Metal forging stands as one of humanity’s oldest and most reliable manufacturing processes, transforming raw metals into components with unmatched strength and durability. This ancient craft has evolved into a sophisticated engineering discipline that powers industries from aerospace to automotive, energy to agriculture. At MAIKONG, we’ve mastered the art and science of metal forging, delivering precision-engineered components that meet the most demanding specifications while maintaining cost-effectiveness.In this comprehensive guide, we’ll walk you through the fascinating journey of metal forging—from raw material selection to finished high-performance parts—and demonstrate why MAIKONG’s expertise makes us the ideal partner for your custom forging and machining needs.

Understanding Metal Forging: Fundamentals and Advantages

Metal forging is a manufacturing process that shapes metal using compressive forces. Unlike casting (where metal is melted and poured into molds) or machining (where material is cut away), forging deforms metal in its solid state through controlled pressure. This fundamental difference creates a refined grain structure that follows the component’s shape, resulting in superior mechanical properties.

Advantages of Metal Forging

- Superior strength-to-weight ratio

- Enhanced grain structure and material integrity

- Excellent resistance to impact and fatigue

- Improved mechanical properties

- Consistent quality and performance

- Reduced material waste compared to machining

- Ability to create complex geometries

Limitations to Consider

- Higher initial tooling costs

- Size limitations for certain processes

- Some complex geometries require additional machining

- Not all metals are suitable for forging

- Production volume considerations for cost-effectiveness

At MAIKONG, we’ve optimized our forging processes to maximize these advantages while minimizing limitations, ensuring you receive components with the ideal balance of performance, quality, and cost-effectiveness.

Classification of Metal Forging Processes

Classification by Temperature

Cold Forging

Performed at or near room temperature. Delivers excellent dimensional accuracy and surface finish but requires greater force. Ideal for high-volume, precision components.

Warm Forging

Conducted at temperatures between cold and hot forging (typically 800-1800°F). Balances formability with precision and requires moderate force.

Hot Forging

Performed above the metal’s recrystallization temperature. Requires less force and allows for significant deformation but with lower precision. Ideal for large or complex parts.

Classification by Tooling and Equipment

Open Die Forging

Metal is shaped between flat or simply shaped dies that don’t completely enclose the workpiece. Allows for large components with relatively simple shapes.

Closed Die Forging

Metal is compressed between two dies containing a cavity that shapes the workpiece. Produces more complex geometries with tighter tolerances.

Roll Forging

Metal is passed between cylindrical or contoured rolls to reduce thickness and increase length. Ideal for elongated parts with varying cross-sections.

Not Sure Which Forging Process Is Right for Your Project?

Our engineering team can help determine the optimal forging method based on your component requirements, production volume, and budget constraints.

Get Expert Advice

Material Selection for Optimal Forging Results

The choice of material significantly impacts both the forging process and the final component performance. At MAIKONG, our material expertise ensures we select the optimal alloy for your specific application requirements.

Common Metals Used in Metal Forging

| Material |

Key Properties |

Common Applications |

Forging Temperature |

| Carbon Steel |

Excellent strength, good machinability, cost-effective |

Gears, shafts, connecting rods |

2100-2300°F |

| Alloy Steel |

High strength, good toughness, wear resistance |

Heavy-duty components, tooling |

2000-2300°F |

| Stainless Steel |

Corrosion resistance, good strength, aesthetic finish |

Food processing, chemical equipment |

2100-2350°F |

| Aluminum |

Lightweight, good corrosion resistance, excellent strength-to-weight ratio |

Aerospace, automotive, sporting goods |

700-900°F |

| Titanium |

Exceptional strength-to-weight ratio, corrosion resistance, biocompatibility |

Aerospace, medical implants |

1500-1800°F |

| Brass |

Good corrosion resistance, electrical conductivity, machinability |

Valves, fittings, decorative hardware |

1300-1650°F |

MAIKONG’s Material Testing Capabilities

Our state-of-the-art material laboratory plays a crucial role in our production process, enabling us to achieve the precise results you demand. We conduct comprehensive testing to verify material composition, mechanical properties, and performance characteristics, ensuring every component meets or exceeds specifications.

The Metal Forging Process: Step by Step

1. Design & Engineering

Our engineering team works closely with clients to optimize component design for the forging process. Using advanced CAD/CAM software and finite element analysis, we simulate the forging process to identify potential issues before production begins.

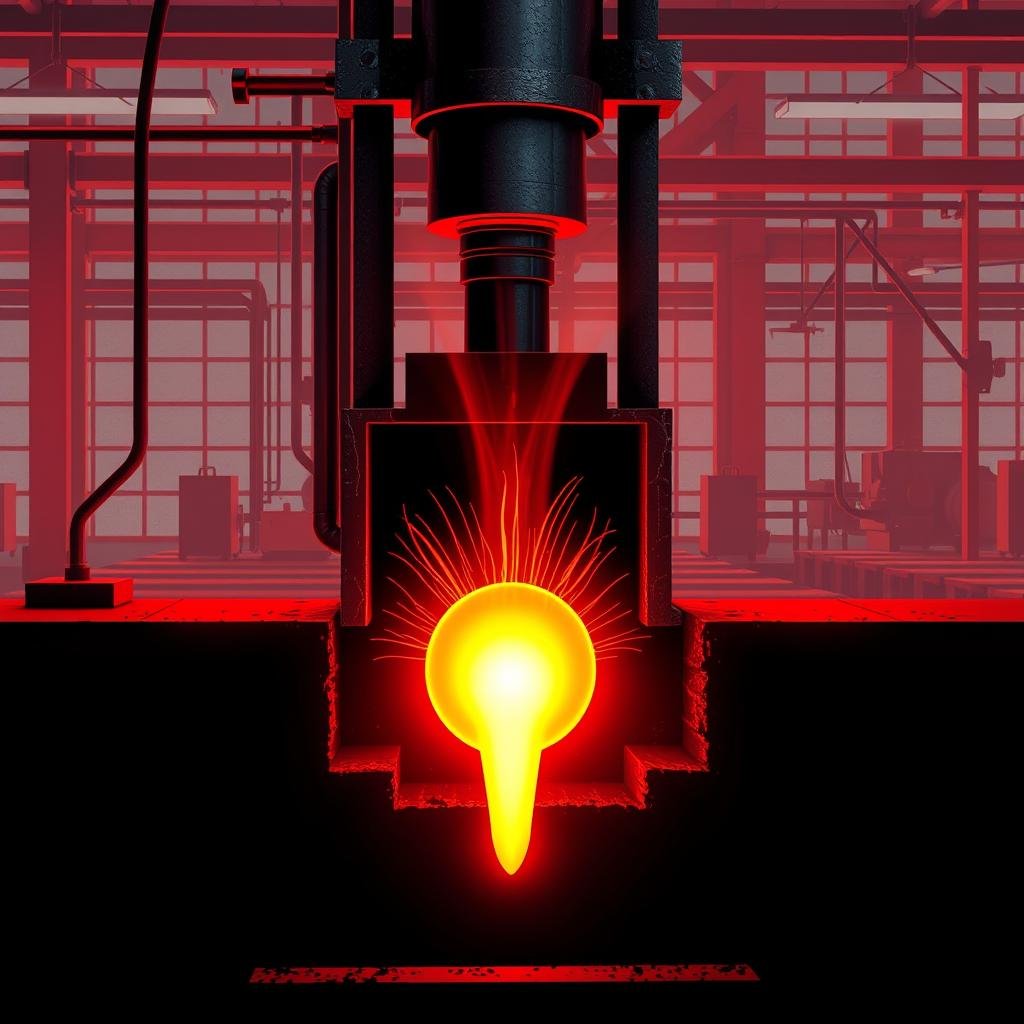

2. Die Design & Manufacturing

Custom dies are designed and manufactured to create the desired component geometry. Die design is critical to ensure proper material flow, minimize defects, and achieve dimensional accuracy.

3. Material Preparation

Raw material is cut to the appropriate size and weight for the forging process. This may involve sawing, shearing, or other cutting methods to create billets or blanks of the correct dimensions.

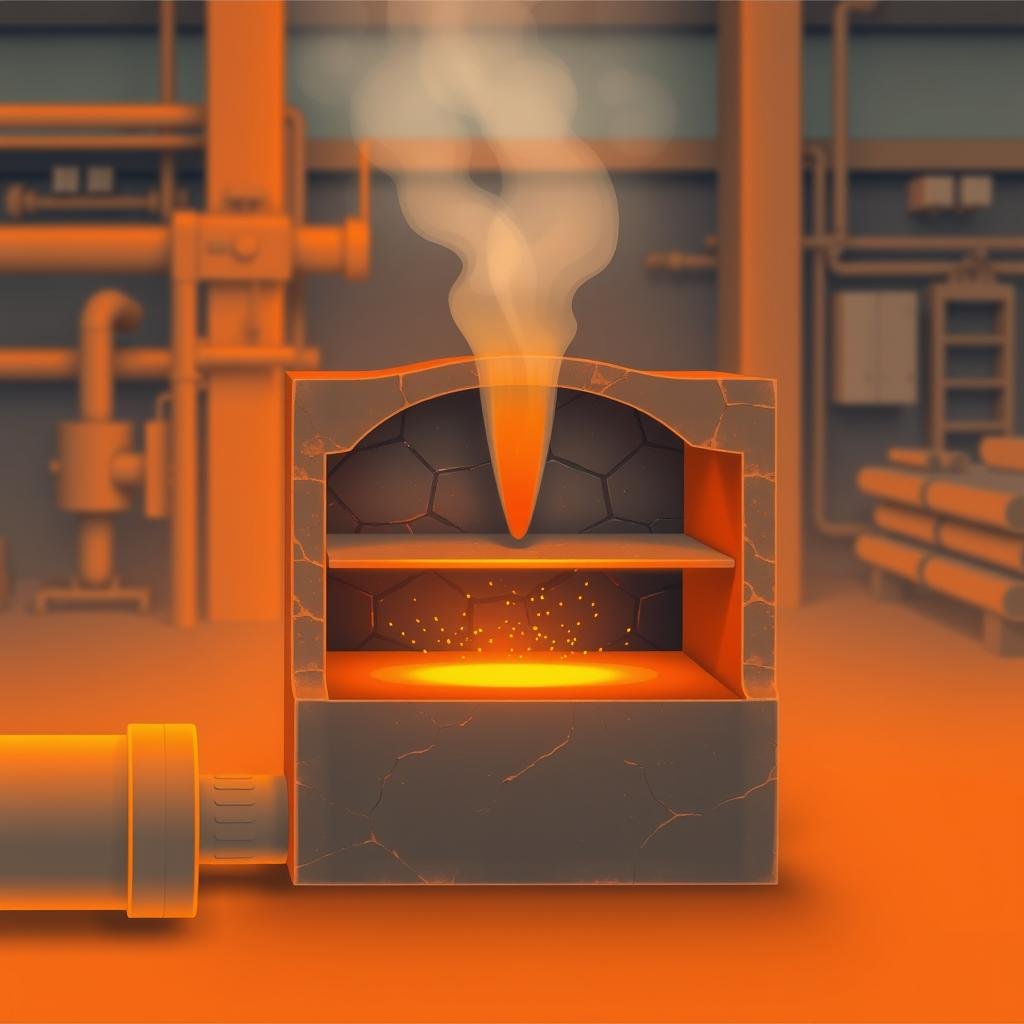

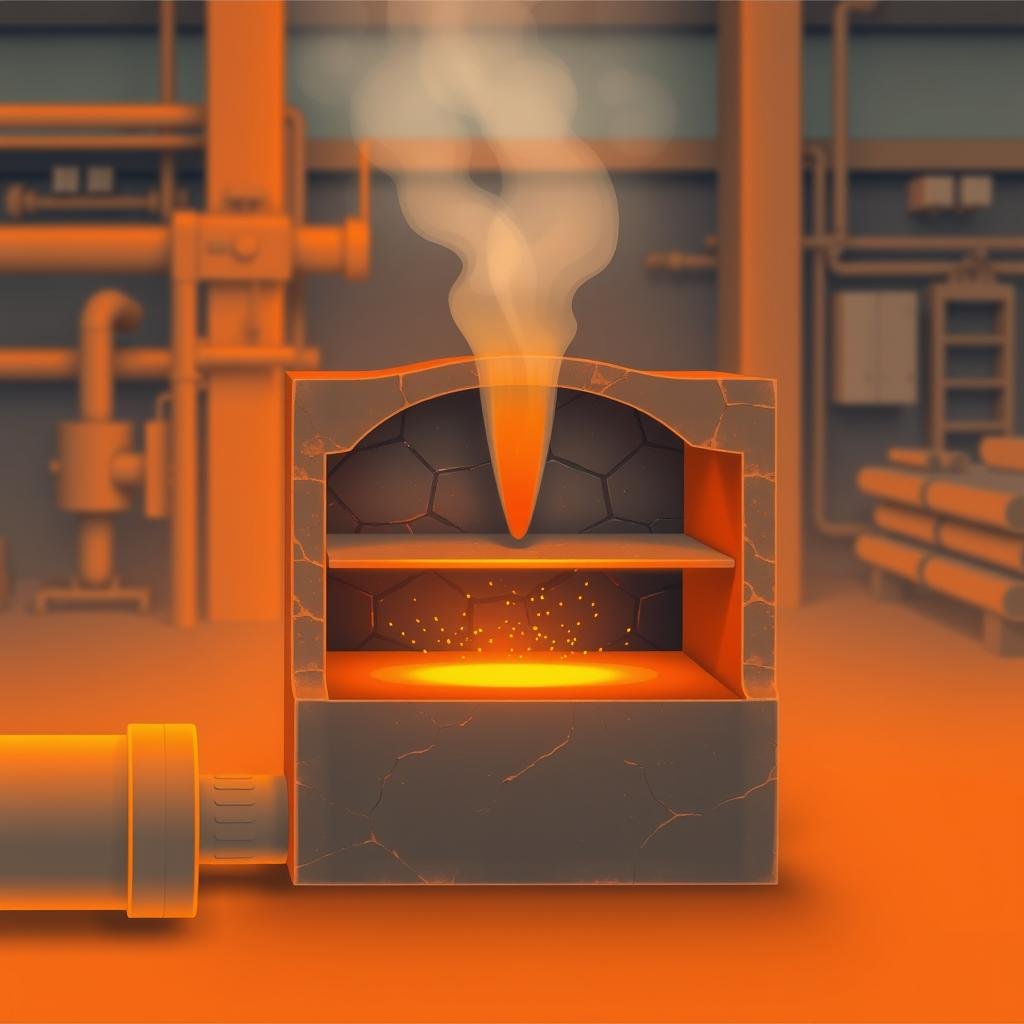

4. Heating

For hot and warm forging, the material is heated to the appropriate temperature in precision-controlled furnaces. Temperature control is critical to ensure optimal material flow and final properties.

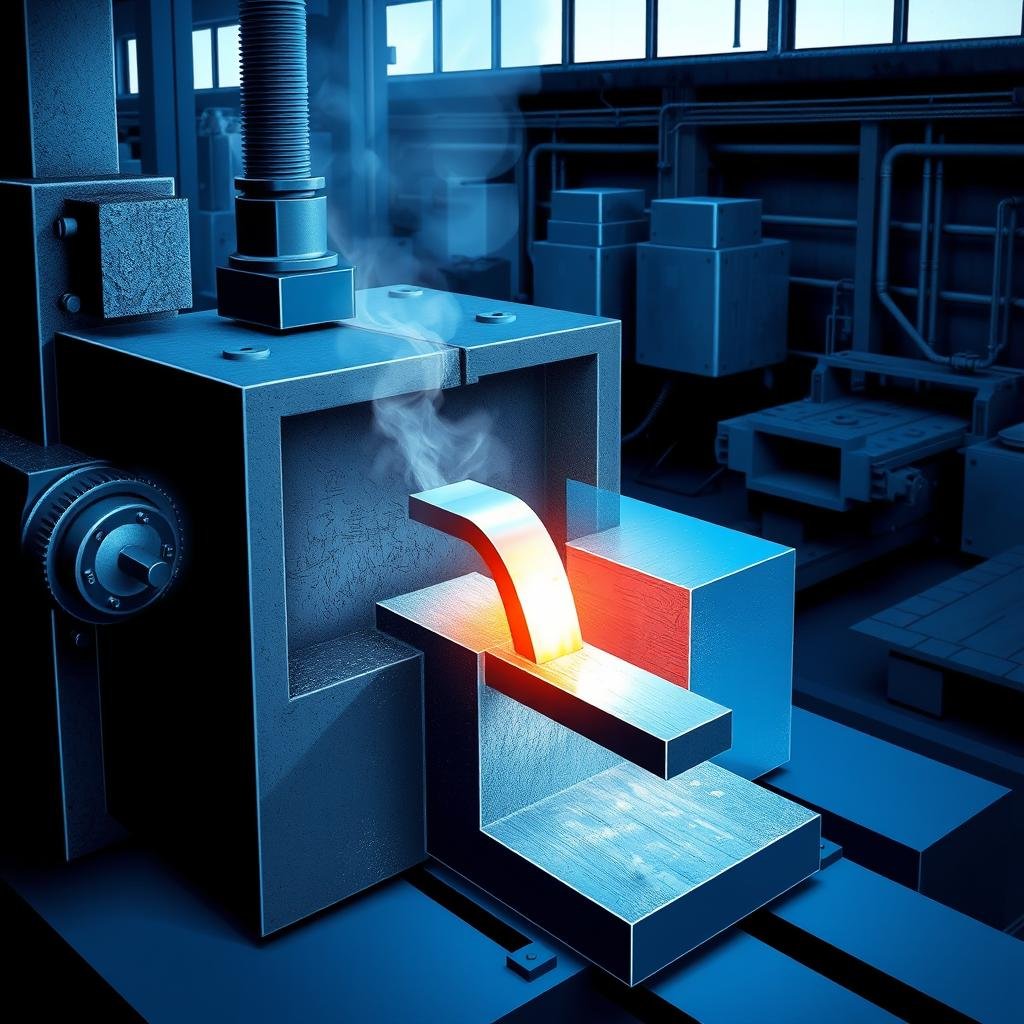

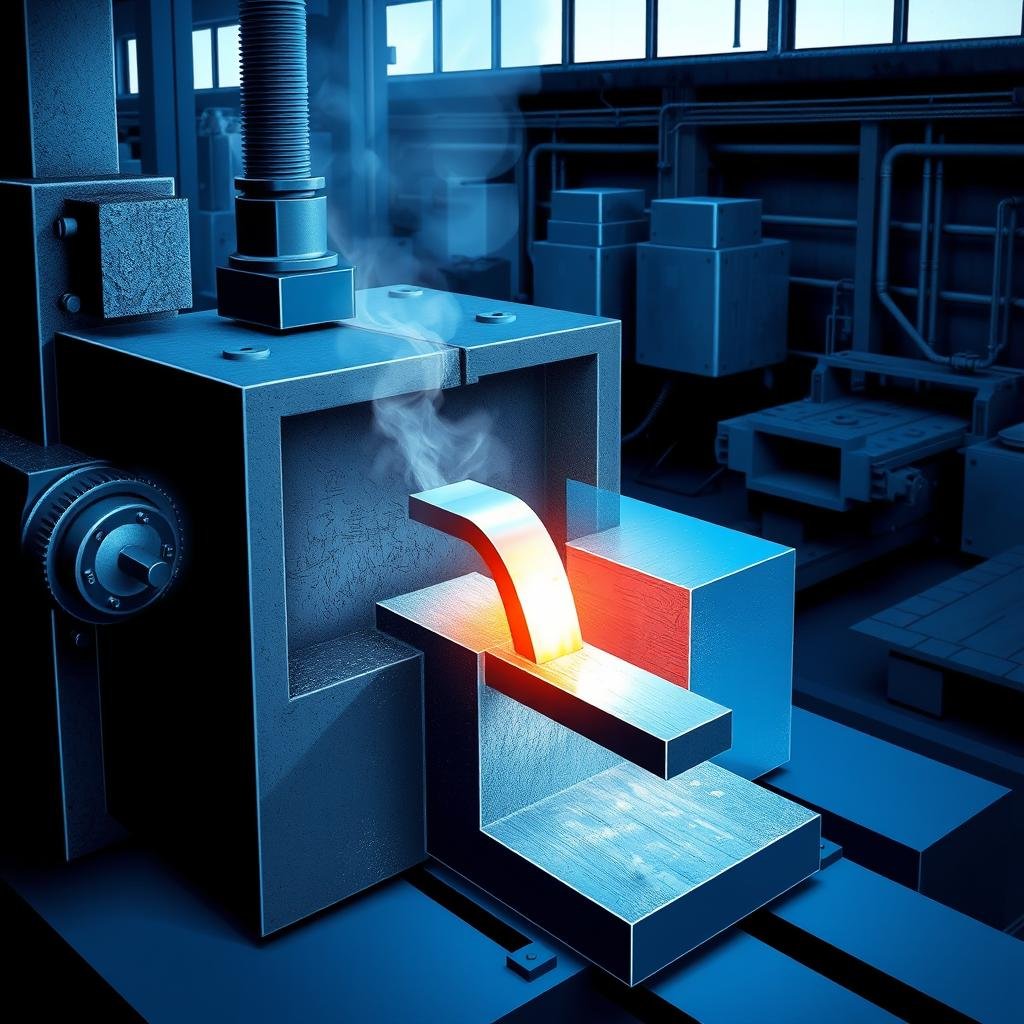

5. Forging Operation

The heated material is placed in the die and subjected to pressure using hydraulic presses, hammers, or other forging equipment. This may involve multiple strikes or stages to achieve the final shape.

6. Trimming & Finishing

Excess material (flash) is removed through trimming operations. Additional finishing processes may include straightening, coining, or other operations to achieve final dimensions.

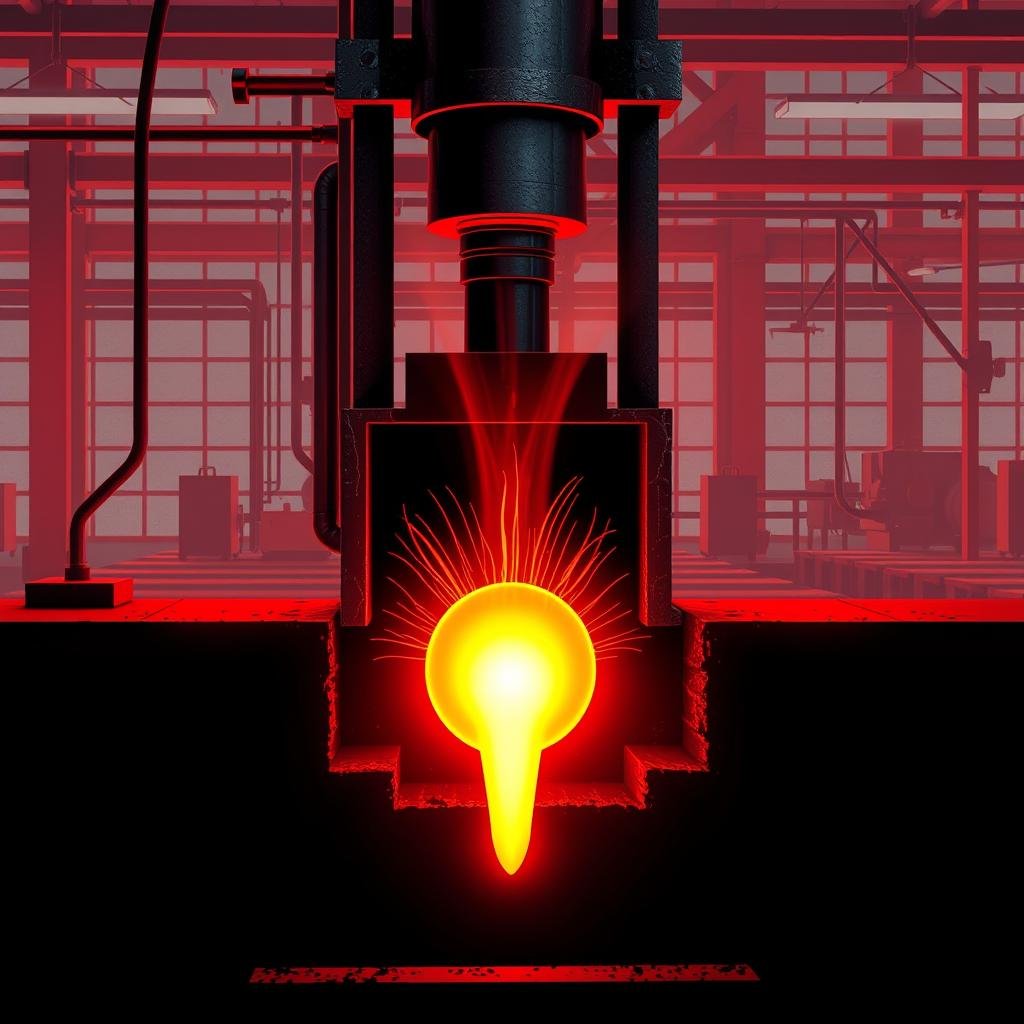

7. Heat Treatment

Components undergo heat treatment to enhance mechanical properties. This may include annealing, normalizing, quenching, tempering, or other processes depending on the material and application requirements.

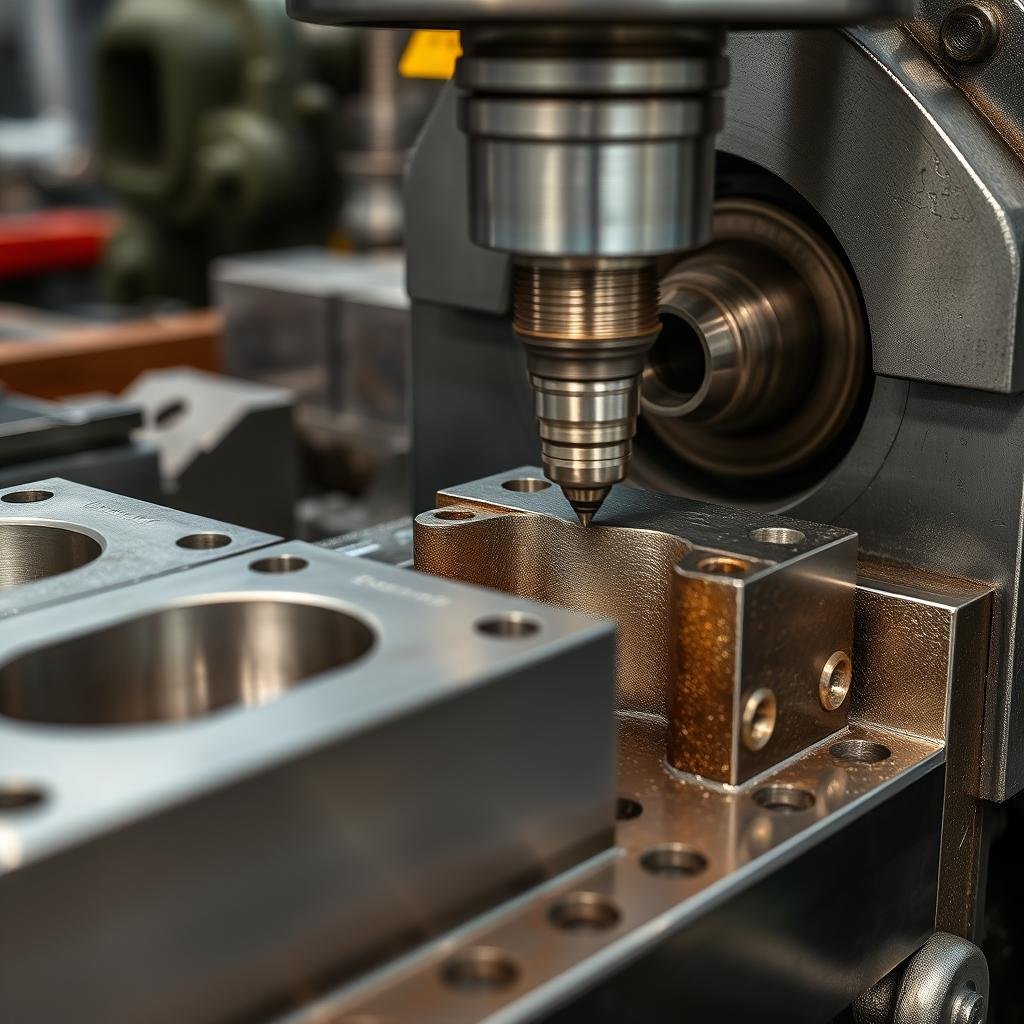

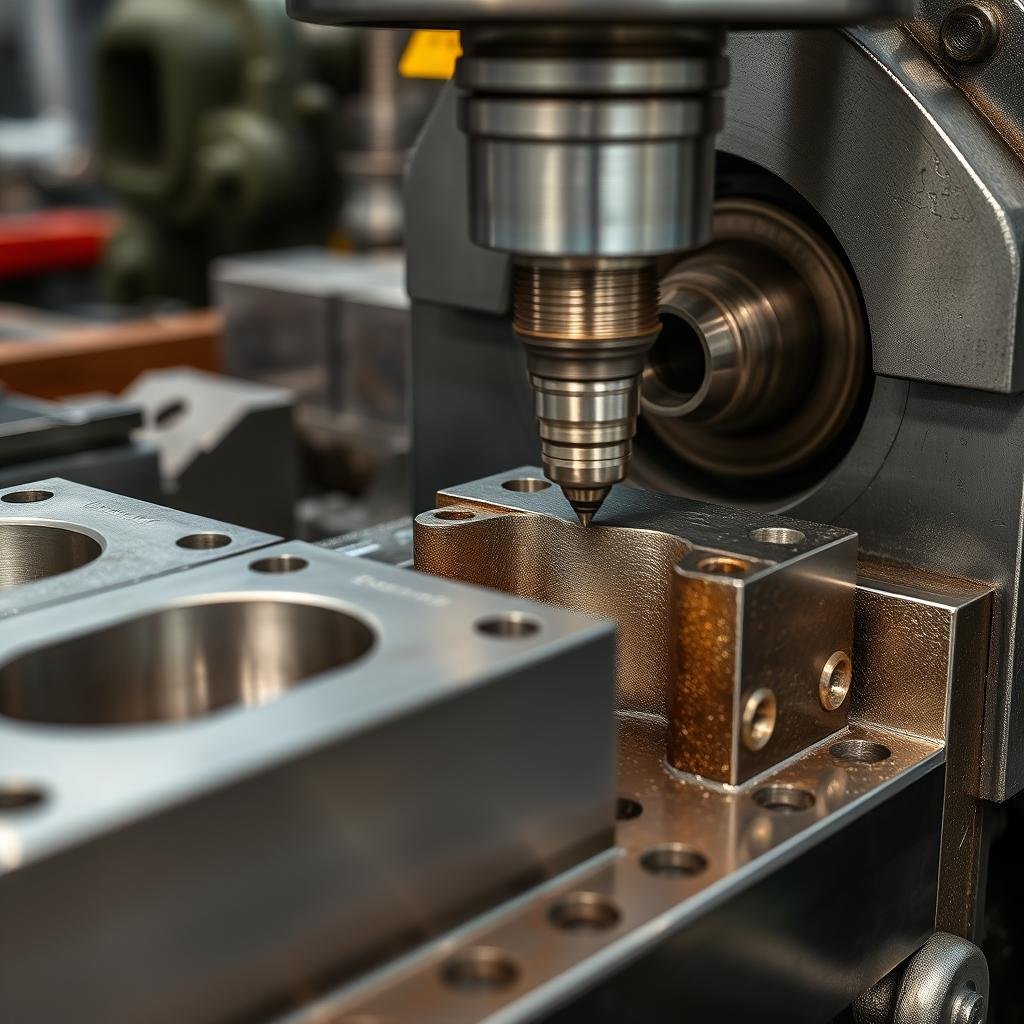

8. Machining & Surface Treatment

Additional machining may be performed to achieve final dimensions and features. Surface treatments such as grinding, polishing, anodizing, or painting may be applied to enhance appearance and performance.

9. Inspection & Testing

Rigorous quality control procedures ensure components meet all specifications. This may include dimensional inspection, non-destructive testing, mechanical testing, and other verification methods.

Ready to Start Your Metal Forging Project?

MAIKONG’s comprehensive capabilities ensure a seamless journey from concept to finished component. Contact us today to discuss your requirements.

Contact via WhatsApp

Email Us

Advanced Forging Equipment at MAIKONG

Our state-of-the-art manufacturing facility in GD, SZ houses a comprehensive array of forging equipment, enabling us to handle projects of various sizes and complexities with precision and efficiency.

Our Forging Machinery

- Hydraulic Presses: Ranging from 500 to 5,000 tons for precision control and consistent pressure application

- Mechanical Presses: For high-speed production of smaller components

- Hammers: For specialized forging applications requiring impact force

- Rolling Mills: For producing elongated components with varying cross-sections

- Heating Furnaces: Precision-controlled for optimal temperature management

- Trimming Presses: For efficient flash removal and finishing

CNC Machining Capabilities

With over 60 CNC machines and 100+ tons of metal processing capacity per month, MAIKONG offers comprehensive secondary operations to transform forged components into finished parts with precise tolerances and features.

CNC Turning

Ideal for creating deep holes, machined threads, and cylindrical shapes with superior surface finishes. Our advanced CNC turning centers deliver precise components with fast turnaround times.

CNC Milling

Creates complex prismatic shapes and flat surfaces for a limitless variety of industrial products. Our multi-axis CNC machines require no fixed tooling, offering flexibility and extreme accuracy.

Swiss-Type Machining

Specializes in precision small parts and long shaft components. Our equipment features dual spindles and multi-axis capabilities, allowing for one-stop solutions with the highest level of accuracy.

Metal Forging vs. Casting: A Comprehensive Comparison

Understanding the differences between forging and casting is crucial when selecting the optimal manufacturing process for your components. While both methods transform raw metal into finished parts, they differ significantly in process, properties, and applications.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps of effort to achieve complex shape |

✅Can achieve complex shape in one session |

| Dimensional Accuracy |

✅Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅Smoother surfaces, reduced post-processing |

Might require more machining due to air pocket |

| Heat Treatment Response |

✅Responsive for controlled material properties |

Less predictable response |

| Grain Structure |

✅Directional grain flow for improved properties |

No directional grain structure |

| Weight-to-Strength Ratio |

✅High strength-to-weight ratio |

Bulkier parts may be needed |

| Resistance to Corrosion |

✅Improved due to denser structure |

Naturally forming oxide layer for resistance |

For applications where performance, reliability, and safety are critical—particularly those involving shock, impact, cyclic loads, or vibration stresses—forged components offer significant advantages over cast alternatives.

Industries and Applications for Metal Forging

Automotive

- Crankshafts

- Connecting rods

- Transmission gears

- Steering components

- Suspension parts

Aerospace

- Turbine discs

- Structural components

- Landing gear parts

- Engine mounts

- Control system components

Energy

- Valve bodies

- Fittings and flanges

- Turbine components

- Pressure vessels

- Pipeline components

Agriculture

- Tractor components

- Implement parts

- Gears and shafts

- Hydraulic fittings

- Structural components

Construction

- Heavy equipment parts

- Structural connectors

- Hydraulic components

- Fasteners and anchors

- Tool components

Medical

- Surgical instruments

- Implant components

- Equipment structural parts

- Precision mechanisms

- Diagnostic device components

Looking for Custom Forged Components for Your Industry?

MAIKONG specializes in creating high-performance forged parts for diverse applications. Our engineering team can help develop solutions tailored to your specific requirements.

Request a Quote

Quality Assurance in the Metal Forging Process

At MAIKONG, quality is built into every step of our manufacturing process. Our comprehensive quality management system, certified to ISO 9001:2015 standards, ensures consistent excellence in all our forged components.

Our Quality Control Procedures

- Material Verification: Chemical composition and mechanical property testing

- In-Process Inspection: Monitoring critical parameters during forging

- Dimensional Inspection: Precision measurement of all critical dimensions

- Non-Destructive Testing: Ultrasonic, magnetic particle, and other methods to detect internal defects

- Mechanical Testing: Tensile, hardness, impact, and fatigue testing

- Surface Quality Inspection: Visual and automated systems to detect surface defects

- Final Inspection: Comprehensive verification of all requirements

Common Defects in Forging and Prevention Methods

Our proactive approach to quality management focuses on preventing defects before they occur. We employ advanced simulation tools, process controls, and continuous improvement methodologies to minimize common forging defects such as:

| Defect Type |

Description |

Prevention Method |

| Underfill |

Incomplete filling of die cavity |

Proper billet sizing, optimal heating, adequate forging pressure |

| Laps and Folds |

Material folding over itself during flow |

Optimized die design, proper lubrication, controlled material flow |

| Cracks |

Surface or internal fractures |

Proper heating, controlled cooling, optimized forging sequence |

| Scale Pits |

Surface depressions from oxide scale |

Controlled atmosphere heating, descaling before forging |

| Die Wear |

Dimensional variations due to worn dies |

Regular die maintenance, proper lubrication, optimal die materials |

The MAIKONG Advantage in Metal Forging

Comprehensive Capabilities

From design to delivery, MAIKONG offers a complete solution for your forging needs. Our integrated services include CAD/CAM design, tooling, forging, heat treatment, machining, and surface finishing—all under one roof for seamless quality control and efficiency.

Technical Expertise

Our team of experienced engineers and metallurgists brings deep knowledge of materials, processes, and applications. We leverage this expertise to optimize component design, select appropriate materials, and develop efficient manufacturing processes.

Advanced Equipment

Our state-of-the-art facility features the latest forging and machining equipment, enabling us to produce components with precision and consistency. From 60+ CNC machines to specialized forging presses, we have the technology to meet your requirements.

Quality Assurance

ISO 9001:2015 certified quality management system ensures consistent excellence in all our products. Our comprehensive testing and inspection capabilities verify that every component meets or exceeds specifications.

Cost-Effectiveness

Our efficient processes, strategic location, and optimized supply chain enable us to offer competitive pricing without compromising quality. We continuously seek ways to reduce costs while maintaining performance.

Customer Focus

We view each client relationship as a partnership, working closely with you to understand your requirements and develop tailored solutions. Our responsive communication and flexible approach ensure your satisfaction.

Experience the MAIKONG Difference

Join the growing number of companies that trust MAIKONG for their critical forging and machining needs. Contact us today to discuss your project requirements or to arrange a facility tour.

Contact Us Today

US Distributor Opportunities

MAIKONG is actively seeking distribution partners throughout the United States to represent our comprehensive metal forging and machining capabilities. As a MAIKONG distributor, you’ll gain access to our extensive manufacturing resources, competitive pricing, and technical expertise.

Distributor Benefits

- Exclusive territorial rights

- Competitive pricing structure

- Technical training and support

- Marketing materials and assistance

- Dedicated account management

- Rapid response to inquiries

- Collaborative relationship

Become a MAIKONG Distributor

Join our network of successful distributors and offer your customers access to high-quality, cost-effective forging solutions from MAIKONG.

- Established business in industrial or manufacturing sectors

- Strong customer relationships in target industries

- Technical understanding of metal components

- Commitment to growth and customer service

Partner with MAIKONG for Your Metal Forging Needs

From raw material to high-performance parts, MAIKONG delivers excellence at every stage of the metal forging journey. Our comprehensive capabilities, technical expertise, and customer-focused approach make us the ideal partner for your critical component needs.

Whether you require custom aluminum forgings, precision steel components, or complex machined parts, MAIKONG has the knowledge, equipment, and experience to exceed your expectations. Our commitment to quality, efficiency, and innovation ensures that your components will perform reliably in the most demanding applications.

Ready to Get Started?

Contact MAIKONG today to discuss your project requirements or to request a quote. Our team is ready to help you achieve your manufacturing goals.