Brass extrusion is a versatile metalworking process that transforms brass alloys into precisely shaped profiles with exceptional consistency and structural integrity. For industrial buyers seeking cost-effective, high-quality brass components, understanding this manufacturing technique is essential for making informed procurement decisions. This comprehensive guide explores the fundamentals of brass extrusion, its advantages over alternative manufacturing methods, and how MAIKONG’s expertise can deliver superior results for your specific application needs.

The Fundamentals of Brass Extrusion Technology

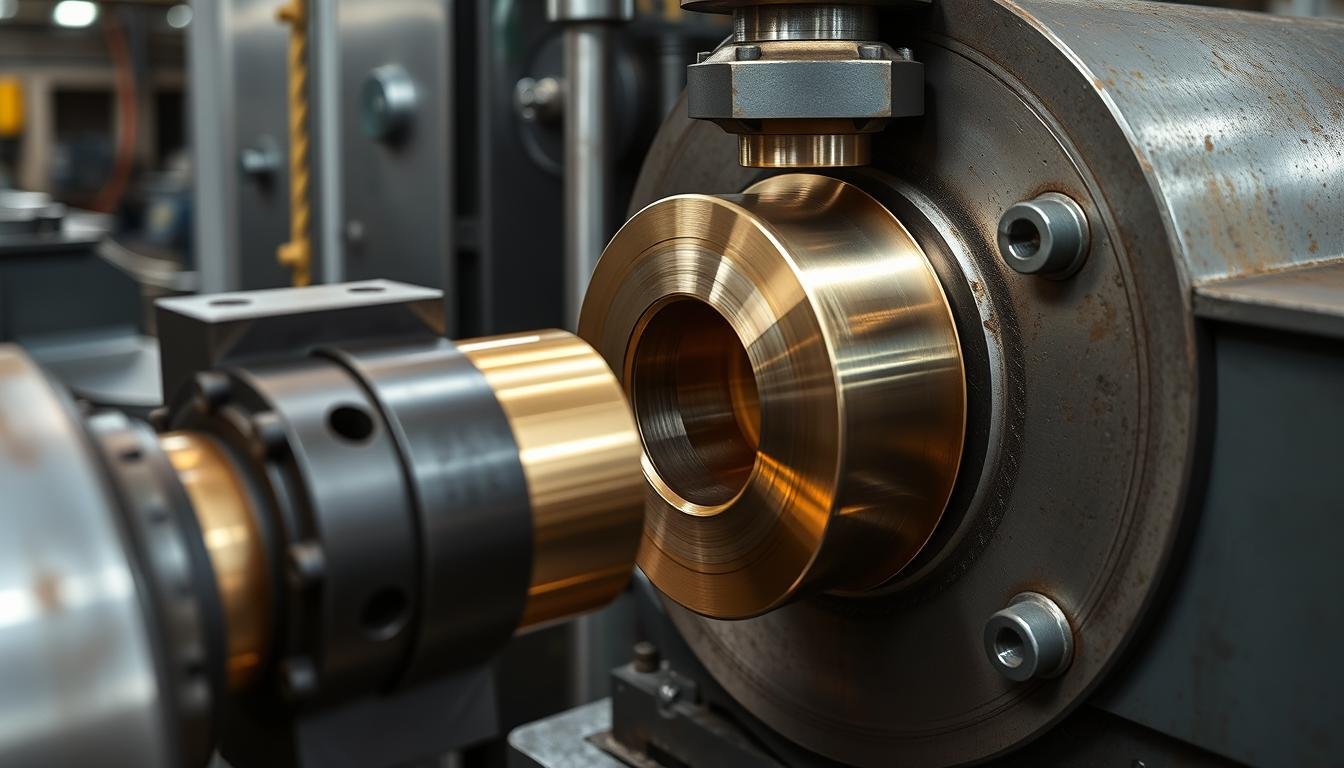

Industrial brass extrusion process at MAIKONG’s state-of-the-art manufacturing facility

At its core, brass extrusion involves forcing heated brass material through a specially designed die to create continuous profiles with consistent cross-sections. This manufacturing technique transforms raw brass billets into functional components with precise dimensions and excellent surface finish. The process leverages brass’s natural malleability and flow characteristics to produce complex shapes that would be difficult or impossible to achieve through other manufacturing methods.

How Brass Extrusion Works: The Manufacturing Process

The brass extrusion process begins with selecting the appropriate brass alloy based on the desired mechanical properties and application requirements. Common alloys include C26000 (70% copper, 30% zinc), C36000 (free-cutting brass), and C38500 (architectural bronze). Each alloy offers different characteristics in terms of strength, machinability, and corrosion resistance.

Various brass alloy billets prepared for the extrusion process at MAIKONG

The manufacturing sequence follows these key steps:

- Material Preparation: Brass billets are cut to size and heated to temperatures between 650-850°C, depending on the specific alloy composition.

- Lubrication: The heated billet is coated with a lubricant to reduce friction during the extrusion process.

- Extrusion: The billet is placed in a container and pressed through a die using hydraulic pressure, forming the desired cross-sectional profile.

- Cooling: The extruded profile is cooled in a controlled environment to prevent warping or dimensional changes.

- Straightening: The profile undergoes straightening to ensure dimensional accuracy.

- Finishing: Additional processes such as cutting, machining, or surface treatments may be applied to meet final specifications.

Types of Brass Extrusion Methods

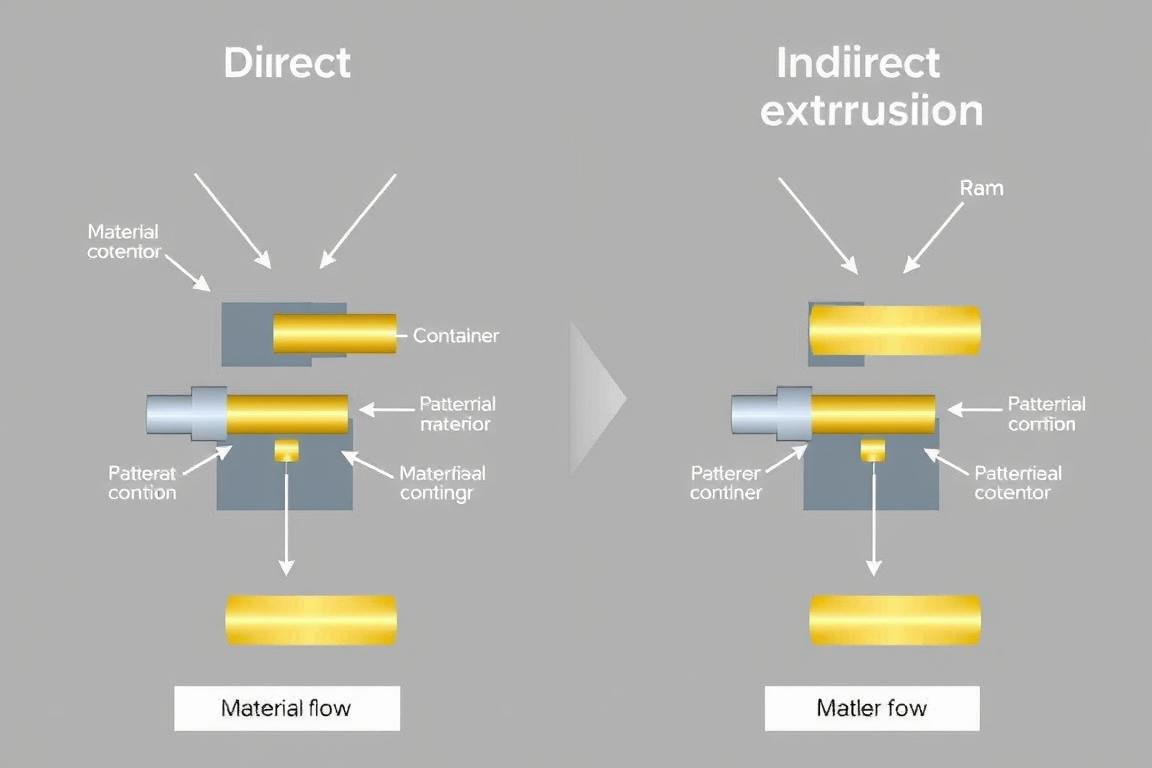

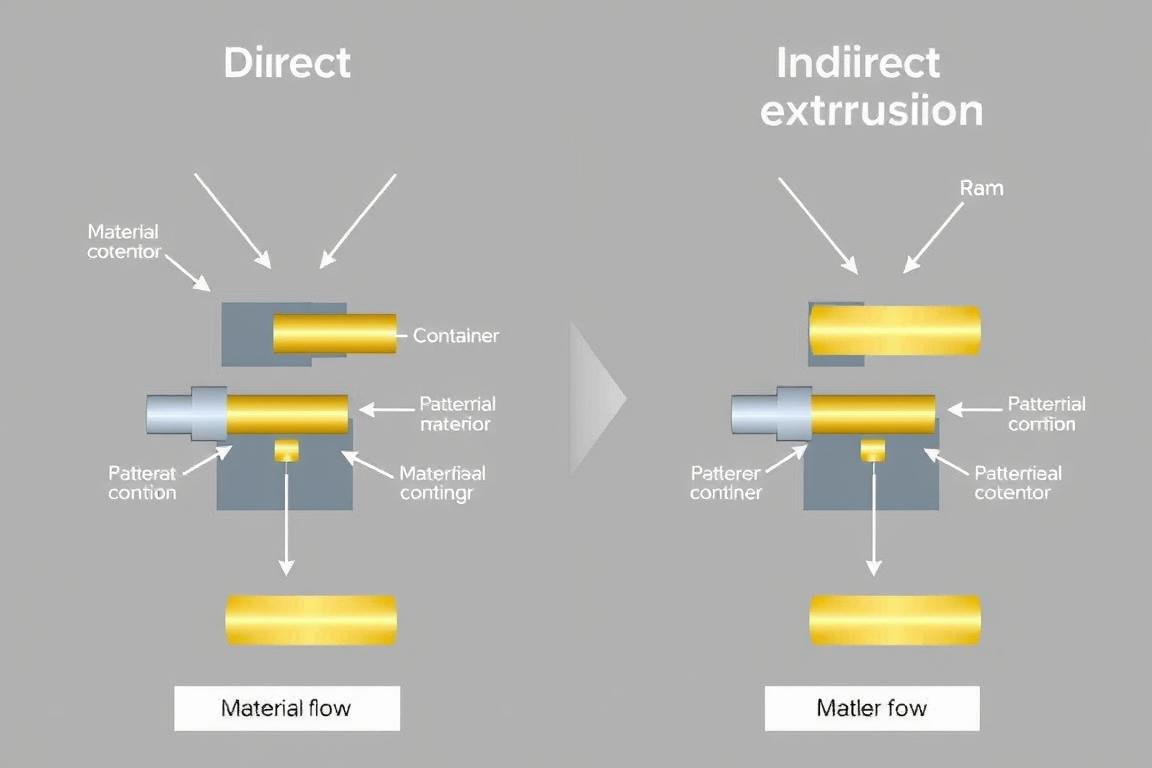

The two primary methods of brass extrusion are:

- Direct Extrusion (Forward Extrusion): The brass billet is placed in a container and pushed through the die by a ram. This method is widely used for producing standard profiles and offers excellent control over the extrusion process.

- Indirect Extrusion (Backward Extrusion): The die moves against the stationary billet, resulting in less friction and allowing for more complex profiles. This method is particularly useful for thin-walled and intricate brass shapes.

Additionally, brass extrusion can be classified based on temperature:

- Hot Extrusion: Performed at elevated temperatures (650-850°C) to increase material plasticity and reduce the force required.

- Cold Extrusion: Conducted at room temperature or slightly elevated temperatures, offering better dimensional accuracy and surface finish but requiring greater force.

Comparison of direct and indirect brass extrusion methods

Advantages of Brass Extrusion Over Other Manufacturing Processes

When compared to alternative manufacturing methods like casting, machining, or forging, brass extrusion offers numerous advantages that make it the preferred choice for many industrial applications.

Complex brass profiles manufactured through MAIKONG’s precision extrusion process

Advantages of Brass Extrusion

- Excellent material utilization with minimal waste

- Consistent cross-sectional dimensions throughout the entire length

- Superior mechanical properties due to aligned grain structure

- Ability to produce complex shapes in a single operation

- Cost-effective for medium to high volume production

- Excellent surface finish requiring minimal post-processing

- Enhanced strength-to-weight ratio compared to cast components

- Tight dimensional tolerances and repeatability

Limitations to Consider

- Initial tooling costs for custom dies

- Size limitations based on press capacity

- Certain complex geometries may require secondary operations

- Not economical for very low production volumes

- Cross-sectional shape must remain constant throughout the length

Strength and Durability Benefits of Brass Extrusion

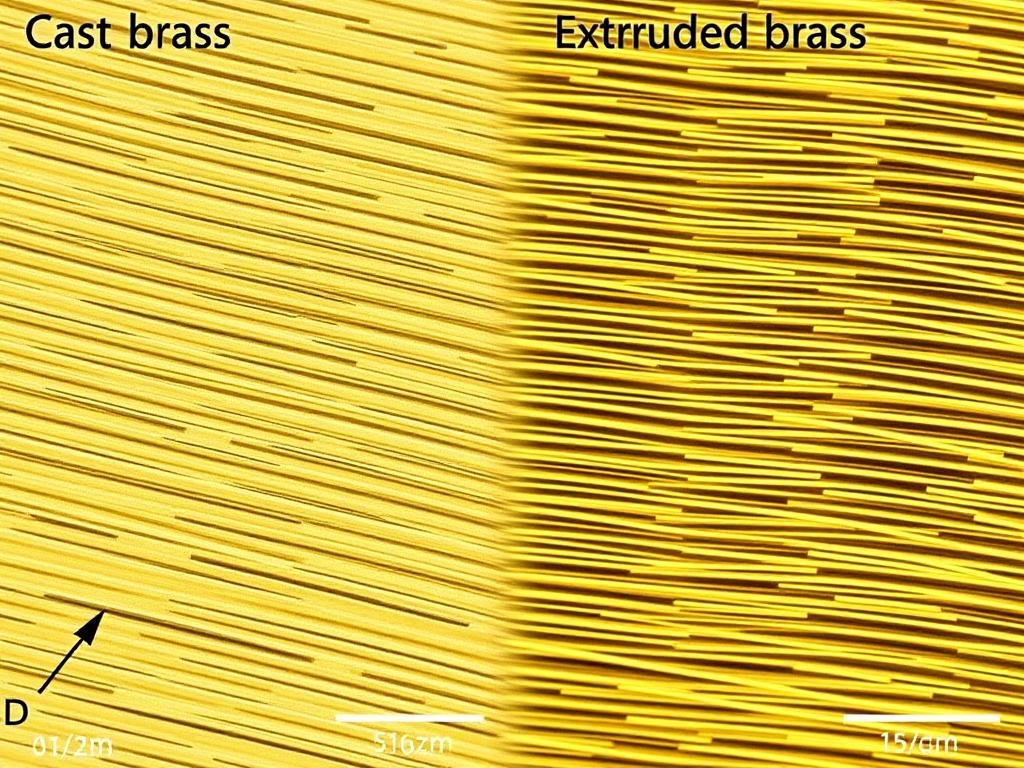

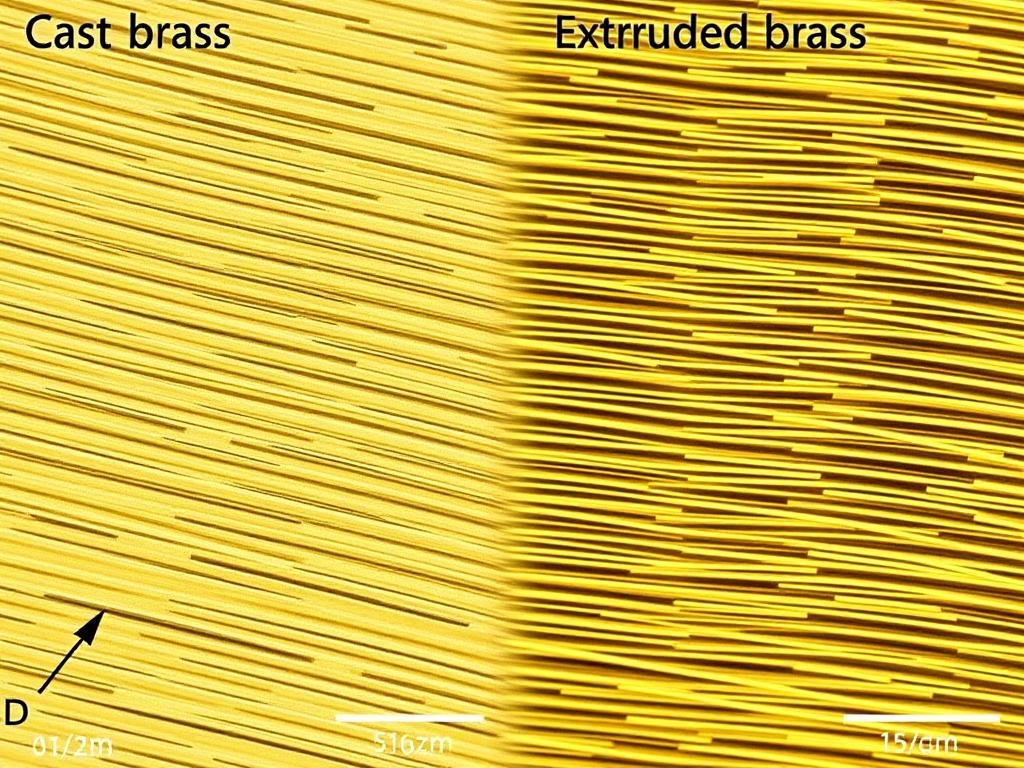

The brass extrusion process significantly enhances the mechanical properties of the final product through grain refinement and alignment. During extrusion, the material’s grain structure becomes oriented in the direction of metal flow, resulting in:

- Improved tensile strength: Extruded brass typically exhibits 15-25% higher tensile strength compared to cast brass of the same composition.

- Enhanced fatigue resistance: The aligned grain structure increases resistance to cyclic loading, making extruded brass ideal for components subject to repeated stress.

- Superior wear resistance: The dense, uniform structure of extruded brass provides excellent wear characteristics, extending component lifespan.

- Better corrosion resistance: The elimination of porosity and inclusions improves the material’s resistance to environmental degradation.

Microscopic comparison showing the superior grain structure of extruded brass (right) versus cast brass (left)

Cost-Effectiveness of Brass Extrusion Production

From an economic perspective, brass extrusion offers compelling advantages for industrial buyers:

- Material efficiency: The extrusion process typically achieves 90-95% material utilization, significantly reducing waste compared to machining operations.

- Reduced secondary operations: The excellent surface finish and dimensional accuracy of extruded profiles often eliminate or minimize the need for costly secondary machining.

- Tooling longevity: Well-maintained extrusion dies can produce thousands of components before requiring replacement, amortizing the initial tooling investment across large production runs.

- Production speed: Once set up, the extrusion process can produce components at rates significantly faster than alternative manufacturing methods.

- Consistent quality: The repeatable nature of the extrusion process reduces inspection costs and minimizes rejection rates.

- Design flexibility: Complex cross-sections that would require multiple machining operations can be produced in a single extrusion pass.

Ready to Optimize Your Brass Component Production?

MAIKONG offers industry-leading brass extrusion services with competitive pricing and exceptional quality. Our engineering team can help you design cost-effective solutions for your specific application needs.

Request a Quote Today

MAIKONG’s Brass Extrusion Capabilities and Services

At MAIKONG, we combine advanced technology with decades of metallurgical expertise to deliver superior brass extrusion solutions for US industrial buyers. Our comprehensive service offering spans from initial design consultation through production and finishing operations.

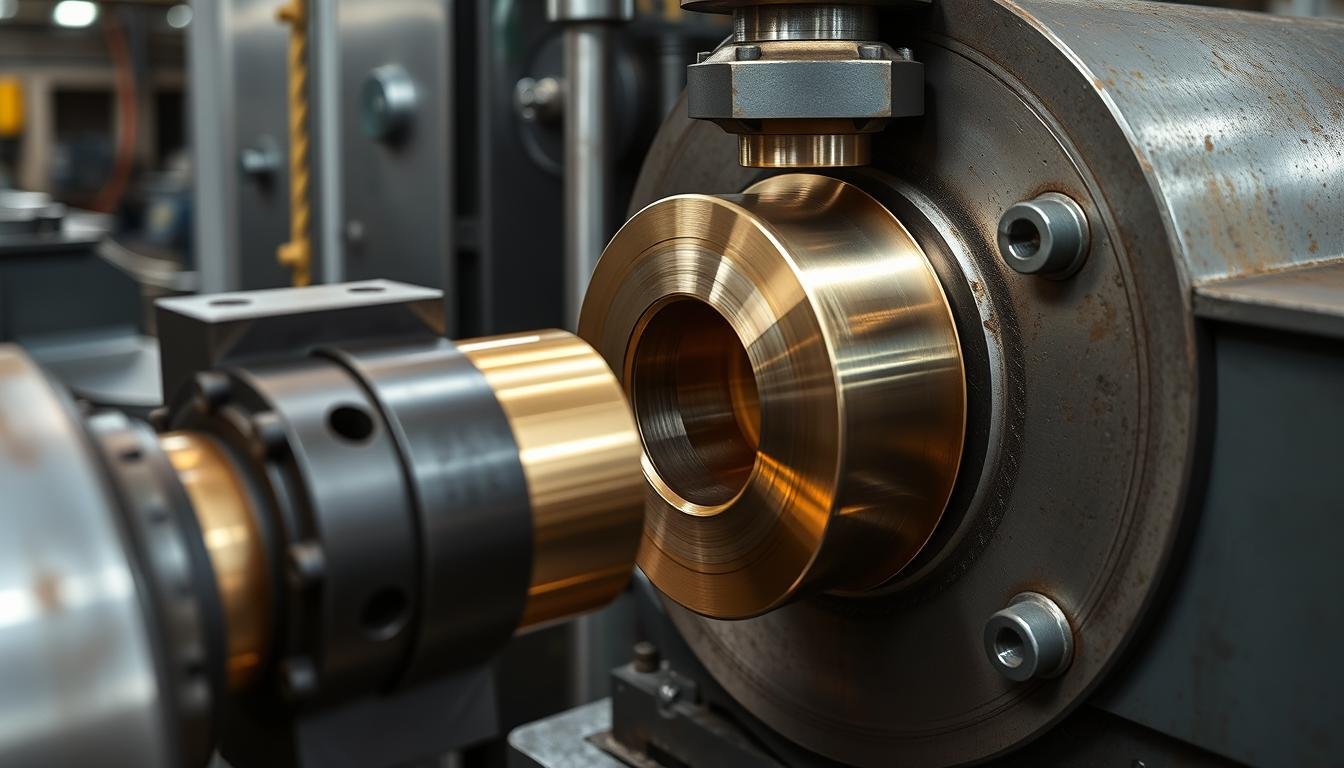

MAIKONG’s state-of-the-art brass extrusion facility in GD, SZ

Our State-of-the-Art Brass Extrusion Facilities

MAIKONG’s manufacturing complex in GD, SZ houses advanced extrusion equipment capable of producing a wide range of brass profiles with exceptional precision:

- Hydraulic extrusion presses: Multiple presses with capacities ranging from 800 to 2,500 tons, capable of handling various billet sizes and production volumes.

- Precision die manufacturing: In-house tooling capabilities for rapid prototyping and production of custom extrusion dies.

- Advanced heating systems: Computer-controlled induction heating for precise temperature control during the extrusion process.

- Automated handling equipment: Robotic systems for consistent material flow and reduced handling damage.

- Comprehensive finishing capabilities: Including cutting, machining, surface treatment, and quality inspection.

| Capability |

Specification |

Advantage |

| Profile Dimensions |

5mm to 190mm cross-sectional dimension |

Accommodates a wide range of component sizes |

| Minimum Wall Thickness |

0.8mm for most alloys |

Enables lightweight, material-efficient designs |

| Length Capability |

Up to 6 meters standard (custom lengths available) |

Flexibility for various application requirements |

| Tolerance Control |

±0.05mm for critical dimensions |

Precision fit and function without secondary operations |

| Surface Finish |

Ra 0.8-1.6 μm typical |

Excellent appearance and reduced finishing requirements |

Quality Assurance in MAIKONG’s Brass Extrusion Process

Quality is the cornerstone of MAIKONG’s manufacturing philosophy. Our comprehensive quality management system ensures consistent excellence in every brass extrusion we produce:

- Material verification: Spectrographic analysis of incoming brass alloys to confirm chemical composition.

- Process monitoring: Continuous monitoring of critical parameters including temperature, pressure, and extrusion speed.

- Dimensional inspection: Advanced coordinate measuring machines (CMM) for precise verification of profile dimensions.

- Mechanical testing: Regular testing of tensile strength, hardness, and other mechanical properties.

- Surface quality inspection: Visual and automated inspection systems to identify surface defects.

- Traceability: Complete lot traceability from raw material to finished product.

MAIKONG’s quality control technician performing dimensional inspection of brass profiles

Experience MAIKONG’s Manufacturing Excellence

Our team of metallurgists and manufacturing engineers is ready to help you optimize your brass component design for maximum performance and cost-effectiveness.

Or reach us via WhatsApp: WhatsApp Contact

Applications of Brass Extrusion Across Industries

The versatility of brass extrusion makes it an ideal manufacturing process for components across numerous industries. The combination of excellent mechanical properties, corrosion resistance, and aesthetic appeal has established brass as a preferred material for both functional and decorative applications.

Diverse applications of MAIKONG’s brass extrusion profiles across multiple industries

Automotive Industry Applications

In the automotive sector, extruded brass components play crucial roles in both functional and aesthetic applications:

- Radiator components: Brass’s excellent thermal conductivity makes it ideal for heat exchangers and cooling system components.

- Electrical connectors: The material’s conductivity and corrosion resistance ensure reliable electrical connections in harsh automotive environments.

- Decorative trim: Extruded brass profiles provide elegant, durable trim elements for both exterior and interior applications.

- Fluid system components: Brass’s compatibility with various fluids makes it suitable for fuel system components and hydraulic fittings.

- Structural elements: In specialized applications, brass extrusions provide structural support with excellent vibration damping characteristics.

- Sensor housings: Precision brass profiles protect sensitive electronic components in engine management systems.

Aerospace and Defense Applications

Precision brass components manufactured by MAIKONG for aerospace applications

The aerospace and defense sectors rely on the precision and reliability of extruded brass for critical components:

- Electrical connectors and terminals: Brass provides reliable electrical connections in mission-critical systems.

- Hydraulic and pneumatic system components: The material’s excellent machinability and pressure resistance make it ideal for fluid system applications.

- Ammunition components: Brass casings offer the perfect balance of strength, ductility, and corrosion resistance.

- Navigation system housings: Precision brass extrusions protect sensitive electronic components from environmental factors.

- Structural elements: In specific applications, brass provides structural support with non-magnetic properties.

Electronics and Electrical Applications

The electronics industry leverages the unique properties of extruded brass for numerous applications:

- Terminal blocks: Brass extrusions provide excellent electrical conductivity and mechanical stability for terminal connections.

- Heat sinks: The material’s thermal conductivity makes it effective for dissipating heat from electronic components.

- Connector housings: Precision brass profiles protect electrical connections while providing electromagnetic shielding.

- Switch components: Brass’s durability and electrical properties make it ideal for high-cycle switching applications.

- PCB standoffs and spacers: Extruded brass provides structural support and electrical grounding for printed circuit boards.

- RF shielding: Brass extrusions create effective barriers against electromagnetic interference in sensitive electronic equipment.

Architectural brass extrusions manufactured by MAIKONG for premium construction projects

Additional industries that benefit from brass extrusion include:

Construction & Architecture

- Decorative trim and moldings

- Handrails and balustrades

- Window and door hardware

- Structural elements

Plumbing & HVAC

- Pipe fittings and valves

- Manifolds and distribution systems

- Heat exchanger components

- Decorative fixtures

Marine Applications

- Corrosion-resistant fittings

- Propeller components

- Electrical connectors

- Decorative hardware

Why Choose MAIKONG for Your Brass Extrusion Needs?

Selecting the right manufacturing partner for your brass components is a critical decision that impacts product quality, cost-effectiveness, and supply chain reliability. MAIKONG offers a compelling value proposition that addresses the key concerns of US industrial buyers.

MAIKONG’s engineering team collaborating with clients on custom brass extrusion solutions

Our Competitive Advantages in Brass Extrusion

Technical Expertise

Our engineering team brings decades of metallurgical and manufacturing experience to every project. We provide comprehensive design support to optimize your components for performance, manufacturability, and cost-effectiveness.

Manufacturing Excellence

MAIKONG’s state-of-the-art production facilities combine advanced technology with rigorous quality control systems to deliver consistent, high-quality brass extrusions that meet or exceed your specifications.

Comprehensive Capabilities

Beyond basic extrusion, we offer a complete range of secondary operations including precision machining, surface finishing, and assembly services, providing a one-stop solution for your brass component needs.

Cost-Effective Solutions

Our efficient manufacturing processes, strategic location in GD, SZ, and economies of scale allow us to offer competitive pricing without compromising quality, helping you optimize your procurement budget.

Responsive Service

We understand the importance of timely communication and reliable delivery. Our dedicated account managers ensure your projects stay on schedule and that any concerns are addressed promptly.

Quality Assurance

MAIKONG’s comprehensive quality management system, including ISO 9001:2015 certification, ensures consistent excellence in every brass extrusion we produce, minimizing your quality control concerns.

MAIKONG’s Commitment to Quality and Precision

Quality is not just a department at MAIKONG—it’s a core value that permeates every aspect of our operation. Our commitment to excellence is reflected in:

- Rigorous material selection: We source only premium brass alloys that meet or exceed industry standards for composition and performance.

- Advanced process controls: Our manufacturing systems incorporate real-time monitoring and statistical process control to ensure consistent quality.

- Comprehensive testing: Every production lot undergoes thorough inspection and testing to verify dimensional accuracy, mechanical properties, and surface quality.

- Continuous improvement: We regularly review and refine our processes to enhance quality, efficiency, and environmental sustainability.

MAIKONG’s advanced quality control laboratory ensures consistent excellence

Partner with MAIKONG for Superior Brass Extrusion Solutions

Join the growing number of US industrial buyers who trust MAIKONG for their critical brass component needs. Our team is ready to discuss your specific requirements and develop a customized manufacturing solution.

Email Us Today

Or call us directly: +86 13-51090-74-01

Conclusion: Advancing Your Manufacturing with Expert Brass Extrusion

Brass extrusion represents an optimal manufacturing solution for a wide range of industrial applications, offering an exceptional combination of performance, aesthetics, and cost-effectiveness. By partnering with MAIKONG, US industrial buyers gain access to world-class manufacturing capabilities, technical expertise, and responsive service that can transform their brass component supply chain.

Whether you’re designing a new product or seeking to optimize an existing component, our team is ready to help you leverage the full potential of brass extrusion technology. With our comprehensive capabilities in CNC machining, metal forging, precision machining, and custom metal fabrication, MAIKONG offers a complete solution for your metal component needs.

Precision brass extrusion products manufactured by MAIKONG for diverse industrial applications

We invite you to experience the MAIKONG difference—where technical excellence, manufacturing precision, and customer-focused service combine to deliver exceptional value for your brass component requirements.

Ready to Discuss Your Brass Extrusion Project?

Contact MAIKONG today to speak with our engineering team about your specific requirements. We’re currently seeking distribution partners and agents throughout the United States.

Email: Lucy@maikongforge.us | Website: https://maikongforge.us