Forged aluminum has emerged as one of the most trusted materials in contemporary engineering and manufacturing. Created through a process that applies high pressure and heat to solid aluminum, forging fundamentally alters the metal’s internal structure, resulting in components with superior strength, durability, and performance characteristics. As industries increasingly prioritize lightweight yet robust materials, forged aluminum continues to gain prominence across aerospace, automotive, medical, and industrial sectors where reliability and precision are non-negotiable requirements.

Understanding Forged Aluminum: The Foundation of Modern Manufacturing

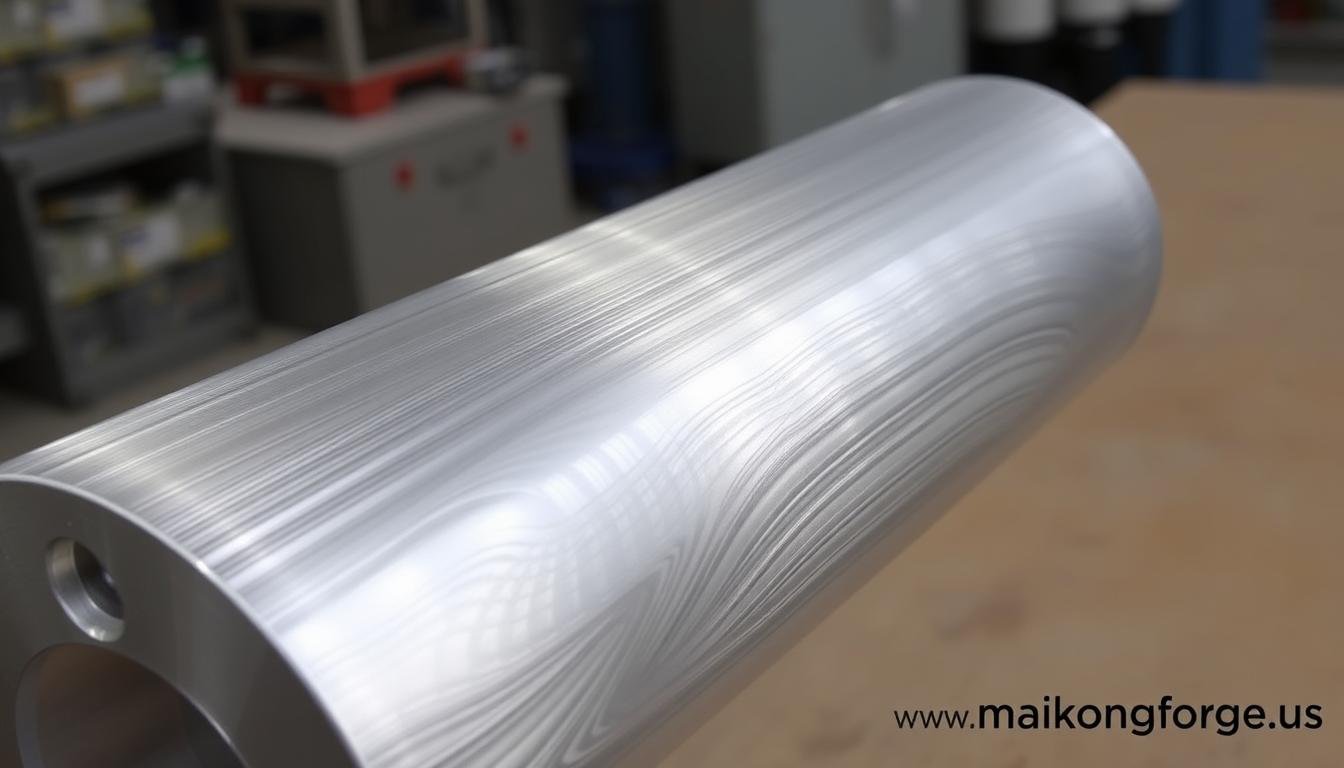

Forged aluminum is produced by applying intense pressure to solid aluminum that has been heated to a malleable state. Unlike casting, which involves pouring molten metal into molds, forging reshapes solid metal through compression forces. This fundamental difference in processing creates a refined grain structure that flows with the shape of the part, eliminating the porosity and internal defects common in cast components.

The forging process at MAIKONG involves several carefully controlled stages:

- Heating – Aluminum billets are heated to a specific temperature range that makes the metal malleable without melting

- Shaping – The heated material is placed in specialized dies and subjected to extreme pressure using hydraulic presses

- Cooling – Controlled cooling ensures the material maintains its enhanced properties

- Finishing – Additional machining or heat treatment may be applied to achieve precise specifications

This comprehensive process results in components with exceptional structural integrity and performance characteristics that simply cannot be achieved through casting or other manufacturing methods.

Superior Mechanical Properties of Forged Aluminum

The mechanical properties of forged aluminum significantly outperform those of cast aluminum across multiple performance metrics. This superiority stems directly from the forging process, which fundamentally alters the metal’s internal structure.

Enhanced Strength and Durability of Forged Aluminum Components

Superior Tensile Strength: Forged aluminum typically exhibits tensile strength values exceeding 50,000 psi, significantly higher than cast aluminum’s range of 23,000-34,500 psi. This enhanced strength results from the elimination of porosity and the alignment of the grain structure during the forging process.

Exceptional Fatigue Resistance: Components manufactured from forged aluminum demonstrate superior resistance to cyclic loading, making them ideal for applications subject to repeated stress cycles. This property is particularly valuable in automotive suspension components, aircraft landing gear, and industrial machinery.

Improved Impact Resistance: The refined grain structure of forged aluminum provides enhanced toughness and impact resistance. This makes forged components significantly more resistant to sudden shocks and impacts compared to their cast counterparts.

Optimized Grain Flow: During forging, the metal’s grain structure aligns with the shape of the component, creating a continuous flow pattern that follows the contours of the part. This alignment significantly enhances structural integrity and resistance to crack propagation.

Need High-Performance Aluminum Components?

MAIKONG specializes in precision forged aluminum parts with superior mechanical properties for demanding applications. Our engineering team can help select the optimal aluminum alloy for your specific requirements.

Discuss Your Project Requirements

Forged Aluminum vs. Cast Aluminum: A Comprehensive Comparison

Understanding the differences between forged aluminum and cast aluminum is crucial for making informed decisions about which manufacturing process best suits your specific application requirements. While both methods produce aluminum components, they differ significantly in terms of mechanical properties, production processes, and suitable applications.

| Comparison Categories |

Forged Aluminum |

Cast Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Lower due to potential air pockets and inclusions |

| Tensile Properties |

Superior tensile strength (typically 30,000-50,000+ psi) |

Lower tensile strength (typically 23,000-34,500 psi) |

| Fatigue Resistance |

Excellent resistance against cyclic loading |

Potentially lower fatigue resistance |

| Complex Geometries |

May require multiple steps for complex shapes |

Can achieve complex shapes in one operation |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies due to shrinkage |

| Surface Finish |

Smoother surfaces, reduced post-processing |

May require more machining due to surface defects |

| Grain Structure |

Directional grain flow for improved properties |

Random grain structure |

| Weight-to-Strength Ratio |

Excellent strength-to-weight ratio |

Requires bulkier parts for equivalent strength |

When to Choose Forged Aluminum for Your Application

Ideal Applications for Forged Aluminum

- Safety-critical components where failure is not an option

- High-stress applications requiring superior mechanical properties

- Parts subject to dynamic loading and fatigue

- Components requiring maximum strength-to-weight ratio

- Applications demanding long-term reliability

Consider Alternatives When

- Extremely complex geometries are required

- Production volume is very high and cost is the primary concern

- Component strength requirements are minimal

- Rapid prototyping is needed

- Visual appearance is more important than structural integrity

For applications where performance, safety, and reliability are paramount, forged aluminum consistently outperforms cast alternatives. While the initial production cost may be higher, the superior mechanical properties and longer service life often result in lower total cost of ownership over the component’s lifetime.

Industrial Applications of Forged Aluminum Components

The exceptional properties of forged aluminum make it the material of choice across numerous industries where performance, reliability, and weight considerations are critical. MAIKONG provides specialized forged aluminum solutions for these diverse applications.

Aerospace Industry

In aerospace applications, forged aluminum components are essential for:

- Aircraft landing gear systems

- Wing and fuselage structural components

- Engine mounts and brackets

- Control surface mechanisms

Automotive Sector

Automotive manufacturers rely on forged aluminum for:

- Suspension components

- High-performance wheels

- Engine connecting rods and pistons

- Drivetrain components

Industrial Equipment

Industrial applications benefit from forged aluminum in:

- Heavy machinery components

- Hydraulic system parts

- Pressure vessels and fittings

- Structural load-bearing elements

Additional Forged Aluminum Applications

Medical Equipment

The medical industry utilizes forged aluminum for surgical instruments, imaging equipment frames, and patient positioning devices where lightweight strength and sterilization capability are essential.

Defense and Military

Military applications include vehicle components, weapons systems, portable equipment, and tactical gear where reliability under extreme conditions is critical.

Sports and Recreation

High-performance bicycles, climbing equipment, golf clubs, and other sporting goods benefit from the exceptional strength-to-weight ratio of forged aluminum.

Marine Applications

Marine environments demand the corrosion resistance and structural integrity that forged aluminum provides for propellers, structural components, and hardware.

Specialized in Your Industry?

MAIKONG has extensive experience providing forged aluminum components across diverse industries. Our engineering team understands the specific requirements of your sector.

Contact Our Industry Specialists

MAIKONG’s Advanced Forged Aluminum Manufacturing Process

At MAIKONG, we’ve developed a comprehensive manufacturing process that ensures the highest quality forged aluminum components. Our integrated approach combines cutting-edge technology with traditional craftsmanship to deliver precision parts that meet the most demanding specifications.

Our Comprehensive Forged Aluminum Production Workflow

Design & Engineering

Our process begins with advanced CAD/CAM integration, where our engineering team works closely with clients to optimize component design for the forging process. We utilize sophisticated simulation software to identify potential issues before production begins.

Material Selection

MAIKONG’s in-house material laboratory ensures that only the highest quality aluminum alloys are used. We carefully consider mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness for each application.

Tooling & Die Design

Our tooling design ensures initial quality, while regular maintenance preserves consistency. We use advanced die designs that optimize material flow during forging to enhance structural integrity and reduce waste.

Production Excellence in Forged Aluminum

Forging Operations

MAIKONG’s forging workshop is equipped with state-of-the-art hydraulic presses capable of delivering precise pressure control. Our forging equipment can accommodate diverse aluminum forging specifications, from small precision components to larger structural parts.

Heat Treatment

We conduct comprehensive statistical analysis and documentation for our in-house heat treatment processes. Our uniform heat treatment furnaces ensure consistent properties throughout each component, enhancing strength and durability.

Precision Machining

With over 60 CNC machines providing 100+ tons of metal processing capacity monthly, our machining workshop performs precise and intricate operations on forged components. We specialize in turning, milling, Swiss machining, and multi-axis machining.

Surface Treatment

Our surface treatment capabilities include anodizing, painting, laser engraving, and sand blasting. We utilize advanced tools like spectrophotometers for color and gloss measurement to ensure consistent, high-quality finishes.

Quality Assurance for Forged Aluminum Components

MAIKONG maintains rigorous quality control procedures throughout the manufacturing process. Our ISO 9001:2015 certified quality management system ensures that every forged aluminum component meets or exceeds industry standards and customer specifications.

Experience Our Manufacturing Excellence

MAIKONG’s integrated manufacturing approach ensures superior quality forged aluminum components. Our team can guide you through the entire process from design to finished product.

Request Manufacturing Consultation

MAIKONG’s Comprehensive Forged Aluminum Services

As a leading provider of forged aluminum components and precision machining services, MAIKONG offers a complete range of manufacturing solutions to meet your specific requirements. Our integrated approach ensures consistent quality and performance across all our services.

CNC Machining Services

Our advanced CNC machining capabilities include:

- CNC Turning for cylindrical shapes and threaded components

- CNC Milling for complex prismatic shapes and flat surfaces

- Swiss-Type Machining for precision small parts and long shaft components

- Multi-axis machining for complex geometries

Forged Aluminum Components

Our specialized aluminum forging services include:

- Custom aluminum forgings for aerospace applications

- Automotive-grade forged aluminum components

- Industrial equipment and machinery parts

- Precision forged components for specialized applications

Additional Metal Services

Beyond aluminum, we offer expertise in:

- Steel Forging for high-strength applications

- Brass Component Manufacturing

- Custom Metal Fabrication

- Precision Prototyping Services

Why Choose MAIKONG for Your Forged Aluminum Needs

4.9

Customer Satisfaction

Manufacturing Capabilities

- 60+ CNC machines with 100+ tons monthly capacity

- Advanced forging equipment for precision components

- In-house heat treatment and surface finishing

- Comprehensive quality control laboratory

Service Excellence

- ISO 9001:2015 certified quality management

- Experienced engineering and technical support

- Competitive pricing with excellent value

- Reliable on-time delivery performance

Conclusion: The Future of Forged Aluminum in Modern Manufacturing

Forged aluminum continues to be one of the most reliable and high-performance materials in modern manufacturing. Its exceptional combination of strength, lightweight properties, and durability makes it indispensable across industries where safety, performance, and efficiency are paramount.

As industries increasingly prioritize lightweight solutions without compromising strength—particularly in automotive, aerospace, and renewable energy sectors—the demand for high-quality forged aluminum components will continue to grow. MAIKONG remains at the forefront of this evolution, combining traditional forging expertise with cutting-edge technology to deliver superior components.

Whether you require precision forged aluminum parts for safety-critical applications or high-performance components for specialized industrial equipment, MAIKONG offers the technical expertise, manufacturing capabilities, and quality assurance to meet your most demanding requirements. Contact us today to discuss how our forged aluminum solutions can enhance your products and applications.

Ready to Experience the MAIKONG Difference?

Join the growing number of companies that trust MAIKONG for their critical forged aluminum components and precision machining needs.

Contact Us Now