Steel forging is a manufacturing process that shapes metal using compressive forces. This ancient metalworking technique has evolved into a sophisticated manufacturing method crucial for producing high-strength components across various industries. For US manufacturers seeking reliable, cost-effective forging solutions, understanding the fundamentals of this process is essential to making informed production decisions.

Understanding Steel Forging: The Fundamentals

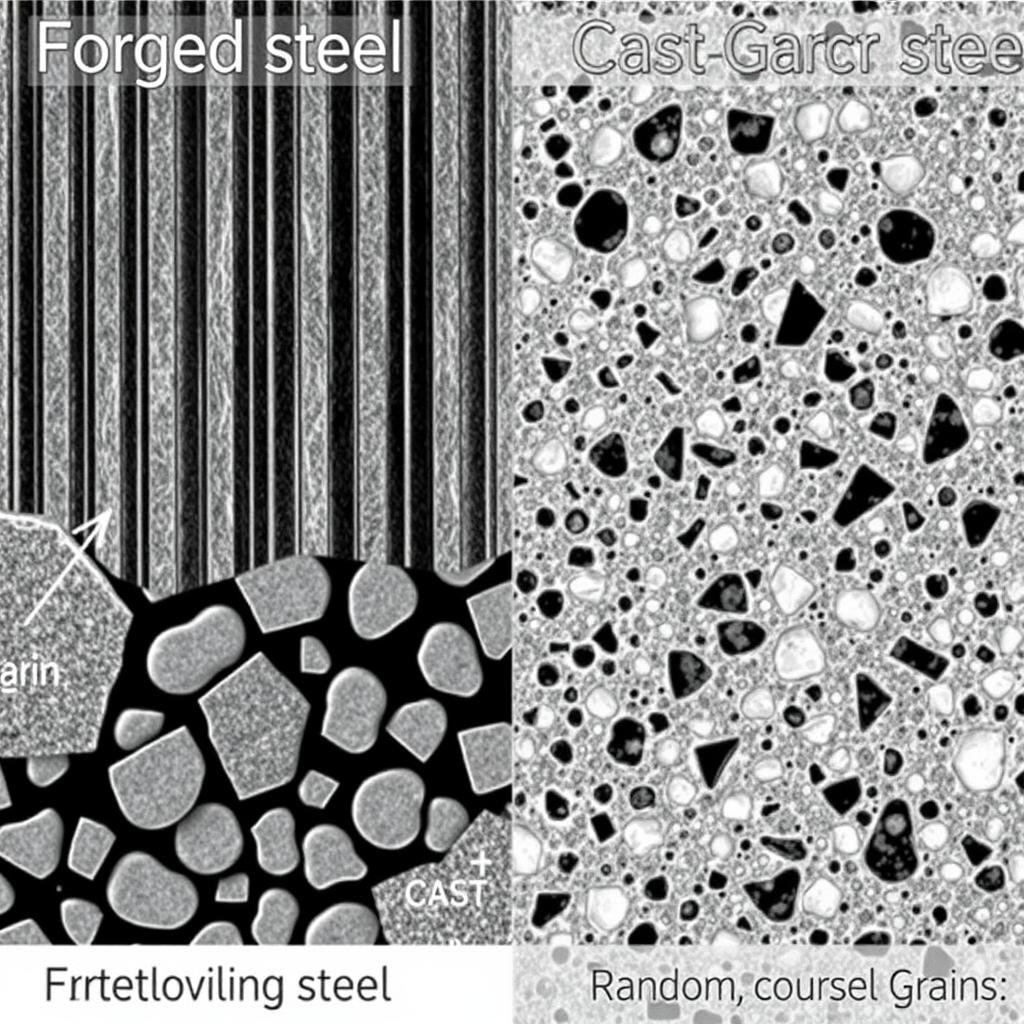

At its core, steel forging involves applying pressure to metal, causing it to plastically deform into desired shapes. Unlike casting, which melts metal completely, forging works the metal in its solid state, enhancing its structural integrity. This results in components with superior mechanical properties, making them ideal for applications where strength and reliability are paramount.

The history of forging dates back thousands of years, with early civilizations using hammers to shape heated metal into tools and weapons. Today, modern steel forging utilizes sophisticated equipment and precise techniques to create components for critical applications in aerospace, automotive, oil and gas, construction, and many other industries.

Why Choose Steel Forging Over Other Manufacturing Methods?

Advantages of Steel Forging

- Superior strength and durability

- Enhanced grain structure and flow

- Excellent fatigue resistance

- Greater structural integrity

- Reduced internal defects

- Better impact and shock resistance

- Consistent mechanical properties

Limitations to Consider

- Higher initial tooling costs

- Limitations on complex geometries

- May require secondary machining

- Higher energy consumption

- Size constraints for certain equipment

Need Expert Guidance on Steel Forging?

Our engineers can help determine if steel forging is the right manufacturing method for your components.

Contact Our Experts

Primary Steel Forging Methods and Processes

The steel forging industry employs several distinct methods, each with specific applications and advantages. Understanding these different approaches helps manufacturers select the optimal process for their particular requirements.

Classification by Tooling Method

Open Die Forging

In open die forging, metal is shaped between flat or simply contoured dies that don’t completely enclose the workpiece. This method is ideal for large components and allows for significant deformation and grain refinement. Typical products include shafts, rings, and custom-shaped parts.

Closed Die Forging

Also known as impression die forging, this method shapes metal by forcing it into die cavities. The metal completely fills the die to create complex shapes with excellent dimensional accuracy. This process is commonly used for high-volume production of components like gears, connecting rods, and crankshafts.

Rolled Ring Forging

Specialized for creating seamless rings, this process involves punching a hole in a round metal billet and then rolling and shaping it into a ring. The method produces rings with excellent grain structure and is used for bearings, flanges, and aerospace components.

Classification by Temperature

| Forging Type |

Temperature Range |

Characteristics |

Typical Applications |

| Hot Forging |

Above recrystallization (typically 2100-2300°F for steel) |

Maximum ductility, lower forces required, refined grain structure |

Large components, complex shapes, structural parts |

| Warm Forging |

Above room temperature but below recrystallization (typically 800-1800°F) |

Balanced ductility and strength, reduced scaling, good dimensional control |

Automotive parts, fasteners, near-net shape components |

| Cold Forging |

Room temperature |

Excellent dimensional accuracy, good surface finish, strain hardening |

Precision parts, fasteners, small components |

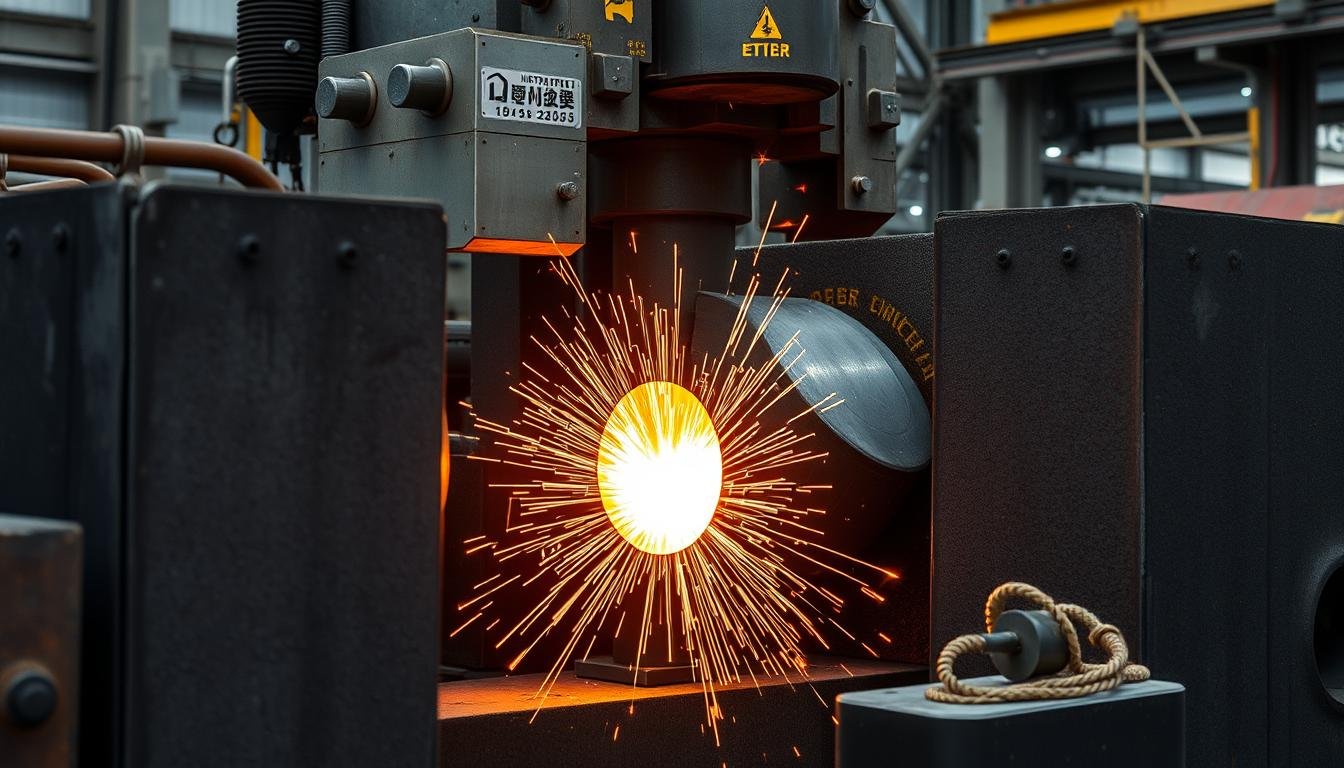

Standard Forging Equipment

Hammers and Presses

- Mechanical Presses: Use a crankshaft mechanism for precise, controlled force

- Hydraulic Presses: Provide consistent pressure throughout the stroke

- Screw Presses: Deliver high energy through a flywheel and screw mechanism

- Drop Hammers: Use gravity or power-assisted falling weight for impact force

- Counterblow Hammers: Feature opposing rams for balanced impact energy

Explore MAIKONG’s Steel Forging Capabilities

Our state-of-the-art equipment can handle a wide range of steel forging requirements.

View Our Equipment

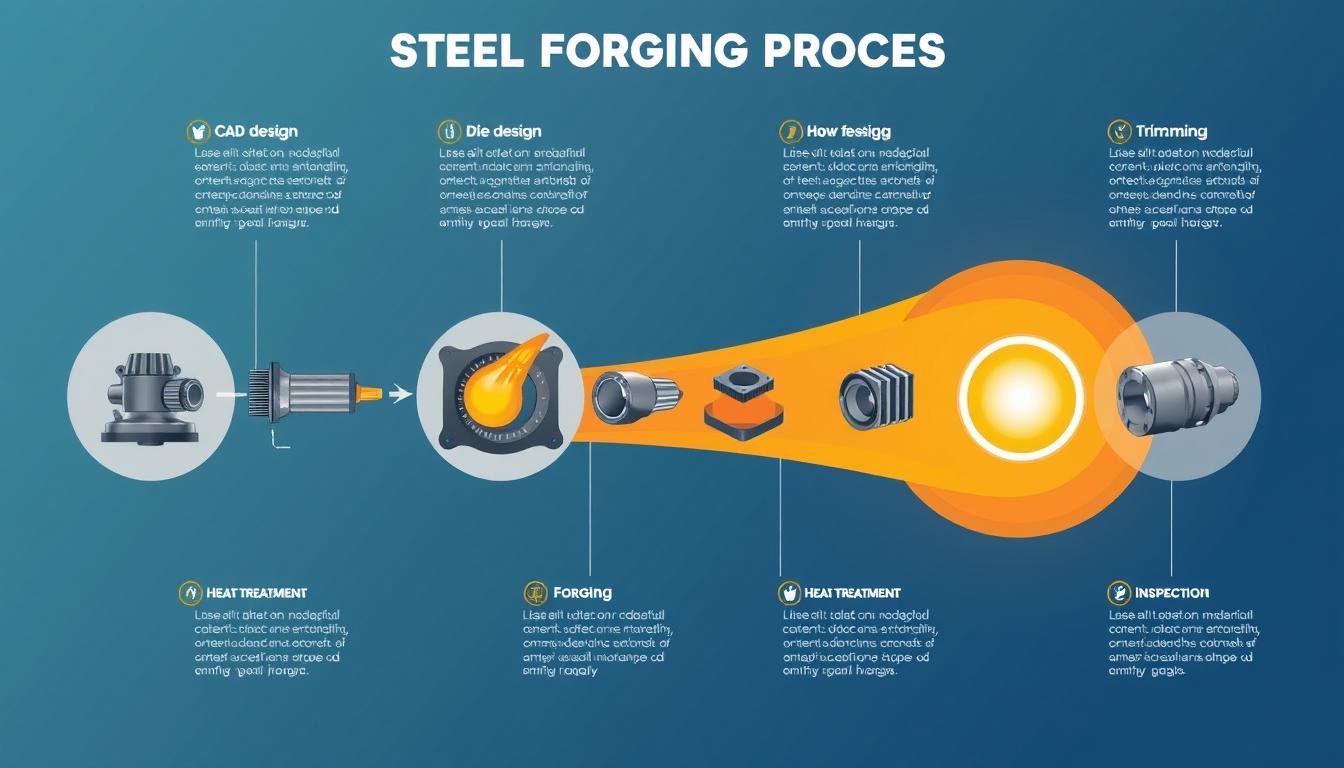

The Steel Forging Process: From Design to Finished Product

The journey from raw material to finished forged component involves several critical stages. At MAIKONG, we’ve optimized each step to ensure consistent quality and performance in our steel forging operations.

Design & Engineering

- CAD/CAM design development

- Material selection and specification

- Die design and simulation

- Process planning and optimization

- Finite element analysis

Pre-Forging Operations

- Raw material inspection

- Cutting stock to required length

- Heating to forging temperature

- Die preparation and lubrication

- Equipment setup and calibration

Forging Operations

- Initial forming/blocking

- Progressive die operations

- Final die impression

- Flash removal/trimming

- Controlled cooling

Post-Forging Operations

- Heat treatment (normalizing, quenching, tempering)

- Cleaning and descaling

- Straightening if required

- Machining to final dimensions

- Surface treatments

Quality Control

- Dimensional inspection

- Non-destructive testing

- Mechanical property testing

- Microstructure analysis

- Documentation and certification

Finishing & Delivery

- Final inspection

- Protective coating application

- Packaging for shipment

- Documentation preparation

- On-time delivery

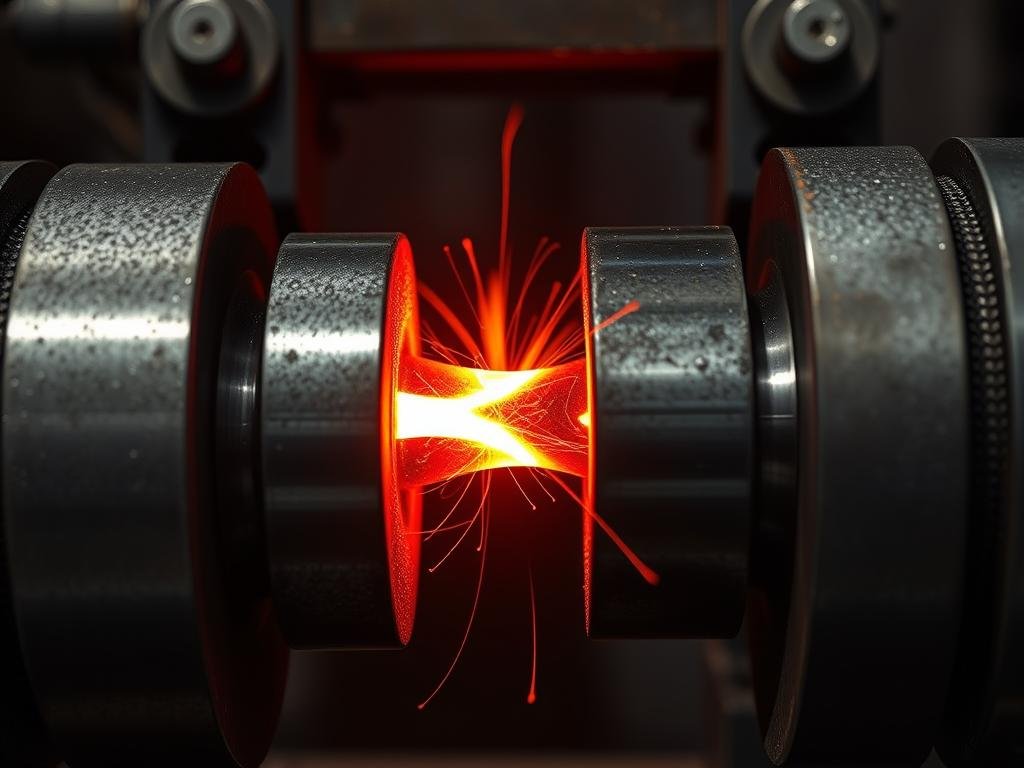

How Steel Forging Enhances Material Properties

The forging process significantly improves the mechanical properties of steel through several metallurgical mechanisms:

Grain Structure Refinement

During forging, the steel’s grain structure is refined and aligned in the direction of metal flow. This directional grain flow significantly enhances strength, ductility, and impact resistance compared to cast or machined components.

Elimination of Defects

The compressive forces applied during forging help close internal voids and heal micro-cracks that might be present in the raw material. This results in a more homogeneous structure with fewer potential failure points.

The directional properties imparted by forging are particularly valuable in applications where components must withstand stress from specific directions. This makes forged parts the preferred choice for critical safety and high-performance applications.

– MAIKONG Engineering Team

Materials and Applications in Steel Forging

Common Steel Grades Used in Forging

| Steel Type |

Common Grades |

Characteristics |

Typical Applications |

| Carbon Steel |

1018, 1045, 1060 |

Good strength, machinability, and weldability |

Gears, shafts, fasteners |

| Alloy Steel |

4140, 4340, 8620 |

Higher strength, toughness, and hardenability |

Crankshafts, connecting rods, heavy machinery |

| Stainless Steel |

304, 316, 410, 17-4PH |

Corrosion resistance, high temperature stability |

Valves, fittings, marine components |

| Tool Steel |

A2, D2, H13, S7 |

Extreme hardness, wear resistance |

Dies, tools, industrial knives |

| Microalloy Steel |

HSLA grades |

High strength with good formability |

Automotive components, structural parts |

Industry Applications for Steel Forging

Automotive Components

Automotive Components

Aerospace Parts

Aerospace Parts

Construction Equipment

Construction Equipment

Oil & Gas Components

Oil & Gas Components

Railway Equipment

Railway Equipment

Tools & Hardware

Tools & Hardware

Looking for Custom Steel Forged Components?

MAIKONG specializes in producing high-quality forged steel parts for diverse industries.

Request a Quote

Quality Control in Steel Forging

Quality assurance is paramount in steel forging, especially for components used in critical applications. At MAIKONG, we implement comprehensive quality control measures throughout the entire production process.

Common Defects and Prevention Strategies

| Defect Type |

Description |

Prevention Strategy |

| Laps and Folds |

Surface defects where metal folds over itself during flow |

Proper die design, adequate lubrication, correct preform shape |

| Unfilled Sections |

Incomplete filling of die cavities |

Adequate starting stock, proper heating, sufficient forging pressure |

| Cold Shuts |

Cracks from metal folding but not fusing |

Maintain proper forging temperature, optimize metal flow |

| Scale Pits |

Surface indentations from oxide scale |

Effective descaling, controlled atmosphere heating |

| Die Wear |

Dimensional variations due to worn dies |

Regular die maintenance, proper lubrication, die material selection |

Non-Destructive Testing Methods

- Ultrasonic Testing: Uses sound waves to detect internal flaws without damaging the component

- Magnetic Particle Inspection: Reveals surface and near-surface defects in ferromagnetic materials

- Dye Penetrant Testing: Identifies surface-breaking defects through liquid penetrant application

- Radiographic Testing: Uses X-rays or gamma rays to detect internal defects

- Eddy Current Testing: Detects surface and near-surface flaws through electromagnetic induction

MAIKONG’s Quality Assurance Process

At MAIKONG, quality is built into every step of our steel forging process. Our comprehensive quality management system ensures consistent product excellence and customer satisfaction.

4.9

Quality Assurance Rating

Material Verification

4.9

ISO 9001:2015 Certified: MAIKONG maintains rigorous quality management systems certified to international standards, ensuring consistent quality across all our forging operations.

MAIKONG’s Comprehensive Steel Forging and Manufacturing Services

MAIKONG offers a complete range of metal manufacturing services, with particular expertise in steel forging and precision machining. Our state-of-the-art facilities in GD, SZ are equipped with advanced machinery and staffed by skilled technicians to deliver exceptional quality at competitive prices.

Steel Forging Services

- Open die forging

- Closed die forging

- Rolled ring forging

- Hot, warm, and cold forging

- Custom tooling design

- Heat treatment services

CNC Machining Services

- CNC turning services

- CNC milling services

- Multi-axis machining

- Swiss-type machining

- Surface grinding

- Precision machining

Additional Services

- Custom metal fabrication

- Aluminum forging services

- Brass component manufacturing

- Prototyping services

- Material testing

- Contract manufacturing

Why Choose MAIKONG as Your Steel Forging Partner?

- 60+ CNC Machines: Extensive manufacturing capacity for all your production needs

- 100+ Tons Monthly Capacity: Scalable production to meet high-volume requirements

- Comprehensive Testing: In-house laboratory for material verification and quality assurance

- Cost-Effective Solutions: Competitive pricing without compromising quality

- One-Stop Manufacturing: From forging to finishing under one roof

- US Distribution Network: Seeking distributors across the United States

Become a MAIKONG Distributor in the US

We’re seeking distribution partners across the United States to represent our high-quality steel forging and machining services.

Explore Distribution Opportunities

Frequently Asked Questions About Steel Forging

What is the difference between forging and casting?

Forging shapes metal through compressive force while it remains in a solid state, resulting in improved grain structure and mechanical properties. Casting involves pouring molten metal into a mold and allowing it to solidify. Forged components typically offer superior strength, ductility, and fatigue resistance compared to cast parts.

What types of steel are best suited for forging?

Carbon steels (1018, 1045), alloy steels (4140, 4340), stainless steels (304, 316), and tool steels are all commonly forged. The best choice depends on your specific application requirements, including strength needs, operating environment, and cost considerations. MAIKONG can help you select the optimal material for your components.

What are the minimum and maximum sizes for forged steel parts?

Steel forging can produce components ranging from small fasteners weighing a few ounces to massive industrial parts weighing several tons. At MAIKONG, our equipment can accommodate a wide range of part sizes. The specific limitations depend on the forging method used and available equipment.

How does forging affect the cost of steel components?

While forging typically has higher initial tooling costs compared to some other manufacturing methods, it often results in lower per-unit costs for medium to high-volume production. Additionally, forged components generally offer longer service life and better performance, providing better long-term value and reduced maintenance costs.

What quality standards does MAIKONG follow for steel forging?

MAIKONG adheres to ISO 9001:2015 quality management standards and can meet industry-specific requirements including ASTM, ASME, and automotive standards. Our comprehensive quality control process includes material verification, in-process inspections, and final testing to ensure all components meet or exceed specified requirements.

Automotive Components

Automotive Components Aerospace Parts

Aerospace Parts Construction Equipment

Construction Equipment Oil & Gas Components

Oil & Gas Components Railway Equipment

Railway Equipment Tools & Hardware

Tools & Hardware