Advanced Forge Tooling Solutions for Precision Manufacturing

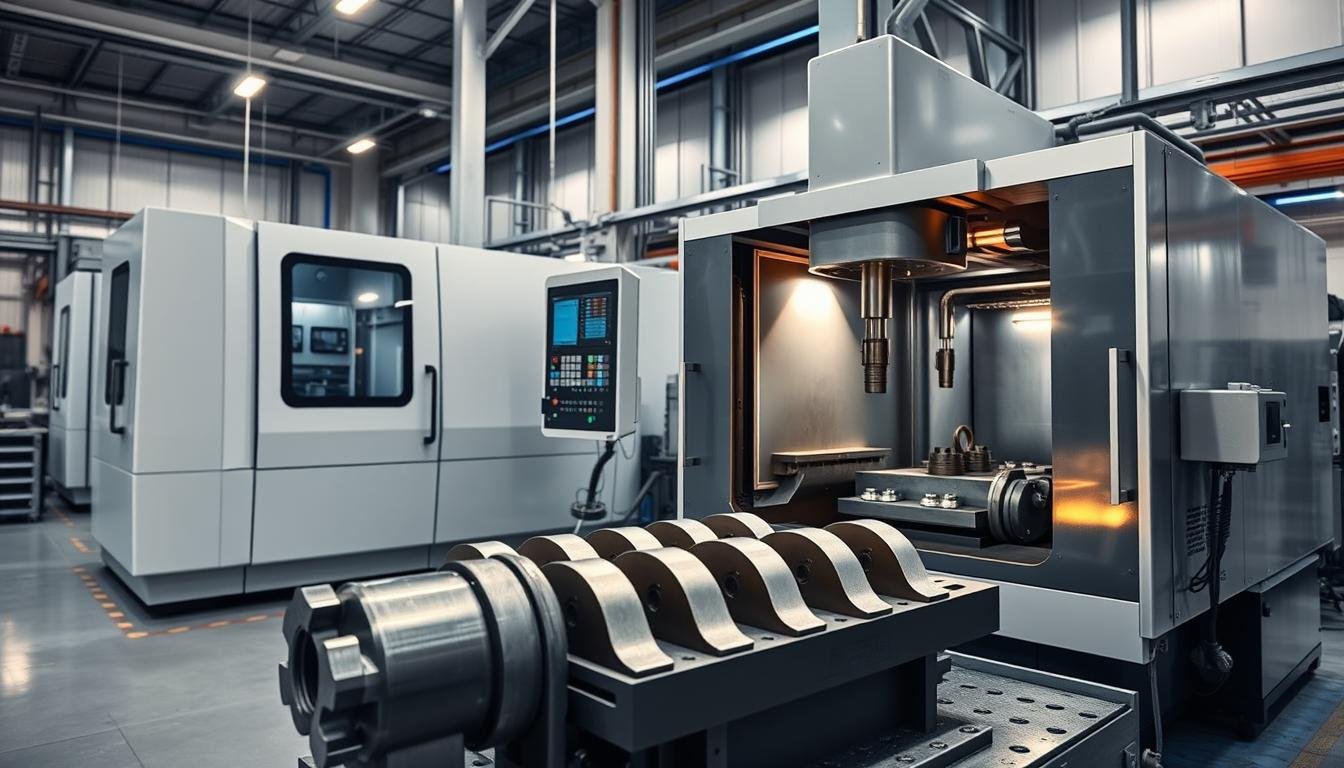

Welcome to MAIKONG, your premier partner for high-quality forge tooling solutions. With our state-of-the-art manufacturing facilities in Shenzhen, China, we deliver precision-engineered tooling that meets the most demanding specifications. Our comprehensive capabilities in CNC machining, metal forging, and custom metal parts manufacturing enable us to provide superior tooling solutions that enhance your production efficiency and product quality.

Ready to Enhance Your Manufacturing Capabilities?

Our team of experts is ready to discuss your specific forge tooling requirements and provide a customized solution that meets your production needs.

Request a Custom Quote

Advanced Manufacturing Process for Superior Forge Tooling

At MAIKONG, we implement a comprehensive manufacturing process that ensures exceptional quality and precision in every forge tooling component we produce. Our state-of-the-art facilities and skilled technical team enable us to deliver superior tooling solutions that meet the most demanding specifications.

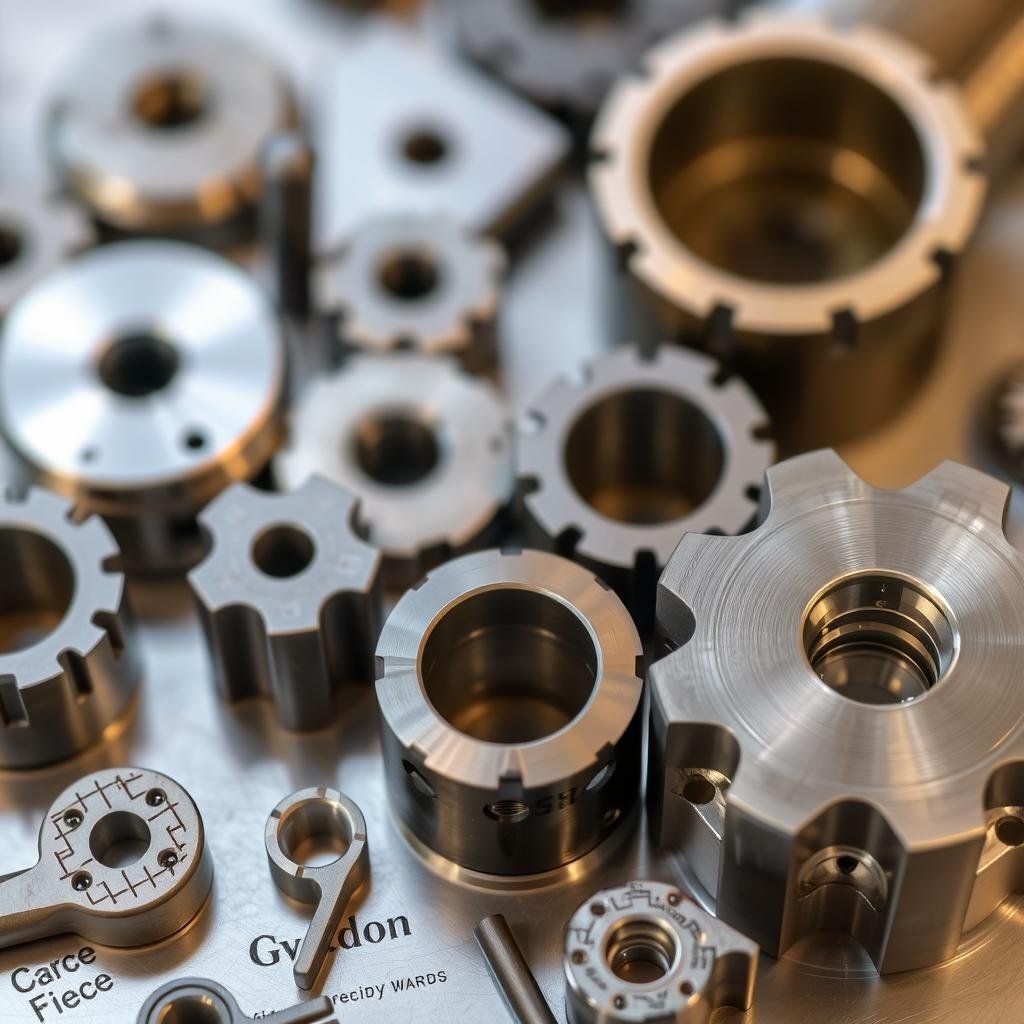

Design and Engineering Excellence

Our process begins with thorough analysis of your requirements and application parameters. Our experienced engineering team utilizes advanced CAD/CAM software to develop optimized tooling designs that maximize performance and durability.

Key Design Considerations:

- Material flow optimization for consistent part quality

- Stress distribution analysis to prevent premature failure

- Thermal management for extended tool life

- Dimensional precision for consistent part production

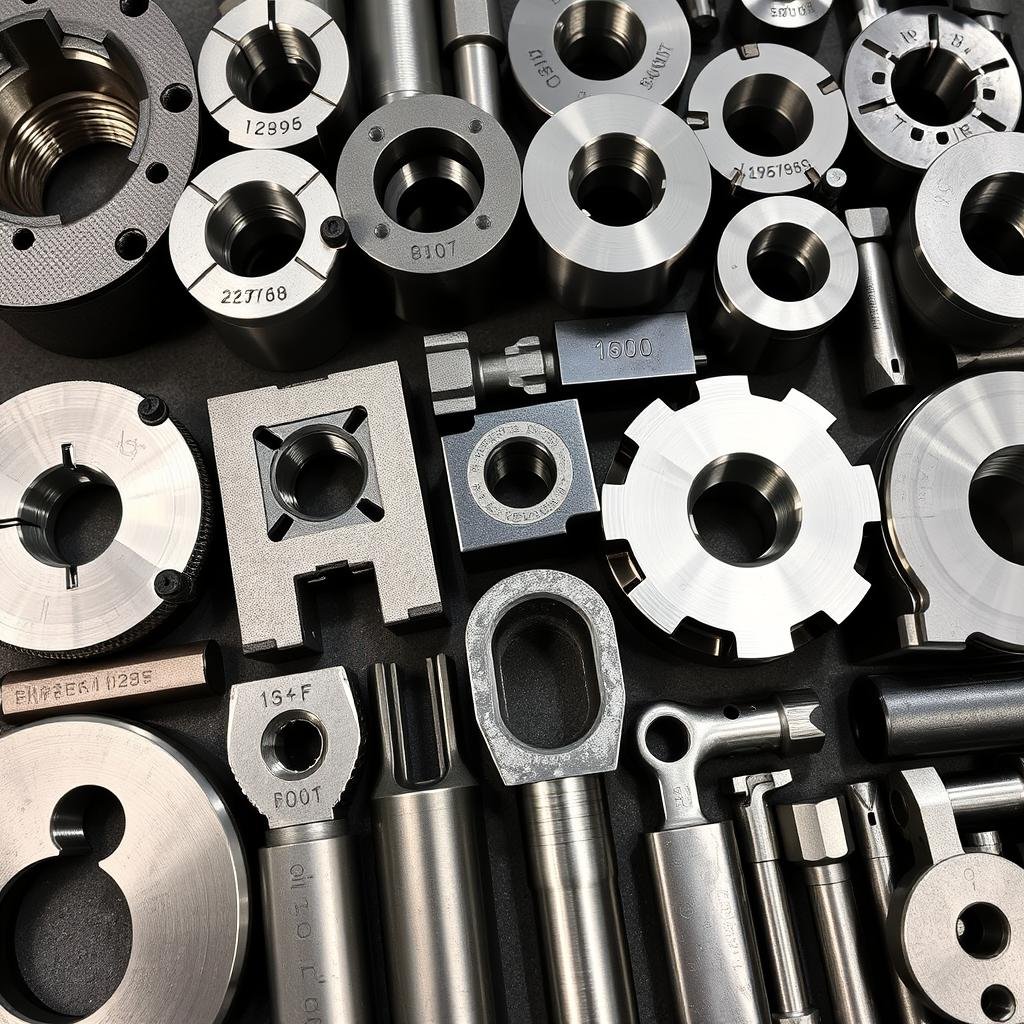

Precision Manufacturing Capabilities

| Manufacturing Process |

Capabilities |

Tolerance Range |

Materials |

| CNC Machining |

5-axis simultaneous machining, high-speed cutting |

±0.005mm |

Tool steel, carbide, aluminum alloys |

| Precision Grinding |

Surface, cylindrical, and profile grinding |

±0.002mm |

Hardened tool steel, carbide |

| Wire EDM |

Complex profile cutting, fine finishing |

±0.003mm |

All conductive materials |

| Heat Treatment |

Vacuum hardening, tempering, nitriding |

Hardness: ±1 HRC |

Tool steel, alloy steel |

Rigorous Quality Control

Every forge tooling component undergoes comprehensive inspection to ensure compliance with specifications and quality standards. Our quality control process includes:

- Dimensional verification using advanced CMM technology

- Material composition analysis and certification

- Surface finish inspection and documentation

- Hardness testing and verification

- First article inspection and reporting

Competitive Pricing and Exceptional Value

At MAIKONG, we understand that competitive pricing is essential for your business success. Our aluminum tool forging pricelist reflects our commitment to delivering exceptional value without compromising quality. As one of the leading rapid aluminum forged tooling companies United States suppliers, we leverage our advanced manufacturing capabilities and efficient operations to provide cost-effective solutions.

Cost-Effective Manufacturing

Our strategic location in Shenzhen, China, combined with our advanced production facilities and efficient operations, enables us to offer competitive pricing for premium forge tooling solutions. We continuously optimize our manufacturing processes to reduce costs while maintaining exceptional quality.

Value-Added Benefits:

- Streamlined production processes that reduce manufacturing time

- Efficient material utilization that minimizes waste

- Advanced automation that enhances productivity

- Comprehensive quality control that prevents costly rework

- Volume pricing options for ongoing production requirements

4.8

Customer Satisfaction

Request Your Customized Forge Tooling Quote Today

Experience the MAIKONG difference with competitive pricing, exceptional quality, and responsive service. Our team is ready to provide a detailed quote for your specific requirements.

Email for Quote: Lucy@maikongforge.us

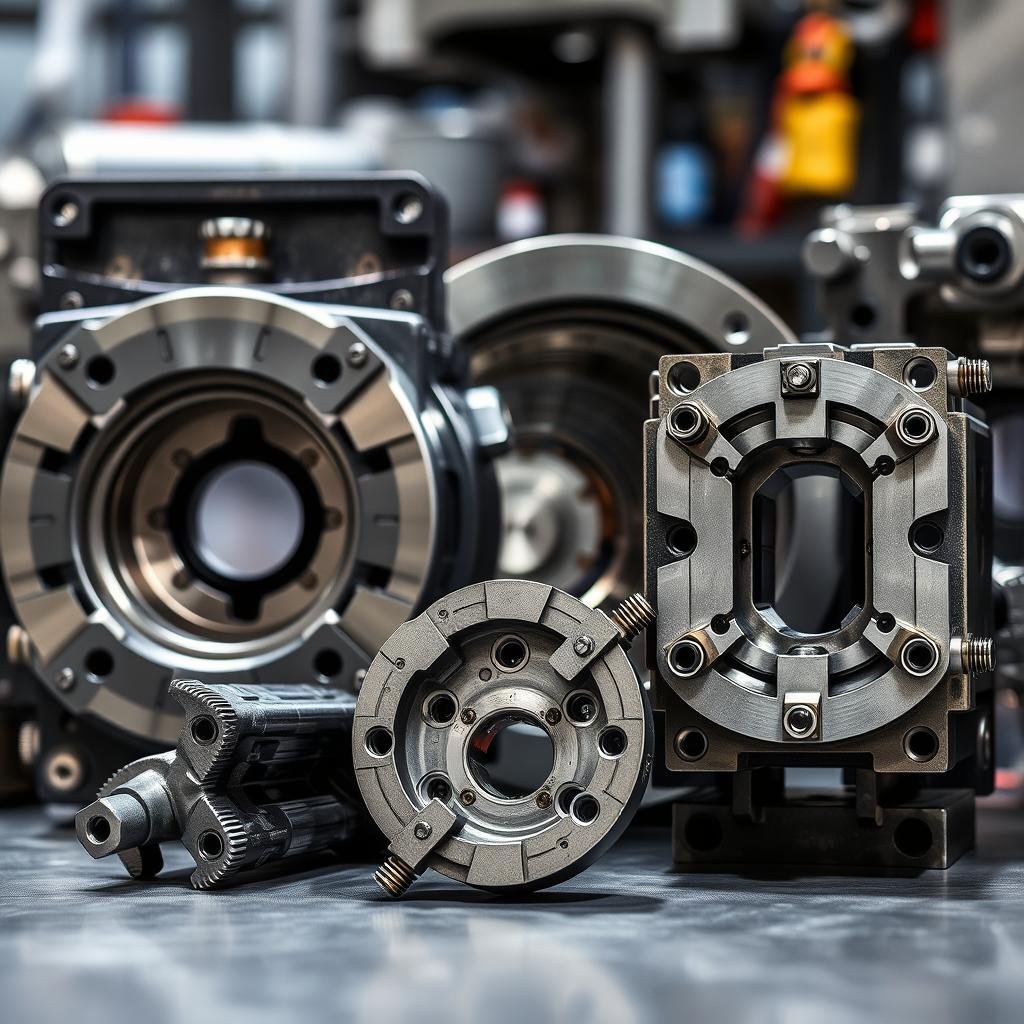

Why Choose MAIKONG for Your Forge Tooling Needs

As one of the leading rapid aluminum forged tooling companies United States suppliers, MAIKONG delivers exceptional value through our comprehensive capabilities, technical expertise, and commitment to customer satisfaction. Our focus on quality, innovation, and responsive service makes us the preferred partner for demanding forge tooling applications.

Advanced Manufacturing Capabilities

- State-of-the-art CNC machining centers

- Precision grinding and EDM capabilities

- Advanced heat treatment facilities

- Comprehensive surface treatment options

- In-house tooling design and optimization

Quality Assurance

- ISO 9001:2015 certified quality management system

- Advanced inspection equipment including CMM

- Comprehensive material certification

- Detailed quality documentation

- 100% inspection of critical dimensions

Customer Service Excellence

- Dedicated project management

- Technical support via WhatsApp

- Responsive communication

- Flexible production scheduling

- Comprehensive documentation and reporting

“MAIKONG has consistently delivered exceptional forge tooling that meets our demanding specifications. Their technical expertise, competitive pricing, and responsive service make them a valued partner for our manufacturing operations.”

– Manufacturing Director, Automotive Components Manufacturer

Partner with MAIKONG for Superior Forge Tooling Solutions

Experience the benefits of working with a leading manufacturer of high-quality forge tooling. Contact us today to discuss your requirements and discover how our expertise can enhance your manufacturing capabilities.

Request a Custom Quote