Forging Press

- Powering Precision: Your Comprehensive Resource for Forging Press Technology in the USA

- What is a Forging Press? An Essential Introduction for US Industrial Buyers

- The Core Function of a Forging Press in Modern Metal Forming

- Understanding the Basic Principles of Forging Press Operation

- Why Forging Presses are Critical for High-Strength Metal Parts in the US

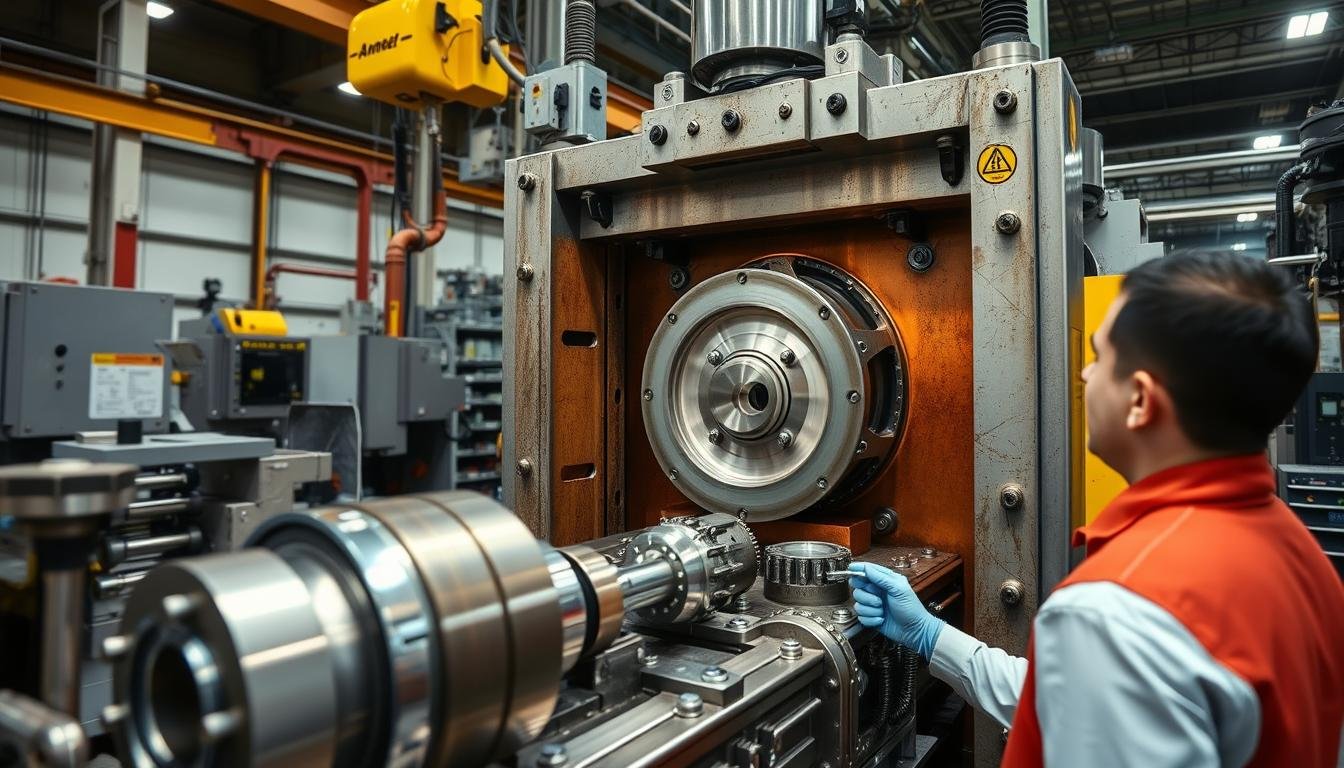

- Key Components of a Robust Forging Press System

- Hot Forging Press: The Ultimate Guide to Advanced Metal Forming Technology

- Small Aluminum Forging Press: Precision Engineering for Metal Forming Excellence