 316, etc.)

- Brass and bronze

- Titanium and titanium alloys

- Exotic alloys (Inconel, Hastelloy)

Plastics & Composites

- Delrin (POM)

- PEEK

- Nylon

- UHMW

- Acrylic

- Composite materials

Ready to Discuss Your Billet Machining Project?

Our engineering team is ready to help you bring your designs to life with precision billet machining.

Get A Quick Quote

Call or WhatsApp: 8613-51090-74-01

Quality Assurance in Billet Machining

Rigorous quality control inspection of billet machined components

At MAIKONG, quality is at the core of our billet machining process. We implement comprehensive quality control procedures to ensure every component meets the most demanding specifications.

Our Quality Control Process

Material Verification

Our in-house material testing laboratory verifies that all raw materials meet exact specifications before machining begins. This ensures consistent performance and quality in the final product.

In-Process Inspection

Throughout the machining process, our technicians perform regular dimensional checks to verify that parts remain within tolerance. This prevents defects and ensures consistency across production runs.

Final Inspection

Every completed part undergoes thorough inspection using precision measuring equipment, including coordinate measuring machines (CMMs), micrometers, and optical comparators.

Documentation & Traceability

We maintain comprehensive documentation for all projects, including material certifications, inspection reports, and process parameters, ensuring complete traceability.

Certifications & Standards

MAIKONG maintains ISO 9001:2015 certification, demonstrating our commitment to quality management systems. Our billet machining processes adhere to international standards, ensuring consistent quality for our global customers.

MAIKONG’s quality certifications and standards

Why Choose MAIKONG for Your Billet Machining Needs

MAIKONG’s comprehensive manufacturing facility in GD, SZ

Manufacturing Excellence

- Advanced Equipment: 60+ CNC machines with multi-axis capabilities

- Capacity: 100+ tons monthly metal processing capacity

- Versatility: Both billet machining and forging capabilities

- One-Stop Solution: From design support to finishing services

Customer Benefits

- Cost-Effective: Competitive pricing without compromising quality

- Responsive Service: Dedicated project managers for each client

- Quick Turnaround: Efficient processes for faster delivery

- Global Shipping: Reliable logistics for US and international clients

US Distributor Opportunities

MAIKONG is actively seeking US distributors for our precision machined and forged components. As a distributor, you’ll benefit from our competitive pricing, consistent quality, and comprehensive manufacturing capabilities.

Conclusion: Making the Right Choice for Billet Machining

Billet machining offers exceptional precision, strength, and versatility for industrial components. By understanding the process, advantages, and applications, you can make informed decisions about whether this manufacturing method is right for your project.

At MAIKONG, we combine advanced billet machining capabilities with comprehensive quality control and customer service to deliver superior components for industrial applications. Whether you need prototype parts or production runs, our team is ready to help you achieve your manufacturing goals with precision and efficiency.

Contact us today to discuss your project requirements and discover why leading industrial buyers choose MAIKONG as their trusted manufacturing partner.

Modern CNC machine performing precision billet machining

Modern CNC machine performing precision billet machining