In today’s competitive manufacturing landscape, the quality of your metal components can make or break your product’s success. Metal forge manufacturing stands as the gold standard for creating components with exceptional strength, durability, and performance characteristics. At MAIKONG, we’ve perfected the art and science of metal forging to deliver superior custom components that outperform cast or machined alternatives in demanding applications.This comprehensive guide explores how our advanced metal forge processes create components with unmatched structural integrity while maintaining cost-effectiveness for businesses across industries. Whether you’re seeking aluminum forging services, steel forge solutions, or precision CNC machining, our expertise ensures your components deliver reliable performance in the most challenging environments.

MAIKONG’s Metal Forge Capabilities and Services

With over 60 CNC machines and 100+ tons of monthly metal processing capacity, MAIKONG stands as a premier provider of comprehensive metal manufacturing solutions. Our state-of-the-art facility in GD, SZ combines traditional forging expertise with cutting-edge technology to deliver exceptional results for every project.

Why Choose MAIKONG for Metal Forge Manufacturing?

- Comprehensive in-house capabilities from design to finished product

- Superior strength-to-weight ratio through optimized grain structure

- Extensive material expertise across aluminum, steel, and brass alloys

- Rigorous quality control with advanced testing facilities

- Competitive pricing with exceptional value

- Fast turnaround times and reliable delivery

Ready to Discuss Your Project?

Our engineering team is available to review your specifications and provide expert recommendations for optimal results.

Contact Us on WhatsApp

CNC Machining Services: Precision Complementing Metal Forge

While forging creates the foundation for superior metal components, precision CNC machining adds the finishing touches that ensure perfect dimensional accuracy and surface quality. MAIKONG’s integrated approach combines the structural advantages of forging with the precision of advanced CNC machining.

CNC Turning Services

Our CNC turning capabilities excel at creating precise cylindrical shapes, deep holes, and machined threads with superior surface finishes. Ideal for shafts, bushings, and cylindrical components that require tight tolerances.

Learn More

CNC Milling Services

MAIKONG’s multi-axis CNC milling services create complex prismatic shapes and flat surfaces with exceptional precision. Our flexible, tooling-free approach ensures accuracy for even the most intricate component designs.

Learn More

Swiss-Type Machining

For small, intricate parts and long shaft components, our Swiss-type machining delivers unmatched precision. With dual spindles and multi-axis capabilities, we provide one-stop solutions for complex small components.

Learn More

The Superior Advantages of Metal Forge Manufacturing

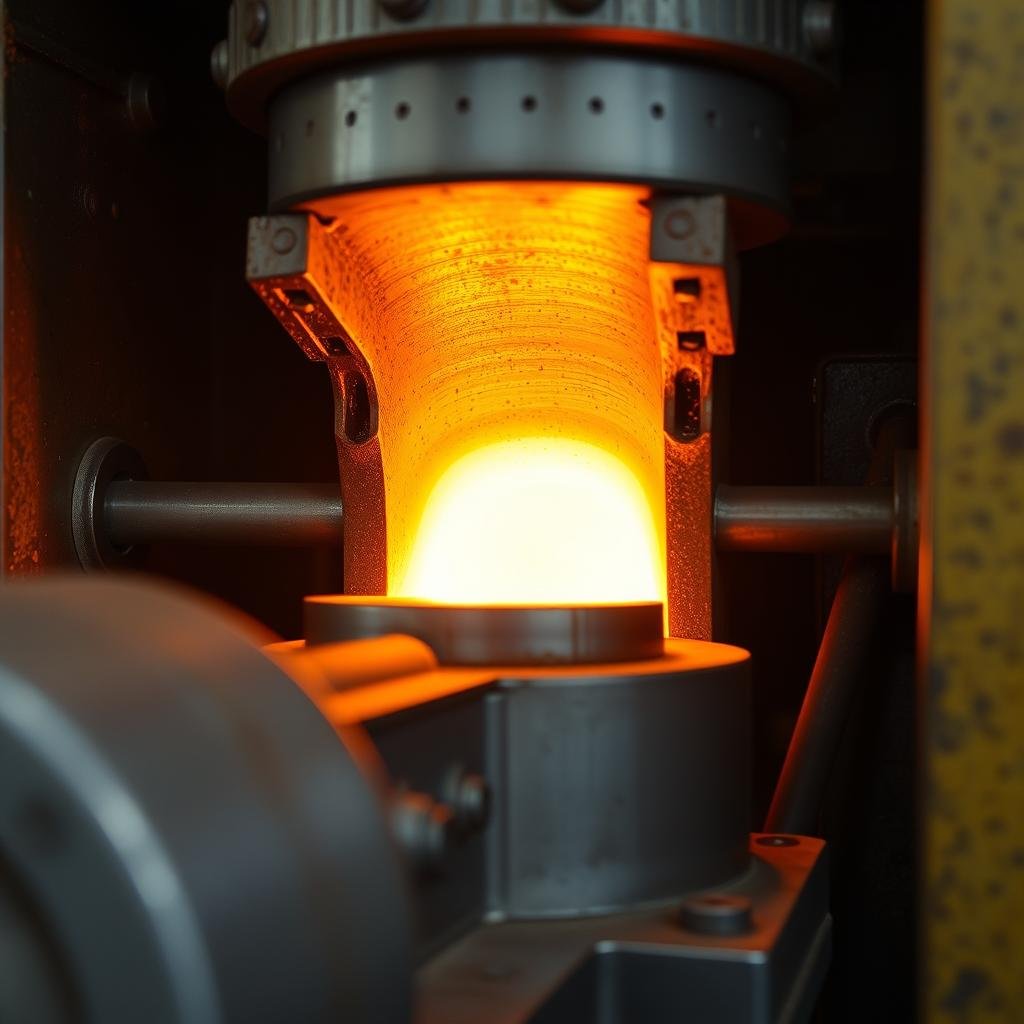

Understanding the Metal Forge Process

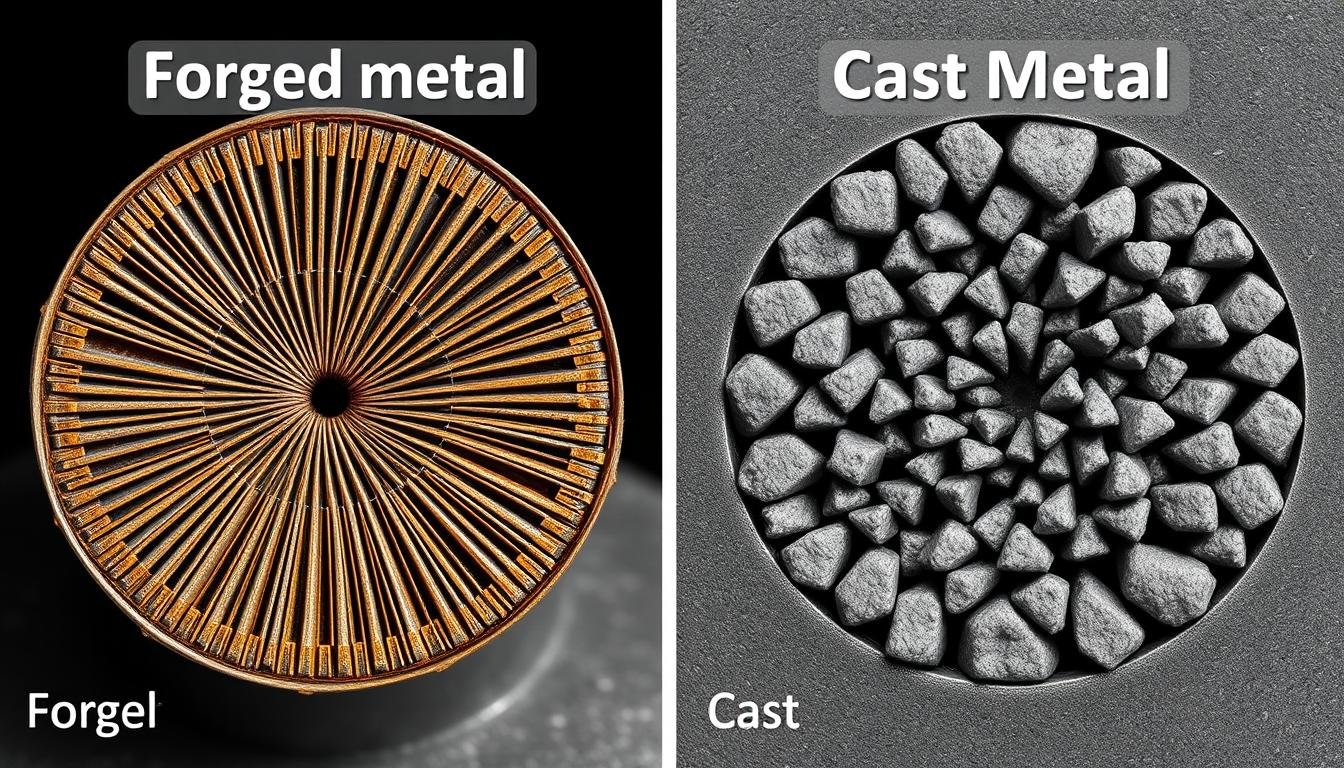

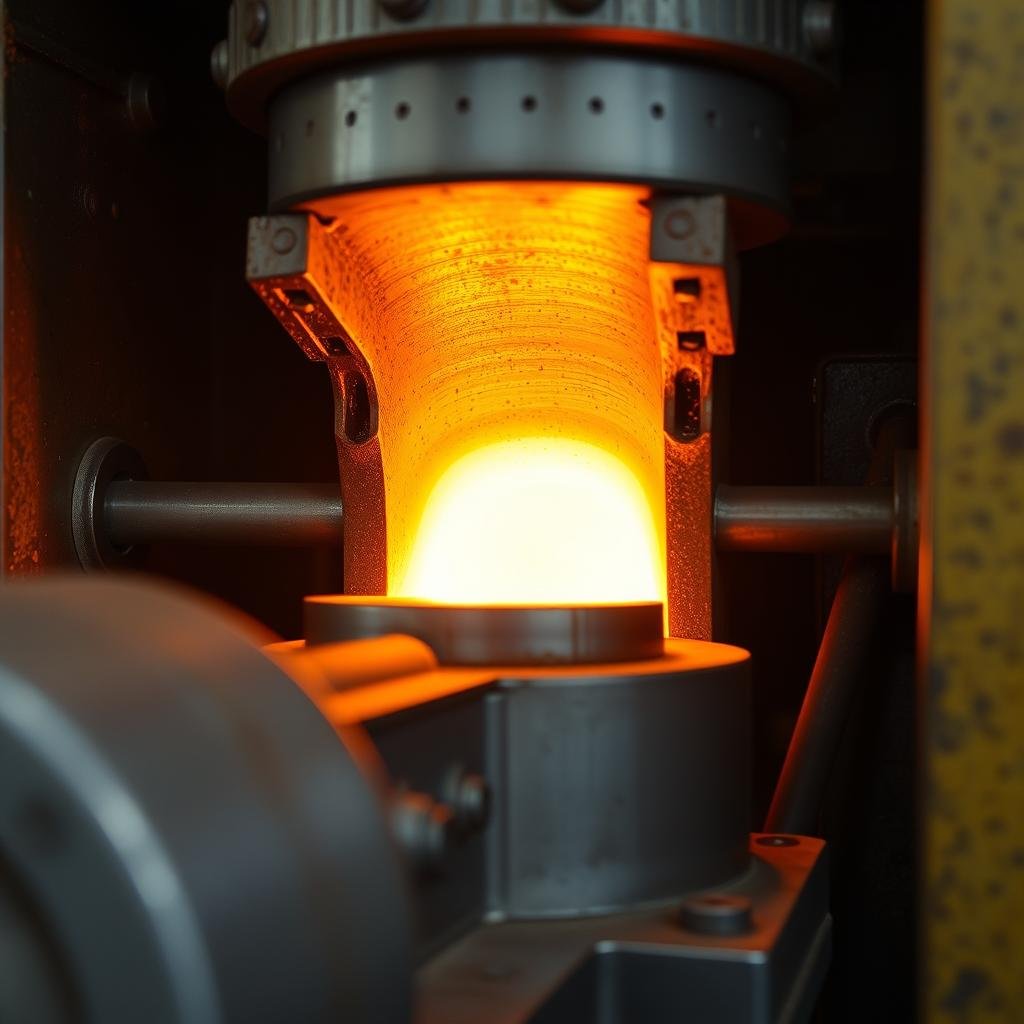

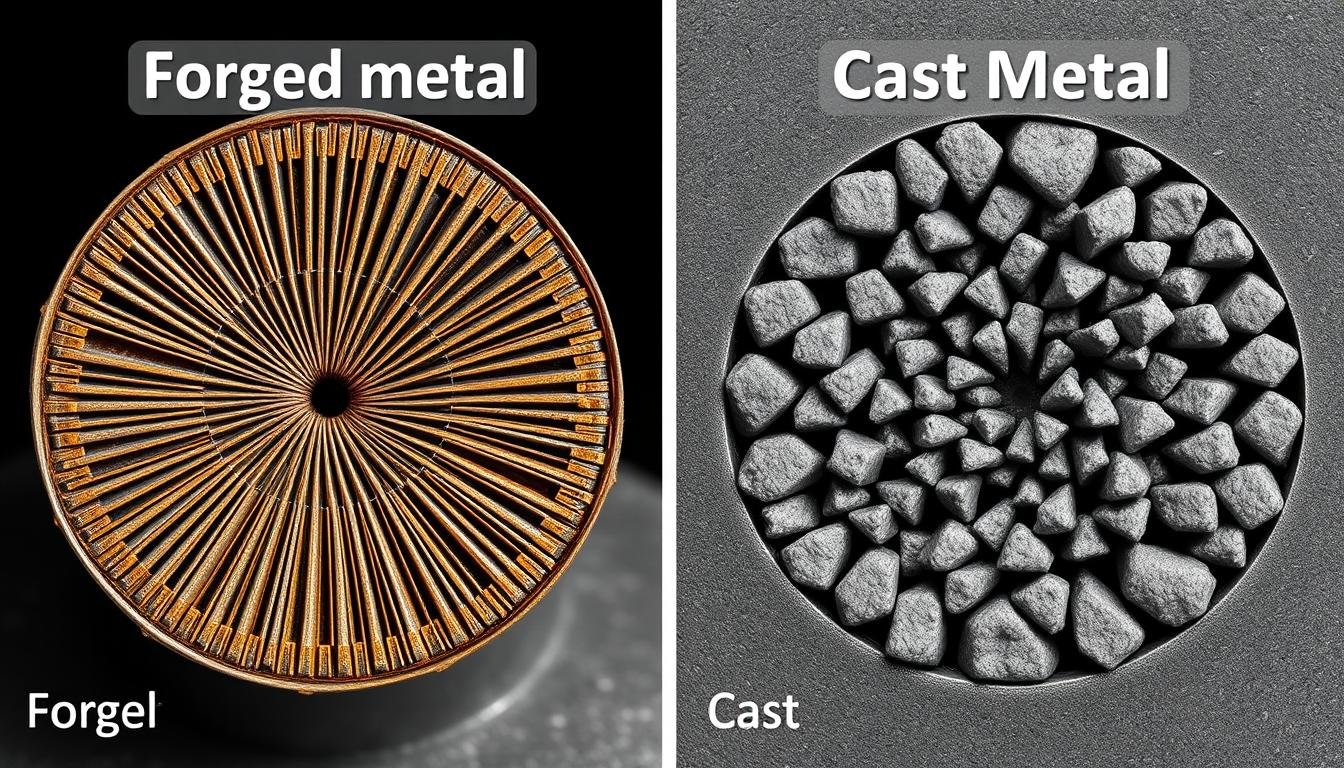

Metal forging is a manufacturing process where metal is shaped using localized compressive forces. The forging process aligns the grain structure of the metal, significantly enhancing its mechanical properties compared to casting or machining from stock. This fundamental difference results in components with superior strength, durability, and performance characteristics.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

Can achieve complex shapes in one session |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

Need Superior Strength Components?

Discover how MAIKONG’s forging expertise can enhance your product’s performance and reliability.

Request Forging Consultation

Material Expertise in Metal Forge Manufacturing

The selection of appropriate materials is crucial to the success of any forging project. At MAIKONG, our metallurgical expertise ensures optimal material selection based on your specific application requirements.

Aluminum Forging

Our aluminum forging services deliver components with an exceptional strength-to-weight ratio. Ideal for aerospace, automotive, and applications where weight reduction is critical without compromising strength.

Steel Forging

Our steel forging capabilities produce components with exceptional strength and durability. Perfect for high-stress applications where reliability under load is non-negotiable.

Brass Forging

MAIKONG’s brass forging services create components with excellent corrosion resistance and electrical conductivity. Ideal for electrical components, decorative hardware, and marine applications.

The mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness must be thoroughly considered when selecting the optimal alloy for your application.

– MAIKONG Engineering Team

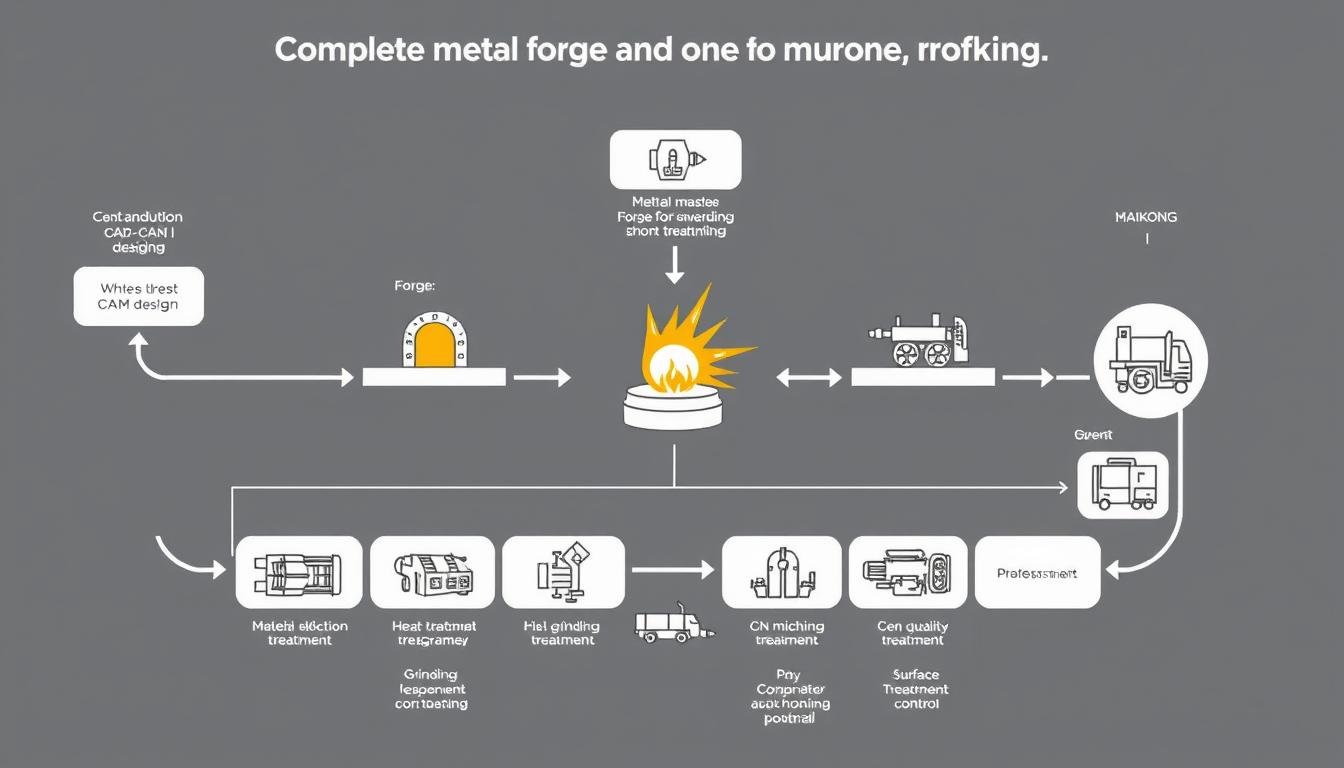

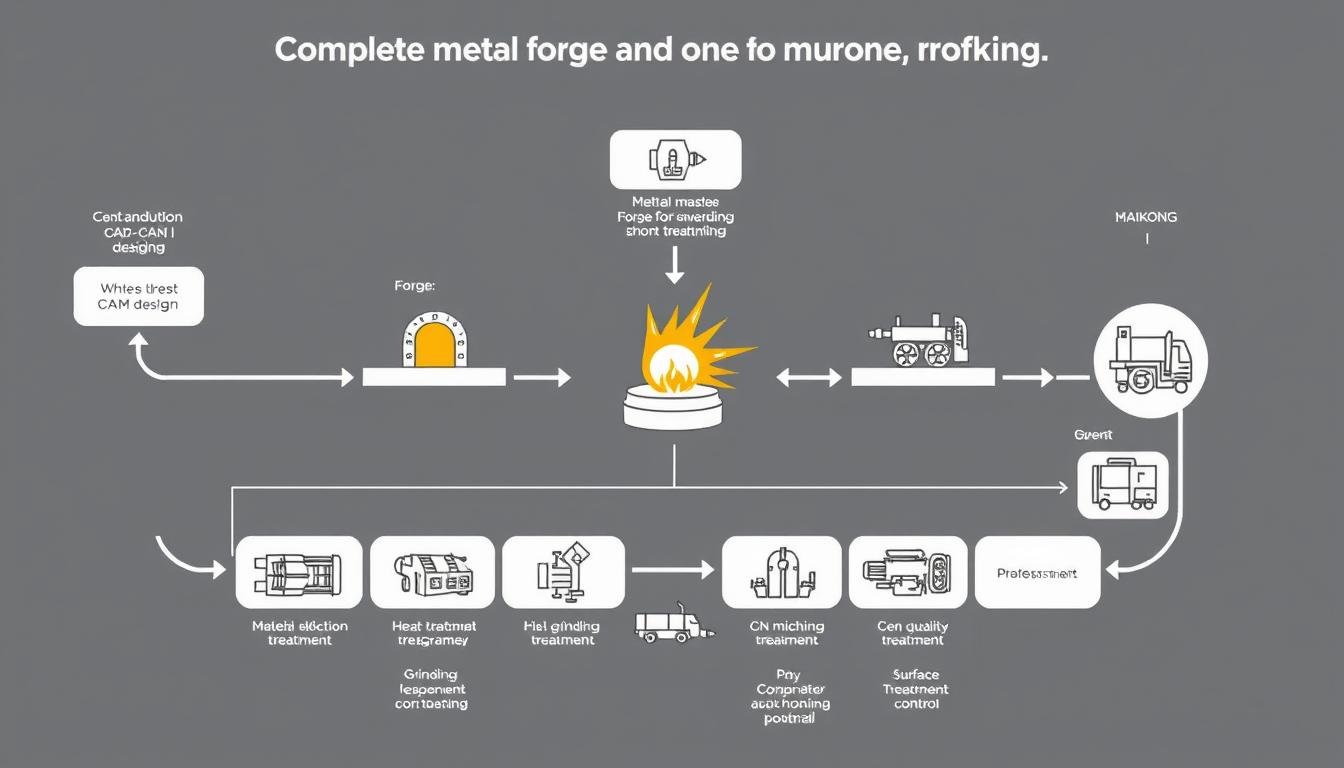

Full-Service Metal Forge Manufacturing

MAIKONG provides a comprehensive end-to-end solution for all your metal component needs. Our integrated approach ensures consistency, quality, and efficiency throughout the manufacturing process.

Design & Engineering

Our engineering team utilizes advanced CAD/CAM software to optimize component design for the forging process. Through finite element analysis and simulation, we identify and address potential issues before production begins, saving time and resources.

Tooling & Die Design

Precision tooling is critical to forging success. Our experienced toolmakers create custom dies designed for optimal metal flow, minimal material waste, and extended tool life. Regular maintenance ensures consistent quality throughout production runs.

Heat Treatment

Our in-house heat treatment capabilities allow precise control over material properties. Through careful temperature management and cooling processes, we optimize the mechanical characteristics of each component to meet your exact specifications.

Surface Treatment

MAIKONG offers comprehensive surface treatment options including anodizing, painting, laser engraving, and sand blasting. Our advanced quality control ensures consistent appearance and performance for all treated components.

One-Stop Manufacturing Solution

From design to finished product, MAIKONG handles every step of the process with precision and care.

Explore Our Full Services

Quality Assurance in Metal Forge Manufacturing

At MAIKONG, quality isn’t just a department—it’s a fundamental aspect of our entire operation. Our comprehensive quality management system ensures that every component meets or exceeds your specifications.

Our Quality Control Process

- Material certification and verification before production

- In-process inspections at critical manufacturing stages

- Dimensional verification using precision measurement equipment

- Mechanical testing to confirm strength and performance characteristics

- Surface quality inspection for aesthetic and functional requirements

- Final inspection and documentation before shipment

Industry Applications for Metal Forge Components

MAIKONG’s forged components deliver exceptional performance across a wide range of industries and applications where strength, durability, and reliability are critical.

Automotive

Engine components, suspension parts, drivetrain elements, and structural components that require exceptional strength and fatigue resistance.

Aerospace

Lightweight, high-strength components for aircraft structures, landing gear, and engine systems where failure is not an option.

Industrial Machinery

Gears, shafts, connectors, and structural elements that must withstand high loads and harsh operating conditions.

Whether your application requires the lightweight strength of aluminum, the robust durability of steel, or the corrosion resistance of brass, MAIKONG’s forging expertise delivers components that perform reliably in the most demanding environments.

Become a US Distributor for MAIKONG Metal Forge Products

MAIKONG is actively seeking distribution partners throughout the United States to represent our high-quality forged components and CNC machining services. As a distributor, you’ll gain access to our comprehensive manufacturing capabilities, competitive pricing, and exceptional quality.

Distributor Benefits

- Exclusive territorial rights in your region

- Comprehensive product training and technical support

- Competitive pricing structure with attractive margins

- Marketing materials and sales support

- Rapid response to customer inquiries and orders

- Reliable delivery and consistent quality

Why MAIKONG is Your Ideal Metal Forge Manufacturing Partner

With our comprehensive capabilities, commitment to quality, and competitive pricing, MAIKONG stands ready to meet all your metal component needs. From initial design through final delivery, our team works tirelessly to ensure your complete satisfaction.

Whether you’re seeking a manufacturing partner for your custom components or interested in becoming a US distributor for our products, we invite you to experience the MAIKONG difference. Contact us today to discuss how we can support your success.

Ready to Get Started?

Contact MAIKONG today to discuss your metal forge manufacturing needs.

Email Us Now