Brass extrusion stands as one of the most versatile and cost-effective manufacturing processes for creating precision components with complex profiles. This comprehensive guide explores why brass extrusion should be your material and process of choice for engineering applications that demand reliability, precision, and aesthetic appeal. MAIKONG brings decades of expertise in brass extrusion to US engineering firms seeking high-quality, cost-effective manufacturing solutions with the perfect balance of performance and value.

Understanding Brass Extrusion: The Manufacturing Process

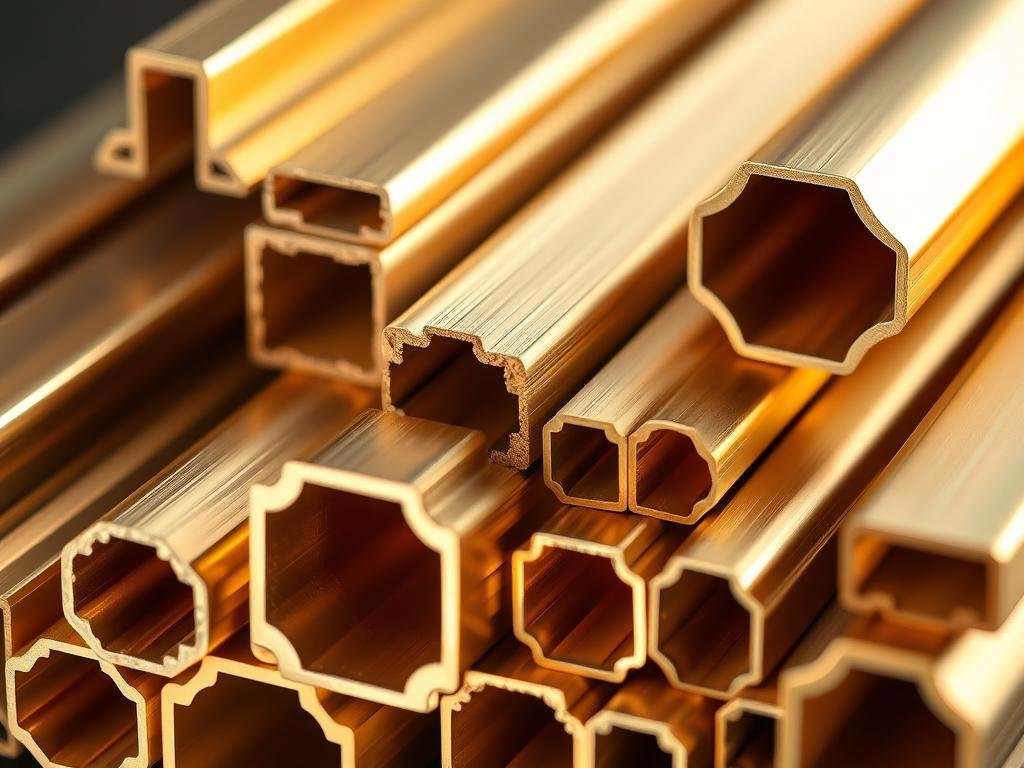

The brass extrusion process at MAIKONG’s state-of-the-art facility

Brass extrusion is a specialized metal working process where brass alloy is heated to a specific temperature and then forced through a die to create a fixed cross-sectional profile. This versatile manufacturing technique allows for the creation of complex shapes with consistent dimensions throughout the length of the extruded piece.

The process begins with selecting the appropriate brass alloy based on the desired mechanical properties and application requirements. The brass is then heated to its recrystallization temperature, where it becomes malleable without fully melting. Using powerful hydraulic presses, the material is forced through precision-engineered dies to form the desired shape.

Types of Brass Extrusion Processes

Direct Extrusion

In direct brass extrusion, the billet, ram, and punch move in the same direction. This method is ideal for creating simple shapes with excellent surface finishes and is highly efficient for large production volumes.

Indirect Extrusion

Indirect extrusion involves the punch and billet moving in opposite directions. This technique requires less force than direct extrusion and produces minimal friction, making it suitable for certain specialized applications.

Expert Brass Extrusion Services

Looking for precision brass extrusion for your engineering project? MAIKONG offers comprehensive manufacturing solutions with industry-leading quality.

Request a Consultation

Key Advantages of Brass Extrusion for Engineering Applications

When considering materials for your engineering project, brass extrusion offers numerous advantages that make it an excellent choice for a wide range of applications. Understanding these benefits helps explain why brass continues to be a preferred material in modern manufacturing.

Advantages of Brass Extrusion

- Exceptional machinability allowing for complex profiles

- Superior corrosion resistance in various environments

- Excellent thermal and electrical conductivity

- Attractive aesthetic appearance with natural gold-like finish

- High strength-to-weight ratio compared to other metals

- Cost-effective manufacturing for both small and large runs

- Excellent dimensional stability and accuracy

- Good resistance to wear and fatigue

Limitations to Consider

- Higher initial tooling costs for complex profiles

- Not suitable for extremely high-temperature applications

- May require additional finishing for certain aesthetic requirements

- Some brass alloys contain lead (though lead-free options are available)

Comparing Brass Extrusion to Other Manufacturing Methods

| Manufacturing Method |

Cost Efficiency |

Dimensional Accuracy |

Surface Finish |

Production Speed |

Material Waste |

| Brass Extrusion |

High |

Excellent |

Very Good |

Fast |

Minimal |

| Brass Casting |

Medium |

Good |

Fair |

Medium |

Medium |

| Brass Machining |

Low |

Excellent |

Excellent |

Slow |

High |

| Brass Forging |

Medium |

Good |

Good |

Medium |

Low |

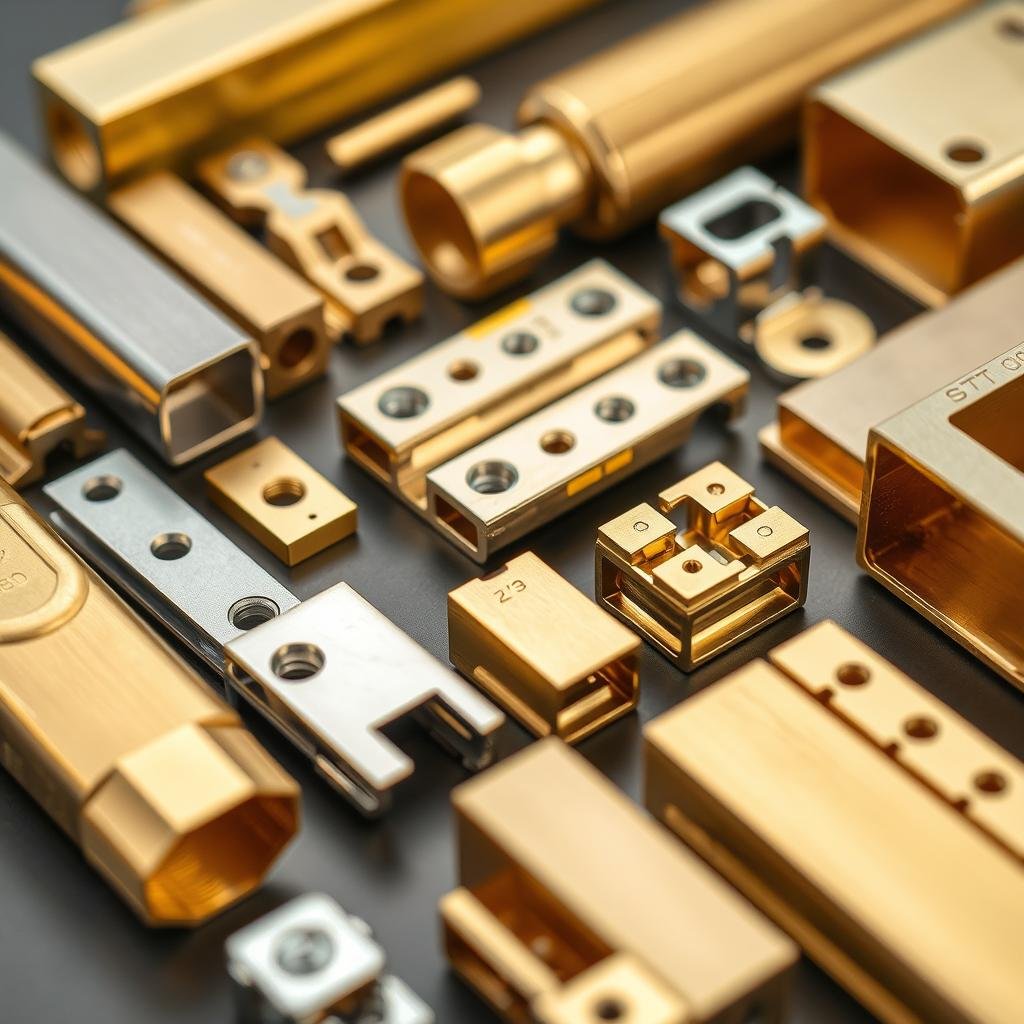

Industrial Applications of Brass Extrusion Products

The versatility of brass extrusion makes it suitable for a wide range of industrial applications across multiple sectors. The unique combination of properties offered by brass—including its corrosion resistance, conductivity, and aesthetic appeal—makes extruded brass components essential in many engineering projects.

Architectural Applications

- Decorative trim and moldings

- Door and window frames

- Handrails and balustrades

- Curtain wall components

Plumbing and HVAC

- Pipes and tubing

- Valves and fittings

- Heat exchanger components

- Manifolds and distribution systems

Electrical Components

- Electrical connectors

- Terminal blocks

- Busbars and conductors

- Switch and relay components

Automotive Industry

- Radiator components

- Fuel system parts

- Electrical connectors

- Decorative trim elements

Industrial Equipment

- Pneumatic and hydraulic fittings

- Bearing components

- Gear and drive elements

- Instrumentation parts

Marine Applications

- Corrosion-resistant fittings

- Propeller components

- Navigation equipment parts

- Decorative hardware

Need Custom Brass Extrusion for Your Industry?

MAIKONG specializes in custom brass extrusion solutions for diverse industrial applications. Our engineering team can help design and manufacture the perfect components for your specific needs.

Request a Custom Quote

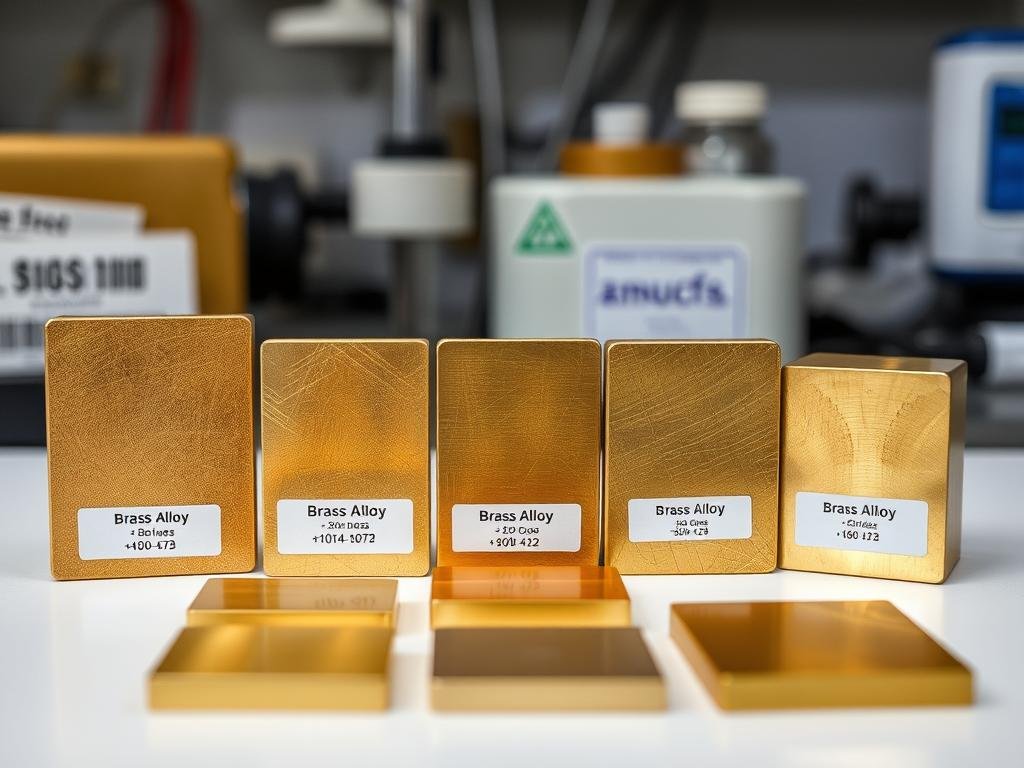

Optimal Brass Alloys for Brass Extrusion

Selecting the right brass alloy is crucial for successful brass extrusion projects. Different alloys offer varying mechanical properties, corrosion resistance, and machinability. At MAIKONG, we work with a wide range of brass alloys to ensure the optimal material selection for your specific application requirements.

Common Brass Alloys for Extrusion

| Alloy Designation |

Composition |

Properties |

Typical Applications |

| C26000 (Cartridge Brass) |

70% Copper, 30% Zinc |

Excellent ductility, good strength |

Cartridge cases, hardware, fasteners |

| C27000 (Yellow Brass) |

65% Copper, 35% Zinc |

Good formability, moderate strength |

Plumbing components, decorative hardware |

| C35300 (High Leaded Brass) |

62% Copper, 36% Zinc, 2% Lead |

Excellent machinability, moderate strength |

Screw machine products, valves, fittings |

| C38000 (Architectural Bronze) |

57% Copper, 40% Zinc, 3% Lead |

Good machinability, moderate strength |

Architectural components, decorative elements |

| C48500 (Naval Brass) |

60% Copper, 39% Zinc, 1% Tin |

Excellent corrosion resistance, good strength |

Marine hardware, propeller shafts |

Lead-Free Brass Alloys

With increasing environmental regulations, particularly in plumbing and potable water applications, lead-free brass alloys have become more important. MAIKONG offers several lead-free brass options for brass extrusion that comply with international standards while maintaining excellent machinability and performance characteristics.

MAIKONG’s Brass Extrusion Manufacturing Capabilities

At MAIKONG, we pride ourselves on our comprehensive brass extrusion capabilities. Our state-of-the-art facility in GD, SZ is equipped with advanced machinery and staffed by skilled technicians with decades of combined experience in precision metal manufacturing.

Our Brass Extrusion Equipment

- Multiple hydraulic extrusion presses (600-2000 ton capacity)

- Precision-engineered dies for complex profiles

- Advanced heating and cooling systems

- Automated cutting and finishing equipment

- State-of-the-art CNC machining centers for secondary operations

Quality Control for Brass Extrusion

Quality is at the heart of everything we do at MAIKONG. Our comprehensive quality control process ensures that every brass extrusion product meets or exceeds industry standards and customer specifications.

- Material certification and testing

- Dimensional inspection using precision measuring equipment

- Surface finish evaluation

- Mechanical property testing

- Chemical composition analysis

- ISO 9001:2015 certified quality management system

Partner with MAIKONG for Your Brass Extrusion Needs

Looking for a reliable manufacturing partner for your brass components? MAIKONG offers cost-effective, high-quality brass extrusion services with quick turnaround times.

Become a US Distributor

Design Considerations for Brass Extrusion Projects

Successful brass extrusion projects begin with thoughtful design that considers both the capabilities of the manufacturing process and the requirements of the end application. Our engineering team at MAIKONG works closely with clients to optimize designs for manufacturability while meeting performance specifications.

Key Design Factors for Brass Extrusion

Wall Thickness

Maintaining uniform wall thickness throughout the profile helps ensure consistent material flow during extrusion. Minimum recommended wall thickness is typically 0.8mm for most brass alloys.

Corner Radii

Sharp corners should be avoided in brass extrusion designs. Internal corners should have a minimum radius of 0.5mm to prevent stress concentration and die failure.

Symmetry

Symmetrical profiles generally extrude more consistently and with better dimensional accuracy than asymmetrical designs. When asymmetry is necessary, additional considerations may be required.

Tolerances and Surface Finish

Brass extrusion can achieve excellent dimensional accuracy and surface finish, but understanding the practical limitations helps set realistic expectations for your project.

| Dimension Type |

Standard Tolerance |

Precision Tolerance |

| Linear dimensions |

±0.2mm |

±0.1mm |

| Angular dimensions |

±1° |

±0.5° |

| Straightness (per meter) |

1.5mm |

0.8mm |

| Surface roughness (Ra) |

1.6μm |

0.8μm |

What is the maximum size for brass extrusion profiles?

At MAIKONG, our equipment can handle brass extrusion profiles with circumscribing circles up to 200mm in diameter. Larger profiles may be possible with special considerations. Contact our engineering team to discuss your specific requirements.

Can complex shapes be achieved with brass extrusion?

Yes, brass extrusion can produce highly complex shapes with multiple hollows, thin walls, and intricate features. However, the complexity of the design affects tooling costs and production efficiency. Our design team can help optimize your profile for both performance and manufacturability.

What secondary operations are available for brass extrusions?

MAIKONG offers comprehensive secondary operations for brass extrusion products, including CNC machining, drilling, tapping, cutting to length, bending, surface finishing, and more. This allows us to deliver components that are ready for assembly or further processing.

Conclusion: The Future of Brass Extrusion in US Engineering

Brass extrusion continues to be a vital manufacturing process for creating precision components across numerous industries. As engineering requirements become more demanding and complex, the versatility, cost-effectiveness, and reliability of extruded brass make it an ideal choice for forward-thinking projects.

At MAIKONG, we remain committed to advancing brass extrusion technology and capabilities to meet the evolving needs of US engineering firms. Our investment in state-of-the-art equipment, ongoing process improvements, and skilled technical staff ensures that we can deliver the highest quality brass components for your most challenging applications.

Contact MAIKONG today to learn how our brass extrusion expertise can benefit your next engineering project. Our team is ready to provide the guidance, technical support, and manufacturing excellence you need to succeed.

Start Your Brass Extrusion Project Today

Ready to bring your design to life? Contact MAIKONG for expert brass extrusion manufacturing services.

Request a Quote

Website: https://maikongforge.us