MAIKONG: Your Premier Hot Forging Aluminum Supplier for Precision Components

Welcome to MAIKONG, a leading hot forging aluminum supplier based in Shenzhen, China. We combine advanced production equipment, superior supply chain capabilities, and decades of expertise to deliver exceptional aluminum forged components for global B2B clients. Whether you need aerospace-grade parts, automotive components, or custom industrial solutions, our team is ready to exceed your expectations with precision manufacturing and competitive pricing.

Advanced Hot Forging Aluminum Capabilities

As a specialized hot forging aluminum supplier in China, MAIKONG offers comprehensive metal forming solutions that deliver superior strength, durability, and precision for your most demanding applications.

Our Core Forging Technologies

- Closed-die forging for complex geometries

- Open-die forging for larger components

- Precision impression die forging

- Ring rolling for seamless components

- Custom-designed tooling and dies

- Heat treatment and aging processes

Production Specifications

- Component weight: 0.1kg to 50kg

- Dimensional tolerance: ±0.05mm

- Surface roughness: Ra 1.6-3.2

- Production capacity: 100,000+ pieces monthly

- Material options: 6061, 7075, 2024, and more

- Full traceability and certification

Ready to Discuss Your Aluminum Forging Requirements?

Our engineering team is available to review your specifications and provide expert recommendations for your project.

Request a Quote

Or contact our technical support via WhatsApp: +86 13510907401

Why Choose MAIKONG as Your Hot Forging Aluminum Supplier

When you partner with MAIKONG, you gain access to world-class manufacturing capabilities and customer-focused service that sets us apart from other suppliers.

Superior Quality Control

Our rigorous quality management system includes material certification, in-process inspections, and final verification to ensure every component meets exact specifications.

Technical Expertise

Our engineering team brings decades of combined experience in aluminum forging, offering design optimization and material selection guidance for your applications.

Competitive Pricing

By leveraging our strategic location in Shenzhen and optimized production processes, we deliver premium quality at competitive prices with transparent quotations.

Advanced Equipment

Our facility features state-of-the-art hydraulic presses, CNC machining centers, and precision measuring instruments for consistent, high-quality production.

Comprehensive Services

From initial design consultation through forging, machining, heat treatment, and surface finishing, we provide end-to-end manufacturing solutions.

Global Supply Capabilities

With established logistics networks and export experience, we ensure reliable delivery to customers worldwide with optimized shipping solutions.

Aluminum Alloys for Hot Forging Applications

As an experienced hot forging aluminum supplier, we work with a comprehensive range of aluminum alloys to meet your specific performance requirements.

| Alloy |

Key Properties |

Common Applications |

Forging Temperature |

| 6061 |

Excellent corrosion resistance, good formability |

Structural components, frames, brackets |

850-925°F (454-496°C) |

| 7075 |

High strength-to-weight ratio, excellent fatigue resistance |

Aerospace components, high-stress parts |

780-870°F (415-465°C) |

| 2024 |

High strength, good machinability |

Aircraft structures, gears, shafts |

800-875°F (427-468°C) |

| 7050 |

Superior stress corrosion resistance, high toughness |

Critical aerospace components |

750-850°F (399-454°C) |

| 2014 |

High strength at elevated temperatures |

Aerospace, automotive pistons |

825-900°F (441-482°C) |

Material Certification and Traceability

All aluminum materials used in our forging processes are sourced from certified suppliers and come with complete material certification. We maintain full traceability throughout the production process, ensuring compliance with industry standards and your specific requirements.

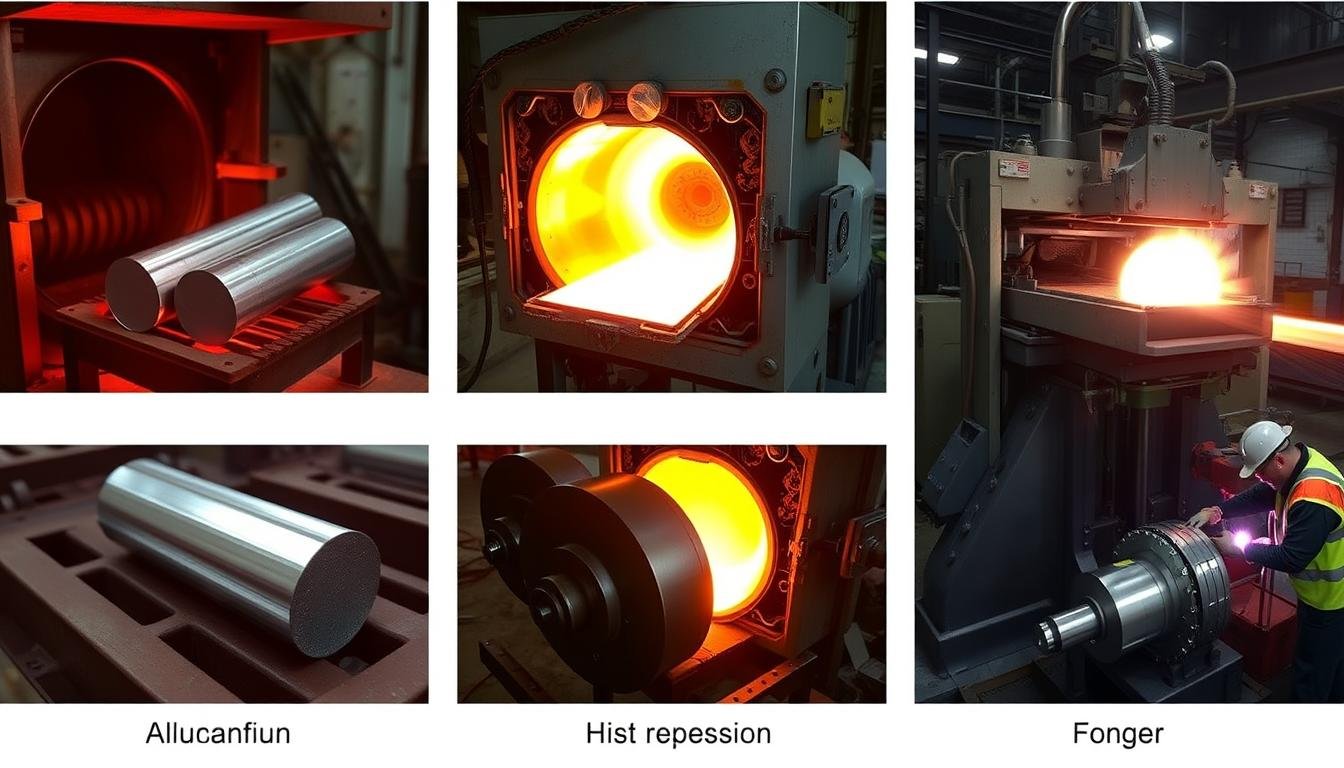

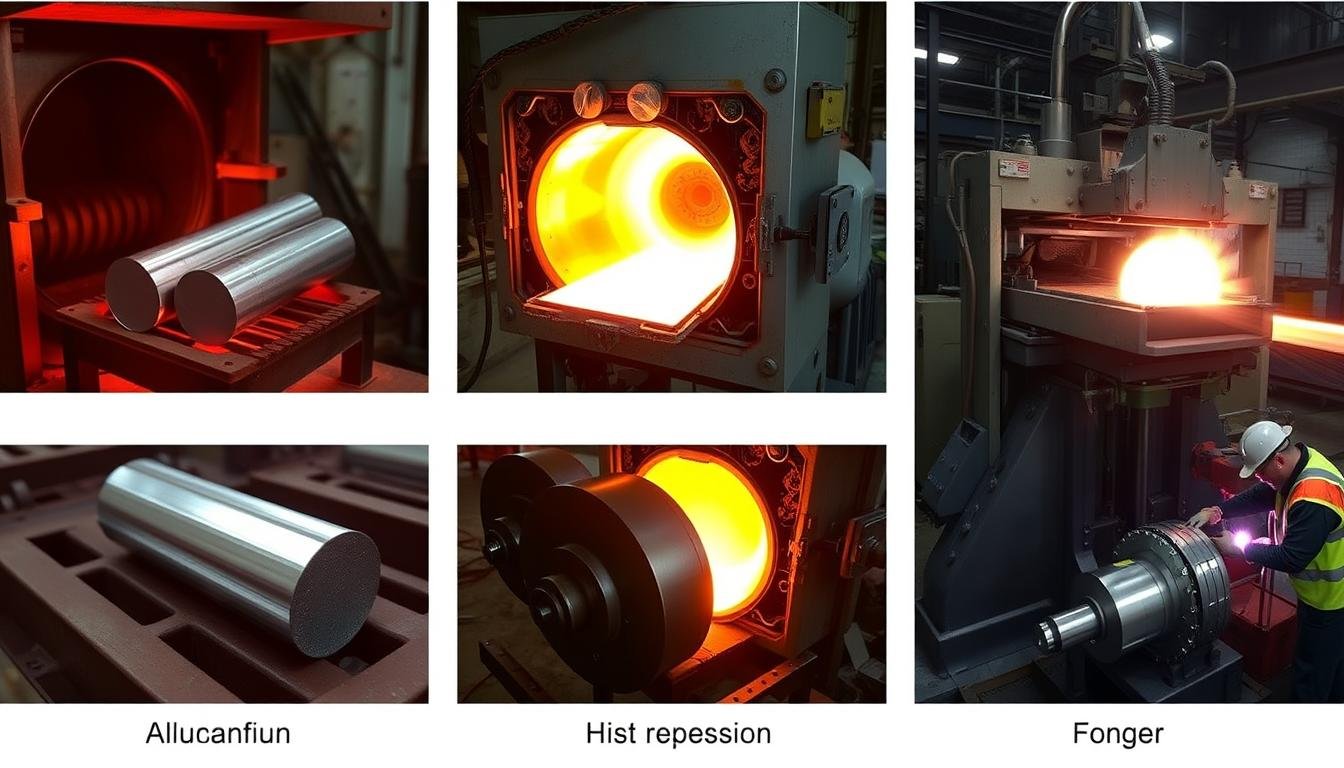

Our Hot Forging Aluminum Process

At MAIKONG, we’ve refined our hot forging process to deliver consistent quality and exceptional performance in every component we manufacture.

-

Design and Engineering

Our process begins with thorough review of your specifications and requirements. Our engineering team analyzes the design for manufacturability and may suggest optimizations to improve performance or reduce costs.

-

Tooling Development

We design and manufacture custom dies and tooling specific to your component. Our advanced CAD/CAM systems ensure precise die creation for optimal material flow and dimensional accuracy.

-

Material Preparation

High-quality aluminum billets are cut to size and prepared for the forging process. Each batch is verified for composition and quality before proceeding.

-

Heating

The aluminum is heated to precise temperatures (typically 750-950°F depending on the alloy) in controlled furnaces to achieve optimal plasticity for forging.

-

Forging Operation

Using hydraulic presses ranging from 500 to 3,000 tons, we apply controlled pressure to form the heated aluminum into the desired shape using single or multi-stage forging processes.

-

Trimming and Cleaning

Excess material (flash) is removed, and parts are cleaned to prepare for heat treatment and finishing operations.

-

Heat Treatment

Components undergo precise heat treatment cycles to achieve the required mechanical properties, including solution treatment, quenching, and aging processes.

-

Quality Inspection

Every component undergoes rigorous inspection including dimensional verification, visual inspection, and when required, non-destructive testing such as ultrasonic or dye penetrant inspection.

-

Finishing Operations

Based on your requirements, we perform additional operations such as CNC machining, surface treatment, or assembly before final inspection and packaging.

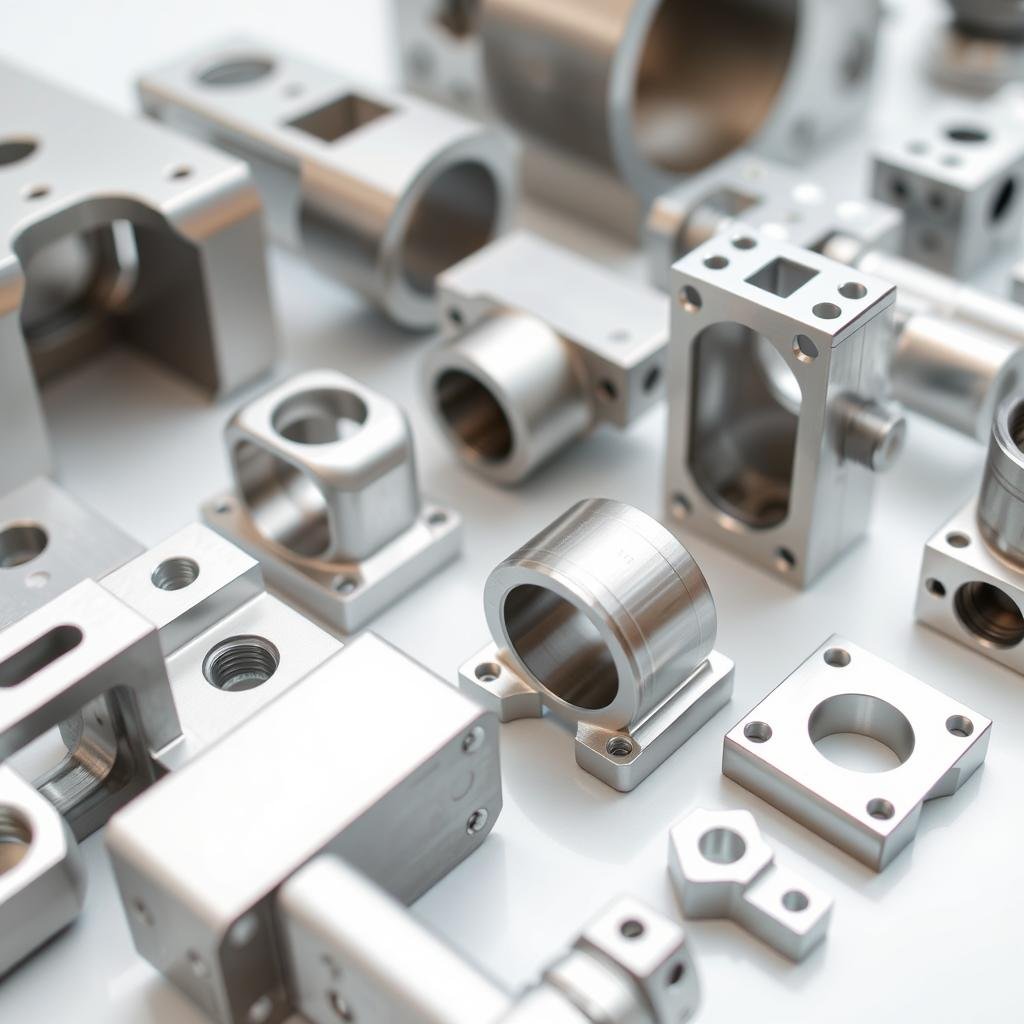

Industry Applications for Hot Forged Aluminum

As a versatile hot forging aluminum supplier, we serve diverse industries with custom forging solutions tailored to specific application requirements.

Aerospace

Our aerospace-grade forged aluminum components meet stringent quality and performance requirements for structural parts, landing gear components, and engine mounts.

Automotive

We produce lightweight, high-strength forged aluminum components for suspension systems, steering components, and drivetrain applications.

Medical

Our precision forged components for medical devices and equipment offer exceptional reliability and performance for critical applications.

Industrial

We deliver durable forged aluminum parts for industrial machinery, hydraulic systems, and heavy equipment applications.

Marine

Our corrosion-resistant forged aluminum components are ideal for marine environments, from propulsion systems to structural applications.

Sports & Recreation

We produce lightweight, high-performance forged components for bicycles, motorsports, and recreational equipment.

Specialized Applications: Scooter Steering Shaft Components

As a leading scooter steering shaft aluminum forgings supplier, we specialize in producing high-performance steering components that combine lightweight design with exceptional durability and safety. Our precision-forged steering shafts feature superior grain flow, enhanced mechanical properties, and excellent fatigue resistance for reliable performance in demanding applications.

Ready to Start Your Custom Forging Project?

From prototype to production, our team is ready to support your aluminum forging needs with expert guidance and competitive pricing.

Request a Quote Today

Technical questions? Contact us via WhatsApp: +86 13510907401

Quality Assurance and Certifications

As a premium hot forging aluminum supplier, quality is at the core of everything we do at MAIKONG.

Quality Management System

Our comprehensive quality management system ensures consistent quality throughout the production process:

- ISO 9001:2015 certified quality management system

- Advanced Statistical Process Control (SPC)

- 100% in-process inspection at critical stages

- Documented quality procedures and work instructions

- Regular internal and external quality audits

- Continuous improvement initiatives

Testing Capabilities

Our in-house testing facilities ensure your components meet all specified requirements:

- Dimensional inspection with CMM technology

- Material composition verification

- Mechanical property testing (tensile, hardness)

- Non-destructive testing capabilities

- Metallurgical analysis and microstructure evaluation

- First article inspection and reporting

Industry Certifications

MAIKONG maintains certifications relevant to our customers’ industries, ensuring compliance with international standards and specific industry requirements. Our quality system is designed to meet the stringent demands of aerospace, automotive, and medical device manufacturers.

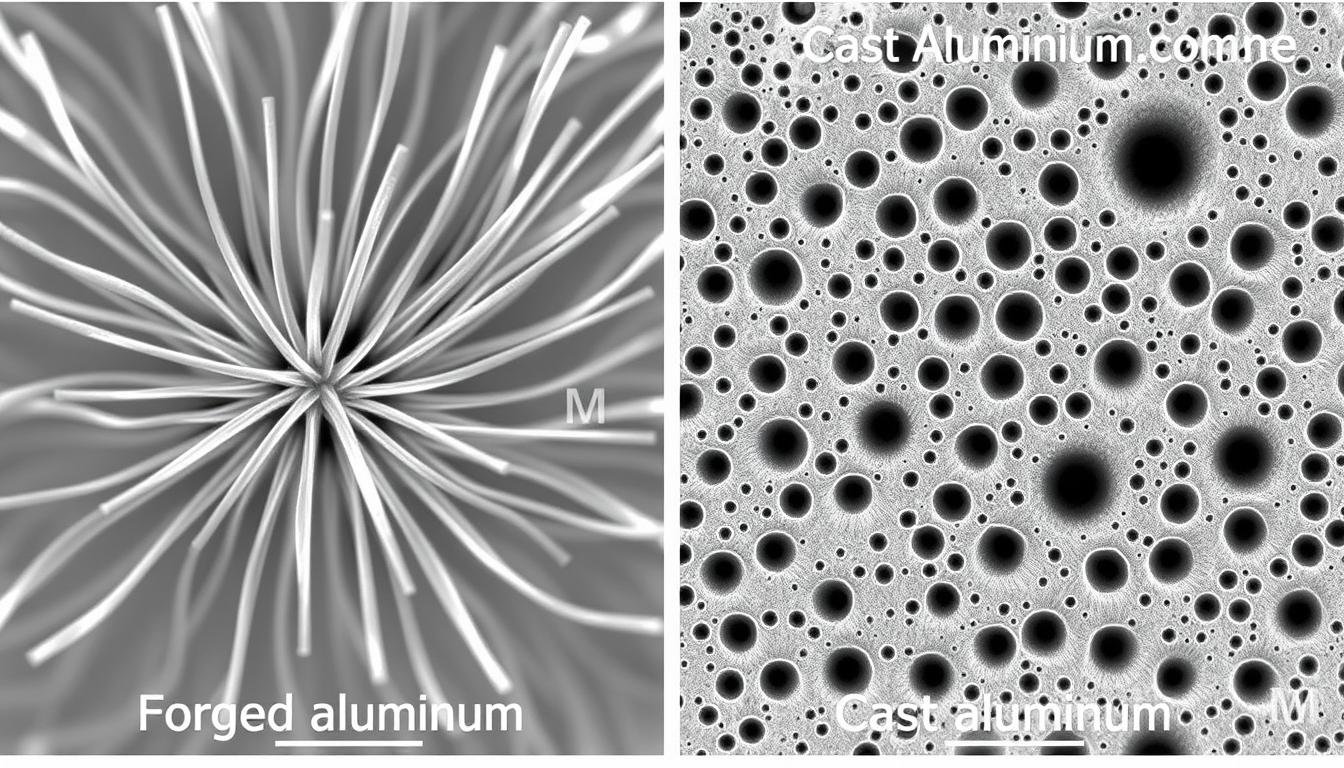

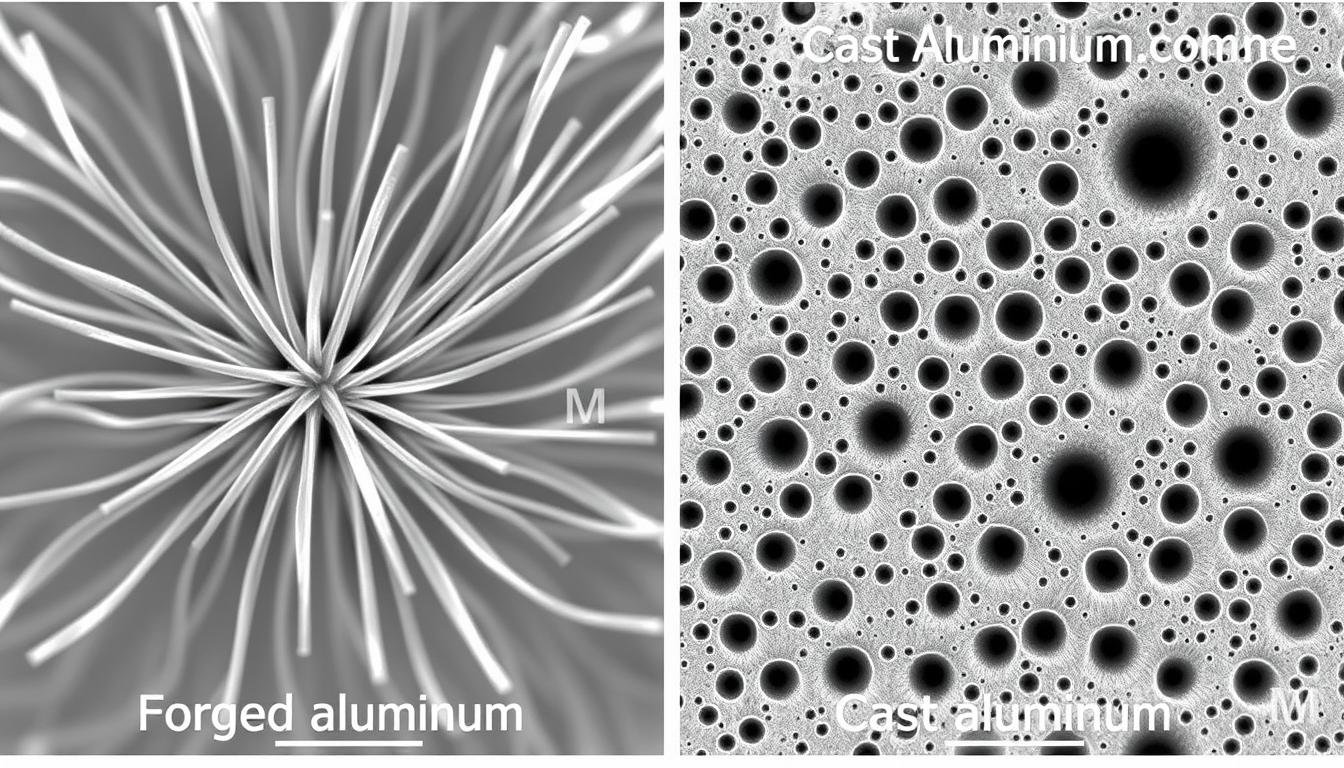

Benefits of Hot Forged Aluminum Components

Choosing hot forged aluminum components from MAIKONG provides numerous advantages over alternative manufacturing methods.

Advantages of Hot Forged Aluminum

- Superior strength-to-weight ratio compared to cast components

- Enhanced grain structure and improved mechanical properties

- Excellent fatigue resistance for dynamic loading applications

- Reduced internal defects and porosity

- Better dimensional stability and consistency

- Improved surface finish and appearance

- Enhanced corrosion resistance

- Greater design flexibility for complex geometries

- Longer service life in demanding applications

Limitations of Alternative Methods

- Cast components often have lower strength and more porosity

- Machined components waste material and have interrupted grain flow

- 3D printed metal parts have lower strength and anisotropic properties

- Welded assemblies have heat-affected zones that can compromise integrity

- Sheet metal fabrications have limited thickness capabilities

- Extruded profiles have limitations in complex geometries

- Powder metallurgy parts may have lower density and strength

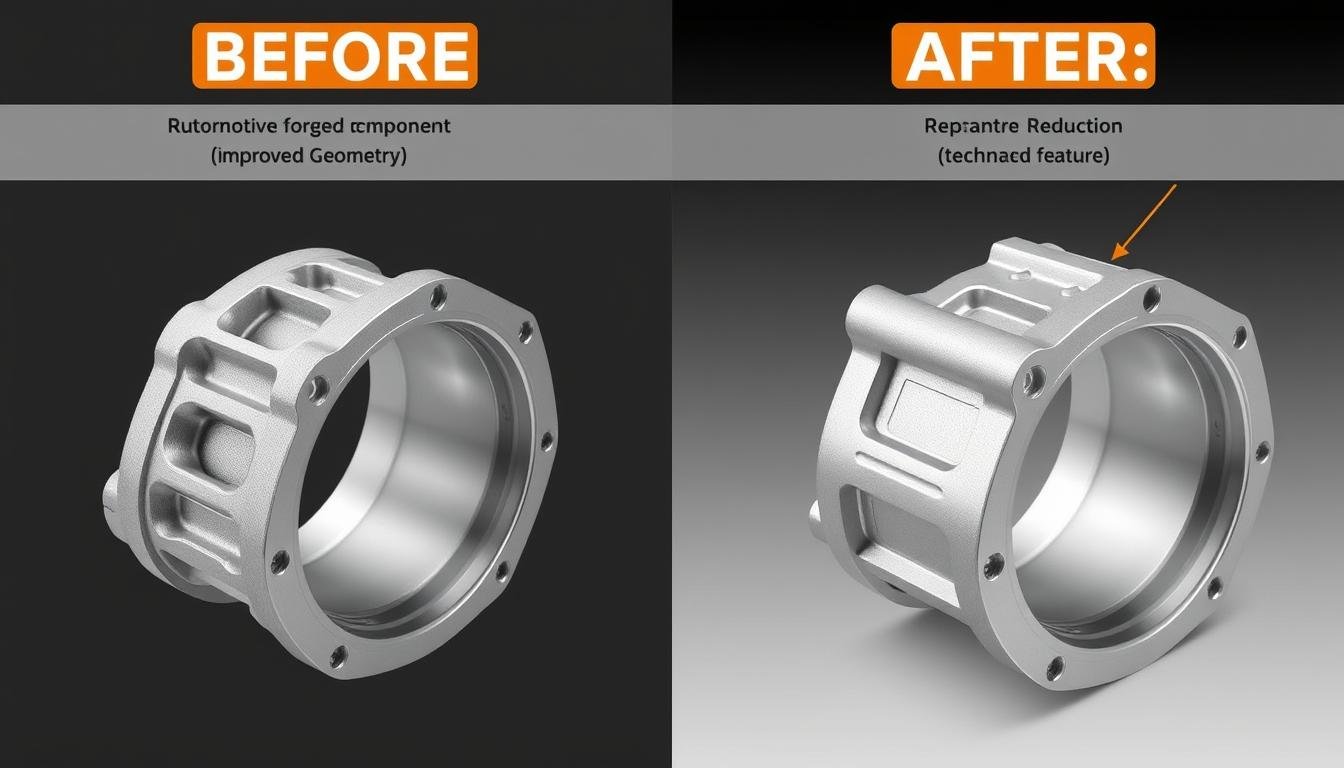

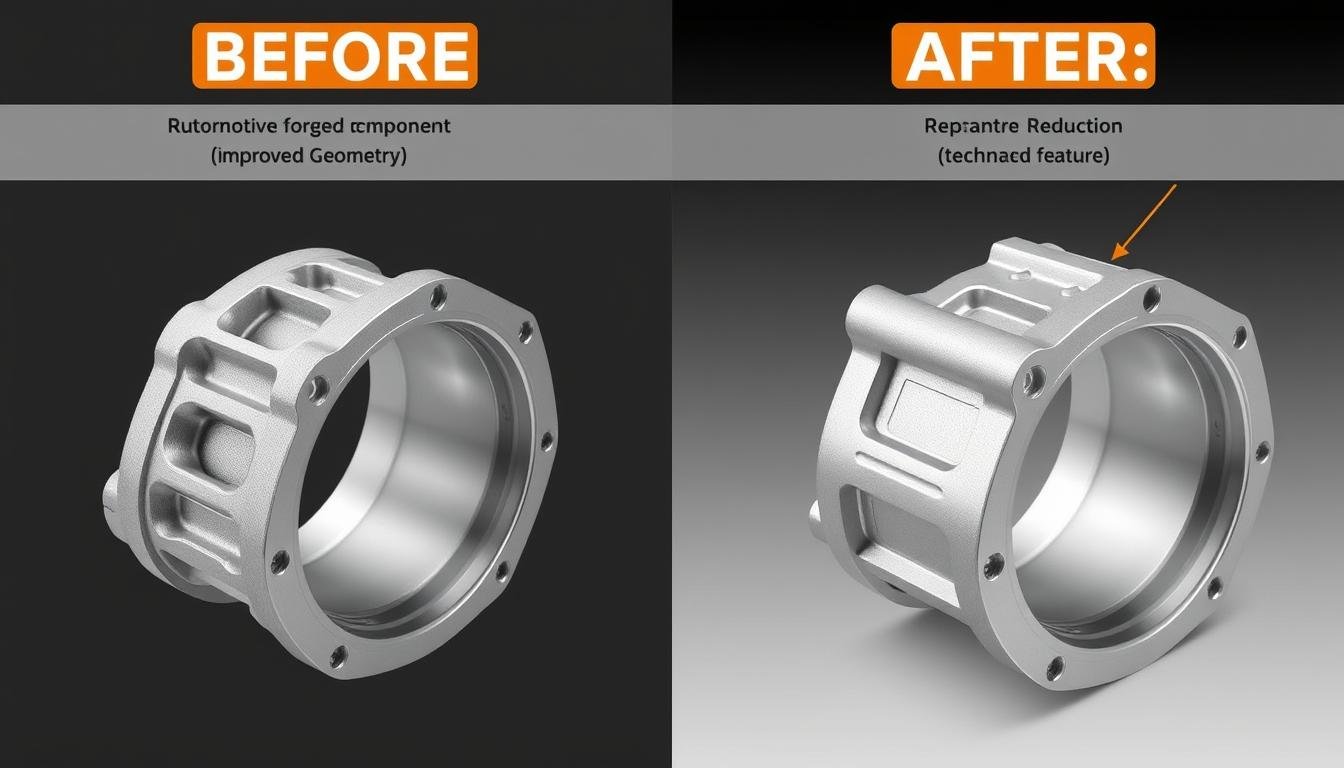

Case Study: Optimized Aluminum Forging Solution

See how MAIKONG helped a leading automotive manufacturer improve performance while reducing costs through innovative aluminum forging techniques.

Challenge

An automotive manufacturer needed to reduce the weight of a critical suspension component while maintaining strength and durability requirements. Their existing cast aluminum part was experiencing premature fatigue failure in certain applications.

Solution

MAIKONG’s engineering team analyzed the application requirements and designed a hot forged aluminum alternative using 7075-T6 aluminum alloy. We optimized the design for the forging process, incorporating strategic reinforcement in high-stress areas while reducing material in non-critical sections.

Results

- 22% weight reduction compared to the original component

- 3.5x improvement in fatigue life under cyclic loading

- 15% cost reduction through optimized material usage and production efficiency

- Zero field failures since implementation

- Successful implementation across multiple vehicle platforms

Frequently Asked Questions About Hot Forging Aluminum

Get answers to common questions about our aluminum forging capabilities and services.

What are the minimum and maximum sizes for your aluminum forgings?

MAIKONG can produce aluminum forgings ranging from small components weighing as little as 0.1kg up to larger parts weighing 50kg. Dimensional capabilities depend on the specific geometry, but we generally work with components up to 1000mm in length. For your specific requirements, please contact our engineering team for a detailed assessment.

What aluminum alloys do you commonly work with?

As an experienced hot forging aluminum supplier, we regularly work with a wide range of aluminum alloys including 6061, 7075, 2024, 7050, 2014, 5083, and many others. Our metallurgists can help you select the optimal alloy based on your specific application requirements, considering factors such as strength, corrosion resistance, machinability, and cost.

What is your typical lead time for aluminum forged components?

Lead times vary depending on component complexity, quantity, and current production schedule. Typical lead times are:

- Tooling development: 2-4 weeks

- First article samples: 1-2 weeks after tooling completion

- Production runs: 3-5 weeks after sample approval

For urgent requirements, we offer expedited services when possible. Please contact us to discuss your specific timeline needs.

What quality certifications does MAIKONG maintain?

MAIKONG maintains ISO 9001:2015 certification for our quality management system. We also have specific industry certifications relevant to automotive and aerospace applications. Our quality system is designed to meet the requirements of major OEMs and tier-one suppliers across multiple industries.

Can you provide additional services beyond forging?

Yes, we offer comprehensive manufacturing services including:

- CNC machining and finishing

- Heat treatment and aging

- Surface treatments (anodizing, painting, powder coating)

- Assembly and testing

- Custom packaging and logistics solutions

Our integrated capabilities allow us to provide complete solutions from raw material to finished component.