Brass extrusion represents one of the most efficient and versatile metal forming processes available to modern manufacturers. This transformative technique allows for the creation of complex cross-sectional profiles with exceptional dimensional accuracy and superior mechanical properties. As global manufacturing continues to demand higher precision, greater efficiency, and more cost-effective production methods, brass extrusion stands out as a premier solution for creating components that excel in both form and function.

Understanding the Brass Extrusion Process

The brass extrusion process creates uniform cross-sections with exceptional precision

Brass extrusion is a specialized manufacturing process where brass alloy is heated to an optimal temperature and then forced through a precisely engineered die to create a specific shape or profile. This technique allows manufacturers to produce components with consistent cross-sections along their entire length, making it ideal for creating everything from simple rods and tubes to complex architectural and industrial components.

The process begins with selecting the appropriate brass alloy based on the desired mechanical properties and application requirements. The brass is then heated to its recrystallization temperature—the point where the metal becomes malleable without fully melting. Using hydraulic presses that can exert tremendous force, the brass is pushed through a die that shapes it into the desired profile.

Types of Brass Extrusion Processes

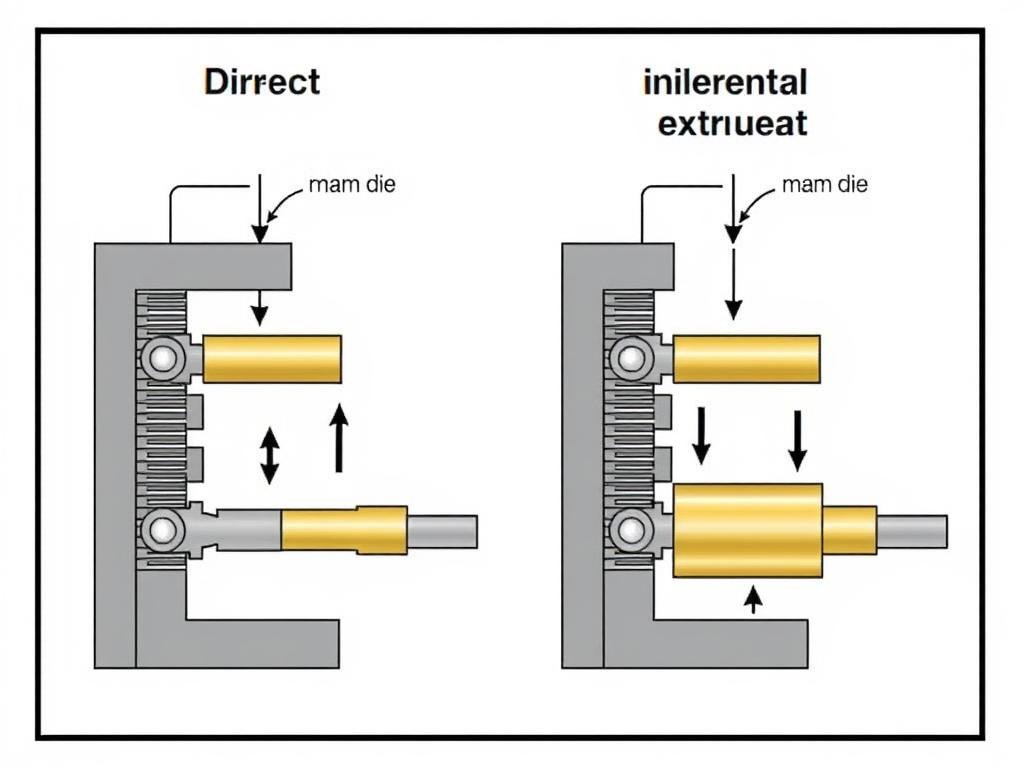

Direct Extrusion

In direct extrusion, the brass billet, ram, and punch move in the same direction. The material flows in the direction of the ram movement, creating friction between the billet and container walls. This method is ideal for producing simple shapes with excellent surface finish and is highly efficient for large production volumes.

Indirect Extrusion

During indirect extrusion, the punch and billet move in opposite directions. Since there is minimal relative motion between the container and billet, this method generates less friction and requires less force than direct extrusion. It’s particularly suitable for complex profiles that require precise dimensional control.

Comparison of direct and indirect brass extrusion methods

Key Advantages of Brass Extrusion Over Other Manufacturing Methods

Advantages of Brass Extrusion

- Exceptional dimensional accuracy and consistency

- Superior surface finish requiring minimal post-processing

- Enhanced mechanical properties through grain alignment

- Efficient material usage with minimal waste

- Cost-effective for medium to high volume production

- Ability to create complex cross-sectional profiles

- Excellent strength-to-weight ratio in finished components

- Improved corrosion resistance compared to cast brass

Limitations to Consider

- Higher initial tooling costs for custom dies

- Size limitations based on available equipment

- Not economical for very small production runs

- Uniform cross-section throughout the length

- Requires specialized equipment and expertise

When compared to alternative manufacturing methods like casting or machining from solid stock, brass extrusion offers significant advantages in terms of material integrity and production efficiency. The extrusion process aligns the grain structure of the brass, resulting in components with superior mechanical properties and consistency.

| Manufacturing Method |

Material Integrity |

Production Speed |

Dimensional Accuracy |

Surface Finish |

Cost-Effectiveness |

| Brass Extrusion |

Excellent – aligned grain structure |

High – continuous process |

±0.120mm typical |

Superior |

High for medium/large volumes |

| Brass Casting |

Fair – potential for voids |

Medium |

±0.250mm typical |

Requires finishing |

Good for complex shapes |

| CNC Machining |

Good – depends on stock |

Low |

±0.050mm typical |

Excellent |

Low for high volumes |

Industrial Applications of Extruded Brass Components

Diverse applications of extruded brass components across industries

The versatility of extruded brass makes it an ideal material for countless applications across various industries. The combination of excellent mechanical properties, corrosion resistance, and aesthetic appeal has established brass as a preferred material for components that demand both performance and visual appeal.

Plumbing & HVAC

- Pipe fittings and connectors

- Valve bodies and components

- Water distribution manifolds

- Heat exchanger components

Electrical & Electronics

- Electrical connectors

- Terminal blocks

- Busbar components

- Heat sink profiles

Architectural & Decorative

- Handrails and balustrades

- Window and door frames

- Decorative moldings

- Furniture components

Automotive

- Radiator components

- Fuel system fittings

- Electrical connectors

- Decorative trim elements

Industrial Equipment

- Pneumatic system components

- Hydraulic fittings

- Bearing housings

- Wear-resistant guides

Marine Applications

- Corrosion-resistant fittings

- Propeller components

- Navigation equipment parts

- Decorative hardware

Explore Custom Brass Extrusion Solutions

Discover how MAIKONG’s precision brass extrusion capabilities can enhance your product performance and reduce manufacturing costs.

Request a Consultation

Technical Considerations for Brass Extrusion Manufacturing

Optimal Brass Alloys for Extrusion

The selection of the appropriate brass alloy is crucial for successful extrusion operations. Different alloys offer varying combinations of strength, ductility, corrosion resistance, and machinability. At MAIKONG, we work with a wide range of brass alloys to meet specific application requirements.

Selection of brass alloy billets ready for the extrusion process

| Brass Alloy |

Composition |

Extrudability |

Strength |

Corrosion Resistance |

Typical Applications |

| C26000 (Cartridge Brass) |

70% Cu, 30% Zn |

Excellent |

Moderate |

Good |

Plumbing, electrical components |

| C27000 (Yellow Brass) |

65% Cu, 35% Zn |

Very Good |

Moderate |

Good |

Hardware, decorative components |

| C35300 (High Leaded Brass) |

62% Cu, 35.5% Zn, 2.5% Pb |

Excellent |

Moderate |

Good |

Machined components, valves |

| C38000 (Architectural Bronze) |

57% Cu, 40% Zn, 3% Pb |

Good |

High |

Excellent |

Architectural elements, marine hardware |

Surface Finishes for Extruded Brass

The appearance and performance of extruded brass components can be enhanced through various surface finishing techniques. These processes not only improve aesthetic appeal but can also enhance corrosion resistance, wear resistance, and other functional properties.

Polishing

Mechanical polishing creates a smooth, reflective surface that highlights brass’s natural golden appearance. This finish is ideal for decorative applications and components where visual appeal is important.

Anodizing

The anodizing process creates a protective oxide layer on the brass surface, enhancing corrosion resistance and providing a base for coloring. This finish is commonly used for architectural and outdoor applications.

Electroplating

Applying a thin layer of another metal (such as nickel, chrome, or gold) to the brass surface can enhance appearance, corrosion resistance, and wear properties. This versatile finish is used across many industries.

Various surface finishes applied to extruded brass components

MAIKONG’s Advanced Brass Extrusion Capabilities

MAIKONG’s state-of-the-art brass extrusion manufacturing facility in GD, SZ

At MAIKONG, we’ve invested in cutting-edge extrusion technology and quality control systems to deliver superior brass components to our global partners. Our comprehensive manufacturing capabilities ensure that we can meet the most demanding specifications while maintaining cost-effectiveness and reliability.

Manufacturing Excellence

- State-of-the-art hydraulic extrusion presses

- Advanced die design and manufacturing

- Precision CNC machining for secondary operations

- Comprehensive heat treatment facilities

- In-house surface finishing capabilities

- Rigorous quality control at every production stage

Quality Assurance

- ISO 9001:2015 certified quality management system

- Advanced material testing laboratory

- Dimensional inspection using precision equipment

- Non-destructive testing capabilities

- Comprehensive documentation and traceability

- Continuous process improvement methodology

Rigorous quality control inspection of brass extrusion components

“Our integrated manufacturing approach allows us to control every aspect of the brass extrusion process, from alloy selection to final finishing. This ensures consistent quality, competitive pricing, and reliable delivery for our global partners.”

– MAIKONG Engineering Team

Custom Brass Extrusion Solutions for Your Specific Requirements

MAIKONG specializes in developing custom brass extrusion solutions tailored to meet the unique requirements of our clients. Our engineering team works closely with customers from concept to production, ensuring that each component is optimized for performance, manufacturability, and cost-effectiveness.

MAIKONG engineers collaborating on custom brass extrusion designs

Our Design-to-Production Process

1. Consultation

We begin by understanding your application requirements, performance specifications, and production volumes to establish clear project parameters.

2. Design & Engineering

Our engineering team develops optimized designs, selects appropriate alloys, and creates detailed production specifications for your approval.

3. Prototyping

We produce prototype components for validation testing, allowing for design refinements before full-scale production begins.

4. Production

Once designs are approved, we implement efficient production processes with comprehensive quality control to ensure consistent results.

Ready to Discuss Your Custom Brass Extrusion Project?

Contact our engineering team today to explore how MAIKONG can deliver precision brass components that meet your exact specifications.

Email Our Team

Become a US Distributor for MAIKONG Brass Components

Join MAIKONG’s growing network of US distribution partners

MAIKONG is actively seeking distribution partners across the United States to represent our high-quality brass extrusion products. As a distributor, you’ll gain access to our comprehensive range of precision components, competitive pricing, and reliable supply chain to serve your local market.

Distributor Benefits

- Exclusive territorial rights in your region

- Competitive pricing structure with attractive margins

- Comprehensive product training and technical support

- Marketing materials and sales support

- Reliable supply chain with consistent quality

- Custom product development capabilities

- Regular new product introductions

- Dedicated account management

Why partner with MAIKONG? Our combination of advanced manufacturing capabilities, competitive pricing, and commitment to quality makes us an ideal partner for distributors looking to expand their product offerings in the US market.

Become a MAIKONG Distributor Today

Take the first step toward a profitable partnership with one of the leading brass extrusion manufacturers. Contact us to discuss distribution opportunities in your region.

Apply for Distributorship

Why Choose MAIKONG for Your Brass Extrusion Needs

Precision brass extrusion components manufactured by MAIKONG

MAIKONG combines advanced manufacturing technology, rigorous quality control, and competitive pricing to deliver superior brass extrusion components to our global partners. Our integrated approach to manufacturing ensures consistent quality, on-time delivery, and exceptional value for our customers.

Manufacturing Quality

4.8/5

Whether you’re looking for standard brass extrusion components or custom-engineered solutions, MAIKONG has the expertise, capabilities, and commitment to quality to meet your needs. Contact us today to discuss how we can support your manufacturing requirements or distribution opportunities.