MAIKONG FACTORY: Your Premier Partner for Metal Forging Excellence

Welcome to MAIKONG, where precision meets passion in metal forging. For over 21 years, I’ve led our team of dedicated specialists in delivering exceptional aluminum forging, brass extrusion, steel forging, and CNC machining services to clients worldwide. Our 1200-square-meter facility in GD, SZ combines cutting-edge technology with traditional craftsmanship to create metal components that exceed expectations. Whether you need custom prototypes or high-volume production, MAIKONG delivers unmatched quality, competitive pricing, and reliable global shipping through trusted carriers like UPS, DHL, and FEDEX.

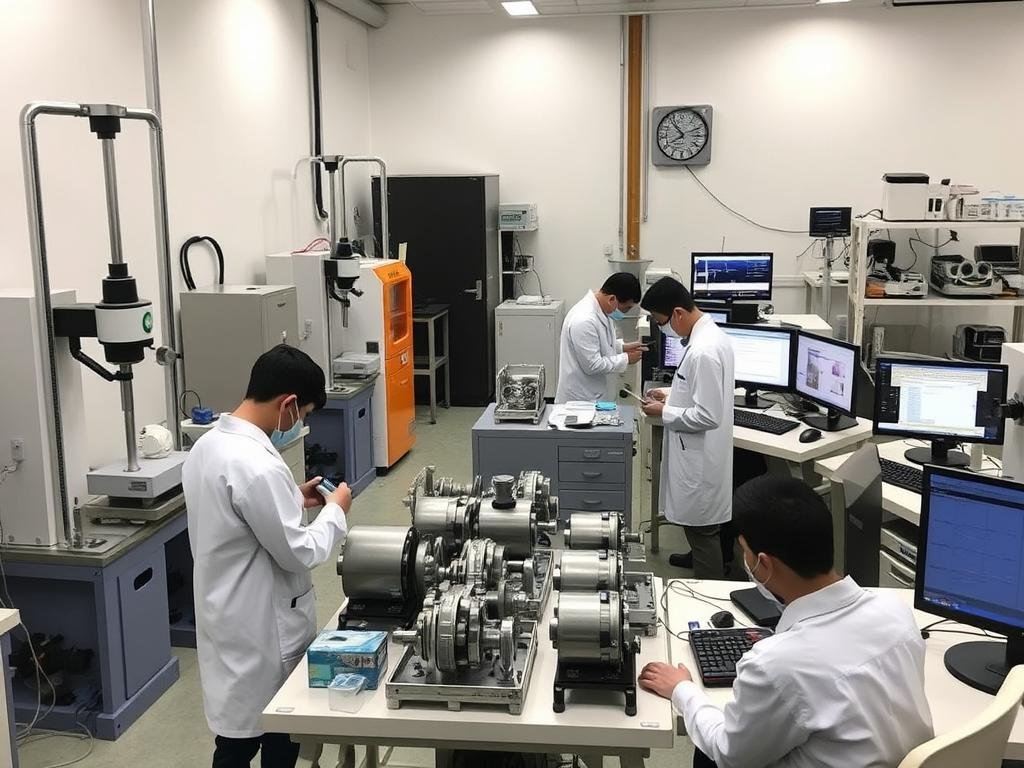

MAIKONG Factory Showcase

Our state-of-the-art 1200 sq.m manufacturing facility in GD, SZ

Our MAIKONG manufacturing facility spans 1200 square meters of purpose-built production space in the heart of GD, SZ. I’ve personally overseen the strategic layout of our factory floor to maximize efficiency while maintaining the highest quality standards in metal forging and machining operations.

Advanced Machinery

Our facility houses over 60 CNC machines with a monthly production capacity exceeding 100 tons of processed metal. Each piece of equipment is regularly calibrated and maintained to ensure precision manufacturing.

Quality Control Center

Our dedicated quality control laboratory features advanced testing equipment for material verification, dimensional inspection, and performance testing to ensure every component meets exact specifications.

Experience Our Factory Capabilities

Interested in learning more about our manufacturing capabilities? Contact us today to discuss your project requirements or schedule a virtual factory tour.

Our Comprehensive Metal Fabrication Services

Aluminum Forging Services

Our aluminum forging services deliver superior strength-to-weight ratio components with enhanced grain structure and mechanical properties. Perfect for aerospace, automotive, and precision engineering applications.

- Enhanced mechanical properties

- Superior grain structure alignment

- Excellent strength-to-weight ratio

- Multiple alloy options available

Brass Extrusion Services

Our brass extrusion capabilities produce precise profiles with excellent dimensional stability and surface finish. Ideal for electrical components, decorative applications, and fluid systems.

- Tight tolerance control

- Consistent material properties

- Complex profile capabilities

- Various brass alloy options

Steel Forging Services

Our steel forging processes create high-strength components with excellent fatigue resistance and structural integrity. Essential for heavy machinery, industrial equipment, and structural applications.

- Superior strength characteristics

- Enhanced fatigue resistance

- Excellent impact toughness

- Multiple steel grade options

CNC Turning Services

Our CNC turning operations deliver precise cylindrical components with exceptional surface finishes and tight tolerances. Perfect for shafts, fasteners, and rotational parts.

- Precision threading capabilities

- Superior surface finishes

- Multi-axis machining options

- High-volume production capacity

CNC Milling Services

Our CNC milling capabilities create complex prismatic shapes and precision flat surfaces for diverse industrial applications. Ideal for housings, brackets, and complex geometries.

- Multi-axis machining capabilities

- Complex geometry production

- Tight tolerance control

- Various material compatibility

Additional Manufacturing Services

Beyond metal forging, we offer comprehensive manufacturing solutions including Swiss-type machining, injection molding, 3D printing, and sheet metal fabrication.

- One-stop manufacturing solutions

- Complementary production processes

- Integrated quality control

- Streamlined project management

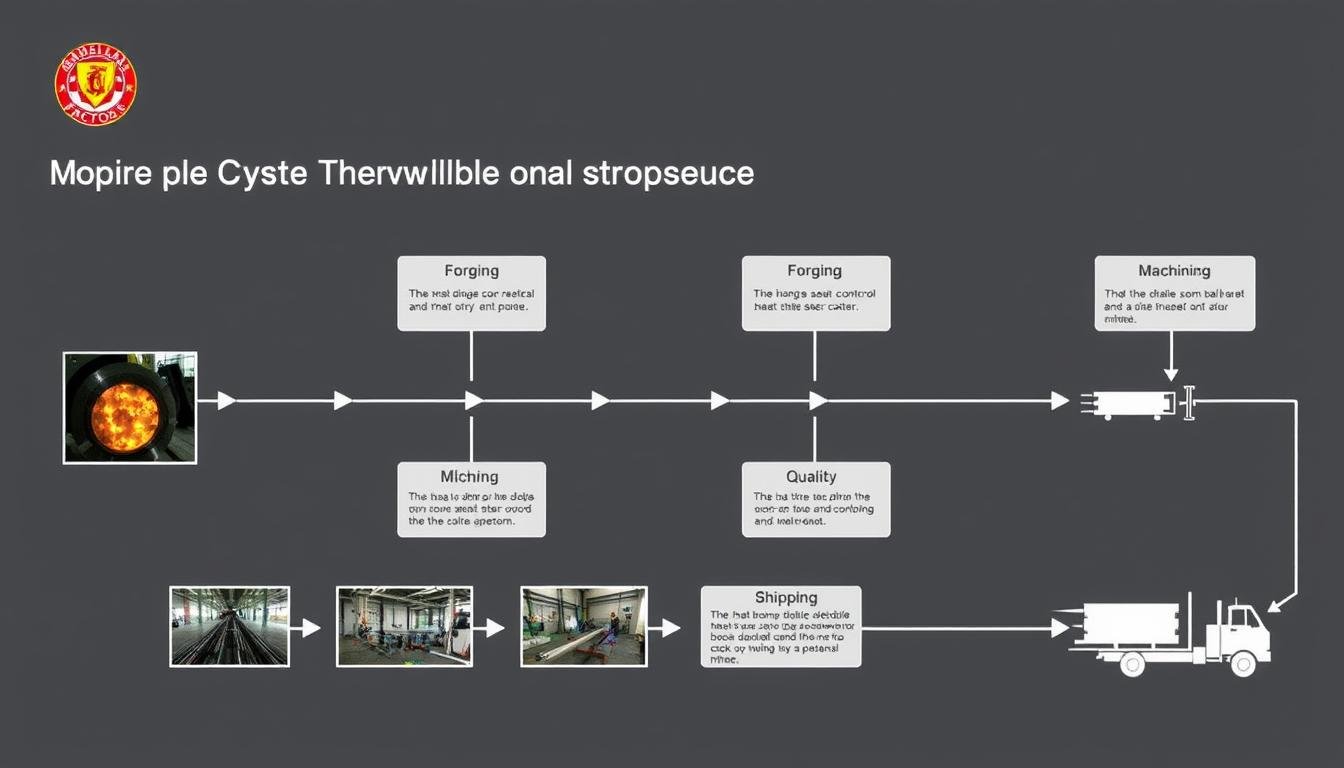

MAIKONG Production Process

Our comprehensive metal forging production workflow

Design & Engineering

Our process begins with comprehensive design analysis using advanced CAD/CAM software. I work closely with our engineering team to optimize component designs for manufacturability, performance, and cost-effectiveness.

Material Selection

We carefully select optimal materials based on mechanical properties, machinability, heat treatment characteristics, and cost-effectiveness. Our in-house testing ensures all raw materials meet exact specifications.

Tooling Preparation

Our tooling design ensures initial quality while regular maintenance preserves consistency. We create custom dies and fixtures specifically engineered for each component to ensure optimal results.

Forging Operations

Our forging workshop accommodates diverse specifications, using controlled deformation to align grain structure and enhance mechanical properties. This critical process creates components with superior strength and durability.

Heat Treatment

We conduct comprehensive statistical analysis and documentation for our in-house heat treatment processes. This crucial step optimizes mechanical properties and ensures consistent performance across production runs.

Precision Machining

Our machining workshop features state-of-the-art CNC machines capable of precise and intricate operations. This allows us to achieve final dimensions and features with exceptional accuracy and surface finish.

Surface Treatment

Surface treatment enhances appearance, performance, and competitiveness. We offer anodizing, painting, laser engraving, and sandblasting with strict quality control to ensure consistent results.

Quality Inspection

Our rigorous quality control procedures ensure every component meets stringent standards. We employ advanced measurement tools and statistical process control to verify dimensional accuracy and performance characteristics.

Packaging & Shipping

We carefully package components to prevent damage during transit and ship worldwide via UPS, DHL, and FEDEX. Our typical processing time is 3-7 days, with delivery within 7-9 days to most global destinations.

Ready to Start Your Project?

Contact us today to discuss your specific requirements and learn how our comprehensive production process can deliver the high-quality components you need.

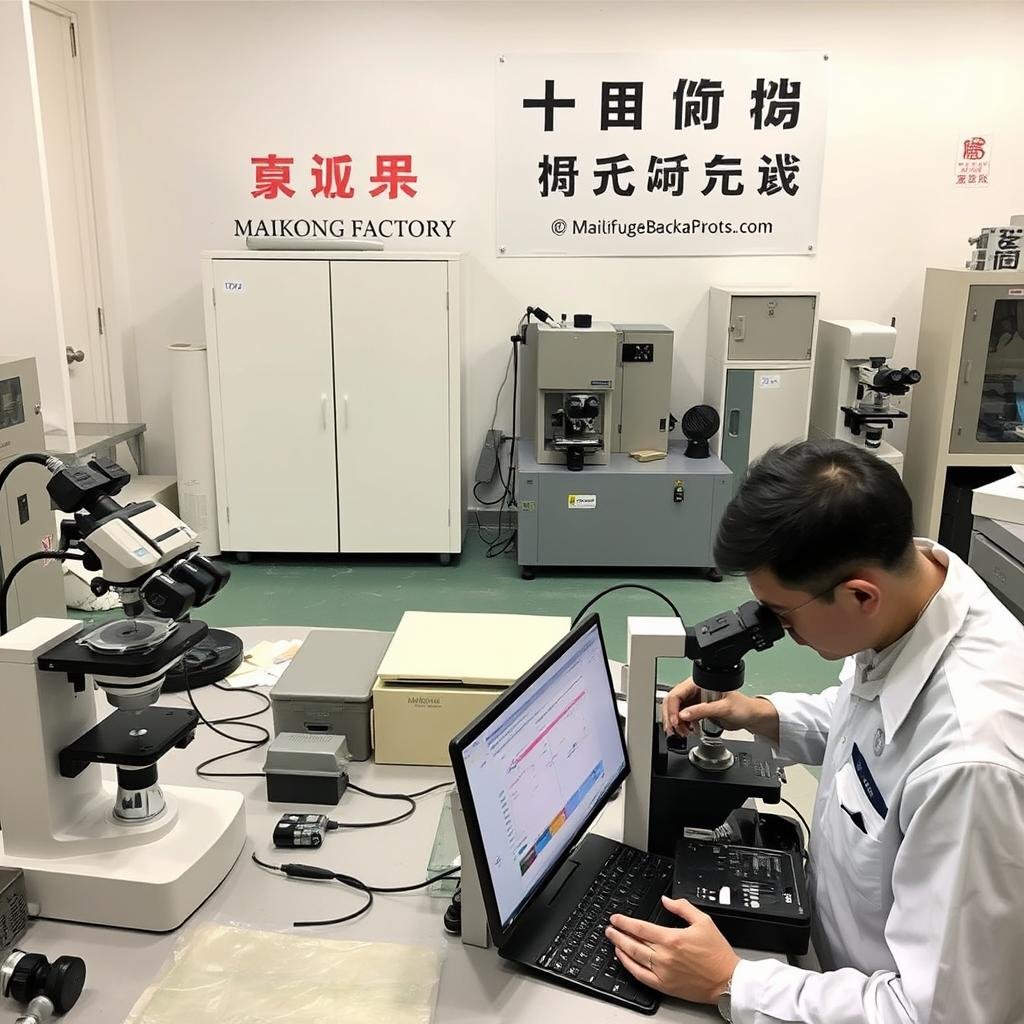

MAIKONG Quality Control

Our dedicated quality control laboratory ensures consistent excellence

At MAIKONG, quality isn’t just a department—it’s our culture. I’ve implemented comprehensive quality management systems that have earned us ISO 9001:2015 certification, ensuring every component we produce meets the highest standards of excellence.

Our Quality Assurance Approach

Quality expresses a component’s capacity to fully satisfy customer needs and expectations. Our quality engineering staff monitors production processes at all times to ensure consistency and excellence in every component we produce.

When a problem is identified, we conduct systematic root cause analysis using methods like the 5 Whys and advanced statistical techniques. Our objective is not just to identify the immediate cause but to understand and address underlying factors to prevent issues from recurring.

The advantages of our in-house production—from raw material selection through forging, heat treatment, CNC milling, to surface treatment—allows our quality team to monitor every stage of production, ensuring consistent excellence.

Quality Control Measures

- Material verification and testing

- In-process inspection at critical stages

- Dimensional verification using CMM technology

- Surface finish measurement and inspection

- Mechanical property testing

- Non-destructive testing when required

- Final inspection before packaging

- Statistical process control

- Comprehensive documentation and traceability

Forging vs. Casting: Why Choose MAIKONG Forged Components

| Comparison Categories | MAIKONG Forged Components | Cast Components |

| Strength and Durability | Higher due to dense, uniform grain structure | Potentially lower due to air pockets and inclusions |

| Tensile Properties | Superior tensile strength and resistance | Lower tensile strength |

| Fatigue Resistance | Better resistance against fatigue failure | Potentially lower fatigue resistance |

| Dimensional Accuracy | Better accuracy and tighter tolerances | Potential inconsistencies |

| Surface Finish | Smoother surfaces, reduced post-processing | Might require more machining due to air pockets |

| Weight-to-Strength Ratio | High strength-to-weight ratio | Bulkier parts may be needed |

| Ideal Applications | Aerospace, automotive, medical devices | Consumer goods, simple parts, non-critical sectors |

Experience the MAIKONG Quality Difference

Ready to experience the superior quality of MAIKONG forged components? Contact us today to discuss your project requirements and quality specifications.

Become a MAIKONG Distributor

Join our growing network of global distribution partners

I’m actively expanding our global network of distributors and partners for MAIKONG’s premium metal forging and machining solutions. Becoming a MAIKONG distributor offers you access to our comprehensive product lineup, technical expertise, and competitive pricing structure.

Distributor Benefits

- Exclusive territory rights

- Competitive wholesale pricing

- Technical training and support

- Marketing materials and assistance

- Regular new product updates

- Dedicated account manager

- Priority production scheduling

- Co-branding opportunities

Ideal Partner Profile

- Established presence in manufacturing sectors

- Technical understanding of metal components

- Existing customer base in relevant industries

- Commitment to quality and service

- Strong sales and marketing capabilities

- Ability to provide local technical support

- Financial stability and growth orientation

Global Shipping & Logistics

We offer reliable global shipping via UPS, DHL, and FEDEX with typical processing times of 3-7 days and delivery within 7-9 days to most international destinations. Our logistics team ensures smooth customs clearance and timely delivery to your location.

Interested in Becoming a MAIKONG Distributor?

Contact us today to discuss partnership opportunities and learn more about our distributor program. We’re looking forward to growing together!

Contact MAIKONG FACTORY

Get in Touch

Ready to discuss your metal forging and machining needs? Our team is available to answer your questions, provide quotes, and help you find the perfect manufacturing solution for your requirements.

Email: info@maikongforge.us

Location: GD, SZ

Business Hours:

Monday – Friday: 9:00 AM – 6:00 PM (GMT+8)

Saturday: 9:00 AM – 12:00 PM (GMT+8)

Sunday: Closed

Request a Quote

Why Choose MAIKONG FACTORY

21 Years of Excellence

With over two decades of manufacturing expertise, we’ve refined our processes to deliver consistent quality and exceptional value across all our metal forging and machining services.

Comprehensive Capabilities

From design assistance to finished components, our integrated manufacturing approach ensures seamless production and quality control at every stage.

Global Reach

With reliable shipping partners and efficient logistics, we deliver premium metal components to customers worldwide with predictable lead times and excellent service.

Ready to Experience MAIKONG Quality?

Contact us today to discuss your project requirements and discover how our metal forging expertise can help you achieve your manufacturing goals.